Abstract

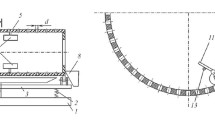

The use of a drum chute instead of the regular chute is proposed in coke sorting prior to classification. A method of calculating the optimal drum dimensions is outlined. The drum’s inclination is plotted as a function of the required number of drum rotations to which the coke is subjected. A simplified method is considered for determining the number of drum rotations to which the coke must be subjected in order to meet specified quality requirements.

Similar content being viewed by others

References

Narkevich, I.P., Pechkovskii, V.V., Plyshevskii, S.V., et al., Using slurries from the station of wastewater neutralization to produce complex fertilizers, Khim. Prom., 1984, no. 1, pp. 32–34.

Kozhevnikov, A.O., Alekhin, A.M., Petrunina, S.I., et al., The practice of introduction of a techproductive drum separator for enrichment of datolitic ores in heavy suspensions, Khim. Prom., 1978, no. 7, pp. 62–63.

Kostyl’kov, I.G. and Rogachev, O.V., Exergy Assessment of Ways for Sulfur Recuperation from Phosphogypsum, Khim. Prom., 1983, no. 11, pp. 36–40.

Sidenko, P.M., Izmel’chenie v khimicheskoi promyshlennosti (Grinding in Chemical Industry), Moscow: Khimiya, 1977.

Gel’perin, N.I., Osnovnye protsessy i apparaty khimicheskoi tekhnologii (Basic Processes and Apparatuses of Chemical Technology), Moscow: Khimiya, 1981, vol. 2.

Muchnik, D.A. and Babanin, V.I., Vozmozhnosti uluchsheniya kachestva koksa posle vydachi iz pechei (Possibility of Coke Improvement after Discharge from Oven), Yekaterinburg: Tipografiya EIBA, 2011.

Babanin, V.I. and Zaidenberg, M.A., RF Patent 2110552, 1998.

Muchnik, D.A., Babanin, V.I., Zagainov, V.S., and Stakheev, S.G., Processes for boosting coke quality, Coke Chem., 2011, vol. 54, no. 3, pp. 94–98.

Levenson, L.B., Barabannye grokhoty, ikh teoriya, raschet i proektirovanie (Drum Screens, Their Theory, Calculation, and Design), Moscow: VSNKh, 1927.

Voroshilov, A.P., The movement of material in elementary drum, in Sovremennye problemy sushil’noi tekhniki (Current Problems of Drying Technique), GONTINKTP SSSR, 1938, pp. 21–27.

Vaganov, N.P., Determining the productivity of drums and rotating furnaces, Ogneupory, 1938, no. 7, pp. 14–17.

Khodorov, E.I., Kichkina, E.S., and Klyueva, N.N., Model-based investigation of heat exchange and movement of the material in a rotating furnace with different inner structures, Tsement, 1952, no. 5, pp. 23–29.

Saeman, W.C., Passage of solids through rotary kilns, Chem. Eng. Prog., 1951, no. 10, p. 508.

Pershin, V.F. and Odnol’ko, V.G., Pererabotka sypuchikh materialov v mashinakh barabannogo tipa (Processing of Bulky Materials in the Drum-Type Machines), Moscow: Mashinostroenie, 2009.

Kryukov, A.N., Kheifets, A.Ya., Pudak, A.I., and Bondarchuk, P.N., Drum-type screens for coke sorting, Koks Khim., 1991, no. 7, pp. 33–34.

Muchnik, D.A., Formirovanie svoistv domennogo koksa (Formation of the Properties of Blast-Furnace Coke), Moscow: Metallurgiya, 1983.

Gulyaev, V.M. and Muchnik, D.A. UA Patent 86398, Byull. Izobret., 2009, no. 8.

Muchnik, D.A. and Gulyaev, V.M., Production of coke with specified physical and chemical properties, Koks Khim., 2006, no. 7, pp. 12–16.

Muchnik, D.A., Sorting of coke with simultaneous stabilization as a means of improving its physicomechanical properties, Coke Chem., 2010, vol. 53, no. 1, pp. 25–30.

Muchnik, D.A. and Gulyaev, V.M., Raschety i prognozirovanie pokazatelei kachestva metallurgicheskogo koksa s ispol’zovaniem PK (Computer Calculation and Prediction of the Quality of Metallurgical Coke), Dneprodzerzhinsk: Izd. DGTU, 2007.

www.uralelectropech.ru. www.speedqueen.com/vend/ru.www.prom-pechi.ru/index.php?id=64. http://sinowatt.ru/service.aspx.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © D.A. Muchnik, V.M. Gulyaev, A.I. Trikilo, 2016, published in Koks i Khimiya, 2016, No. 6, pp. 40–45.

About this article

Cite this article

Muchnik, D.A., Gulyaev, V.M. & Trikilo, A.I. Using drum chutes in coke preparation. Coke Chem. 59, 243–247 (2016). https://doi.org/10.3103/S1068364X16060041

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068364X16060041