Abstract

The concurrent goals of cement hydration are to percolate (bridge) the original cement particles into a load-bearing network and to depercolate (dam) the original water-filled capillary porosity. The initial volume, particle size distribution, and flocculation/dispersion state of the cement particles have a large influence on both hydration rates and microstructure development. Likewise, the capillary porosity as characterized by its pore size distribution, percolation state, and saturation state also influences both hydration kinetics and microstructure. In this paper, experimental techniques and computer modeling are applied to further understanding several of the critical connections between these physical parameters and performance properties. First, the setting or bridging process is explored via a combination of needle penetration and rheological measurements, in concert with three-dimensional microstructural modeling. Second, low temperature calorimetry is shown to be a valuable indicator of the percolation state or damming of the water-filled pores with various size entryways in the three-dimensional microstructure. Porosity percolation (or depercolation) is shown to be strongly influenced by both curing conditions and the alkali content of the cement pastes. Finally, it is proposed that future efforts in this field be directed towards a greater understanding of the (nano)structures of cement hydration products, particularly the calcium silicate hydrate gel, and their influence on performance properties.

Similar content being viewed by others

References

Bentz DP (2006) Influence of water-to-cement ratio on hydration kinetics: simple models based on spatial considerations. Cem Concr Res 36:238–244

Bentz DP, Garboczi EJ, Haecker CJ, Jensen OM (1999) Effects of cement particle size distribution on performance properties of cement-based materials. Cem Concr Res 29:1663–1671

Knudsen T (1984) The dispersion model for hydration of portland cement 1. General concepts. Cem Concrete Res 14:622–630

Osbaeck B, Johansen V (1989) Particle size distribution and rate of strength development of portland cement. J Am Cer Soc 72(2):197–201

Bentz DP, Garboczi EJ, Martys NS (1996) Application of digital-image-based models to microstructure, transport properties, and degradation of cement-based materials. In: Jennings HM et al. (eds) The modelling of microstructure and its potential for studying transport properties and durability. Kluwer Academic Publishers, pp 167–186

Bentz DP, Mizell S, Satterfield S, Devaney J, George W, Ketcham P, Graham J, Porterfield J, Quenard D, Vallee F, Sallee H, Boller E, Baruchel J (2002) The visible cement data set. J Res Natl Inst Stand Technol 107(2):137–148

Bentz DP (2006) Quantitative comparison of real and CEMHYD3D model microstructures using correlation functions. Cem Concr Res 36:259–263

Holzer L, Gasser Ph, Münch B (2005) Three Dimensional Analysis of the Pore-Network in Cement Pastes Using FIB-Nanotomography. Int. Conf. Cementitious Materials as Model Porous Media: Nanostructure and Transport. Verita, Switzerland, pp. 71–76

Powers TC (1959) Capillary continuity or discontinuity in cement paste. PCA Bull 10:2–12

Cement and Concrete Reference Laboratory (2001) Cement and concrete reference laboratory proficiency sample program: final report on portland cement proficiency samples number 139 and 140. Gaithersburg, MD

Cement and Concrete Reference Laboratory (2004) Cement and concrete reference laboratory proficiency sample program: final report on portland cement proficiency samples number 151 and 152. Gaithersburg, MD, April available at http://www.ccrl.us

Bentz DP, Stutzman PE (2006) Curing, hydration, and microstructure of cement paste. ACI Mater J (accepted)

Bentz DP (2006) Modeling the influence of limestone filler on cement hydration using CEMHYD3D. Cem Concr Compo 28:124–129

Bentz DP (2006) Influence of alkalis on porosity percolation in hydrating cement pastes. Cem Concr Compo 28:427–431

ASTM C191-04b (2004) Standard Test Method for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM Annual Book of Standards, vol 04.01 (Cement; Lime; Gypsum) American Society for Testing and Materials, West Conshohocken, PA

Amziane S, Ferraris CF (2005) Monitoring of setting evolution of cementitious materials by measurements of rheological properties and hydraulic pressure variations. ACI Mater J (submitted)

Amziane S, Ferraris CF (2005) SCC evolution of formwork hydraulic pressure and rheological properties. ACI Proc, New York

Amziane S, Ferraris CF (2004) Caractérisation de la prise des matériaux cimentaires. Proc. of the GFR convention, Mulhouse (France) October (in French)

Bentz DP (2005) CEMHYD3D: a three-dimensional cement hydration and microstructure development modelling package. Version 3.0. NISTIR 7232, U.S. Department of Commerce, June

Haecker CJ, Bentz DP, Feng XP, Stutzman PE (2003) Prediction of cement physical properties by virtual testing. Cem Int 1(3):86–92

Princigallo A, Lura P, van Breugel K, Levita G (2003) Early development of properties in a cement paste: a numerical and experimental study. Cem Concr Res 33:1013–1020

Geiker M (1983) Studies of portland cement hydration: measurement of chemical shrinkage and a systematic evaluation of hydration curves by means of the dispersion model. Ph.D. Thesis, Technical University of Denmark, Lyngby, Denmark

Bager DH, Sellevold EJ (1986) Ice formation in hardened cement paste, Part II- Drying and resaturation on room temperature cured pastes. Cem Concr Res 16:835–844

Villadsen J (1989) Hærdetemperaturens indflydelse på hærdnet cementpastas porestruktur: projektrapport. The Technical University of Denmark, Lyngby, Denmark

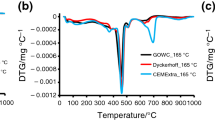

Snyder KA, Bentz DP (2004) Suspended hydration and loss of freezable water in cement pastes exposed to 90% relative humidity. Cem Concr Res 34(11):2045–2056

Bentz DP, Jensen OM, Hansen KK, Oleson JF, Stang H, Haecker CJ (2001) Influence of cement particle size distribution on early age autogenous strains and stresses in cement-based materials. J Am Ceram Soc 84(1):129–135

Swayze MA (1942) Early concrete volume changes and their control. J Am Concr Inst 13(5):425–440

Powers TC (1947) A discussion of cement hydration in relation to the curing of concrete. Proc Highway Res Board 27:178–188

Richardson IG (2004) Tobermorite/jennite- and tobermorite/calcium hydroxide-based models for the structure of C–S–H: applicability to hardened pastes of tricalcium silicate, β-dicalcium silicate, portland cement, and blends of portland cement with blast-furnace slag, metakaolin, or silica fume. Cem Concr Res 34:1733–1777

Bentz DP, Jensen OM, Coats AM, Glasser FP (2000) Influence of silica fume on diffusivity in cement-based materials. I. Experimental and computer modeling studies on cement pastes. Cem Concr Res 30:953– 962

Nonat A, (2004) The structure and stoichiometry of C–S–H. Cem Concr Res 34:1521–1528

Cong X, Kirkpatrick RJ (1996) 29Si MAS NMR study of the structure of calcium silicate hydrate. Adv Cement-Based Mater 3:144–156

Acknowledgements

The author would like to thank Dr. Chiara Ferraris and Mr. John Winpigler of BFRL/NIST for obtaining and processing the needle penetration and rheological data presented in this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bentz, D.P. Cement hydration: building bridges and dams at the microstructure level. Mater Struct 40, 397–404 (2007). https://doi.org/10.1617/s11527-006-9147-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-006-9147-3