Abstract

A new insight into the interfacial transition zone (ITZ) in cement mortar specimens (CMSs) that is influenced by cement fineness is reported. The importance of cement fineness in ITZ characterizations such as morphology and thickness is elucidated by backscattered electron images and by consequences to the compressive (Fc) and flexural strength (Ff), and porosity at various water/cement ratios. The findings indicate that by increasing the cement fineness the calcium silicate hydrate formation in the ITZ is favored and that this can refine the pore structures and create a denser and more homogeneous microstructure. By increasing cement fineness by about 25% of, the ITZ thickness of CMSs was reduced by about 30% and Fc was increased by 7%–52% and Ff by 19%–40%. These findings illustrate that the influence of ITZ features on the mechanical strength of CMSs is mostly related to the cement fineness and ITZ microstructure.

Similar content being viewed by others

References

Azimi-Pour M, Eskandari-Naddaf H. Synergistic effect of colloidal nano and micro-silica on the microstructure and mechanical properties of mortar using full factorial design. Construction & Building Materials, 2020, 261: 120497

Madadi A, Eskandari-Naddaf H, Shadnia R, Zhang L. Digital image correlation to characterize the flexural behavior of lightweight ferrocement slab panels. Construction & Building Materials, 2018, 189: 967–977

Ghanei A, Eskandari-Naddaf H, Ozbakkaloglu T, Davoodi A. Electrochemical and statistical analyses of the combined effect of air-entraining admixture and micro-silica on corrosion of reinforced concrete. Construction & Building Materials, 2020, 262: 120768

Kargari A, Eskandari-Naddaf H, Kazemi R. Effect of cement strength class on the generalization of Abrams’ law. Structural Concrete, 2019, 20(1): 493–505

Abousnina R, Manalo A, Ferdous W, Lokuge W, Benabed B, Saif Al-Jabri K. Characteristics, strength development and microstructure of cement mortar containing oil-contaminated sand. Construction & Building Materials, 2020, 252: 119155

Yu P, Manalo A, Ferdous W, Abousnina R, Salih C, Heyer T, Schubel P. Investigation on the physical, mechanical and microstructural properties of epoxy polymer matrix with crumb rubber and short fibres for composite railway sleepers. Construction & Building Materials, 2021, 295: 123700

Huang J. Microstructural study of the interfacial transition zone in concrete using backscatter-mode scanning electron microscopy with image analysis. Dissertation for the Doctoral Degree. West Lafayette: Purdue University, 1998

Lilliu G, Van Mier J. On the relative use of micro-mechanical lattice analysis of 3-phase particle composites. Engineering Fracture Mechanics, 2007, 74(7): 1174–1189

Wong H, Zobel M, Buenfeld N R, Zimmerman R W. Influence of the interfacial transition zone and microcracking on the diffusivity, permeability and sorptivity of cement-based materials after drying. Magazine of Concrete Research, 2009, 61(8): 571–589

Metha P K, Monteiro P J M. Concrete: Microstructure, Properties, and Materials. New York: McGraw-Hill Education, 2017

Akçaoğlu T, Tokyay M, Çelik T. Effect of coarse aggregate size and matrix quality on ITZ and failure behavior of concrete under uniaxial compression. Cement and Concrete Composites, 2004, 26(6): 633–638

Korouzhdeh T, Eskandari-Naddaf H. Mechanical properties and microstructure evaluation of cement mortar with different cement strength classes by image analysis. Arabian Journal for Science and Engineering, 2021: 1–21

Scrivener K L, Crumbie A K, Laugesen P. The interfacial transition zone (ITZ) between cement paste and aggregate in concrete. Interface Science, 2004, 12(4): 411–421

Gao Y, De Schutter G, Ye G, Huang H, Tan Z, Wu K. Porosity characterization of ITZ in cementitious composites: Concentric expansion and overflow criterion. Construction & Building Materials, 2013, 38: 1051–1057

Liao K Y, Chang P K, Peng Y N, Yang C C. A study on characteristics of interfacial transition zone in concrete. Cement and Concrete Research, 2004, 34(6): 977–989

Lyu K, She W, Chang H, Gu Y. Effect of fine aggregate size on the overlapping of interfacial transition zone (ITZ) in mortars. Construction & Building Materials, 2020, 248: 118559

Elsharief A, Cohen M D, Olek J. Influence of aggregate size, water cement ratio and age on the microstructure of the interfacial transition zone. Cement and Concrete Research, 2003, 33(11): 1837–1849

Vargas P, Restrepo-Baena O, Tobón J I. Microstructural analysis of interfacial transition zone (ITZ) and its impact on the compressive strength of lightweight concretes. Construction & Building Materials, 2017, 137: 381–389

Gao Y, De Schutter G, Ye G, Tan Z, Wu K. The ITZ microstructure, thickness and porosity in blended cementitious composite: Effects of curing age, water to binder ratio and aggregate content. Composites. Part B, Engineering, 2014, 60: 1–13

Prokopski G, Langier B. Effect of water/cement ratio and silica fume addition on the fracture toughness and morphology of fractured surfaces of gravel concretes. Cement and Concrete Research, 2000, 30(9): 1427–1433

Prokopski G, Halbiniak J. Interfacial transition zone in cementitious materials. Cement and Concrete Research, 2000, 30(4): 579–583

Xiao J, Li W, Sun Z, Shah S P. Crack propagation in recycled aggregate concrete under uniaxial compressive loading. ACI Materials Journal, 2012, 109(4): 451–461

Erdem S, Dawson A R, Thom N H. Influence of the micro-and nanoscale local mechanical properties of the interfacial transition zone on impact behavior of concrete made with different aggregates. Cement and Concrete Research, 2012, 42(2): 447–458

European Committee for Standardization. Cement: Composition, Specifications and Conformity Criteria for Common Cements. London: British Standard Institution, 2000

ASTM. Standard Specification for Standard Sand, ASTM C778. West Conshohocken, PA: ASTM, 2006

Bentz D P, Garboczi E J, Schlangen E. Computer simulation of interfacial zone microstructure and its effect on the properties of cement-based composites. In: Materials Science of Concrete. American Ceramic Society, 1995

ASTM. Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency, ASTM C305. West Conshohocken, PA: ASTM, 2006

ASTM. Standard Test Methods for Apparent Porosity, Liquid Absorption, Apparent Specific Gravity, and Bulk Density of Refractory Shapes by Vacuum Pressure, ASTM C830. West Conshohocken, PA: ASTM, 2011

ASTM. Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars, ASTM C348. West Conshohocken, PA: ASTM, 2002

ASTM. Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure), ASTM C349–97. West Conshohocken, PA: ASTM, 2002

Scrivener K L, Bentur A, Pratt P. Quantitative characterization of the transition zone in high strength concretes. Advances in Cement Research, 1988, 1(4): 230–237

Diamond S. Considerations in image analysis as applied to investigations of the ITZ in concrete. Cement and Concrete Composites, 2001, 23(2–3): 171–178

Diamond S, Huang J. The ITZ in concrete-a different view based on image analysis and SEM observations. Cement and Concrete Composites, 2001, 23(2–3): 179–188

Xie Y, Corr D J, Jin F, Zhou H, Shah S P. Experimental study of the interfacial transition zone (ITZ) of model rock-filled concrete (RFC). Cement and Concrete Composites, 2015, 55: 223–231

MountainsMap. Besançon: Digital Surf. Version 7.4. 2021

Wong H, Head M, Buenfeld N. Pore segmentation of cement-based materials from backscattered electron images. Cement and Concrete Research, 2006, 36(6): 1083–1090

Zhu Z, Provis J L, Chen H. Quantification of the influences of aggregate shape and sampling method on the overestimation of ITZ thickness in cementitious materials. Powder Technology, 2018, 326: 168–180

Sicat E, Gong F, Ueda T, Zhang D. Experimental investigation of the deformational behavior of the interfacial transition zone (ITZ) in concrete during freezing and thawing cycles. Construction & Building Materials, 2014, 65: 122–131

Zhang M H, Gjørv O E. Pozzolanic reactivity of lightweight aggregates. Cement and Concrete Research, 1990, 20(6): 884–890

Zhang M H, Gjørv O E. Microstructure of the interfacial zone between lightweight aggregate and cement paste. Cement and Concrete Research, 1990, 20(4): 610–618

Divanedari H, Eskandari-Naddaf H. Insights into surface crack propagation of cement mortar with different cement fineness subjected to freezing/thawing. Construction & Building Materials, 2020, 233: 117207

Wu K, Shi H, Xu L, Ye G, De Schutter G. Microstructural characterization of ITZ in blended cement concretes and its relation to transport properties. Cement and Concrete Research, 2016, 79: 243–256

EN. Methods of Testing cement. Part 6: Determination of Fineness, EN 196–6. Brussels: European Committee for Standardization, 2019

ABNT-NBR. Portland Cement and Other Powdered Materials—Determination of Fineness by the Air Permeability Method (Blaine method). Brazilian Association of Technical Standards. Brasil: Rio de Janeiro, 2015

Hu J, Ge Z, Wang K. Influence of cement fineness and water-to-cement ratio on mortar early-age heat of hydration and set times. Construction & Building Materials, 2014, 50: 657–663

Ehikhuenmen S O, Igba U T, Balogun O O, Oyebisi S O. The influence of cement fineness on the structural characteristics of normal concrete. IOP Conference Series: Materials Science and Engineering. Bristol: IOP Publishing, 2019

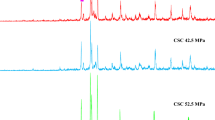

Eskandari-Naddaf H, Kazemi R. Experimental evaluation of the effect of mix design ratios on compressive strength of cement mortars containing cement strength class 42.5 and 52.5 MPa. Procedia Manufacturing, 2018, 22: 392–398

Eskandari-Naddaf H, Kazemi R. ANN prediction of cement mortar compressive strength, influence of cement strength class. Construction & Building Materials, 2017, 138: 1–11

Korouzhdeh T, Eskandari-Naddaf H, Kazemi R. Hybrid artificial neural network with biogeography-based optimization to assess the role of cement fineness on ecological footprint and mechanical properties of cement mortar expose to freezing/thawing. Construction & Building Materials, 2021, 304: 124589

Mahdinia S, Eskandari-Naddaf H, Shadnia R. Effect of cement strength class on the prediction of compressive strength of cement mortar using GEP method. Construction & Building Materials, 2019, 198: 27–41

Tanaka K, Kurumisawa K. Development of technique for observing pores in hardened cement paste. Cement and Concrete Research, 2002, 32(9): 1435–1441

Castañeda A, Howland Albear J J, Marrero R, Corvo F. Concrete quality assessment before building structures submitting to environmental exposure conditions. Revista de la Construcción, 2017, 16(3): 374–387

Duan P, Shui Z, Chen W, Shen C. Effects of metakaolin, silica fume and slag on pore structure, interfacial transition zone and compressive strength of concrete. Construction & Building Materials, 2013, 44: 1–6

Ismail S, Ramli M. Effects of adding fibre on strength and permeability of recycled aggregate concrete containing treated coarse RCA. International Journal of Civil, Architectural, Structural and Construction Engineering, 2014, 8(8): 890–896

Hu X, Shi C, Shi Z, Zhang L. Compressive strength, pore structure and chloride transport properties of alkali-activated slag/fly ash mortars. Cement and Concrete Composites, 2019, 104: 103392

Peng H, Cui C, Cai C S, Liu Y, Liu Z. Microstructure and microhardness property of the interface between a metakaolin/GGBFS-based geopolymer paste and granite aggregate. Construction & Building Materials, 2019, 221: 263–273

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Korouzhdeh, T., Eskandari-Naddaf, H. & Kazemi, R. The ITZ microstructure, thickness, porosity and its relation with compressive and flexural strength of cement mortar; influence of cement fineness and water/cement ratio. Front. Struct. Civ. Eng. 16, 191–201 (2022). https://doi.org/10.1007/s11709-021-0792-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-021-0792-y