Abstract

Fruity smelling esters play an important role for the aroma of hops and beer and they have been characterized as key aroma compounds in different hop varieties. Studies on the transfer of hop-derived compounds into beer during dry-hopping showed calculated transfer rates of different ethyl esters far above 100%, leading to the assumption that these esters must be newly formed. To investigate this formation, dry-hopping was imitated in water to eliminate the influence of the beer matrix on the formation of these odorants. Thereby, the formation of ethyl esters of 2-methylbutanoic acid, 3-methylbutanoic acid, and methylpropanoic acid, induced by the addition of hops, was shown. Different approaches inhibiting enzyme activities and experiments with different hop extracts might lead to the assumption that enzymes are involved in the formation of these esters, beside possible transesterification.

Graphical abstract

Similar content being viewed by others

Introduction

Previous studies on dry-hopping have evaluated the transfer of, among other odorants, different ethyl esters from hops into beer. Thereby, calculated transfer rates far above 100% were observed (Brendel et al. 2020; Neiens and Steinhaus 2019). It is already known that hops can be the source of monocarboxylic acids, that are needed for the formation of these esters, namely, 2- and 3-methylbutanoic acid and methylpropanoic acid, formed by the degradation of humulones (Rettberg et al. 2014; Williams and Wagner 1979). Thus, a subsequent esterification of the respective monocarboxylic acids with ethanol was assumed, but has not been verified by further investigations (Schnaitter et al. 2016a, b). In beer, different formation pathways of ethyl esters have already been suggested, e.g., a non-enzymatic reaction during beer storage (Vanderhaegen et al. 2003, 2007; Williams and Wagner 1978, 1979). Other studies have postulated the formation of ethyl esters via transesterification of other hop-derived esters like methylpropyl methylpropanoate, 3-methylbutyl methylpropanoate, and 2-methylbutyl methylpropanoate during fermentation (Takoi et al. 2018; Forster and Gahr 2013). A further possibility is the enzymatic esterification during yeast fermentation by acetyl-CoA:ethanol O-acetyltransferases (AEATs) (Dank et al. 2018; Rettberg et al. 2014; Saerens et al. 2008). Two AEATs in yeast have already been identified as Eht1 and Eeb1, catalyzing a condensation of medium chain fatty acids with ethanol (Saerens et al. 2006; Mason and Dufour 2000). Isoleucine, leucine, and valine are known as precursors for 2-methylbutyl and 2-methylbutanoate esters, 3-methylbutyl and 3-methylbutanoate esters, and methylpropyl and methylpropanoate esters (Matich and Rowan 2007; Rowan et al. 1996).

However, in a very recent study (Brendel et al. 2020), ethyl ester formation has mainly been observed in dry-hopped samples, even if the concentrations of the respective monocarboxylic acids as precursors would have been high enough (in the same ranges as some of the dry-hopped beers) in the non-hopped reference samples. Due to the fact that the samples before and after dry-hopping were stored under the same conditions and for the same time, ester formations should have taken place in both. Thus, only the transfers from acids into the beer, followed by their esterification cannot explain this phenomenon. On the other hand, yeast metabolism can also not be the origin of these ethyl esters, because then, no difference between the dry-hopped and non-hopped samples should have been obtained. If hops contain unknown AEATs, an enzymatic ester formation might be induced by hop addition into beer (Brendel et al. 2020).

Thus, this study should clarify the role of hops in the formation of ethyl esters and give hints on monocarboxylic acids or methylpropanoic acid esters as precursors within a possible transesterification. Therefore, model studies in water were performed to confirm the formation of the target esters and to exclude the influence of yeast enzymes on the reaction. To arrive at a more accurate picture, different hop extracts were used in the model system studies and different methods of enzyme inhibition should give deeper insights into the reaction type.

Materials and methods

Hop samples

Hallertauer Mandarina Bavaria hop pellets type 90, harvest year 2015, were provided by Hopsteiner (Mainburg, Germany). Identification and quantitation of odorants in this batch have already been performed in a previous study (Brendel et al. 2019). Hop extracts were also provided by Hopsteiner: Alpha extract contained 20.0 ± 1.0% α-acids. Beta rich hop extract was specified with 40 ± 0.2% β-acid content. XanthoFlav™ extract was coated on diatomaceous earth with a specification of 7–12% xanthohumol (without carrier material). Tannin extract contained 2–6% low molecular weight polyphenols.

Chemicals

The following reference compounds were purchased from commercial sources: ethyl 2-methylbutanoate, ethyl 3-methylbutanoate, ethyl methylpropanoate, 2-methylbutanoic acid, 3-methylbutanoic acid, and methylpropanoic acid (Sigma-Aldrich, Taufkirchen, Germany).

The following chemicals were obtained commercially: calcium chloride dihydrate, diethyl ether, ethanol, anhydrous sodium sulfate (Merck, Darmstadt, Germany); L-ascorbic acid (Sigma-Aldrich); and argon, helium, hydrogen, and nitrogen (Westfalen, Münster, Germany).

Stable isotopically labeled internal standards

The stable isotopically labeled internal standards were synthesized as previously described (Guth and Grosch 1993): [2H5]-ethyl 2-methylbutanoate, [2H9]-ethyl 3-methylbutanoate, and [2H5]-ethyl methylpropanoate via esterification of the respective labeled carboxylic acid with ethanol.

Isolation of the esters from hop extracts

To hop extract (0.1–1 g), diethyl ether (2 × 100 mL) and the stable isotopically labeled internal standards (0.2–0.8 μg, dissolved in ethanol; amounts depending on the concentration of the respective analyte, determined in preliminary experiments) were added. After equilibration, the sample was extracted by stirring for 2 × 1.5 h at room temperature. The extract obtained was subjected to high vacuum distillation using the solvent assisted flavor evaporation (SAFE) technique (Engel et al. 1999). After drying over anhydrous sodium sulfate, the filtered sample was concentrated to ~ 100 μL using a Vigreux column (50 cm × 1 cm id), followed by microdistillation. The concentrated extract was used for two-dimensional high-resolution heart-cut gas chromatography-mass spectrometry (HRGC/HRGC-MS).

Model system studies with hops

For the dry-hopping model, water (500 mL), ethanol (250 μL), hops (0.8 g), 2-methylbutanoic acid, 3-methylbutanoic acid, and methylpropanoic acid (250 μg each) were used to prepare six different models: model A containing all compounds mentioned above; model B without hops; model C without ethanol; model D without carboxylic acids; model E without argon atmosphere; and model F in a clear glass bottle. The samples were stirred at room temperature for 10 days in amber glass bottles (except for model F) under argon (except for model E). The concentrations of the esters were measured via headspace solid phase microextraction comprehensive two-dimensional high-resolution gas chromatography-time-of-flight mass spectrometry (HS-SPME-HRGCxHRGC-TOF-MS).

Model system studies to evaluate the reaction type

A further model in a clear glass bottle with the addition of ascorbic acid (5 g) as antioxidant was prepared (model G). Next, model A (as described above) was modified by the addition of calcium chloride (5 g) to evaluate the influence of enzyme activities (model H) on the ester formation. For the next experiment, hops were heat-processed in water under reflux for 20 min prior to the addition of ethanol and the acids (model I) to evaluate the influence of a heat treatment on a possibly enzymatic activity. The concentrations of the esters were analyzed again via HS-SPME-HRGCxHRGC-TOF-MS.

Model system studies with hop extracts

For each hop extract, two further models were prepared: water (100 mL), ethanol (50 μL), and the respective hop extract (0.15 g) were stirred under argon in amber glass bottles for 10 days at room temperature, once without the addition of carboxylic acids (model J) and once with carboxylic acids (250 μg each) (model K). Again, the concentrations of the esters were measured via HS-SPME-HRGCxHRGC-TOF-MS.

Two-dimensional high-resolution heart-cut gas chromatography-mass spectrometry (HRGC/HRGC-MS)

For quantitation of the esters in the hop extracts, HRGC/HRGC-MS was performed as recently described (Brendel et al. 2019).

Headspace solid phase microextraction-comprehensive two-dimensional high-resolution gas chromatography-time-of-flight mass spectrometry (HS-SPME-HRGCxHRGC-TOF-MS)

To an aliquot of the aqueous samples (50 mL), the stable isotopically labeled internal standards (10–35 ng, dissolved in ethanol; amounts depending on the concentration of the respective analyte, determined in preliminary experiments) were added and the mixture was stirred for 15 min at room temperature for equilibration. An aliquot (5 mL) and sodium chloride (2 g) were filled into a headspace vial (20 mL) and the measurements were performed as previously described (Brendel et al. 2020).

Results and discussion

Model system studies with hops

The study setup using water, ethanol, hops, and monocarboxylic acids was chosen to simulate the dry-hopping process and to exclude the possible influence of the beer matrix with yeast enzymes on the formation of the odorants. By performing the experiments with an alcohol content of 0.05% vol, also alcohol-free beers can be included into the resulting considerations, for which an ester formation has also been observed (Brendel et al. 2020). Therefore, the study should also answer the question whether this low alcohol content, that for instance can be reached via thermal dealcoholization, is sufficient for esterification.

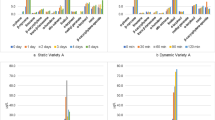

Figure 1 shows the results of all models, for which hop pellets were used, in comparison to the concentrations of the respective esters in the used amount of hops. All models are compared to model A (consisting of water, ethanol, hops, and acids in an amber glass bottles under argon), which functions as a dry-hopping model without any additives or special treatments. Already the comparison of the results obtained for model A (0.37–2.3 μg/L) to the concentrations of ethyl esters in hop pellets (6.9–96 μg/kg, which is equivalent to 0.011–0.15 μg/L, based on a theoretical 100% transfer from hops into water) underlines the hypothesis, that a formation of these esters is caused by the addition of hops due to their clearly increased concentrations. In contrast, the esterification of the added carboxylic acids with ethanol without hop addition (model B) was clearly lower (0.007–0.025 μg/L) than in the dry-hopped approach (model A). This experiment also showed that the fermentation process and the activity of yeast enzymes is not relevant for the observed formation of ethyl esters in real beer samples. As a control, the model without ethanol (model C) showed ester concentrations in the same range as the concentrations in the used hop pellets, showing an ester transfer during dry-hopping.

Interestingly, the added monocarboxylic acids in model A did not influence the ester formation since their concentrations (0.29–1.8 μg/L) did not change significantly without the addition of the acids (model D). These results indicated that monocarboxylic acids derived from hop humulones and lupulones may not be the precursors for the esterification. Also Takoi et al. concluded that the concentrations of the formed esters should be much higher, if they are formed from the respective acids, as there is a high excess of hop bitter acids in beer (Takoi et al. 2018). Thus, a transesterification of other hop-derived esters seems to be more likely than the esterification of ethanol with hop-derived acids.

It has already been shown that also methyl 2-methylbutanoate is formed during dry-hopping of (alcohol-free) beer (Brendel et al. 2020; Neiens and Steinhaus 2019). This increase interferes with a possible decrease of methyl ester concentrations by transesterification to ethyl esters, and thus, cannot be used as indicator for the ethyl ester formation. The same behavior could be shown by a semi-quantitative estimation of the contents of methyl 3-methylbutanoate and methyl methylpropanoate in hops and dry-hopped beer (data not published). However, also 2-methylbutyl methylpropanoate, 3-methylbutyl methylpropanoate, and methylpropyl methylpropanoate have been postulated as precursors for the formation of ethyl esters in beer (Forster and Gahr 2013). These esters have been identified in different hop varieties and dry-hopped beer (Forster and Gahr 2013, 2014; Schmidt and Biendl 2016). Thereby, transfer rates of 40–72% were reported during dry-hopping with Hallertauer Cascade and Hallertauer Mandarina Bavaria and, therefore, the remaining 28–60% might be transesterified to ethyl esters (Forster and Gahr 2013, 2014). On the other hand, after dry-hopping with Hallertauer Huell Melon, Hallertauer Blanc, and Hallertauer Polaris, transfer/formation rates up to 161% (3-methylbutyl methylpropanoate) and 222% (2-methylbutyl methylpropanoate) were observed (Forster and Gahr 2013), and thus, these esters did not seem to be the precursors of ethyl esters, or these esters did show even higher transfer/formation rates and were partially transesterified to ethyl esters.

In previous studies, the concentrations of 2-methylbutyl methylpropanoate (40–300 mg/kg), 3-methylbutyl methylpropanoate (10–40 mg/kg), and methylpropyl methylpropanoate (10–120 mg/kg) were quantitated in Hallertauer Mandarina Bavaria, Hallertauer Cascade, and Hallertauer Mittelfrüh (Forster and Gahr 2013, 2014). The concentrations were much higher compared to those of the investigated ethyl esters in the hop varieties of the present study, with a maximum concentration of 96 μg/kg (Brendel et al. 2019). In beer, concentrations of 22–26 μg/L (3-methylbutyl methylpropanoate), 32–63 μg/L (methylpropyl methylpropanoate), and 200–340 μg/L (2-methylbutyl methylpropanoate) were reported (Forster and Gahr 2013, 2014).

In the model experiments, the concentrations of possible “precursor esters”, e.g., 2-methylbutyl methylpropanoate and methylpropyl methylpropanoate, were semiquantitated (due to the missing corresponding labeled standard) in model A and model C using the concentration of ethyl methylpropanoate as a reference value (Table 1).

While the concentration of ethyl methylpropanaote was much higher in model A compared to model C (without ethanol), the related esters 2-methylbutyl methylpropanoate and methylpropyl methylpropanoate only showed a slight and not significant increase in their concentrations from model C to model A (Table 1). Furthermore, based on literature data, the estimated concentrations correspond to a transfer from hops into the solution of < 100%, so the differences can also be caused by a variability of transfer (Forster and Gahr 2013). In the case of transesterification of the precursor esters to the corresponding ethyl esters, the precursor concentrations should be higher in model C. But as the formed amount of ethyl methylpropanoate is quite low related to the concentrations of the possible precursor esters, the possibility of transesterification cannot be excluded based on this semiquantitative data.

The presence of oxygen (model E without argon atmosphere) did not show any effects on the amount of the formed esters (0.36–2.2 μg/L). Next, the influence of light on the formed amounts of esters was analyzed using a clear glass bottle (model F). Thereby, the ester formation increased by a factor of 3–5 to 1.7–8.3 μg/L, which might be a hint to a radical mechanism in ester formation. To reduce radical, but also enzymatic reactions, the clear glass sample was additionally treated with ascorbic acid (model G), which has antioxidative properties and influences the pH value as well. With this approach, the ester concentrations decreased by 62–81% to 0.087–0.84 μg/L. Normally, a lower pH value should lead to a faster formation of esters of monocarboxylic acids and ethanol and also to a faster transesterification. If the reaction occurs due to an enzymatic activity, the respective enzymes can be inhibited by a suboptimal pH value. Possibly, beside the change of the pH value of the solution, the influence of the antioxidant properties of ascorbic acid on the reaction might be secondary, as hops already contain antioxidants like xanthohumol and other polyphenols.

To further test the involvement of enzymatic reactions, heat treatment and salt addition was used to decrease the enzymatic activity. Using calcium chloride (model H), the ester concentrations decreased by 69% for ethyl methylpropanoate (0.68 µg/L), by 84% for ethyl 2-methylbutanoate (0.06 µg/L), and by 87% for ethyl 3-methylbutanoate (0.21 µg/L). Also a heat treatment of the hops (model I) for a thermal inactivation of enzymes prior to the addition of ethanol decreased the ester concentrations by 85% for ethyl 2-methylbutanoate (0.06 µg/L), by 89% for ethyl 3-methylbutanoate (0.17 µg/L), and by 93% for ethyl methylpropanoate (0.15 µg/L). Thus, hops that is added during wort boiling may not have this ester formation activity. Since the addition of calcium chloride and an elevated temperature showed a clear impact on the ester formation, it can be postulated that the formation is induced by enzymes that are present in hops.

Model system studies with hop extracts

While the addition of monocarboxylic acids did not show an effect on the ester formation in the model studies above, performing the same model approach with different hop extracts did show an influence of acids on the formation of the ethyl esters (Fig. 2). A clear increase in the ester concentrations was found for alpha and beta extracts (both containing bitter acids), whereas the models treated with xanthohumol or tannin extracts did only show low rates of ester formation. However, the alpha and beta extracts cannot be directly compared, as they did not have an equal bitter acid concentration. Furthermore, the beta extract also had a residual content of α-acids of 0.5%. Therefore, they differ in their potential to release the respective monocarboxylic acids. It is also unknown, how effective the ethyl esters, that are already present in the hop extracts, are transferred into the aqueous system, as the extracts showed different textures and solubility in water.

Overall, the xanthohumol and tannin extracts showed the lowest ester formation activity, also if carboxylic acids were added. These models with xanthohumol and tannin extracts did not exceed the concentrations of formed esters (total concentration minus the potential transfer from the extract) of 0.63 μg/L (ethyl 3-methylbutanoate in the xanthohumol extract with the addition of acids). Without the addition of acids, the xanthohumol and tannin extracts only formed 0.016–0.17 μg/L of the different esters (Table 2, Fig. 2). Also by estimating the concentrations of the possible “precursor esters” semi-quantitatively, the lowest amounts were observed in the xanthohumol extract.

The alpha extract showed nearly no ester formation activity, yielding not more than 0.08 μg/L (sum of all three ethyl esters), if no carboxylic acids were added. However, with the addition of carboxylic acids, especially the concentration of newly formed ethyl methylpropanoate increased to 5.7 μg/L. The beta extract showed the highest activity already in the samples without acid addition (22 μg/L ethyl methylpropanoate, 7.1 μg/L ethyl 3-methylbutanoate). After adding the respective carboxylic acids, ester formation increased up to 38 μg/L (ethyl methylpropanoate) (Table 2, Fig. 2).

Generally, the highest formation rates of ethyl methylpropanoate and ethyl 3-methylbutanoate were observed in the beta extract, of ethyl 2-methylbutanoate in the alpha extract. The xanthohumol and tannin extracts only showed concentrations < 0.2 μg/L for each ester without the addition of carboxylic acids, but up to 0.63 μg/L, if acids were added (Table 2, Fig. 2). In contrast to the models using hop pellets (A-I), an increase of esters was observed by adding monocarboxylic acids to the models with hop extracts (J and K).

Conclusions

In conclusion, the present study demonstrated that hops induce the formation of ethyl esters of 2- and 3-methylbutanoic acid and methylpropanoic acid during dry-hopping. Thereby, also the residual alcohol content of alcohol-free beer is sufficient for this esterification. The reaction type cannot be clearly specified based on the performed model studies, but according to the inhibition of the reaction via pH value, heat treatment, and salt concentration, an enzymatic pathway can be postulated. Therefore, the transfer of these esters from hops into beer during dry-hopping is secondary, as the amounts of newly formed ethyl esters is much higher than their original contents in hops.

The question about the precursors of the ethyl esters could not fully be answered within this study, as by simulating dry-hopping with hop pellets, humulone- and lupulone-derived acids did not show a great influence on the concentration of ethyl esters, whereas in dry-hopping models with hop extracts, the addition of these acids clearly led to higher concentrations of ethyl esters. Furthermore, other hop-derived esters as 2-methylbutyl methylpropanoate and methylpropyl methylpropanoate can also act as possible precursor structures for an ester formation via transesterification. As already reported earlier, this would be an important reaction regarding the sensory properties of the final product, as the odor thresholds of the ethyl esters are much lower compared to those of the “precursor esters” (Takoi et al. 2018).

Availability of data and materials

All needed data is presented in this manuscript. Other necessary data, that leaded to the underlying theory, has already been published and is cited at the corresponding position within this publication.

Abbreviations

- AEAT:

-

Acetyl-CoA:ethanol O-acetyltransferase

- HRGC/HRGC-MS:

-

Two-dimensional high-resolution heart-cut gas chromatography-mass spectrometry

- HS-SPME-HRGCxHRGC-TOF-MS:

-

Headspace solid phase microextraction-comprehensive two-dimensional high-resolution gas chromatography-time-of-flight mass spectrometry

References

Brendel, S., Hofmann, T., & Granvogl, M. (2019). Characterization of key aroma compounds in pellets of different hop varieties (Humulus Lupulus L.) by means of the sensomics approach. Journal of Agricultural and Food Chemistry, 67, 12044–12053.

Brendel, S., Hofmann, T., & Granvogl, M. (2020). Dry-hopping to modify the aroma of alcohol-free beer on a molecular level. Journal of Agricultural and Food Chemistry accepted. https://doi.org/10.1021/acs.jafc.0c01907.

Dank, A., Smid, E. J., & Notebaart, R. A. (2018). CRISPR-Cas genome engineering of esterase activity in Saccharomyces cerevisiae steers aroma formation. BMC Research Notes, 11, 682.

Engel, W., Bahr, W., & Schieberle, P. (1999). Solvent assisted flavour evaporation - a new and versatile technique for the careful and direct isolation of aroma compounds from complex food matrices. European Food Research and Technology, 209, 237–241.

Forster, A., & Gahr, A. (2013). On the fate of certain hop substances during dry hopping. BrewingScience, 66, 93–103.

Forster, A., & Gahr, A. (2014). A comparison of the analytical and brewing characteristics of Cascade and Comet hop varieties as grown in Yakima (USA) and Hallertau (Germany). BrewingScience, 67, 137–148.

Guth, H., & Grosch, W. (1993). Quantitation of potent odorants of virgin olive oil by stable-isotope dilution assays. Journal of the American Oil Chemists’ Society, 70, 513–518.

Mason, A. B., & Dufour, J.-P. (2000). Alcohol acetyltransferases and the significance of ester synthesis in yeast. Yeast, 16, 1287–1298.

Matich, A., & Rowan, D. (2007). Pathway analysis of branched-chain ester biosynthesis in apple using deuterium labeling and enantioselective gas chromatography-mass spectrometry. Journal of Agricultural and Food Chemistry, 55, 2727–2735.

Neiens, S. D., & Steinhaus, M. (2019). Investigations on the impact of the special flavor hop variety Huell Melon on the odor-active compounds in late hopped and dry hopped beers. Journal of Agricultural and Food Chemistry, 67, 364–371.

Rettberg, N., Thoerner, S., Labus, A. B., & Garbe, L.-A. (2014). Aroma active monocarboxylic acids - origin and analytical characterization in fresh and aged hops. BrewingScience, 67, 33–47.

Rowan, D. D., Lane, H. P., Allen, J. M., Fielder, S., & Hunt, M. B. (1996). Biosynthesis of 2-methylbutyl, 2-methyl-2-butenyl, and 2-methylbutanoate esters in Red Delicious and Granny Smith apples using deuterium-labeled substrates. Journal of Agricultural and Food Chemistry, 44, 3276–3285.

Saerens, S. M. G., Verstrepen, K. J., Thevelein, J. M., & Delvaux, F. R. (2008). Ethyl ester production during brewery fermentation: a review. Cerevisia, 33, 82–90.

Saerens, S. M. G., Verstrepen, K. J., van Laere, S. D. M., Voet, A. R. D., van Dijck, P., Delvaux, F. R., & Thevelein, J. M. (2006). The Saccharomyces cerevisiae EHT1 and EEB1 genes encode novel enzymes with medium-chain fatty acid ethyl ester synthesis and hydrolysis capacity. The Journal of Biological Chemistry, 281, 4446–4456.

Schmidt, C., & Biendl, M. (2016). Headspace trap GC-MS analysis of hop aroma compounds in beer. BrewingScience, 69, 9–15.

Schnaitter, M., Kell, A., Kollmannsberger, H., Schüll, F., Gastl, M., & Becker, T. (2016a). Scale-up of dry hopping trials: importance of scale for aroma and taste perception. Chemie Ingenieur Technik, 88, 1955–1965.

Schnaitter, M., Wimmer, A., Kollmannsberger, H., Gastl, M., & Becker, T. (2016b). Influence of hop harvest date of the ‘Mandarina Bavaria’ hop variety on the sensory evaluation of dry-hopped top-fermented beer. Journal of the Institute of Brewing, 122, 661–669.

Takoi, K., Itoga, Y., Koie, K., Takayanagi, J., Kaneko, T., Watanabe, T., … Nomura, M. (2018). Behaviour of hop-derived branched-chain esters during fermentation and unique characteristics of Huell Melon and Ekuanot (HBC366) hops. BrewingScience, 71, 100–109.

Vanderhaegen, B., Delvaux, F., Daenen, L., Verachtert, H., & Delvaux, F. R. (2007). Aging characteristics of different beer types. Food Chemistry, 103, 404–412.

Vanderhaegen, B., Neven, H., Coghe, S., Verstrepen, K. J., Verachtert, H., & Derdelinckx, G. (2003). Evolution of chemical and sensory properties during aging of top-fermented beer. Journal of Agricultural and Food Chemistry, 51, 6782–6790.

Williams, R. S., & Wagner, H. P. (1978). The isolation and identification of new staling related compounds from beer. Journal of the American Society of Brewing Chemists, 36, 27–31.

Williams, R. S., & Wagner, H. P. (1979). Contribution of hop bitter substances to beer staling mechanisms. Journal of the American Society of Brewing Chemists, 37, 13–19.

Acknowledgements

The authors thank Miss Ines Otte for her technical assistance.

Funding

This IGF Project of the FEI was supported via AiF within the program for promoting the Industrial Collective Research (IGF) of the German Ministry of Economic Affairs and Energy (BMWi), based on a resolution of the German Parliament (AiF 18626 N).

Author information

Authors and Affiliations

Contributions

Miss S. Brendel and Prof. Dr. M. Granvogl came up with the research question. S. Brendel investigated the analytical method, performed the measurements, evaluated the received data, and wrote the draft manuscript. M. Granvogl contributed in acquiring the research money, in supervising the full project, in discussing and interpreting the results, and in revising the manuscript. Prof. Dr. T. Hofmann supervised the project as owner of the chair at the Technical University of Munich, where the project was performed. The author(s) read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that there is no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Brendel, S., Hofmann, T. & Granvogl, M. Hop-induced formation of ethyl esters in dry-hopped beer. Food Prod Process and Nutr 2, 18 (2020). https://doi.org/10.1186/s43014-020-00030-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43014-020-00030-0