Abstract

Azadirachta indica (AZI, commonly recognized as “Neem”) is noteworthy both for its chemical and for its biological actions. It is one of the most fruitful sources of secondary metabolites in nature. To date, more than 300 natural products have been isolated from different sections of the tree, with new compounds added to the list every year. As a contribution to the current interest on green corrosion inhibitors, the present study aims at broadening the application of plant extracts for metallic corrosion inhibition by investigating the inhibiting properties of A. indica especially for mild steel, aluminum, and tin. In the present article, we discuss the potential of AZI extract as a corrosion inhibitor on metal surfaces, especially of mild steel, aluminum, and tin. The adsorption isotherm studies, chemical composition of AZI, effect of temperature on inhibition efficiency and computational analysis related with AZI adsorption on metals have also been discussed in detail. This work will further help in the understanding of the adsorption mechanism involved and hence inhibition effect of plant extract against metal corrosion.

Similar content being viewed by others

Review

Introduction

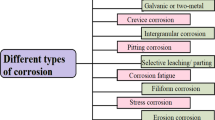

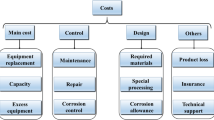

“Green chemistry” provides an opportunity to design any research in non-polluting way with minimum production of waste and minimum consumption of energy. It is a philosophy which is equally applicable in all fields wherever chemistry involves (Sharma et al. 2010a; Sharma et al. 2011; Sharma et al. 2009a; Linthorst 2010). “Corrosion” is a phenomenon where chemistry helps to explain its mechanism and role of ions and energy behind it. It is simply a destruction of materials resulting from an exposure and the interaction with the environment. One of the latest and popular approaches is the use of substances called corrosion inhibitor. These inhibitor molecules consist ofheterocyclic compounds with polar functional groups (e.g. N, S, O, and P) and conjugated double bonds with different aromatic system. Basically, these substances adsorb on the metal surface to block the destruction reaction with aggressive media. They are both physically and chemically active adsorbate type substances (Thompson et al. 2007; Buchweishaija 2009). It is a major problem that must be confronted for safety, environmental, and economic reasons in various chemical, mechanical, metallurgical, biochemical, and medical engineering applications and more specifically, in the design of a much more varied number of mechanical parts which equally vary in size, functionality, and useful lifespan. Corrosion attack can be prevented by various methods such as materials improvement, combination of production fluids, process control, and chemical inhibition. Among these methods, the implementation of corrosion inhibition is the most excellent approach to avoid disastrous destruction of metals and alloys in corrosive media. The use of corrosion inhibitors is the most economical and convenient technique to control corrosive attack on metals. Corrosion inhibitors are chemicals either synthetic or natural which, when added in small amounts to an environment, decrease the rate of attack by the environment on metals. A number of synthetic compounds are known to be applicable as good corrosion inhibitors for metals (Quraishi et al. 2012; Kabanda et al. 2012a; Ebenso et al. 2012a). The importance of a corrosion study depend in the fact that corrosion causes great loses to our economy and is a major threat for human safety. Corrosion costs worldwide are therefore on the order of US$552 billion (Chauhan and Gunasekaran 2007; Schmitt et al. 2009a). Even countries like India is suffering badly due to this problem of corrosion (Sharma and Sharma 2011). Several efforts have been made using corrosion-preventive practices, and the use of green corrosion inhibitors is one of them (Anuradha et al. 2008; Mudhoo and Sharma 2010; Sharma et al. 2010b; Sharma et al. 2010c; Aboia and James 2010; Sharma et al. 2009b; Sharma et al. 2009c). On the other hand, the attractiveness and utilization of synthetic compounds as a corrosion inhibitor has come under severe criticism due to the harsh environmental regulations and toxic effects of synthetic compounds on human and animal life. Consequently, there exists the need to build up a new class of corrosion inhibitors with low toxicity, eco-friendliness, and good efficiency. Throughout the ages, plants have been used by human beings for their basic needs such as assembly of food stuffs, shelters, clothing, fertilizers, flavors and fragrances, medicines, and last but not least, as corrosion inhibitors (Ajmal et al. 1994; Bentiss et al. 2002). The use of natural products as corrosion inhibitors can be traced back to the 1930s when plant extracts of Chelidonium majus (Celandine) and other plants were used for the first time in H2SO4 pickling baths (Sanyal 1981). After then, interest in using natural products as corrosion inhibitors increased substantially and scientists around the world reported several plant extracts as promising green anticorrosive agents (Schmitt et al. 2009b). Most of the gums were also reported as good corrosion inhibitor due to their gum-metal complex forming capacity, availability of п-electrons and hetero atoms, and less toxic properties (Peter et al. 2015). The adsorption of organic molecules depends on the presence of п-electrons and hetero atoms (Jin et al. 2006; Raja and Sethuraman 2008a). Although synthetic organic inhibitors have shown effective corrosion inhibition, their cost, toxicity, and non-biodegradability lead us to look for green options. In this review, we are discussing about the various plant extract and especially Azadirachta indica as green corrosion inhibitor for mild steel, Al, and tin (Tables 1, 2, and 3).

Use of A. indica as a corrosion inhibitor against mild steel, aluminum, and tin corrosion

A. indica (AZI, common name “Neem”) is noteworthy for its biological and chemical uses (Fig. 1). It is known as “magical plant” for many diseases treatment (Kliˇski´c et al. 2000). It is very effective in the production of secondary metabolites (Kumar et al. 1996; Schaaf et al. 2000; Barton 1999). Neem is a member of the mahogany family, Meliaceae. Neem trees are attractive broad-leaved evergreens that can grow up to 30 m tall and 2.5 m in girth. Their scattering branches form rounded crowns as much as 20 m across. The fruit is a smooth, ellipsoidal drupe, up to almost 2 cm long (Jacobson 1986b).

The chemical compounds of neem belonged to a general class of natural products called “triterpenes” or “limonoids.” These limonoids have an ability to block insects’ growth who are responsible for harmful outcomes in agriculture and human health sector. New limonoids are still being discovered in neem, but azadirachtin, salannin, meliantriol, and nimbin are the best known and most significant ones (Qurasishi 2004). Nowadays, the use of neem as a corrosion inhibitorhas been widely investigated., so in Table 4, we summarize the corrosive properties of neem with respect to mild steel, aluminum, and tin metals.

Arab et al. (2008) found that AZI extract inhibits the corrosion of aluminum in 0.5 M HCl. Sharma et al. (2013) investigated the inhibitory efficacy of ethanolic extract of A. indica fruit for acid corrosion of aluminum.

The corrosion inhibition and adsorption properties of neem (AZI) mature leaves extract as a green inhibitor of mild steel (MS) corrosion in nitric acid (HNO3) solutions have been studied and investigated by Sharma et al. (2009a; Sharma et al. 2010c; Sharma et al. 2010d) using a gravimetric technique for experiments conducted at 30 and 60 °C. According to Ayssar et al. (2010), the aqueous neem leaves extract was found to be an excellent potential corrosion inhibitor for carbon steel in 1.0 M HCl. Obiukwu et al. (2013) mentioned that the A. indica had a better effect with an inhibitive efficiency of 85 % for stainless steel. Investigation of Eddy and Mamza (2009) demonstrates that the rate of corrosion of mild steel in H2SO4 increases with the increase in the concentration of the acid and that ethanol extracts of the seeds and leaves of A. indica inhibit the corrosion of mild steel in H2SO4. According to Loto et al. (2011), the corrosion inhibition performance of neem leaf (A. indica) extract on the corrosion of mild steel was achieved in the dilute hydrochloric acid at 0.25 g/l extract concentration and also at 30 °C. In a recent study by Desai (2015a), it has been discussed that in HCl, AZI was an effective inhibitor against mild steel corrosion, the rate of corrosion increases with the increase in acid concentration and temperature. He also observed that a straight line in the plots of Langmuir adsorption isotherm suggests that the inhibitor’s adsorption on steel followed Langmuir isotherm. Polarization study involved in this case indicates that the inhibitor functions as a mixed inhibitor (Desai 2015b). In an another study carried out by Ajanaku et al. (2015), authors highlighted that in the corrosion inhibition study of AZI against aluminum metal in 1.85 M hydrochloric acid, the rate of the reaction has been studied by monitoring and measuring the volume of hydrogen gas evolved and the results were supported by various adsorption theories and the surface morphology studies using scanning electron microscopy (SEM). Authors suggested that the plant extract retards the acid-induced corrosion of aluminum and the volume of hydrogen gas evolved reduced with increasing extract concentration. Also, the Langmuir isotherm as the best model for the adsorption of A. indica indicates the suggested mechanism of adsorption—chemisorption (Ajanaku et al. 2015). A research conducted by Jain et al. (a research group at Tata Steel, Jamshedpur) published in Tata Search (2014) also highlighted the inhibition effect of AZI against mild steel in acid media (HCl and HNO3), and the results of weight loss studies correlated well with polarization studies (Jain et al. 2014).

In a very interesting study by Bhola et al. (2014) published in Engineering Failure Analysis, authors investigated the inhibition effect of AZI extract on microbiologically influenced corrosion of API 5L X80 line pipe steel by a sulfate reducing bacterial (SRB) consortium. On the basis of the field emission scanning electron microscopy (FE-SEM) and energy dispersive spectroscopy (EDS) studies, electrochemical impedance spectroscopy (EIS), linear polarization resistance (LPR), and open circuit potential (OCP) were used to investigate the in situ corrosion behavior, and they concluded that neem extract has the capability to reduce the biocorrosion rate by approximately 50 % (Bhola et al. 2014), which is fairly high and very encouraging, clearly underlining the importance of AZI extract as a corrosion inhibitor.

Corrosion inhibition by AZI and computational modeling

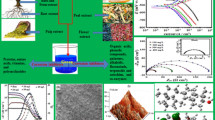

Computational methods are more and more appropriate in the study of corrosion inhibition capacity because they have the potential to support in the design of new compounds with good corrosion inhibition properties. These studies are assisting in reducing the experimental costs for testing many compounds with the objective of synthesizing the ones that have high promise for corrosion inhibition. Density functional theory (DFT) and molecular dynamics (MD) approaches are increasingly used for predicting the inhibition potential of compound for corrosion on geometrical, electronic, and binding property bases on metal surface (Kabanda et al. 2012b; Kabanda and Ebenso 2012; Ebenso et al. 2012b). Recently, more corrosion publications contained substantial quantum chemical calculations and molecular dynamics simulations (Obot et al. 2013; Kabanda et al. 2013; Obot and Gasem 2014). Such calculations are usually used to explore the relationship between the inhibitor molecular properties and their corrosion inhibition efficiencies. The use of quantum chemical methods in corrosion inhibitor studies of large number of small organic compounds has been highlighted by Gece (2008) and Obot (2014) in their detailed review. Attempt has also been made recently to extend the application of DFT-based quantum chemical and molecular dynamic simulations methods in order to understand the mechanism of adsorption of plant extract components on metal and alloys surfaces (Oguzie et al. 2013; Oguzie et al. 2010; Oguzie et al. 2012a; Umoren et al. 2014; Oguzie et al. 2012b; Obi-Egbedi et al. 2012). This is because the major criticism of the use of plant extract as corrosion inhibitor is often the inability to pinpoint which of the component(s) is/are actually responsible for the observed corrosion inhibition effect given that they are comprised of mixtures of organic compounds.

Although experimental studies on the application of AZI extract as a green corrosion inhibitors for different metals and alloys have been extensively reviewed in the work; the mechanism of interactions between the AZI extract component and the metal surfaces at the atomic level using molecular modeling studies is lacking and is still a matter of speculation. This difficulty can be tackled by the methodology of density functional theory and molecular dynamics simulations where selected DFT reactivity parameters of the individual major extracts components such as energy of the highest occupied molecular orbital (E HOMO), energy of the lowest unoccupied molecular orbital (E LUMO), energy band gap (ΔE), and the interaction energy between the extract components and the metal surface can be correlated with the corrosion inhibitive effect of the plant extract. According to the description of frontier orbital theory (ObiEgbedi et al. 2011), HOMO is often associated with the electron-donating ability of an inhibitor molecule. High E HOMO values indicate that the molecule has a tendency to donate electrons to the metal with unoccupied d orbitals. E LUMO indicates the ability of the molecules to accept electrons (Obot and Obi-Egbedi 2010). The lower the value of E LUMO of inhibitor molecule is, the easier its acceptance of electrons from the metal surface (Obot et al. 2009). The gap between the LUMO and HOMO energy levels of the inhibitor molecules is another important index, low absolute values of the energy band gap (ΔE = E LUMO − E HOMO) can indicate a good stability of the formed complex on the metal surface, therefore increasing the adsorption of a molecule on the metal surface (Xia et al. 2008). Some important reactivity parameters from DFT and molecular dynamics simulations (MDS) are summarized in Table 5. Also, Figs. 2 and 3 show examples of molecular modeling of major extract components from some plants used as corrosion inhibitors.

Computational modeling of capsaicin and dihydrocapsaicin (the two main extract components of Capsicum frutescens) (Oguzie et al. 2013)

The highest occupied molecular (HOMO) orbital density of a ascorbic acid, b riboflavin (RB), c thiamine (TH), and d nicotinic acid (NA) which constitute the main constituents of Spondias mombin extract (Obi-Egbedi et al. 2012)

Conclusions

From the above discussion, it is quite obvious that AZI is an effective green corrosion inhibitor against various metals, especially for mild steel, aluminum, and tin. A lot of potential is still untapped especially computational modeling of the major extract components of AZI on different metal surfaces, and many other plant materials and should be further explored by researchers working in the area of corrosion science and engineering. This will help in the understanding of the adsorption mechanism and hence inhibition effect of plant extracts against metal corrosion. Also of importance is the exploration of AZI and other plant materials in other corrosive environment such as CO2 corrosion, H2S corrosion, and in cooling water systems.

References

Abd-El-Nabey BA, Abdel-Gaber AM, Elawady GY, El-Houssein S (2012) Inhibitive action of some plant extracts on the alkaline corrosion of aluminum. Int J Electrochem Sci 7:7823–7839

Aboia KO, James O (2010) The effects of aloe vera extract on corrosion and kinetics of corrosion process of zinc in HCl solution. Corrosion Science 52(2):661–664

Ajanaku KO, Aladesuyi O, Ajanaku CO, Adedapo EA, Akiusiku AA, Sodiya FE (2015) Adsorption properties of Azadirachta indica extract on corrosion of aluminium in 1.85 M hydrochloric acid. Journal of International Association of Advanced Technology and Science 16:4

Ajmal M, Mideen AS, Quraishi MA (1994) 2-Hydrazino-6-methyl-benzothiazole as an effective inhibitor for the corrosion of mild steel in acidic solutions. Corrosion Science Volume 36(1):79–84

Anozie IU, Akoma CS, Nnanna LA (2011) Corrosion inhibition of aluminium alloy in acidic medium by Euphorbia hirta and Dialum guineense extracts. Int J Pure Appl Sci Technol 6(2):79–88

Anuradha K, Vimala R, Narayanasamy B, Arockia JS, Rajendran S (2008) Corrosion inhibition of carbon steel in low chloride media by an aqueous extract of Hibiscus rosa-sinensis Linn. Chemical Engineering Communications 195:352–366

Arab TS, Turkustani-Al MA, Dhahiri-Al HR (2008) Synergistic effect of Azadirachta indica extract and iodide ions on the corrosion inhibition of aluminium in acid media. Journal of the Korean Chemical Society 52(3):281–294

Avwiri O, Igho OF (2003) Inhibitive action of Vernonia amygdalina on the corrosion of aluminium alloys in acidic media. Material Letter 57:3705–3711

Ayssar N, Ideisan AA, Ibrahim AR, Maysoon A-K (2010) UAE neem extract as a corrosion inhibitor for carbon steel in HCl solution. International Journal of Corrosion 2010:1–9

Barton D. Comprehensive natural products chemistry. In: Meth-Cohn O, editor. Elsevier Science, Oxford: Newnes; 1999

Bentiss F, Traisnel M, Chaibi N, Mernari B, Vezin H, Lagrenée M (2002) 2,5-Bis(n-methoxyphenyl)-1,3,4-oxadiazoles used as corrosion inhibitors in acidic media: correlation between inhibition efficiency and chemical structure. Corrosion Science 44(10):2271–2289

Bhola SM, Alabbas FM, Rahul B, Spear JR, Mishra B, Olson DL, Kakporbia AE (2014) Neem extract as an inhibitor for biocorrosion influenced by sulfate reducing bacteria: a preliminary investigation. Engineering Failure Analysis 36:92–103

Buchweishaija J (2009) Phytochemicals as green corrosion inhibitors in various corrosive media: a review. J Sci 35:77–92

Chauhan LR, Gunasekaran G (2007) Corrosion inhibition of mild steel by plant extract in dilute HCl medium. Corrosion Science 49(3):1143–1161

Desai PS (2015a) Hibiscus rosa-sinensis (Jasud) leaves extracts used as corrosion inhibitors for mild steel in hydrochloric acid. E-jpmr 2(1):470–485

Desai PS (2015b) Azadirachta indica (neem) leaf extract used as corrosion inhibitors for mild steel in hydrochloric acid. GE-International Journal of Engineering Research 3(1):8–23

Ebenso EE, Udofot JJ, Ibok JU, Ekpe (1998) Studies on the inhibition of mild steel corrosion by some plant extracts in acidic medium. Discovery and Innovation 10(1–2):52–59

Ebenso EE, Ibok JU, Ekpe JU, Umeron S, Jackson E, Abiola K, Oforka CN, Martinez S (2004) Corrosion inhibition studies of some plant extracts on aluminium in acidic medium. Transactions-Society for the Advancement of Electrochemical Science and Technology 39(4):117–123

Ebenso EE, Kabanda MM, Arslan T, Saracoglu M, Kandemirli F, Murulana LC, Singh AK, Shukla SK, Hammouti B, Khaled KF (2012a) Quantum chemical investigations on quinoline derivatives as effective corrosion inhibitors for mild steel in acidic medium. Int J Electrochem Sci 7:5643–5676

Ebenso EE, Kabanda MM, Murulana LC, Singh AK, Shukla SK (2012b) Electrochemical and quantum chemical investigation of some azine and thiazine dyes as potential corrosion inhibitors for mild steel in hydrochloric acid solution. Ind Eng Chem Res 51:12940–12958

Eddy ON, Mamza PAP (2009) Inhibitive and adsorption properties of ethanol extract of seeds and leaves of Azadirachta indica on the corrosion of mild steel in H2SO4. Portugaliae Electrochimica Acta 27(4):443–456

El-hosary A, Saleh MR, Sharns MA (1972) Corrosion inhibition by naturally occurring substances—I. The effect of Hibiscus subdariffa (karkade) extract on the dissolution of Al and Zn. CorrosionSci 12:897–904

El-Sherif Rabab M, Badawy Waheed A (2011) Mechanism of corrosion and corrosion inhibition of tin in aqueous solutions containing tartaric acid. Int J Electrochem Sci 6:6469–6482

Gece G (2008) The use of quantum chemical methods in corrosion inhibitor studies. Corrosion Science 50(11):2981–2992

Gupta P, Jain G (2014) Corrosion inhibition by Aloe barbadensis (aloe vera) extract as green inhibitor for mild steel in HNO3. IJSRR 3(4):72–83

Jacobson. http://www.nap.edu/read/1924/chapter/5. 1986b

Jain R, Kotha A, Bhadu MK, Choudhary SK, Sairullah M, Rout AK, Rout TK (2014) Pickling inhibition efficiency of extracts of Azadirachta indica and Momordica charantia acidic medium on steel, Tata Search., pp 159–168

Jin L, Wang L, Chen D (2006) Corrosion inhibition of a hygroscopic inorganic dust depressor. J Univ Sci Technol 13:368–371

Kabanda MM, Ebenso EE (2012) Density functional theory and quantitative structure-activity relationship studies of some quinoxaline derivatives as potential corrosion inhibitors for copper in acidic medium. Int J Electrochem Sci 7:8713–8733

Kabanda MM, Murulana LC, Ozcan M, Karadag F, Dehri I, Obot IB, Ebenso EE (2012a) Quantum chemical studies on the corrosion inhibition of mild steel by some triazoles and benzimidazole derivatives in acidic medium. Int J Electrochem Sci 7:5035–5056

Kabanda MM, Murulana LC, Ebenso EE (2012b) Theoretical studies on phenazine and related compounds as corrosion inhibitors for mild steel in sulphuric acid medium. Int J Electrochem Sci 7:7179–7205

Kabanda MM, Obot IB, Ebenso EE (2013) Computational study of some amino acid derivatives as potential corrosion inhibitors for different metal surfaces and in different media. International Journal of Electrochemical Science 8:10839–10850.

Kliˇski´c M, Radoˇsevi´c J, Gudi´c S S, Atalini´c V (2000) Aqueous extract of Rosmarinus officinalis L. as inhibitor of Al–Mg alloy corrosion in chloride solution. Journal of Applied Electrochemistry 30(7):823–830

Kumar CSSR, Srinivas M, Yakkundi S (1996) Limonoids from the seeds of Azadirachta indica. Phytochemistry 43:451–455

Kumpawat N, Chaturvedi A, Upadhyay RK (2012) Comparative study of corrosion inhibition efficiency of naturally occurring ecofriendly varieties of holy basil (tulsi) for tin in HNO3 solution. Open Journal Of Metal 2(03):68–73

Linthorst JA (2010) An overview: origins and development of green chemistry. Foundations of Chemistry 12(1):55–68

Loto AC, Loto RT, Popoola API (2011) Effect of neem leaf (Azadirachta indica) extract on the corrosion inhibition of mild steel in dilute acids. International Journal of the Physical Sciences 6(9):2249–2257

Majeed MH, Sultan AA, Al-Sahlanee HH (2014) Corrosion inhibition of carbon steel in 1M HCl solution by Ruta graveolens extract. J Chem Pharm Res 6(5):998

Mudhoo A, Sharma SK (2010) International Journal of Water Treatment and Green Chemistry 1(1):29–38

Muller B (2002) Corrosion inhibition of aluminium and zinc pigments by saccharides. Corros Sci 44:1583–1591

Nnanna LA, Obasi VU, Nwadiuko OC, Mejeh KI, Ekekwe ND, Udensi SC (2012) Inhibition by Newbouldia laevis leaf extract of the corrosion of aluminium in HCl and H2SO4 solutions. Archives of Applied Science Research 4(1):207–217

Noor EA (2007) Temperature effects on the corrosion inhibition of mild steel in acidic solutions by aqueous extract of fenugreek leaves. International Journal of Electrochemical Science 2:996–1017

ObiEgbedi NO et al (2011) Computational simulation and statistical analysis on the relationship between corrosion inhibition efficiency and molecular structure of some phenanthroline derivatives on mild steel surface. Int J Electrochem Sci 6:5649–5675

Obi-Egbedi NO, Obot IB, Umoren SA (2012) Spondias mombin L. as a green corrosion inhibitor for aluminium in sulphuric acid: correlation between inhibitive effect and electronic properties of extracts major constituents using density functional theory. Arabian Journal of Chemistry 5:361–373

Obiukwu OO, Opara OI, Oyinna CB (2013) Corrosion inhibition of stainless steel using plant extract Vernonia amygdalina and Azadirachta indica. The Pacific Journal of Science and Technology 14(2):31–35

Obot IB (2014) In: Aliofkhazraei M (ed) Developments in corrosion protection. INTECH, Croatia, pp 123–151

Obot IB, Gasem ZM (2014) Theoretical evaluation of corrosion inhibition performance of some pyrazine derivatives. Corrosion Science 83:359–366

Obot IB, Obi-Egbedi NO (2010) Adsorption properties and inhibition of mild steel corrosion in sulphuric acid solution by ketoconazole: experimental and theoretical investigation. Corrosion Science 52(1):198–204

Obot IB, Obi-Egbedi NO, Umoren SA (2009) The synergistic inhibitive effect and some quantum chemical parameters of 2,3-diaminonaphthalene and iodide ions on the hydrochloric acid corrosion of aluminium. Corrosion Science 51(2):276–282

Obot IB, Ebenso EE, Kabanda MM (2013) Metronidazole as environmentally safe corrosion inhibitor for mild steel in 0.5 M HCl: experimental and theoretical investigation. Journal of Environmental Chemical Engineering 1:431–439

Oguzie EE (2006) Adsorption and corrosion inhibitive properties of Azadirachta indica in acid solutions. Pigment and Resin Technology 35(6):334–340

Oguzie EE (2008) Evaluation of the inhibitive effect of some plant extracts on the acid corrosion of mild steel. Corrosion Science 50(11):2993–2998

Oguzie EE, Enenebeaku CK, Akalezi CO, Okoro SC, Ayuk AA, Ejike EN (2010) Adsorption and corrosion-inhibiting effect of Dacryodis edulis extract on low-carbon-steel corrosion in acidic media. Journal of Colloid and Interface Science 349:283–292

Oguzie EE, Adindu CB, Enenebeaku CK, Ogukwe CE, Chidiebere MA, Oguzie KL (2012a) Natural products for materials protection: mechanism of corrosion inhibition of mild steel by acid extracts of Piper guineense. Journal of Physical Chemical 116:13603–13615

Oguzie EE, Ogukwe CE, Ogbulie JN, Nwanebu FC, Adindu CB, Udeze IO, Oguzie KL, Eze FC (2012b) Broad spectrum corrosion inhibition: corrosion and microbial (SRB) growth inhibiting effects of Piper guineense extract. Journal of Material Science 47:3592–3601

Oguzie EE, Oguzie KL, Akalezi CO, Udeze IO, Ogbulie JN, Njoku VO (2013) Natural products for materials protection: corrosion and microbial growth inhibition using Capsicum frutescens biomass extracts. ACS Sustainable Chemistry and Engineering 1:214–225

Okafor PC, Uwah IE, Ekerenam OO, Ekpe UJ (2009) Combretum bracteosum extracts as eco-friendly corrosion inhibitor for mild steel in acidic medium. Pigment and Resin Technology 38(4):236–241

Okafor PC, Ikpi ME, Ekanem UI, Ebenso EE (2013) Effects of extracts from Nauclea latifolia on the dissolution of carbon steel in H2SO4 solutions. Int J Electrochem Sci 8:12278–12286

Peter A, Sharma SK, Obot IB (2015) Use of natural gums as green corrosion inhibitors: an overview. International Journal of Industrial Chemistry 6(3):153–164

Quraishi AM, Ansari AF, Jamal D (2004) Corrosion inhibition of tin by some amino acids in citric acid. Indian Journal Or Chemical Technology 11:271–274

Quraishi MA, Obot IB, Eddy NO, Kabanda MM, Shukla SK, Singh AK, Murulana LC, Ebenso EE (2012) Electrochemical and quantum chemical studies on calmagite and fast sulphone black F dyes as corrosion inhibitors for mild steel in hydrochloric medium. Int J Electrochem Sci 7:8813–8831

Qurasishi AM (2004) NACE meeting papers

Raja PB, Sethuraman MG (2008a) Atropine sulphate as corrosion inhibitor for mild steel in sulphuric acid medium. Material Letters 62:1602–1604

Raja PB, Sethuraman MG (2008b) Natural products as corrosion inhibitor for metals in corrosive media—a review. Materials Letters 62(1):113–116

Rehan HH (2003) Corrosion control by water‐soluble extracts from leaves of economic plants. Materialwissenschaft und Werkstofftechnik 34(2):232–237

Salami L, Wewe TOY, Akinyemi OP, Patinvoh RJ. A Study Of The Corrosion Inhibitor Of Mild Steel In Sulphuric Acid Using Musa Sapientum Peels Extract. Global Engineers & Technologists Review. 2012; 2(12)

Sangeetha TV, Fredimoses M (2011) Inhibition of mild copper metal corrosion in HNO3 medium by acid extract of Azadirachta indica seed. E-Journal of Chemistry 8(S1):S1–S6

Sangeetha M, Rajendran S, Sathiyabama J, Prabhakar P (2012) Eco friendly extract of banana peel as corrosion inhibitor for carbon steel in sea water. J Nat Prod Plant Resour 2(5):601–610

Sanyal B (1981) Organic compounds as corrosion inhibitors in different environments—a review. Progress in Organic Coatings 9(2):165–236

Schaaf O, Jarvis AP, van der Esch SA, Giagnacovo G, Oldham NJ (2000) Rapid and sensitive analysis of Azadirachtin and related triterpenoids from neem (Azadirachta indica) by high-performance liquid chromatography–atmospheric pressure chemical ionization mass spectrometry. Journal of Chromatography A 886(1):89–97

Schmitt G, Hays GF, Burns W, Han EH, Pourbaix A, Jacobson G (2009a) World Corrosion Organization., pp 1–44

Schmitt G, Hays GF, Burns W, Han EH, Pourbaix A, Jacobson G (2009b) Global needs for knowledge dissemination, research, and development in materials deterioration and corrosion control., World Corrosion Organization 1–44

Sharma SK, Sharma A (2011) Green corrosion inhibitors: status in developing countries. In: Sharma SK (ed) Green corrosion chemistry and engineering. Wiley–VCH Publications, Germany, pp 157–176

Sharma SK, Mudhoo A, Khamis E (2009a) Corrosion inhibition of neem (Azadirachta indica) leaves extract as a green corrosion inhibitor for zinc in H2SO4. Journal of Corrosion Science and Engineering 11:1–25

Sharma SK, Jain G, Sharma J, Mudhoo A, Sharma J (2009b) RASAYAN. Journal of Chemistry 2 2:332–339

Sharma SK, Mudhoo A, Jain G, Khamis E (2009c) Gray chemistry verses green chemistry: challenges and opportunities. Green Chemistry Letters and Reviews 2(1):47–51

Sharma SK, Mudhoo A, Zhang W (2010a) Green chemistry and engineering: a versatile research perspective. In: Sharma SK, Mudhoo A (eds) Green chemistry for environmental sustainability, vol 1. Taylor & Francis Group, LLC, Florida, Boca Raton, pp 1–52

Sharma SK, Jain G, Sharma J, Mudhoo A (2010b) Journal of the Indian Council of Chemists 27(1):35–39

Sharma SK, Jain G, Sharma J, Mudhoo A (2010c) Corrosion inhibition behaviour of Azadirachta indica (neem) leaves extract as a green corrosion inhibitor for zinc in hydrochloric acid: a preliminary study. International Journal of Applied Chemistry 6(1):83–94

Sharma SK, Mudhoo A, Jain G, Sharma J (2010d) Corrosion inhibition and adsorption properties of Azadirachta indica mature leaves extract as green inhibitor for mild steel in HNO3. Green Chemistry Letters and Reviews 3(1):7–15

Sharma SK, Sanghi Rashmi, Singh Vandana (2011) Environment and the role of green chemistry. In: Sanghi R (ed) Green chemistry for environmental remediation. Scrivener Publishing LLC, Massachusetts, pp 3–34

Sharma A, Choudhary G, Sharma A, Yadav S (2013) Effect of temperature on inhibitory efficacy of Azadirachta indica fruit on acid corrosion of aluminum. International Journal of Innovative Research in Science Engineering and Technology 2(12):7982–7992

Shyamala M, Arulanantham A (2009) Eclipta alba as corrosion pickling inhibitor on mild steel in hydrochloric acid. Journal of Materials Science and Technology 25(5):633–636

Singh A, Kumar A, Pramanik T (2013) A theoretical approach to the study of some plant extracts as green corrosion inhibitor for mild steel in HCl solution. Oriental Journal of Chemistry 29(1):277–283

Souza TF, Magalhães M, Torres VV, D’Elia E (2015) Inhibitory action of ilex paraguariensis extracts on the corrosion of carbon steel in HCl solution. Int J Electrochem Sci 10:22–33

Subhashini S, Rajalakshmi R, Prithiba A, Mathina A (2010) Corrosion mitigating effect of Cyamopsis tetragonoloba seed extract on mild steel in acid medium. E-Journal of Chemistry 7(4):1133–1137

Thompson NG, Yunovich M, Dunmire D (2007) Cost of corrosion and corrosion maintenance strategies. Corrosion Reviews 25(3–4):247–262

Tuaweri TJ, Ogbonnaya EA, Onyemaobi OO (2015) Corrosion inhibition of heat treated mild steel with neem leave extract in a chloride medium. International Journal of Research in Engineering and Technology 04(6):2321–7308

Ulaeto SB, Ekpe UJ, Chidiebere MA, Oguzie EE (2012) Corrosion inhibition of mild steel in hydrochloric acid by acid extracts of Eichhornia crassipes. International Journal of Materials and Chemistry 2(4):158–164

Umoren SA, Eduok UM, Israel AU, Obot IB, Solomon MM (2012) Coconut coir dust extract: a novel eco-friendly corrosion inhibitor for Al in HCl solutions. Green Chemistry Letters and Reviews 5(3):303–313

Umoren S, Obot IB , Gasem Z, Odewunmi NA. Experimental and theoretical studies of red apple fruit extract as green corrosion inhibitor for mild steel in HCl solution. Journal of Dispersion Science and Technology (just-accepted). 2014

Vasudha VG, Saratha R (2011) Studies on inhibition of acid corrosion of mild steel by Terminalia catappa (tropical almond) leaves. Orient J Chem 27(3):1165–1171

Xia S, Qiu M, Yu L, Liu F, Zhao H (2008) Molecular dynamics and density functional theory study on relationship between structure of imidazoline derivatives and inhibition performance. Corrosion Science 50:2021–2029

Yamuna J, Athony N (2014) Citrus sinensis L. leaf extract as an efficient green corrosion inhibitor for mild steel in aqueous medium. International Journal of ChemTech Research 7(01):37–43

Yetri Y, Emriadi, Jamarun N, Gunawarman (2014) Corrosion inhibition efficiency of mild steel in hydrochloric acid by adding Theobroma cacao peel extract. International conference on biological, chemical and environmental sciences Penang (Malaysia)

Acknowledgements

The author (AP) thankfully acknowledges the scholarship given by the president of the JECRC University for her PhD work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.ᅟ

Authors’ contributions

SKS, KM and IBO all contributed equally in this manuscript. All authors read and approved the final manuscript.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Sharma, S.K., Peter, A. & Obot, I.B. Potential of Azadirachta indica as a green corrosion inhibitor against mild steel, aluminum, and tin: a review. J Anal Sci Technol 6, 26 (2015). https://doi.org/10.1186/s40543-015-0067-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40543-015-0067-0