Abstract

The control of grain structure, which develops during solidification processes in investment casting of nozzle guide vanes (NGVs), is a key issue for optimization of their mechanical properties. The main objective of this part of the work was to develop a simulation tool for predicting grain structure in the new generation NGVs made from MAR-M247 Ni-based superalloy. A cellular automata - finite element (CAFE) module is employed to predict the three-dimensional (3D) grain structure in the as-cast NGV. The grain structure in the critical sections of the experimentally cast NGV is carefully analyzed, the experimental results are compared with the modeling outcomes, and the model is calibrated via tuning parameters which govern grain nucleation and growth. The grain structures predicted by the calibrated model show a very good accordance with the real ones observed in the critical sections of the as-cast NGV. It is demonstrated that the calibrated CAFE model is a reliable tool for the foundry industry to predict grain structure of the as-cast NGVs with very high accuracy.

Similar content being viewed by others

Background

Solidification microstructure is of great importance for controlling the properties and the quality of the nozzle guide vanes (NGVs) produced via investment casting. In the last decades, emergence of accurate simulation capabilities and development of rigorous analytical models have contributed to a better understanding of solidification process and enabled prediction of solidification grain structure.

Phase-field models have attracted considerable interest since the early 90s to describe phase transitions for a wide range of systems [1]. Phase-field models based on the rigorous framework of reversible thermodynamics [2],[3] have been developed to describe both the solidification of pure materials [4] and binary alloys [5],[6]. They also have been used extensively to simulate numerically dendritic growth into an undercooled liquid [7]-[10]. These computations provide realistic simulations of dendritic growth, including side arm production and coarsening. Systems with three phases as well as grain structures with an ensemble of grains of different crystallographic orientations have also been modeled by the phase-field method using a vector-valued phase field [11]-[16]. The shortcoming of phase-field method is the very fine grid size (<1 μm) required to capture the solid–liquid boundary layer, limiting the size of domains which can be simulated (e.g., <1 mm2 in 2D) [17].

Cellular automata (CA) is another technique widely applied in modeling of solidification. The CA technique was originally developed by Hesselbarth and Göbel [18]. It is based on the division of the simulation domain into cells, which contain all the necessary information to represent a given solidification process. Each cell is assigned information regarding the state (solid, liquid, interface, grain orientation, etc.) and the value of the calculated fields (temperature, composition, solid fraction, etc.). In addition, a neighborhood configuration is selected, which includes the cells that can have a direct influence on a given cell. The fields of the cells are calculated by analytical or numerical solutions of the transport and transformation equations. The change of the cell states is calculated through transition rules, which can be analytical or probabilistic. When these rules are probabilistic, the technique is called stochastic. The important feature of the method is that all cells are considered at the same time to define the state of the system in the following time step. Thus, the computational time step can be directly related to the physical time step.

The CA technique is often coupled with finite difference (FD) or finite element (FE) methods that makes it possible to obtain more accurate results. The modeling technique based on combining the CA method for tracking the solid–liquid front location with a FD solution of solute diffusion is referred to as CAFD model. This model was successfully used to simulate dendritic growth in a range of alloys [19],[20]. The CAFD model solves the solute conservation equation subjected to equilibrium conditions at the solid–liquid interface. The model simulates the solutal interaction within the developing dendritic network, predicting when overgrowth or branching will occur. The model was applied to investigate the effect of changing the pulling velocity on directionally solidified dendritic structures in Ni-based superalloys [20].

Rappaz and Gandin [21] started to explore the possibility of coupling FE heat flow computations with two-dimensional (2D) CA calculations describing the mechanisms of nucleation and growth of dendritic grains. The first model was applied only to small specimens of uniform temperature, i.e., it was an isothermal model. One year later, Gandin and Rappaz [22] extended the model to non-uniform temperature situations, and the modeling tool was referred to as cellular automata - finite element (CAFE) module. In 1997, Gandin and Rappaz [23] proposed a three-dimensional (3D) CA algorithm to model the growth of octahedral dendritic grains from the liquid phase. The 3D CAFE module was able to account for different cooling conditions, crystallographic orientations, and growth kinetics parameters. The CAFE model is based on the concept of marginal stability to uniquely define the dendrite tip radius, allowing the analytical solution of Kurz, Giovanola, and Trivedi (KGT) to be applied [24]. CAFE models do not incorporate details of dendritic growth, but they are very useful for simulating grain structures on orders of magnitude larger simulation domains than is possible using the phase-field method. Another advantage of CAFE models is a clear prediction of grain size and shape.

The developed 3D CAFE module found a wide application for simulation of solidification grain structure in casting of complex shape parts. Gandin et al. [25] were first to apply it for grain structure prediction in directionally solidified blades. In particular, the growth competition occurring among columnar grains was directly reproduced, taking into account the crystallographic orientation of the grains and the temperature evolution in representative 3D investment cast parts. Seo et al. [26] successfully applied the model to predict grain structure in turbine blades produced via investment casting of CM247LC Ni-based superalloy. The overall appearance of grain structure in the cast blades was very well reproduced by the CAFE module at various investment casting conditions. Wang et al. [27] applied the CAFE module for simulation of grain selection during single crystal casting of a DD403 Ni-based superalloy with spiral grain selector, and the model was validated experimentally via investment casting using different spiral geometries. It was demonstrated that the CAFE module was a reliable tool for optimization of crystal orientation via manipulation with mold geometry.

The second part of our work aims to develop the CAFE module for grain structure prediction in the new generation NGVs to be produced via investment casting in a real plant process. Along with the thermal model and ProCast model for porosity prediction, it will form a modeling tool for further optimization of the NGV design at industrial scale.

Description of the modeling tool

The CAFE module is a software tool which allows the prediction of structures of castings in which columnar and equiaxed crystals are formed. CAFE is based on a stochastic model which combines grain nucleation and grain growth algorithms with the calculation of the heat transfer by FE as described by Gandin et al. [28]. These algorithms and their parameters are considered below.

Grain nucleation algorithm

The CAFE model assumes that grains may nucleate on the surface of the mold (surface nucleation) or in the bulk (volume nucleation). Both types of nucleation are described by Gaussian distributions as

where ΔT is the local undercooling, ΔTm the mean undercooling, σΔT the standard deviation, and nmax the maximum nucleation density which can be reached when all the nucleation sites are activated while cooling. These parameters mainly depend on the selected alloy, the shape of the cast part, its volume, and the casting procedure. Their determination is difficult in our case, since no previous references can be found in the literature. Calibration with experimental results is the only possible procedure for their precise estimation. Precicast Bilbao has provided a set of preliminary values from previous experimental work on investment casting of Ni-based superalloys (Table 1), but their final calibration and validation are still necessary for reaching more accurate results.

Grain growth algorithm

Grain growth kinetics during metal solidification can be determined by the undercooling at dendrite tips. Different theories have been developed for growth kinetics, with the Lipton-Glicksman-Kurz (LGK) model selected as the one to make the linkage between growth velocity and the given undercooling as described by Kurz et al. [24] and Lipton et al. [29]. Thus, the following simplified equation is used by CAFE module for calculations:

where v is the dendrite tip velocity, ΔT the undercooling, and a2 and a3 are the specific material parameters. The value of the local undercooling (ΔT) is provided by the thermal resolution of the model during ProCAST calculation [28] as the difference between the liquidus temperature and the local temperature in each finite element. The value of the parameters a2 and a3 may be calculated by the CAFE module based on the alloy chemical composition and the phase diagram properties, such as liquidus temperature (1,366°C for Mar-M247 Ni-based superalloy), Gibbs-Thomson coefficient of the solvent (2 · 10−7 for Ni), chemical concentration of each solute element (Table 2), liquidus slope, and partition coefficient of each element. For multi-component systems, the latter two can only be obtained with the help of thermodynamic databases [30]. Once input data are known, values of parameters a2 and a3 are calculated (Table 3).

At the same time, when grains grow, their orientation is randomly determined by the model. Since growth velocity of each grain tip is calculated by undercooling in front of each dendrite tip, the grains better aligned with the maximum undercooling direction will grow faster than those which are not (Figure 1). This effect makes possible the growth of secondary and tertiary side arms on dendrites having favorable orientation as shown in Figure 1.

To obtain good results from calculation, a proper ‘cell size’ must be defined. If the cell size is too big, poor results will be achieved, but if too small, time calculation will shoot up. A proper cell size is given by the value of the typical secondary dendrite arm spacing measured in the casting, being values between 50 and 100 μm most commonly used [20]. This small size of the cells means that the amount of cells to be considered for the calculation can be extremely high. To tackle this problem, the software first divides the part into ‘blocks’, which will be composed by a defined number of cells (Figure 2). The number of cells contained in a single block is chosen by the user in order to improve the calculation. Once the software has divided the part into blocks, each block is given one of three statuses: stand by, active, or inactive (Figure 2). Blocks in stand by position are located in the liquid but out of the mushy zone where solidification is taking place. The active ones are located in the mushy zone and, therefore, these blocks enter into calculation by the solver. Finally, the inactive blocks correspond to those in the solid zone. The inactive blocks have undergone calculation and their results have been stored. This approach is applied in order to reduce the number of blocks that are in calculation simultaneously, so the solution can be achieved faster. This technique is especially useful for parts produced via directional solidification as demonstrated by Qingyan et al. [31], since the number of blocks that are being calculated simultaneously, can be much smaller than in the cases when the solidification process is more distributed.

All parameters defined above are considered by the software to calculate the transition from equiaxed to columnar grains. No specific parameter is used to determine this transition, being described by the grain growth competition, which depends on the mean undercooling in each location of the mushy zone [23].

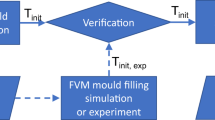

It is seen that the most important data to perform correct calculations with the CAFE module are provided by the thermal model, so a reliable thermal model well describing the real solidification process is required. A detailed description of the thermal model used in our work can be found in the first part of this manuscript.

Model definition

For the prediction of the NGV grain structure, a reliable thermal model was developed (see part I). This model is imported to the CAFE pre-processor, where parameters necessary to define the nucleation and growth algorithms and the calculation conditions are established. For the given example of NGV, the pre-processor is setup as described below.

-

Domain selection: the model includes not only the cast part but also other elements such as the mold, insulation layer, etc. Therefore, the domain of interest is to be selected. The areas of no interest, such as the feeding system, the pouring cap, etc. can be ignored.

-

General parameters: the cell size and the number of cells per block are defined at this point. In our case, the selected values are 60 μm for the cell size, and each block is composed of a cube of 10 × 10 × 10 cells.

-

Window definition: the zones for calculations are to be defined. In our case, only critical sections of the NGV are investigated. Modeling results for these sections will be compared with results from experimental analyses of real grain structure. Otherwise, analysis of a whole part would lead to very time-consuming calculations.

-

Surface nucleation (nucleation algorithm): values that describe Gaussian distribution for surface nucleation (Equation 1) must be defined (Table 1). Since these values depend on the alloy, cast shape and casting procedure, they are calibrated by comparison of modeling and experimental results.

Volume nucleation (nucleation algorithm): no volume nucleation is expected for this part so all parameters for volume nucleation set to zero (Table 4).

Physical data (growth algorithm): defines the growth kinetics of the given alloy (Mar-M247 Ni-based superalloy), parameters a2 and a3 for Equation 2 are introduced (Table 3).

Results: after definition of zones for modeling (window definition), the CAFE module may request to store additional information such as cuts/planes of interest.

Once the CAFE pre-processor is settled, the CAFE solver is run. The obtained grain structure is demonstrated by Visual-Viewer (CALCOM Software).

Methods

Material and experimental procedures

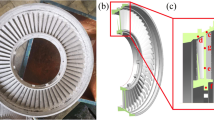

The MAR-M247 Ni-based superalloy was chosen as the material for this investigation. The chemical composition of the material is presented in Table 2. Preparation of the ceramic molds and investment casting process was described in detail in the first part of the manuscript. The as-cast NGV was cut into smaller specimens for analysis of grain structure. The selected areas for grain structure evaluation are shown below in the ‘Conclusions’ section. The specimens were ground and polished to a mirror-like surface using standard metallographic technique. The polished specimens were etched using a chemical solution consisting of 25 g FeCl3, 60 ml HCl, and 25 ml H2O to reveal grain structure.

The optical microscope OLYMPUS BX51 (Olympus Corporation, Shinjuku-ku, Japan) was used for characterization of grain structure. At least three images were taken from each area of interest. Quantitative analysis of grain structure (grain size, standard deviation of grain size, and aspect ratio) was performed using ANALYSIS software. The grain size was measured as an equivalent circle diameter due to complex shape of some grains. Aspect ratio was calculated as a ratio of grain length to its width, as specified in the ANALYSIS software.

Results and discussion

Modeling vs. experimental

After first comparison between experimental and calculated results, the parameters governing the nucleation algorithm in the CAFE module were calibrated. The final grain structure predicted by the CAFE module for four critical NGV sections (transversal section of a hollow vane, transversal and longitudinal sections of a solid vane, and longitudinal section of the bottom platform) is compared with the real grain structure of the as-cast NGV. The comparison is based on (1) visual comparison of grain structure for critical sections of the NGV and (2) comparison of average grain size, standard deviation of the grain size, and aspect ratio of grains for these NGV sections.

The final calibrated values for the surface and volume nucleation algorithms are presented in Table 4. As calibrated values will remain the same for the full cast part, the prediction of the grain structure at any location of the piece will be possible. It should be noted that the final values of parameters for surface nucleation are close to the original ones proposed by Precicast Bilbao (Table 1). Nevertheless, even such a small difference can significantly affect the final modeling result.

Grain structure on transversal section of a hollow vane

The location of the selected section is marked by a red circle in the NGV icons in Figure 3, where the general view of the grain structure predicted by CAFE (Figure 3b) and grain structure of the real NGV (Figure 3a) are illustrated. An accurate comparison of the modeling and experimental results can be made analyzing optical microscopy images taken at higher magnification from leading and trailing edges of the hollow vane and its middle part (Figure 4). Qualitative and quantitative analysis shows that the modeling results perfectly match the grain structure of the hollow vane in all areas of the hollow vane. Fast solidification occurs in the thin walls (Figure 4b) resulting in the formation of homogeneous grain structure consisting of small equiaxed grains. Both equiaxed and columnar grains are observed in the leading edge (Figure 4a) and trailing edge (Figure 4c) of the hollow vane due to a more complex character of the local heat flux during solidification. The average grain size, its standard deviation, and aspect ratio from modeling and experimental results have nearly the same values in all areas of the hollow vane (Table 5).

Microstructure of transversal section of a hollow vane (Figure3) at higher magnifications. Optical microscopy images (left) are compared with CAFE prediction (right): a) leading edge, b) middle part, and c) trailing edge.

Grain structure on transversal section of a solid vane

The analyzed transversal section of the solid vane is marked by a red circle on the NGV icons (Figure 5). A very good agreement between modeling and experimental results is observed (Figure 5). The fast solidification in the thin trailing edge leads to formation of small equiaxed grains (Figure 6a). As the mushy zone moves towards the middle part of the solid vane, the condition of directional solidification is achieved resulting in transition from equiaxed to columnar grains (Figure 6b). A similar effect is observed on the leading edge of the solid vane, where equiaxed grains initially appear on the edge and transform into columnar grains when solidification proceeds into middle part (Figure 6c).

Microstructure of transversal section of solid vane (Figure5) at higher magnifications. a) trailing edge, b) middle part, and c) leading edge. Optical microscopy images (left) are compared with CAFE prediction (right).

Average grain size and its standard deviation from the CAFE prediction are in a good accordance with those experimentally measured on the transversal section of the solid vane (Table 6). However, the model predicts somewhat higher aspect ratio in all parts of the transversal section of the solid vanes. Nevertheless, the visual comparison of the predicted and real grain structures shows a good match also for grain shape (Figure 6).

Grain structure on longitudinal section of a solid vane

For analysis of grain structure on the longitudinal section of a solid vane, it was cut along its axis. The cut plane is marked by a blue line on Figure 5b. The location of the analyzed section is marked by a red circle in the NGV icon in Figure 7a, where grain structure of the real NGV is also presented. The grain boundaries have been marked by a red line for easier identification. The grain structure predicted by CAFE model (Figure 7b) is similar to the experimental results. Microstructure with small grains close to the surface of solid vane (on the top of images), where solidification begins, is gradually transformed into microstructure with coarse grains when the mushy zone moves towards the central part of the solid vanes which is solidified in the last stage. It should be noted that the grain structure does not vary along the vane axis (horizontal axis in Figure 7).

Quantitative analysis shows that the CAFE model underestimates the average grain size, though the values of grain size from the model and experimental measurements overlap if standard deviation is taken into account (Table 7). The CAFE model provides a somewhat higher average value of grain aspect ratio which fits better to the grains close to the solid vane surface (top part of the images in Figure 7). Nevertheless, it can be concluded that there is a good match between the modeling and experimental results.

Grain structure on longitudinal section of a bottom platform

The location of the selected section in the bottom platform is marked by a red circle in the NGV icon in Figure 8. For convenience, the longitudinal section has been divided into four zones as shown in Figure 8, which also illustrates the grain structure predicted by the CAFE module. The modeling results show a good match with the real grain structure on the longitudinal section of the bottom platform in all four zones (Figure 9). Again, fast solidification in very thin elements (zones 2 and 3) leads to formation of homogeneous microstructure consisting of small equiaxed grains as seen from the optical microscopy image and grain structure generated by the model (Figure 9). On the contrary, columnar grains prevail in the microstructure of the thicker element (zones 1 and 4).

Microstructure of longitudinal section in zones 1 and 2 of the bottom platform (Figure8). Optical microscopy images (left) are compared with CAFE prediction (right).

The average grain size measured from optical microscopy images in zones 1 and 2 are in a very good accordance with the model prediction (Table 8). The model tends to underestimate the average grain size in zones 3 and 4, though the ranges of grain size from model and experiment overlap (Table 8). The shape of grains in the modeled grain structure is very similar to that observed in the optical microscopy images in all four zones (Figure 9). From Table 8, it is seen that the CAFE model predicts well the aspect ratio of grains in all analyzed zones of the bottom platform.

The comparison of the modeled grain structure with the real one formed in the critical sections of the as-cast NGV clearly shows that the CAFE module is a very useful tool for prediction of grain structure in the complex shape parts manufactured from Ni-based superalloys via investment casting. It is able to predict with high accuracy the size, shape, and orientation of grains throughout the complex shape part. The thermal model and models for porosity and grain structure prediction constitute a tool for further improvement of NGV design. This tool can provide the optimum parameters for investment casting at low cost in a quick manner. It should be also noted that thus obtained modeling results on porosity and grain structure could potentially be used for modeling of mechanical and functional properties of various sections of NGVs. So the integrated modeling tools could be developed in the future, which will dramatically minimize or even eliminate the number of experimental casting trials.

Conclusions

A CAFE module was employed to predict the 3D grain structure in NGVs manufactured from Ni-based superalloys via investment casting. The grain structure of the critical sections in the experimentally cast NGV was carefully analyzed, the experimental results were compared with preliminary grain structure prediction, and the model was calibrated via tuning parameters in the algorithms describing grain nucleation and growth.

It is demonstrated that the calibrated CAFE model is a reliable tool for the foundry industry to predict grain structure in the new design NGVs with high accuracy. Microstructure consisting of small equiaxed grains is predicted in the trailing edge and thin walls of the vanes, where fast solidification occurs. Grain growth follows the heat flux directions described by the thermal model, so larger grains appear in the thicker sections. The predicted grain size is always in the range of grain sizes measured in the real as-cast NGV, though the CAFE module provides smaller standard deviation. Transition from equiaxed to columnar grains is correctly predicted in the bottom platform of the NGV.

It is outlined that the calibrated CAFE module is a useful and reliable tool for the foundry industry to predict grain structure of the as-cast NGVs.

Change history

25 October 2021

A Correction to this paper has been published: https://doi.org/10.1007/s40192-021-00234-3

References

Janssens KGF, Raabe D, Miodownik Y, Kozeschnik MA, Nestler B: Computational Materials Engineering. Elsevier Academic Press, Burlington, MA, USA; 2007.

Penrose O, Fife PC: Thermodynamically consistent models of phase-field type for the kinetic of phase transitions. Phys D 1990, 43: 44–62. doi:10.1016/0167–27890167–2789(90)90015-H

Wang SL, Sekerka RF, Wheeler AA, Coriell SR, Murray BT, Braun RJ, McFadden GB: Thermodynamically-consistent phase-field models for solidification. Phys D 1993, 69: 189–200. doi:10.1016/0167–27890167–2789(93)90189–8

Caginalp G, Fife PC: Phase field methods of interfacial boundaries. Phys Rev B 1986, 33: 7792–7794. doi:10.1103/PhysRevB.33.7792

Lowen H, Bechoefer J, Tuckerman LS: Crystal growth at long times: critical behavior at the crossover from diffusion to kinetics-limited regimes. Phys Rev A 1992, 45: 2399–2415. doi:10.1103/PhysRevA.45.2399

Warren JA, Boettinger WJ: Prediction of dendritic growth and microsegregation patterns in a binary alloy using the phase-field method. Acta Metall Mater 1994, 43: 689–703. doi:10.1016/0956–7151(94)00285-P

Kobayashi R: Modeling and numerical simulations of dendritic crystal-growth. Phys D 1993, 63: 410–423. doi:10.1016/0167–2789(93)90120-P

Wheeler AA, Murray BT, Schaefer RJ: Computation of dendrites using a phase field model. Phys D 1993, 66: 243–262. doi:10.1016/0167–27890167–2789(93)90242-S

Wang SL, Sekerka RF: Algorithms for phase eld computations of the dendritic operating state at large su-. percoolings. J Comp Phys 1996, 127: 110–117. 10.1006/jcph.1996.0161

Provatas N, Goldenfeld N, Dantzig J: Efficient computation of dendritic microstructures using adaptive mesh refinement. Phys Rev Lett 1998, 80: 3308–3311. doi:10.1103/PhysRevLett.80.3308

Chen LQ, Young W: Computer simulation of the domain dynamics of a quenched system with a large number of nonconserved order parameters: the grain-growth kinetics. Phys Rev B 1994, 50: 15752–15756. doi:10.1103/PhysRevB.50.15752

Chen LQ: A novel computer simulation technique for modeling grain growth. Scr Metall Mater 1995, 32: 115–120. doi:10.1016/S0956–716X(99)80022–3

Steinbach I, Pezzolla F, Nestler B, Seesselberg M, Schmitz GJ, Rezende J: A phase field concept for multiphase systems. Phys D 1996, 94: 135–147. doi:10.1016/0167–27890167–2789(95)00298–7

Nestler B, Wheeler AA: Anisotropic multi-phase-field model: interfaces and junctions. Phys Rev E 1998, 57: 2602–2609. doi:10.1103/PhysRevE.57.2602

Kobayashi R, Warren JA, Carter WC: Vector-valued phase field model for crystallization and grain boundary formation. Phys D 1998, 119: 415–423. doi:10.1016/S0167–2789(98)00026–8

Garcke H, Nestler B, Stoth B: On anisotropic order parameter models for multi-phase systems and their sharp interface limits. Phys D 1998, 115: 87–108. doi:10.1016/S0167–2789(97)00227–3

Boettinger WJ, Warren JA: The phase-field method: simulation of alloy dendritic solidification during recalescence. Metall Mater Trans A 1996, 27: 657–669. doi:10.1007/BF02648953

Hesselbarth HW, Göbel IR: Simulation of recrystallization by cellular automata. Acta Metall 1991, 39: 2135–2143. 10.1016/0956-7151(91)90183-2

Wang W, Kermanpur A, Lee PD, McLean M: Simulation of dendritic growth in the platform region of single crystal superalloy turbine blades. J Mater Sci 2003, 38: 4385–4391. doi:10.1023/A:1026303720544

Wang W, Lee PD, McLean M: A model of solidification microstructures in nickel based superalloys: predicting primary dendrite spacing selection. Acta Mater 2003, 51: 2971–2987. doi:10.1016/S1359–6454(03)00110–1

Rappaz M, Gandin CA: Probabilistic modelling of microstructure formation in solidification processes. Acta Metall Mater 1993, 41: 345–360. doi:10.1016/0956–7151(93)90065-Z

Gandin CA, Rappaz M: A coupled finite element-cellular automaton model for the prediction of dendritic grain structures in solidification processes. Acta Metall Mater 1994, 42: 2233–2246. doi:10.1016/0956–7151(94)90302–6

Gandin CA, Rappaz M: A 3D cellular automaton algorithm for the prediction of dendritic grain growth. Acta Mater 1997, 45: 2187–2195. doi:10.1016/S1359–6454(96)00303–5

Kurz W, Giovanola B, Trivedi R: Theory of microstructural development during rapid solidification. Acta Metall 1986, 34: 823–830. doi:10.1016/0001–6160(86)90056–8

Gandin CA, Rappaz M, Desbiolles JL, Lopez R, Swierkosz M, Thevoz PH (1997) 3D modeling of dendritic grain structures in turbine blade investment cast parts. In: Loria EA (ed) Proceedings of the TMS Meeting. TMS, p 121

Seo SM, Kim IS, Jo CY, Ogi K: Grain structure prediction of Ni-base superalloy castings using the cellular automaton-finite element method. Mater Sci Eng A 2007, 449–451: 713–716. doi:10.1016/j.msea.2006.02.400

Wang N, Liu L, Gao S, Zhao X, Huang T, Zhang J, Fu H: Simulation of grain selection during single crystal casting of a Ni-base superalloy. J Alloys Compd 2014, 586: 220–229. doi:10.1016/j.jallcom.2013.10.036

Gandin CA, Desbiolles JL, Rappaz M, Thevoz P: A three-dimensional cellular automation-finite element model for the prediction of solidification grain structures. Metall Mater Trans A 1999, 30: 3153–3165. doi:10.1007/s11661–999–0226–2

Lipton J, Glicksman ME, Kurz W: Equiaxed dendrite growth in alloys at small supercooling. Metall Trans A 1987, 18: 341–345. doi:10.1007/BF02825716

ProCast user Manual & Technical Reference:Technical Reference (2007). Version 6.1. ESI software, France; 2007.

Qingyan X, Baicheng L, Dong P, Jing Y: Progress on modeling and simulation of directional solidification of superalloy turbine blade casting. Res Develop 2012, 2: 69–77.

Acknowledgements

This investigation was carried out in frame of the VANCAST project (EU, FP7, ERA-NET MATERA+). SM and IS acknowledge gratefully the Spanish Ministry of Economy and Competitiveness for financial support through the Ramon y Cajal fellowships.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

AJT applied the CAFE model and created the initial draft of the manuscript. OK and LC provided the materials science guidance and expertise in modeling. LM performed the experimental casting trials. ECM contributed with the overall development of the main concepts presented in this paper. MR performed the quantitative analysis of grain structure in the as-cast NGV. SM and IS helped with the validation of the developed grain structure prediction tool and manuscript writing. JL formulated the concept of this work and conceived the workflow, as well as provided materials science guidance. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Torroba, A.J., Koeser, O., Calba, L. et al. Investment casting of nozzle guide vanes from nickel-based superalloys: part II – grain structure prediction. Integr Mater Manuf Innov 3, 369–384 (2014). https://doi.org/10.1186/s40192-014-0026-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1186/s40192-014-0026-4