Abstract

Ciprofloxacin (CIP) antibiotic is considered as an emerging and biological resistant pollutant. This study aimed to improve of the removal of CIP from synthetic aqueous solutions in photocatalytic process through copper oxide nanoparticles as catalyst (CuO/UV). The effect of CIP concentration (10–200 mg/l), catalyst dosage included CuO (0.01–0.1 g/l) and pH (3–11) as independent variables on the COD removal efficiency as response in photocatalytic process using UV-C lamps with three different powers of 8, 15 and 30-W were optimized through the central composite design in response surface method using design-expert software. A second order model was selected as the best model with R2 values and lack of fit as 0.85 and 0.06 for lamp 8-W, 0.89 and 0.11 for lamp 15-W, and 0.86 and 0.19 for lamp 30-W, respectively. Optimum conditions were obtained in CIP concentration of 11.2 (mg/l), CuO dosage of 0.08 (g/l), and pH value of 8.17. In this condition, predicted maximum COD removal was respectively found 83.79, 93.18, and 98.90% for lamps 8, 15 and 30-W. According to the results, photocatalytic process using copper oxide nanoparticles can effectively compose CIP in aqueous solutions.

Similar content being viewed by others

Introduction

Antibiotics, especially fluoroquinolones, have been considered as the important emerging pollutants in water sources and municipal wastewater (Guo et al. 2013). They are priority pollutants due to the high toxicity for algae and bacteria in trace concentration (Hernando et al. 2006). These compounds are extensively used to prevent or treat bacterial infections in humans, animals and plants (Balarak et al. 2017). Antibiotics use in modern aquacultures in diverse areas including Iran in large scale to prevent or treat the infectious diseases in fishes (Adel et al. 2017). The WHO has declared that widespread application of antibiotic in the aquacultures may cause risks for the consumer contributing to the antibacterial resistance in human and veterinary medicine due to the accumulation of their residues in edible tissues of fish (Adel et al. 2017; Conti et al. 2015). Also, antibiotics can release into the surrounding waters during treatment of fish stocks and cause some environmental problems (Adel et al. 2017). Furthermore, presence of antibiotics in the aquatic environments may pose toxicological effects on non-target organisms, disturb the biological balance and photosynthetic cycles of plants (Rakshit et al. 2013).

Ciprofloxacin (CIP) as the most common fluoroquinolones is broadly consumed (Dodd et al. 2006). CIP with kbio = 0.02–0.55 l/gMLSS day appeared not to be easily biodegraded during biological wastewater treatment processes (Tran et al. 2017). Mean concentration of CIP is reported 2.5 μg/l in the hospital wastewater effluent, 0.6 μg/l in influents of the municipal wastewater treatment plant and 14–42 ng/l in the surface waters (Watkinson et al. 2009; El-Shafey et al. 2012). Therefore, wastewater treatment plants should be upgraded with novel unites included effective physiochemical processes such as coagulation, advanced oxidation processes (AOPs) and adsorption with activated carbon or nanoparticles to removal of CIP (Rakshit et al. 2013; Sui et al. 2012; Khoshnamvand et al. 2017).

In previous studies, the degradation and removal of CIP have been reported using hazelnut shell activated carbon (Balarak et al. 2016), magnetite (Fe3O4(s)) (Rakshit et al. 2013), ozonation and sonolysis (Vasconcelos et al. 2009; Paul et al. 2010), UV/TiO2 (Paul et al. 2010), visible light/TiO2 (Paul et al. 2007), UV and UV/H2O2 (Guo et al. 2013). Researches demonstrated that physical processes not be able to effectively remove CIP. On the other hand, chemical processes may generate harmful by-products (Shi et al. 2013). So, AOPs have been introduced as the effective methods to degradation and elimination of antibiotics and other organic compounds. Recent studies were reported a high removal efficiency for CIP through photocatalytic process with semi-conductors such as Tio2–ZnO (Skoumal et al. 2006; Norzaee et al. 2017). The mechanism of AOPs is radiation of UV to a semi-conductor material and, consequently, the electron excitation and its emission from the valence band to conduction band. This excitation results in production of active hydroxyl radical (OH·) that effectively oxidize organic pollutants (Xiao et al. 2015). Among the semi-conductors, copper oxide (CuO) nanoparticles have been considered as the high-efficiency catalysts from 1990 due to the extremely effective surface area and more effect of quantum size compared to masses of copper (Han et al. 2006).

Response surface methodology (RSM) is a collection of mathematical and statistical methods to set the experimental models, in which, two stages are essential, the estimation of function and the experimental design. RSM was effectively applied in the experimental studies. The application of RSM is to control the cost of analytical methods and related numerical noise (Dehghani et al. 2017; Amiri et al. 2018; Khayet et al. 2011).

This study aimed to improve of the removal of CIP from synthetic aqueous solutions in photocatalytic process through copper oxide nanoparticles as catalyst (CuO/UV) using UV-C lamps with power of 8, 15 and 30-W. To the best of our knowledge, present study is first study considering CuO nanoparticles as catalyst to removal of CIP from solutions in photocatalytic process.

Materials and methods

Chemical

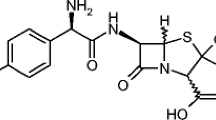

In this study, all materials included Ciprofloxacin hydrochloride, C17H18FN3O3, (≥ 98%) (Fig. 1), sodium hydroxide (NaOH), hydrochloric acid (HCl), copper oxide (CuO) nanoparticles (size > 50 nm, molecular weight: 79.55 g/mol, purity ≥ 99%) were purchased from Sigma-Aldrich Company. Also, UV-C lamps with power 8, 15 and 30-W and wavelength of 254 nm were bought from Philips company (Germany). The surface textural and morphological structure of the CuO nanoparticles were analyzed with a scanning electron microscope (SEM) (HITACHI Model S-4160). Also, CuO nanoparticles was analyzed by X-ray diffraction (XRD) (Philips, Model XPERT PW 3040/60). SEM image and XRD pattern are shown in Fig. 2a, b, respectively.

Experimental design

The effect of independent variables mentioned in Table 1 on the dependent variable or response (COD removal efficiency) and the optimum conditions were investigated using the central composite design (CCD) in RSM. A second-order model can be efficiently constructed with CCD. CCD is actually a first-order (2 N) designs that amplified by center and axial points to estimation of the second-order model parameters (Amiri et al. 2018). p-value less than 0.05 was considered significant in all statistical analyses. At first, a factorial design was done to determine significant variables. Then, experiments were designed based on Montgomery method (Myers et al. 2016) in a central composite rotatable design for mentioned independent variables in 20 runs.

The experimental method results were used to specify an empirical second order polynomial regression model that is shown as follows (Eq. 1):

where Y is the response; xi and xj are independent variables (i and j ranged from 1 to k); β0 is the constant term; βj is the linear coefficient, βij is the interaction coefficient, and βjj is the quadratic coefficient; k is the number of independent variables (k = 3 in this study) (Amiri et al. 2018).

Batch studies

The photocatalytic process was run in a batch Plexiglas reactor (Fig. 3) included two chambers. The main chamber (reaction chamber) had a useful volume of 500 ml. The secondary chamber with a volume of 3 l and a continuous flow of water surrounded the main chamber to keep temperature constant at 27 ± 3 °C. Reactor was equipped with the UV lamp (LU 100A) with different powers, 8, 15 and 30-W. The reactor was wrapped in aluminum foil to prevent UV reflection and increase lamp efficiency. Magnetic stirring was used to homogenization of solution in the reaction reactor. Batch experiments were performed according to the designed runs in a constant time 60 min, triplicate. CIP stock solution was daily prepared and stored at 4 °C. Then, different concentrations of CIP were made from stock in deionized water. The CIP solution and CuO nanoparticles were injected into the reactor. pH of solutions was adjusted by HCl and NaOH, 1 N. Suspension was maintained in the dark for 30 min so the CIP solution and nanoparticles attain equilibrium condition. Nanoparticles in outlet solutions were separated through centrifugation for 10 min at 3000 rpm followed filtration with the 0.22 μm polytetrafluoroethylene syringe filters (Schleicher & Schuell, Germany). COD concentration in inlet and outlet solutions was analyzed using UV/VIS spectrophotometer (HACH, DR-5000) according to the D5220 method in the handbook of standard methods for the examination of water and wastewater (Federation and Association 2005). COD removal efficiency (Y) was calculated from Eq. 2:

where C e and C0 are COD concentrations in inlet and outlet solutions (mg/l), respectively.

Statistical analysis

Multiple regression analysis through the generalized least square was used to analyze the experimental data and explore the relationship between the independent variables and response using the design-expert software (version-10). Two-way analysis of variance (ANOVA) test was used to compare the mean difference of COD removal between independent variables. Results were defined statistically significant if p-value was lower than 0.05.

Results

Model fitting and statistical analysis

Independent variables and COD removal percent in form of experimental and predicted responses in 20 runs for the development of mathematical equations were represented in Table 2. Different regression models were analyzed and finally a second order model was fitted, as the best model for COD removal percent, between the experimental results obtained on the basis of the central composite experimental design and the input variables. COD removal efficiency was assessed as a function of CIP concentration (X1), CuO nanoparticles dosage (X2) and pH (X3) and calculated as the sum of a constant, three first-order effects (X1, X2 and X3), three interaction effects (X1X2, X1X3 and X2X3) and three second-order effects (X 21 , X 22 and X 23 ). The model fitness was verified by the correlation coefficient R2 of the model and p-value for lack of fit, the R2 values were gained 0.85, 0.89 and 0.86 for lamps 8, 15 and 30-W, respectively. p-value for lack of fit values was found higher than 0.05 for all three models. The F values as 5.98, 3.72 and 2.61 and p-values as 0.03, 0.01 and 0.009 were calculated respectively for 8, 15 and 30-W lamps (Tables 3, 4, 5).

The coefficients of the models for the response were estimated using multiple regression analysis technique included in the RSM. The second order models obtained in terms of actual factors for significant coefficients (p-values < 0.05) were given as follows by Eqs. 3–5. The insignificant coefficients (p-values > 0.05) were removed from the model.

where X1, X2 and X3 are CIP concentration, CuO nanoparticles dosage and pH, respectively.

Effect of various parameters on COD removal efficiency

Results of ANOVA test for three lamps, 8, 15 and 30-W, are presented in Tables 3, 4 and 5. The COD removal was graphically shown through contour plots. Graphs were plotted as the effect of two variables on the removal efficiency that vary within the determined experimental ranges, keeping one of variables at a fixed level (central level).

Effect of CIP concentration

Figure 4 compares the effect of CIP concentration and CuO dosage on the COD removal efficiency at central level of pH equal to 7 for three lamps. Optimum CIP concentration was obtained 11.2 mg/l the based on optimization data results (Table 6).

Effect of CuO dosage

COD removal efficiency according to the CuO dosage in different concentrations of CIP in Fig. 4 demonstrated that addition of CuO improved COD removal efficiency, but according to optimum CuO dosage as 0.08 g/l (Table 6), COD removal was decreased in the CuO dosage higher than 0.08 g/l.

Effect of solution pH

The effect of solution pH on the COD removal in different concentrations of CIP and CuO is presented in Figs. 5 and 6, respectively. It is clearly shown that the performance of CuO/UV process is dependent of pH and increased efficiency was observed in the pH range of 3–8. Also, efficiency was decreased in pH values higher than 8. The pH value equal to 8 was found as optimum pH in this study (Table 6).

Validation of the model

Based on the optimization results using the numerical method in Table 6, the maximum efficiencies for COD removal were obtained as 83.79, 93.18 and 98.90% by the lamps of 8, 15 and 30-W, respectively at CIP concentration 11.2 (mg/l), CuO dosage 0.08 (g/l) and pH value 8.17. The experimental removal efficiencies for COD were 82.23 ± 1.23, 92.96 ± 1.47 and 96.58 ± 1.04% in three experiments based on optimum condition, corresponding well to the predicted efficiencies, that approved that the models were adequate for the optimization of variables.

Discussion

Second order models were fitted between the experimental results of COD removal obtained on the basis of the central composite experimental design and the independent variables in Table 2. The R2 values of models obtained as 0.85, 0.89 and 0.86 for lamps 8, 15 and 30-W, respectively were shown that there was a high correlation between predicted values from the fitted model and experimental data points.

However, a high value of R2 does not mean that the model is the best. For this reason, the variances were applied to measure the lack of fit between the predicted and the experimental data. Lack of fit value is calculated using the difference between of sum of the squares for the experimental response variable and the its predicted values by the model (Yaghmaeian et al. 2016; Amiri et al. 2018). Based on the p-value for lack of fit values, there is no significant difference between experimental and predicted model data, so it can be concluded the models has a good prediction for COD removal. F values greater than unity and p-values higher than 0.05 for three lamps were approved that the fitted models were significant (Tables 3, 4, 5). According to Eqs. 3–5, CIP concentration, CuO nanoparticles dosage and pH were important factors in the COD removal process related to the photocatalytic degradation of CIP drug in aqueous solutions using CuO nanoparticles. According to the model coefficients, the linear term of CuO nanoparticles dosage and after that, pH had the largest effect on COD removal in photocatalytic process.

It was determined by ANOVA test that mean of COD removal percent was significantly different between variables of CIP concentration, CuO nanoparticles dosage and pH in the defined range for all three lamps.

According to Fig. 4, COD removal efficiency was decreased by increased CIP concentration from optimum value equal to 11.2 mg/l. This finding could be attributed to the more time needed to decompose of CIP when a more concentration of CIP be exposed to UV. Also, CIP acts as a barrier and suppresses UV penetration to the suspension (Guo et al. 2013). On the other hand, increasing CIP concentration can be led to adsorption of irradiated UV by CIP molecules and reduction of COD removal efficiency (Kümmerer 2003). This finding was accordance to the other studies (El-Sayed et al. 2014; Guo et al. 2013, Mostafapour et al. 2016).

The amount of catalyst greatly affected the degradation rate of compounds as if addition of CuO improved COD removal efficiency (Fig. 4), but efficiency was decreased in the values of CuO dosage greater than optimum point as 0.08 g/l. An overdose of the catalyst decreases process efficiency through decreasing the UV penetration due to turbidity associated to the excess catalyst clusters, diffusing UV radiation and reducing the total surface area that can be stimulated (Alimoradzadeh et al. 2012). This result was similar to other researches (Mostafapour et al. 2016; Alimoradzadeh et al. 2012).

The pH is an important parameter in removal of pollutants from aqueous solutions (Faraji et al. 2017). Maximum efficiency was gain in pH value of 8 and after that increased pH resulted in decreasing efficiency. The pH affects AOPs through effects on the rate of chemical reactions and production of radicals in the process (Pouran et al. 2014). Also, pH can change the surface charge properties of the photocatalyst and possibly the chemical structure of the CIP; so solution pH affects photocatalyst reactions. At low pH values, high concentration of protons delayed the photodegradation of CIP under UV light. Protons had high affinity for the hydroxyl anion, preventing the production of hydroxyl radicals. Anionic form of CIP can be generated in solutions with pH values greater than 7.7 (El-Kemary et al. 2010). Bobu et al. concluded that very high pH values lead to increasing HO2− and consumption of OH radicals by carbonate and bicarbonate ions (Bobu et al. 2008). At pH less than 5.7 and higher than 9.4, the tendency of the two substances CIP and CuO nanoparticles may reduce due to the neutrality of the surface charge of two substances to each other, and recovery can reduce. Between these two pH values, the removal efficiency would be increased (El-Kemary et al. 2010).

Our study suggests that advanced oxidation process using copper oxide nanoparticles as the high-efficiency catalysts and UV lamps be able to mineralization of antibiotics such as ciprofloxacin that are biological resistant pollutants.

Abbreviations

- CIP:

-

ciprofloxacin

- AOPs:

-

advanced oxidation processes

- CuO:

-

copper oxide

- RSM:

-

response surface methodology

- XRD:

-

X-ray diffraction

- COD:

-

chemical oxygen demand

- CCD:

-

central composite design

- ANOVA:

-

analysis of variance

References

Adel M, Dadar M, Oliveri Conti G (2017) Antibiotics and malachite green residues in farmed rainbow trout (Oncorhynchus mykiss) from the Iranian markets: a risk assessment. Int J Food Prop 20:402–408

Alimoradzadeh R, Assadi A, Nasseri S, Mehrasbi MR (2012) Photocatalytic degradation of 4-chlorophenol by UV/H2O2/NiO process in aqueous solution. Iran J Environ Health Sci Eng 9:12

Amiri H, Nabizadeh R, Martinez SS, Shahtaheri SJ, Yaghmaeian K, Badiei A, Nazmara S, Naddafi K (2018) Response surface methodology modeling to improve degradation of Chlorpyrifos in agriculture runoff using TiO2 solar photocatalytic in a raceway pond reactor. Ecotoxicol Environ Saf 147:919–925

Balarak D, Mostafapour FK, Azarpira H (2016) Adsorption kinetics and equilibrium of ciprofloxacin from aqueous solutions using Corylus avellana (Hazelnut) activated carbon. Br J Pharm Res 13(3):1–4

Balarak D, Mostafapour FK, Azarpira H, Joghataei A (2017) Langmuir, Freundlich, Temkin and Dubinin–radushkevich isotherms studies of equilibrium sorption of ampicilin unto montmorillonite nanoparticles. J Pharm Res Int 20:1–9

Bobu M, Yediler A, Siminiceanu I, Schulte-Hostede S (2008) Degradation studies of ciprofloxacin on a pillared iron catalyst. Appl Catal B Environ 83:15–23

Conti GO, Copat C, Wang Z, D’Agati P, Cristaldi A, Ferrante M (2015) Determination of illegal antimicrobials in aquaculture feed and fish: an ELISA study. Food Control 50:937–941

Dehghani MH, Faraji M, Mohammadi A, Kamani H (2017) Optimization of fluoride adsorption onto natural and modified pumice using response surface methodology: isotherm, kinetic and thermodynamic studies. Korean J Chem Eng 34:454–462

Dodd MC, Buffle M-O, von Gunten U (2006) Oxidation of antibacterial molecules by aqueous ozone: moiety-specific reaction kinetics and application to ozone-based wastewater treatment. Environ Sci Technol 40:1969–1977

El-Kemary M, El-Shamy H, El-Mehasseb I (2010) Photocatalytic degradation of ciprofloxacin drug in water using ZnO nanoparticles. J Lumin 130:2327–2331

El-Sayed G, Dessouki H, Jahin H, Ibrahiem S (2014) Photocatalytic degradation of metronidazole in aqueous solutions by copper oxide nanoparticles. J Basic Environ Sci 1:102–110

El-Shafey E-SI, Al-Lawati H, Al-Sumri AS (2012) Ciprofloxacin adsorption from aqueous solution onto chemically prepared carbon from date palm leaflets. J Environ Sci 24:1579–1586

Faraji M, Bazrafshan E, Almasian M, Khoshnamvand N (2017) Investigation of fluoride adsorption from aqueous solutions by modified eucalyptus leaves: isotherm and kinetic and thermodynamic studies. Iran J Health Sci 5:65–77

Federation WE, Association APH (2005) Standard methods for the examination of water and wastewater. American Public Health Association (APHA), Washington, DC

Guo H-G, Gao N-Y, Chu W-H, Li L, Zhang Y-J, Gu J-S, Gu Y-L (2013) Photochemical degradation of ciprofloxacin in UV and UV/H2O2 process: kinetics, parameters, and products. Environ Sci Pollut Res 20:3202–3213

Han W-K, Choi J-W, Hwang G-H, Hong S-J, Lee J-S, Kang S-G (2006) Fabrication of Cu nano particles by direct electrochemical reduction from CuO nano particles. Appl Surf Sci 252:2832–2838

Hernando M, Mezcua M, Fernández-Alba A, Barceló D (2006) Environmental risk assessment of pharmaceutical residues in wastewater effluents, surface waters and sediments. Talanta 69:334–342

Khayet M, Zahrim A, Hilal N (2011) Modelling and optimization of coagulation of highly concentrated industrial grade leather dye by response surface methodology. Chem Eng J 167:77–83

Khoshnamvand N, Ahmadi S, Mostafapour FK (2017) Kinetic and isotherm studies on ciprofloxacin an adsorption using magnesium oxide nanopartices. J Appl Pharm Sci 7:079–083

Mostafapour FK, Bazrafshan E, Belark D, Khoshnamvand N (2016) Survey of Photo-catalytic degradation of ciprofloxacin antibiotic using copper oxide nanoparticles (UV/CuO) in aqueous environment. J Rafsanjan Univ Med Sci Health Serv 15:307–318

Kümmerer K (2003) Significance of antibiotics in the environment. J Antimicrob Chemother 52:5–7

Myers RH, Montgomery DC, Anderson-Cook CM (2016) Response surface methodology: process and product optimization using designed experiments. Wiley, New York

Norzaee S, Djahed B, Khaksefidi R, Mostafapour FK (2017) Photocatalytic degradation of aniline in water using CuO nanoparticles. J Water Supply Res Technol Aqua 66:178–185

Paul T, Miller PL, Strathmann TJ (2007) Visible-light-mediated TiO2 photocatalysis of fluoroquinolone antibacterial agents. Environ Sci Technol 41:4720–4727

Paul T, Dodd MC, Strathmann TJ (2010) Photolytic and photocatalytic decomposition of aqueous ciprofloxacin: transformation products and residual antibacterial activity. Water Res 44:3121–3132

Pouran SR, Raman AAA, Daud WMAW (2014) Review on the application of modified iron oxides as heterogeneous catalysts in Fenton reactions. J Clean Prod 64:24–35

Rakshit S, Sarkar D, Elzinga EJ, Punamiya P, Datta R (2013) Mechanisms of ciprofloxacin removal by nano-sized magnetite. J Hazard Mater 246:221–226

Shi W, Yan Y, Yan X (2013) Microwave-assisted synthesis of nano-scale BiVO4 photocatalysts and their excellent visible-light-driven photocatalytic activity for the degradation of ciprofloxacin. Chem Eng J 215:740–746

Skoumal M, Cabot P-L, Centellas F, Arias C, Rodríguez RM, Garrido JA, Brillas E (2006) Mineralization of paracetamol by ozonation catalyzed with Fe2+, Cu2+ and UVA light. Appl Catal B Environ 66:228–240

Sui M, Xing S, Sheng L, Huang S, Guo H (2012) Heterogeneous catalytic ozonation of ciprofloxacin in water with carbon nanotube supported manganese oxides as catalyst. J Hazard Mater 227:227–236

Tran NH, Reinhard M, Gin KY-H (2017) Occurrence and fate of emerging contaminants in municipal wastewater treatment plants from different geographical regions—a review. Water Res 133:182–207

Vasconcelos TG, Henriques DM, König A, Martins AF, Kümmerer K (2009) Photo-degradation of the antimicrobial ciprofloxacin at high pH: identification and biodegradability assessment of the primary by-products. Chemosphere 76:487–493

Watkinson A, Murby E, Kolpin D, Costanzo S (2009) The occurrence of antibiotics in an urban watershed: from wastewater to drinking water. Sci Total Environ 407:2711–2723

Xiao J, Xie Y, Cao H (2015) Organic pollutants removal in wastewater by heterogeneous photocatalytic ozonation. Chemosphere 121:1–17

Yaghmaeian K, Silva martinez S, Hoseini M, Amiri H (2016) Optimization of As(III) removal in hard water by electrocoagulation using central composite design with response surface methodology. Desalination Water Treat 57:27827–27833

Authors’ contributions

NKH and FKM were the main investigator, synthesized the nanocomposite. AM and MF drafted the manuscript and contributed to data analysis. All authors read and approved the final manuscript.

Acknowledgements

We thank the Health Promotion Research Center of Zahedan University of Medical Sciences for supporting of this work.

Competing interests

The authors declare that they have no competing interests.

Availability of data and materials

The dataset supporting the conclusions of this article is included within the article.

Consent for publication

All authors gave their consent and agree to publish the article.

Ethics approval and consent to participate

No human participants were involved in the study.

Funding

This work was financially supported by the Zahedan University of Medical Sciences (Grant Number 66).

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Khoshnamvand, N., Kord Mostafapour, F., Mohammadi, A. et al. Response surface methodology (RSM) modeling to improve removal of ciprofloxacin from aqueous solutions in photocatalytic process using copper oxide nanoparticles (CuO/UV). AMB Expr 8, 48 (2018). https://doi.org/10.1186/s13568-018-0579-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13568-018-0579-2