Abstract

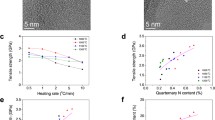

CARBON fibre can be made by the pyrolysis of organic polymer fibre precursors. Up to now, cellulose1 and polyacrylonitrile (PAN)2 have been found to produce carbon fibre of good strength and modulus. Preliminary details of the structure of PAN based carbon fibre, similar to that prepared and used by us, have been published by Johnson and Watt3 and Badami, Joiner and Jones4. One of us5 has reported that the strength of PAN carbon fibre declines when heated above 1,200° C. It is therefore of interest to report that increasing strength with Young's modulus can be obtained if stress is applied to the fibre at graphitizing temperatures.

Similar content being viewed by others

References

Bacon, R., and Tang, M. M., Carbon, 2, 211 (1964).

Shindo, A., Report No. 317 (Government Industrial Research Institute, Osaka, 1961).

Johnson, W., and Watt, W., Nature, 215, 384 (1967).

Badami, D. V., Joiner, J. C., and Jones, G. A., Nature, 215, 386 (1967).

Johnson, J. W., Polymer Preprints Amer. Chem. Soc., 9, 1316 (1968).

Jackson, P. W., and Marjoram, J. R., Nature, 218, 83 (1968).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

JOHNSON, J., MARJORAM, J. & ROSE, P. Stress Graphitization of Polyacrylonitrile Based Carbon Fibre. Nature 221, 357–358 (1969). https://doi.org/10.1038/221357b0

Received:

Issue Date:

DOI: https://doi.org/10.1038/221357b0

- Springer Nature Limited

This article is cited by

-

Fabrication of crystalline submicro-to-nano carbon wire for achieving high current density and ultrastable current

Microsystems & Nanoengineering (2022)

-

A one-step hot pressing molding method of polyacrylonitrile carbon fibers: influence on surface morphology, microstructure and mechanical property

Journal of Materials Science (2022)

-

A comparison of the effect of hot stretching on microstructures and properties of polyacrylonitrile and rayon-based carbon fibers

Journal of Materials Science (2014)

-

Effect of drawing ratio during spinning and oxidation on the properties of polyacrylonitrile precursor and resulting carbon fibre

Journal of Materials Science Letters (1992)

-

The change of crystal orientation from polyacrylonitrile precursor to its resulting carbon fibre

Journal of Materials Science Letters (1990)