Abstract

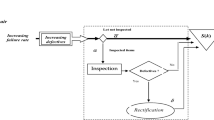

The paper deals with the layout and operation of an inspection system used for detecting malfunctioning processors in a multistage production system. This problem involves three inter-related decisions: (i) the overall inspection capacity; (ii) the assignment of inspection tasks to inspectors; and (iii) the scheduling of the inspector's tasks. These decisions require a trade-off between the cost of inspectors and the loss associated with non-conforming products. A hierarchical heuristic solution procedure is proposed to support these three related decisions. Numerical experiments demonstrate the performance of the heuristic, showing that solution criteria are very close to their lower bounds. Although we use production terminology, the results might be applicable to any organization, which inspects and maintains a variety of characteristics of its branches or activities.

Similar content being viewed by others

References

Ballou, D.P. and Pazer, H.L. (1982) The impact of inspection fallibility on the inspection policy in serial production systems. Management Science, 28, 387–399.

Barad, M. and Braha, D. (1996) Control limits for multi-stage manufacturing processes with binomial yield (single and multiple production runs). Journal of the Operational Research Society, 47(1), 98–112.

Barker, T.B. (1986) Quality engineering by design: Taguchi's philosophy. Quality Progress, 32–42.

Bazaraa, M.S. and Shetty, C.M. (1979) Nonlinear Programming Theory and Algorithms, John Wiley, New York, NY.

Beightler, C.C. and Mitten, L.G. (1964) Design of an optimal sequence of interrelated sampling plans. Journal of the American Statistical Association, 59, 96–104.

Britney, R. (1972) Optimal screening plans for nonserial production systems. Management Science, 18, 550–559.

Brown, E.C. (1968) Some mathematical models of inspection along a production line. Technical report no. 36, Operations Research Center, MIT, Cambridge, MA.

Buzacott, J.A. and Shanthikumar, J.G. (1993) Stochastic Models of Manufacturing Systems, Prentice Hall, New York, NY.

Coffman, E.G. Jr., Lueker, G.S. and Rinnooy Kan, A.H.G. (1988) Asymptotic methods in the probabilistic analysis of sequencing and packing heuristics. Management Science, 34, 266–290.

Deliman, N.C. and Feldman, R.M. (1996) Optimization of process improvement and inspection location for serial manufacturing. International Journal of Production Research, 34, 395–405.

Dietrich, D.L. (1971) A Bayesian quality assurance model for a multistage production process, in ASQC Technical Conference Transactions, pp. 338–348.

Do, S.B. and Hyung, J.Y. (1996) Optimal allocation of inspection effort in a serial multi-stage production system. Computers and Industrial Engineering, 30(3), 387–396.

Dorris, A.L. and Foote, B.L. (1978) Inspectors errors and statistical quality control: a survey. American Institute of Industrial Engineers Transactions, 10, 148.

Eppen, G. and Hurst, E. (1974) Optimal location of inspection stations in multistage production process. Management Science, 20, 1194–1200.

Ercan, S.S. (1972) Systems approach to the multistage manufacturing connected unit situation. Naval Research Logistics Quarterly, 19, 493–500.

Garey, M.R. (1971) Optimal test point selection for sequential manufacturing processes. Bell System Technical Journal, 51, 291–300.

Hurst, E.G. Jr. (1973) Imperfect inspection in multistage production processes. Management Science, 20, 378–384.

Lee, H.L. and Rosenblatt, M.J. (1987) Simultaneous determination of production cycle and inspection schedules in a production system.Management Science, 33(9), 1125–1136.

Lee, H.L. and Rosenblatt, M.J. (1989) A production and maintenance planning model with restoration cost dependent on detection delay.IIETransactions, 21(4), 368–375.

Lee, H.L. and Yano, C.A. (1988) Production control for multi-stage systems with variable yield losses. Operations Research, 36, 269–278.

Lee, J.S. and Park, K.S. (1991) Joint determination of production cycle and inspection intervals in a deteriorating production system.Journal of the Operational Research Society, 42(9), 775–783.

Lin, T.M., Tseng, S.T. and Liou, M.J. (1991) Optimal inspection schedule in the imperfect production system under general shift distribution. Journal of the Chinese Institute of Industrial Engineers, 8(2), 73–81.

Lindsay, G.F. and Bishop, A.B. (1964) Allocation of screening inspection effort - a dynamic programming approach. Management Science, 10, 342–352.

Makis, V. (1998) Optimal lot sizing and inspection policy for an EMQ model with imperfect inspection. Naval Research Logistics, 45, 165–186.

Menipaz, E. (1978) A taxonomy of economically based quality control procedures. International Journal of Production Research, 16(2), 153–167.

Peters, M.H. and Williams, W.W. (1984) Location of quality inspection stations: an experimental assessment of five normative rules.Decision Sciences, 15, 389–408.

Pruzan, P.M. and Jackson, J.T.R. (1967) A dynamic programming application in production line inspection. Technometrics, 9, 73–81.

Rabinowitz, G. and Emmons, H. (1997) Optimal and heuristic inspection schedules for multistage production systems. IIETransactions, 29(12), 1063–1071.

Rabinowitz, G. and Yahalom, O. (2001) Imperfect inspection of a multi-attribute deteriorating production system - a continuous time model. Quality and Reliability Engineering International 17, 1–12.

Rahim, M.A. (1994) Joint determination of production quality, inspection schedule and control chart design. IIETransactions, 26(6), 2–11.

Rahim, M.A. and Banerjee, P.K. (1993) A generalized model for the economic design of _xx control chart for production systems with increasing failure rate and early replacement. Naval Research Logistics, 40, 787–809.

Raz, T. (1986) A survey of models for allocating of inspection effort in multistage production systems. Journal of Quality Technology, 18(4), 239–247.

Raz, T. and Kaspi, M. (1991) Location and sequencing of imperfect inspection operations in serial multi-stage production systems.International Journal of Production Research, 29(8), 1645–1659.

Rosenblatt, M.J. and Lee, H.L. (1986a) A comparative study of continuous and periodic inspection policies in deteriorating production systems. IIETransact ions, 18, 2–9.

Rosenblatt, M.J. and Lee, H.L. (1986b) Economic production cycles with imperfect production process. IIETransactions, 18, 48–55.

Ruey, Y.Y. (1997) Optimal inspection and replacement policies for multi-state deteriorating systems. European Journal of Operational Research, 96(2), 248–259.

Seog, J.C., Park, Y.H. and Park, E.H. (1996) Quality costs in multistage manufacturing systems. Computers and Industrial Engineering, 31(1-2), 115–118.

Trippi, R.R. (1975) The warehouse location formulation as a special type of inspection problem. Management Science, 986–988.

Tseng, S.T. (1996) Optimal preventive maintenance policy for deteriorating production systems. IIETransactions, 28, 687–694.

Wein, A.S. (1992) Random yield rework and scrap in a multi-stage batch manufacturing environment. Operations Research, 40, 551–563.

White, L.S. (1966) The analysis of a single class of multistage inspection plans. Management Science, 21, 685–693.

White, L.S. (1969) Shortest route models for the allocation of inspection efforts on a production line. Management Science, 15, 249–259.

Woo, W.K. and Metcalfe, T.E. (1972) Optimal allocation of inspection effort in multistage manufacturing processes. Western Electric Engineer, 16, 8–16.

Yum, B.J. and McDowell, E.D. (1981) The optimal allocation of inspection effort in a class of nonserial production systems. IIE Transactions, 13, 285–293.

Yum, B.J. and McDowell, E.D. (1987) Optimal inspection policies in a serial production system Including scrap rework and repair: an MILP approach. International Journal of Production Research, 25(10), 1451–1464

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Emmons, H., Rabinowitz, G. Inspection allocation for multistage deteriorating production systems. IIE Transactions 34, 1031–1041 (2002). https://doi.org/10.1023/A:1019658111999

Issue Date:

DOI: https://doi.org/10.1023/A:1019658111999