Abstract

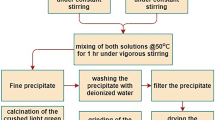

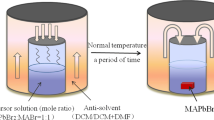

In this study, low-temperature solid-state synthesis of pure nanocrystalline ytterbium hexaboride (YbB6) employing iodine-based reduction method has been discussed. For the reduction reaction, the mechanically activated powder mixture of ytterbium oxide, boron oxide, magnesium, and iodine was heated up under Ar in a quartz tube to 85 °C. All reaction byproducts, viz. MgO, Mg3(BO3)2, and YbI2, were removed by hot acid leaching with 3 M HCl solution to form pure YbB6. The morphological and phase structure of the synthesized YbB6 powder were analyzed by X-ray diffractometry (XRD), high-resolution transmission electron microscopy (HRTEM), and Raman spectroscopy. The crystalline phases obtained were refined by multi-phase Rietveld refinement. XRD and Raman spectroscopy showed a contrast between the nano-YbB6 formed by the present low-temperature iodine-based reduction method versus mechanochemical method. The YbB6 produced by the low-temperature iodine reduction method is highly crystalline in nature, whereas YbB6 produced by mechanochemical method is less crystalline or conversely more amorphous in nature. The iodine-based reduction method indeed played a definitive role to allow the reaction to take place at a lower temperature enabling the formation of nanocrystalline YbB6.

Similar content being viewed by others

References

Yuan, Y.F., Zhang, L., Liang, L.M., He, K., Liu, R., Min, G.H.: A solid-state reaction route to prepare LaB6 nanocrystals in vacuum. Ceram. Int. (2011). https://doi.org/10.1016/j.ceramint.2011.03.073

Xu, J., Hou, G., Mori, T., Li, H., Wang, Y., Chang, Y., Luo, Y., Yu, B., Ma, Y., Zhai, T.: Excellent field-emission performances of neodymium hexaboride (NdB6) nanoneedles with ultra-low work functions. Adv. Funct. Mater. (2013). https://doi.org/10.1002/adfm201301980

Selvan, R.K., Genish, I., Perelshtein, I., Moreno, J.M.C., Gedanken, A.: Single step, low-temperature synthesis of submicron-sized rare earth hexaborides. J. Phys. Chem. C. (2008). https://doi.org/10.1021/jp0765502

Tanaka, T., Nishitani, R., Oshima, C., Bannai, E., Kawai, S.: The preparation and properties of CeB6, SmB6, and GdB6. J. Appl. Phys. (1980). https://doi.org/10.1063/1.328133

Han, W., Wang, Z., Li, Q., Lian, X., Liu, X., Fan, Q., Zhao, Y.: Semiconductor-insulator transition in a YbB6 nanowire with boron vacancy. J. Solid State Chem. (2018). https://doi.org/10.1016/j.jssc.2018.03.029

Wang, X.F., Xiang, H.M., Sun, X., Liu, J.C., Hou, F., Zhou, Y.C.: Porous YbB6 ceramics prepared by in situ reaction between Yb2O3 and B4C combined with partial sintering. J. Am. Ceram. Soc. (2015). https://doi.org/10.1111/jace.13606

Ogita, N., Nagai, S., Okamoto, N., Udagawa, M., Iga, F., Sera, M., Akimitsu, J., Kunii, S.: Raman scattering investigation of RB6 (R=Ca, La, Ce, Pr, Sm, Gd, Dy, and Yb). Phys. Rev. B. (2003). https://doi.org/10.1103/PhysRevB.68.224305

Blomberg, M.K., Merisalo, M.J., Korsukova, M.M., Gurin, V.N.: Single-crystal X-ray diffraction study of NdB6, EuB6 and YbB6. J. Alloys Compd. (1995). https://doi.org/10.1016/0925-8388(94)01313-7

Aprea, A., Maspero, A., Masciocchi, N., Guagliardi, A., Albisetti, A.F., Giunchi, G.: Nanosized rare-earth hexaborides: low-temperature preparation and microstructural analysis. Solid State Sci. (2013). https://doi.org/10.1016/j.solidstatesciences.2013.04.001

Glushkov, V.V., Bozhko, A.D., Bogach, A.V., Demishev, S.V., Dukhnenko, A.V., Filipov, V.B., Kondrin, M.V., Kuznetsov, A.V., Sannikov, I.I., Semeno, A.V., Shitsevalova, N.Y., Voronov, V.V., Sluchanko, N.E.: Bulk and surface electron transport in topological insulator candidate YbB6–δ. Phys. Status Solidi (RRL). (2016). https://doi.org/10.1002/pssr.201510452

Xia, M., Jiang, J., Ye, Z.R., Wang, Y.H., Zhang, Y., Chen, S.D., Niu, X.H., Xu, D.F., Chen, F., Chen, X.H., Xie, B.P., Zhang, T., Feng, D.L.: Angle-resolved photoemission spectroscopy study on the surface states of the correlated topological insulator YbB6. Sci. Rep. (2014). https://doi.org/10.1038/srep05999

Kanakala, R., Escudero, R., George, G.R., Ramisetty, M., Graeve, O.A.: Mechanisms of combustion synthesis and magnetic response of high-surface-area hexaboride compounds. ACS Appl. Mater. Interfaces. (2011). https://doi.org/10.1021/am1012276

Simsek, T.: Pure YbB6 nanocrystals: first time synthesis via mechanochemical method. Adv. Powder Technol. (2019). https://doi.org/10.1016/j.apt.2019.03.018

Larson, A.C., Dreele, R.B.V.: GSAS: general structure analysis system report LAUR 86–748. Tech. Rep., Los Alamos National Laboratory (2000)

Sonnoveld, E.J., Visser, J.W.: Automatic collection of powder data from photographs. J. Appl. Crystallogr. 8, 1–7 (1995). https://doi.org/10.1107/S0021889875009417

Williamson, G.K., Hall, W.H.: X-ray line broadening from filed aluminium and wolfram. J Acta Metall. 1, 22–31 (1953)

Suryanarayana, C.: Mechanical alloying and milling. Prog. Mater. Sci. (2001). https://doi.org/10.1016/S0079-6425(99)00010-9

Baris, M., Simsek, T., Simsek, T., Ozcan, S., Kalkan, B.: High purity synthesis of ZrB2 by a combined ball milling and carbothermal method: structural and magnetic properties. Adv. Powder Technol. (2018). https://doi.org/10.1016/j.apt.2018.06.024

Akçamlı, N., Ağaoğulları, D., Balcı, O., Oveçoğlu, M.L., Duman, I.: Synthesis of HfB2 powders by mechanically activated borothermal reduction of HfCl4. Ceram. Int. (2016). https://doi.org/10.1016/j.ceramint.2015.11.041

Balcı, O., Agaogulları, D., Ovalı, D., Ovecoglu, M.L., Duman, I.: In situ synthesis of NbB2–NbC composite powders by milling-assisted, carbothermal reduction of oxide raw materials. Adv. Powder Technol. (2015). https://doi.org/10.1016/j.apt.2015.06.001

Baris, M., Simsek, T., Akkurt, A.: Mechanochemical synthesis and characterization of pure Co2B nanocrystals. Bull. Mater. Sci. (2016). https://doi.org/10.1007/s12034-016-1231-x

Simsek, T., Baris, M., Kalkan, B.: Mechanochemical processing and microstructural characterization of pure Fe2B nanocrystals. Adv. Powder Technol. 3056–3062 (2017). https://doi.org/10.1016/j.apt.2017.09.017

Wang, L., Xu, L., Ju, Z., Qian, Y.: A versatile route for the convenient synthesis of rare-earth and alkaline-earth hexaborides at mild temperatures. Cryst. Eng. Commun. (2010). https://doi.org/10.1039/c001167c

Zhou, Y., Wang, X., Xiang, H., Feng, Z., Wang, G.: Theoretical prediction, preparation, and mechanical properties of YbB6, a candidate interphase material for future UHTCf/UHTC composites. J. Eur. Ceram. Soc. (2016). https://doi.org/10.1016/j.jeurceramsoc.2016.02.053

Zhang, M., Yuan, L., Wang, X., Fan, H., Wang, X., Wu, X., Wang, H., Qian, Y.: A low-temperature route for the synthesis of nanocrystalline LaB6. J. Solid State Chem. (2008). https://doi.org/10.1016/j.jssc.2007.12.011

Besmel, R., Ghaffari, M., Shokrollahi, H., Chitsazan, B., Karimi, L.: Influence of milling time on the structural, microstructural and magnetic properties of mechanically alloyed Ni58Fe12Zr10Hf10B10 nanostructured/ amorphous powders. J. Magn. Magn. Mater. (2011). https://doi.org/10.1016/j.jmmm.2011.05.025

Amini, R., Hadianfard, M.J., Salahinejad, E., Marasi, M., Sritharan, T.: Microstructural phase evaluation of high-nitrogen Fe–Cr–Mn alloy powders synthesized by the mechanical alloying process. J. Mater. Sci. (2009). https://doi.org/10.1007/s10853-008-3117-9

Abbasi, S., Eslamizadeh, H., Raanaei, H.: Study of synthesis, structural and magnetic properties of nanostructured (Fe67Ni33)70Ti10B20 alloy. J. Magn. Magn. Mater. (2018). https://doi.org/10.1016/j.jmmm.2017.12.015

Ogita, N., Nagai, S., Okamoto, N., Iga, F., Kunii, S., Akamtsu, T., Akamtsu, T., Akimitsu, J., Udagawa, M.: Raman scattering study of CaB6 and YbB6. J. Solid State Chem. 177 (2004). https://doi.org/10.1016/j.jssc.2003.02.014

Acknowledgments

The author would like to thank Eti Maden Works General Managements for the used laboratory facilities and Dr. Arun K. Chattopadhyay of Uniformity Labs, California, for the critical reading and ungrudging assistance for preparing the manuscript, and the author is also thankful to the Middle East Technical University, Central Laboratory for sample analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Simsek, T. Preparation of single-phase YbB6 by low-temperature solid-state reaction method using iodine. J Aust Ceram Soc 57, 125–136 (2021). https://doi.org/10.1007/s41779-020-00521-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-020-00521-w