Abstract

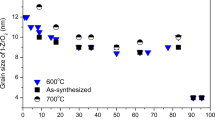

Prediction and design of various nanomaterials is a long-term dream in nanoscience and nanotechnology, which depends on the deep understanding on the growth mechanism. Herein, we report the successful prediction on the growth of AlN nanowires by nitriding Al69Ni31 alloy particles across the liquid-solid (β) phase region (1133–1638°C) based on the phase-equilibrium-dominated vapor-liquid-solid (PED-VLS) mechanism proposed in our previous study. All predictions about the growth of AlN nanowires, the evolutions of lattice parameters and geometries of the coexisting Al-Ni alloy phases are experimentally confirmed quantitatively. The preconditions for the applicability of the PED-VLS mechanism are also clarified. This progress provides the further evidence for the validity of the PED-VLS mechanism and demonstrates a practical guidance for designing and synthesizing different nanomaterials according to corresponding phase diagrams based on the insight into the growth mechanism.

摘要

纳米材料的预测和设计是纳米科学与技术领域的长期梦想, 该梦想的实现有赖于对生长机理的深刻理解. 本文基于我们前期研究揭示 的相平衡主导的气-液-固(VLS)生长机理, 成功地预测了在1133~1638°C温区内通过氮化Al69Ni31合金颗粒生长AlN纳米线的过程, 有关AlN纳米 线的生长、共存Al-Ni合金相的晶格参数及形貌演变等预测均得到了定量化实验结果的证实, 并界定了相平衡主导的VLS生长机理的适用条件. 本文为相平衡主导的VLS生长机理的有效性提供了进一步的实验证据, 同时展示了在生长机理的指导下根据相图设计和制备纳米材料的一个 实例.

Similar content being viewed by others

References

Wang X, Zhuang J, Peng Q, et al. A general strategy for nanocrystal synthesis. Nature, 2005, 437: 121–124

Morin SA, Bierman MJ, Tong J, et al. Mechanism and kinetics of spontaneous nanotube growth driven by screw dislocations. Science, 2010, 328: 476–480

Meng F, Morin SA, Forticaux A, et al. Screw dislocation driven growth of nanomaterials. Acc Chem Res, 2013, 46: 1616–1626

Wagner RS, Ellis WC. Vapor-liquid-solid mechanism of single crystal growth. Appl Phys Lett, 1964, 4: 89–90

Morales AM, Lieber CM. A laser ablation method for the synthesis of crystalline semiconductor nanowires. Science, 1998, 279: 208–211

Xia YN, Yang PD, Sun YG, et al. One-dimensional nanostructures: synthesis, characterization, and applications. Adv Mater, 2003, 15: 353–389

Wacaser BA, Dick KA, Johansson J, et al. Preferential interface nucleation: an expansion of the VLS growth mechanism for nanowires. Adv Mater, 2009, 21: 153–165

Tian BZ, Xie P, Kempa TJ, et al. Single-crystalline kinked semiconductor nanowire superstructures. Nat Nanotech, 2009, 4: 824–829

Wu YY, Yang PD. Direct observation of vapor-liquid-solid nanowire growth. J Am Chem Soc, 2001, 123: 3165–3166

Hannon JB, Kodambaka S, Ross FM, et al. The influence of the surface migration of gold on the growth of silicon nanowires. Nature, 2006, 440: 69–71

Kodambaka S, Tersoff J, Reuter MC, et al. Diameter-independent kinetics in the vapor-liquid-solid growth of Si nanowires. Phys Rev Lett, 2006, 96: 096105

Glas F, Harmand JC, Patriarche G. Why does wurtzite form in nanowires of III-V zinc blende semiconductors? Phys Rev Lett, 2007, 99: 146101

Sutter E, Sutter P. Phase diagram of nanoscale alloy particles used for vapor-liquid-solid growth of semiconductor nanowires. Nano Lett, 2008, 8: 411–414

Kim BJ, Tersoff J, Kodambaka S, et al. Kinetics of individual nucleation events observed in nanoscale vapor-liquid-solid growth. Science, 2008, 322: 1070–1073

Oh SH, Chisholm MF, Kauffmann Y, et al. Oscillatory mass transport in vapor-liquid-solid growth of sapphire nanowires. Science, 2010, 330: 489–493

Chou YC, Hillerich K, Tersoff J, et al. Atomic-scale variability and control of III-V nanowire growth kinetics. Science, 2014, 343: 281–284

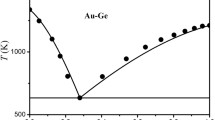

He CY, Wang XZ, Wu Q, et al. Phase-equilibrium-dominated vapor-liquid-solid growth mechanism. J Am Chem Soc, 2010, 132: 4843–4847

Nash P, Singleton MF, Murray JL. Al-Ni phase diagram, ASM Handbook Volume 3: Alloy Phase Diagrams. Materials Park: ASM International, 1992

Zhang XH, Shao RW, Jin L, et al. Helical growth of aluminum nitride: new insights into its growth habit from nanostructures to single crystals. Sci Rep, 2015, 5: 10087

Meng F, Estruga M, Forticaux A, et al. Formation of stacking faults and the screw dislocation-driven growth: a case study of aluminum nitride nanowires. ACS Nano, 2013, 7: 11369–11378

Al-Ni phase diagram. Data from FSstel-FactSage steel alloy databases 2010. 〈http://www.crct.polymtl.ca/fact/phase_diagram.php?-file=Al-Ni.jpg&dir=FSstel〉

Bradley AJ, Taylor A. An X-ray analysis of the nickel-aluminium system. Proc R Soc London Ser A, 1937, 159: 56–72

Taylor A, Doyle NJ. Further studies on the nickel-aluminum system. I. The b-NiAl and d-Ni2Al3 Phase Fields. J Appl Cryst, 1972, 5: 201–209

Huo KF, Hu YM, Fu JJ, et al. Direct and large-area growth of one-dimensional ZnO nanostructures from and on a brass substrate. J Phys Chem C, 2007, 111: 5876–5881

Sheng X, Wang L, Chang LT, et al. Growth and photoelectrochemical properties of ordered CuInS2 nanorod arrays. Chem Commun, 2012, 48: 4746–4748

Moutanabbir O, Isheim D, Blumtritt H, et al. Colossal injection of catalyst atoms into silicon nanowires. Nature, 2013, 496: 78–82

Author information

Authors and Affiliations

Corresponding authors

Additional information

Yongliang Zhang is currently a lecturer at Hefei University of Technology, China. He obtained his BSc degree (2008) in applied chemistry from Nanjing University of Information Science & Technology, and PhD degree (2015) in chemistry from Nanjing University. His research interests focus on the design and field emission property of one-dimensional nanostructures.

Qiang Wu is currently a professor at the School of Chemistry and Chemical Engineering, Nanjing University, China. He obtained his BSc (1999) and PhD (2004) degrees in chemistry from Nanjing University. His research interests focus on the rational design of nano- and meso-structured materials and their applications in field emission, energy storage, and electrocatalysis.

Zheng Hu is currently a Cheung Kong Scholar professor at the School of Chemistry and Chemical Engineering, Nanjing University, China. He received his BSc (1985) and PhD (1991) degrees in physics from Nanjing University. He is the owner of the highly competitive NSFC fund for outstanding young scientists of China (2005). His current research interests focus on physical chemistry and materials chemistry addressing the growth mechanism, materials design and energy applications of a range of nano- and meso-structured materials.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Zhang, Y., Cai, J., Wu, Q. et al. Phase-equilibrium-dominated vapor-liquid-solid mechanism: further evidence. Sci. China Mater. 59, 20–27 (2016). https://doi.org/10.1007/s40843-016-0111-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-016-0111-4