Abstract

In order to boost contributions of power systems to a low-carbon economy, the installed capacity of renewable power generation, such as wind and photovoltaic (PV) power generation should be well planned. A bilevel formulation is presented to optimize the proportion of wind and PV capacity in provincial power systems, in which, carbon emissions of generator units and features of renewable resources are taken into account. In the lower-level formulation, a time-sequence production simulation (TSPS) model that is suitable for actual power system has been adopted. In order to maximize benefits of energy conservation and emissions reduction resulting from renewable power generation, the commercial software called General Algebraic Modeling System (GAMS) is employed to optimize the annual operation of the power system. In the upper-level formulation, the optimal pattern search (OPS) algorithm is utilized to optimize the proportion of wind and PV capacity. The objective of the upper-level formulation is to maximize benefits of energy conservation and carbon emissions reductions optimized in the lower-level problem. Simulation results in practical provincial power systems validate the proposed model and corresponding solving algorithms. The optimization results can provide support to policy makers to make the polices related to renewable energy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The increasing CO2 emissions have been reported as one main cause of global warming that is widely considered as a great threat to our society in the foreseeable future. Developing low-carbon electricity technologies is the fundamental way to meet the challenge of global warming mainly caused by power generation [1–3]. Fortunately, there are rich wind and solar resources in many provinces of China. Due to the features of sustainability and zero carbon emissions, wind and solar power have developed rapidly in recent years with the stimulus from the government. In 2013, newly added wind power generation capacity is as high as 16.09 GW and the cumulative capacity integrated with power grid has reached 91.4 GW. Both of them have topped other countries in the world [4]. The photovoltaic power generation (PV) integrated with power grid in a variety of ways has claimed a growing proportion of renewable energy capacity. Newly added PV power capacity in 2013 in China is as high as 12.06 GW. China has surpassed Germany to become the top one in the world for the first time [5].

At present, many provinces in China plan their wind power and PV power industry separately and normally ignore inherent complementary features between wind and solar power. The high penetration of wind power and PV power may greatly threaten the way power systems have been operated. If conventional power generation units fail to compensate fluctuating wind and PV power, a certain portion of wind and PV power output will have to be curtailed. Reports show that curtailments of wind and PV power in ‘Three North’ areas (Northeast, North China and Northwest) of China are very serious. Reasonable capacity planning of wind farms and PV stations is therefore crucial to reduce wind and PV power curtailments. In order to achieve the goal, the time-sequence production simulation (TSPS) technology which is based on space-time complementary advantages between wind and solar energy has been utilized in [6–8]. One major advantage of TSPS is the capability of incorporating some annual plan of power systems such as thermal unit maintenance schedule and actual wind and PV power plan [9].

There are efforts published in studying the optimal proportion of wind and PV capacity in power systems. The optimal proportion of wind and PV capacity in a microgrid has been studied in [10–12], in which the proposed methodologies cannot extend to practical provincial power systems comprising several tens of generators because of their limited capacities in solving large-scale problems. Sizing optimization for a hybrid photovoltaic-wind energy system was conducted only based on a typical day without considering annual output characteristics of wind and PV power [13]. In addition, the results reported in [13] tend to be conservative because the difference between the peak and valley load of the typical day is the maximum and accommodation condition for wind and PV power is consequently the worst. Moreover, the methodology presented in [13] is that energy conservation and emission reduction of wind and PV power can not be considered sufficiently. In [14–16], optimal proportion of hybrid wind and PV power generation systems have been studied without considering the features of heating units. As a result, the conclusions in [14–16] may mislead the planning of power grid and the operation of real systems in China, because heating units exist widely in ‘Three North’ areas of China and always operate in winter. Meanwhile, all references described above leave out of consideration of CO2 emissions of power systems.

A novel formulation based on bilevel optimization under low-carbon economy is proposed to optimize the proportion of wind and PV power capacity in provincial systems of China [17, 18]. A time-sequence output model of wind and PV power that considers regional resources in the provincial power systems is proposed in lower-level problem. Besides, the objective function of the lower-level model is to maximize energy conservation and emission reduction benefits of the provincial power grid. Load characteristics, peak-load regulation capability, thermoelectric coupling characteristics of different thermal units, transmission capacity and some other factors are also considered in this model. The lower-level problem is an annual TSPS model requiring a single set of binary variables therefore the model is a large-scale mixed integer program problem (MIP). CPLEX solver in General Algebraic Modeling System (GAMS) [19] is applied to optimize the annual operation of power systems. TSPS technology utilized in present paper has following advantages:

-

1)

Both the rationality and credibility of planning results could be improved in this method because it is actually more in line with the power systems.

-

2)

Temporal variation characteristics of renewable output can be reflected.

-

3)

Some annual plan of power system such as thermal unit maintenance schedule or annual wind and PV power plan can also be made by this method.

-

4)

A comprehensive evaluation for annual renewable power generation, energy-saving capacity of power grid as well as thermal power index could be calculated more accurately. A simple model of optimal proportion of wind and PV capacity is developed in the upper-level problem, of which the objective function is maximizing benefits of energy conservation and emissions reductions after solving the lower-level problem. This is because the upper-level problem does not require the gradient of the problem to be optimized. The efficiency and accuracy of optimization can be improved by the optimal pattern search (OPS) method [20].

The remaining sections of this paper are organized as follows. Section 2 describes the lower-level and upper-level formulations. Section 3 presents the bilevel optimization algorithm framework and how it is used in the optimal proportion of wind and PV capacity model. Numerical examples are provided in Section 4. Section 5 concludes the paper with discussions.

2 Model description

2.1 Model of time sequence output

Three kinds of time-sequence outputs are constructed in the lower-level model: annual load time sequence output, annual wind power time sequence output and annual PV power time sequence output. In this paper, the normalized values are adopted for all of these three time series. The definition methods in the planning progress are as follows: First of all, the history data from all substations including wind power output, PV power output and electrical load in one province should be collected and organized. In the next place, all the historical data above are used to divide the wind power installed capacity, the PV power installed capacity and the maximum load in the corresponding year so that the annual load time sequence output, annual wind power time sequence output and annual PV power time sequence output can be obtained respectively. Finally, the value of wind power output, PV power output and load in the planning year can be calculated by using these normalized time series output multiplied by the predicted wind installed capacity, the predicted PV installed capacity and the predicted maximum load.

2.2 Model of annual time sequence production simulation under low-carbon economy in the lower level

2.2.1 Objective function in the lower-level model

Developing the low-carbon electricity technologies for the power industry is a fundamental way to meet challenges of global warming. Minimizing CO2 emissions from power systems conforms to current trend of national policy and social development in China. The impacts of large scale wind power and PV integration on low-carbon benefits are divided into two aspects, i.e., positive contributions and negative contributions. On one hand, wind and PV power are sustainable and have zero carbon emissions. On the other hand, wind and PV power are intermittent and can be hardly predicted. The fluctuation in wind and PV power output requires more frequent start-stop of thermal units which leads to more CO2 emissions. Since a large number of cases must be calculated in the planning processes, the coal consumption of thermal units should be modeled as a linear function so that efficiency of model calculation could be greatly improved.

Above all, the objective function in low-carbon economy of the lower-level model is shown below:

where g denotes the index of the generating units; G denotes total number of thermal units; t is the hourly scheduling intervals; T is the number of periods of the time span in the lower-level problem; γ is the coefficient of CO2 emissions; \( U_{g}^{t} \) is a binary decision variable that indicates whether unit g will be started up or not during the period t (1/0 are startup/not startup respectively); \( V_{g}^{t} \) is a binary decision variable that indicates unit g will be shut down or not during period t (1/0 are shutdown/not shutdown respectively); \( P_{g}^{t} \) is the output of unit g during the period t; A g , B g , a g and b g are all constants that denote startup coal consumption of unit g, shutdown coal consumption of unit g, production coal consumption of unit g and coal consumption of unit g respectively.

2.2.2 Thermal unit constraints

where \( \Delta P_{g}^{\text{up}} \) and \( \Delta P_{g}^{\text{dow}} \) are respectively ramp-up rate limit and ramp-down limit of generator g; \( P_{g}^{\hbox{max} } \) and \( P_{g}^{\hbox{min} } \) are respectively output power upper and lower bound of generator g; \( O_{g}^{t} \) is a binary decision variable that indicates on/off status of generator g during the period t; \( P_{{{\text{BP,}}g}}^{t} \) and \( P_{{{\text{CG,}}g}}^{t} \) are respectively the output of back pressure generator of generator g and extraction turbo-generator during their heating period; α g and β g are ratios between heat output and electricity output; \( H_{g}^{t} \) is heat output during the period t.

The hourly TSPS model constraints listed above include the unit ramping-up constraints shown in (3), unit shut-down constraints in (4), unit generation capacity constraints in (5), output of heating units during heating period constraints in (6) and (7), unit minimum-up time constraints in (8) (e.g., if a generator is turned on, it should be kept on for at least K periods), unit minimum-down time constraints in (9) (e.g., if a generator is turned off, it should be kept off at least K periods), the logical state of unit start-up, unit shut-down and unit operations constraints in (10).

2.2.3 System constraints

where \( P_{l}^{t} \) is the electrical load of during the period t; \( P_{w}^{t} \) and \( P_{v}^{t} \) are respectively output of wind and PV power during the period t; \( R_{\text{N}}^{t} \) is renewable power credible capacity during the period t. The value of \( R_{\text{N}}^{t} \) is normally decided by renewable power prediction accuracy and is usually set to 60%–80% of the total renewable output [21]. The start-up capacity of thermal unit would be greatly reduced when the renewable power credible capacity is considered so that the concept of “green dispatch” under low-carbon economy could be reflected quite well. \( R_{\text{Pos}} \) and \( R_{\text{Neg}} \) are the system positive and negative reserve demand respectively during period t. \( P_{w}^{{t^{ * } }} \) and \( P_{v}^{{t^{ * } }} \) are the normalized time sequence output, \( C_{w}^{k} \) and \( C_{v}^{k} \) are respectively installed capacity of wind farms and PV stations. It is noted that these two variables are the kth optimization variables in the upper-level optimization formulation that will be described in Section 2.3.

Hourly system constraints listed above include system power balance constraints in (11), system spinning reserve requirement in (12) and (13), wind power and PV power output constraints in (14) and (15).

2.3 Model of optimal proportion of wind and PV capacity in the upper level

The upper-level model of optimal proportion of wind and PV capacity does not need to calculate the derivative so that it could be effectively solved by the OPS method. The objective function and constrains of the upper-level model are as follows.

2.3.1 Objective function in the upper level

where \( F_{\text{Upper}} \) is the objective function of the upper-level optimization formulation. It is in fact the energy conservation and emissions reductions of renewable power generation are optimized in the lower-level formulation. Due to the objective function \( F_{\text{Lower}} \) is determined by the optimization of the TSPS model with different C w and C v in every group, the OPS algorithm is employed to update the particle optimization direction according to the value of \( F_{\text{Lower}} \) (C k w , C k v ).

2.3.2 Variable solution space constraints

where θ denotes optimization variables in the upper-level formulation; v is the index of variables mentioned above, in this paper, v = 1 indicates the wind capacity and v = 2 indicates the PV capacity; \( \theta_{v}^{\hbox{max} } \) is the maximum planning installed capacity and \( \theta_{v}^{\hbox{min} } \) is the existing installed capacity.

In summary, the objective functions above and constraints constitute the model of optimal proportion of wind and PV capacity under low-carbon economy. A certain number of constraints can be chosen depending on the requirements of real power systems. The upper-level model is implemented in Matlab. The lower-level model is implemented in GAMS using CPLEX solvers. Matlab calls GAMS and retrieves data based on the methodology reported in [22].

3 Bilevel optimization algorithm

3.1 Overview of bilevel optimization algorithm

For practical power systems comprising several hundreds of generators, the TSPS is a MIP model required a large number of binary variables. The CPLEX solver in GAMS is applied to solve this problem to optimize the annual power system operation. However, if every different proportion of wind power and PV power capacity are calculated by the exhaustive method based on TSPS method, computation burden will be so large that the formulation cannot be applied into practical power systems.

Hence, the optimization process in provincial power systems can be divided into two sub-optimization problem named as upper-level optimization problem and lower-level optimization problem respectively. In the whole optimization process, reliability, efficiency and accuracy of optimization are considered comprehensively. The provincial system production simulation model based on time sequence which conforms to real power system operation is proposed in the lower-level model, in order to maximize benefits of energy conservation and emission reductions of the provincial grid. A simple model of optimal proportion of wind and PV capacity is developed in the upper-level problem, in which objective function is maximizing the benefit of energy conservation and emission reduction after solving the lower-level problem, some optimization method that is to solve the problem of no gradients could be used to update the particle optimization direction in upper-level according to this value.

Moreover, the OPS method was coined by Hooke and Jeeves in 1961 and it is a family of numerical optimization methods that do not require the gradient of the problem to be optimized. Its basic idea is as follows: the axial search and the pattern search are included in OPS method. New optimization point and direction which is conducive to minimize the function value are determined by the former search method after searching n th axis directions. The latter search method makes the function value decrease faster in the direction of attachment between adjacent two optimization points. Hence OPS can be used on functions that are not continuous or differentiable.

Based on this, after the upper-level model is solved by the OPS method, the planning wind power capacity and planning PV power capacity are uploaded to lower-level model, then TSPS is applied to maximize benefit of energy conservation and emission reduction of the power grid. The result which is calculated by this bilevel optimization algorithm with high computational efficiency would be more realistic.

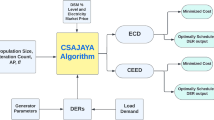

3.2 Flow of bilevel optimization algorithm

The flowchart of the proposed bilevel algorithm is shown in Fig. 1, in which S denotes optimum step, η denotes accelerated factor, α denotes step growth factor, β denotes step reduction factor, maxiter denotes the maximum iterations.

4 Case studies

An actual provincial power system is selected as the case study system. The methodology is utilized to optimize installed capacities of wind power and PV in a planning year.

4.1 Data

4.1.1 Time-sequence data collection

The normalized data of load curve, wind power curve and PV power curve during a typical day and the whole year in this province are obtained from Electricity Regulatory Authority of this province and are illustrated in Figs. 2 and 3 respectively.

As shown in Fig. 2, the maximum daily gap between peak load and valley load in the case system appears in the 328th day, with a value as high as 1756 MW. According to the information in Fig. 3, the theoretical utilization hours of wind power and PV power can be calculated as 1913 hours and 1550 hours, respectively. The utilization hour of wind power is larger than that of PV power because the output power of PV is always zero.

4.1.2 System data

Thermal generator units of the studied province can be divided into three types, i.e. condensate gas, back pressure and extraction turbo. The installed capacities and numbers of these three types of generators are presented in Table 1. The parameters of heating units and the coal consumption parameters of thermal units are presented in Table 2 and Table 3 respectively.

The installed capacity of maximum units (660 MW) is selected as the amount of spinning reserve. The heating period of this province starts on 25th October and ends on 25th April in the next year.

4.1.3 Planning target

At present, the installed capacities of wind power and PV power in this province are 2646.4 MW and 530.83 MW, which account for 11.67% and 2.34% of the total installed capacity respectively. Due to the limitations of geographical, government policy, economy and other factors, total installed capacity of wind power and PV power is expected to be less than 8000 MW in the planning year. The predicted maximum load in the planning year is assumed to be 14230 MW.

4.2 Illustrative examples

Apart from the methodology presented in this paper, two other algorithms are also utilized to optimize installed capacity of the case system. Three optimization results with different algorithms are illustrated in Fig. 4. PSO is an abbreviation of particle swarm optimization algorithm [23].

Figure 4 shows that if the typical day analysis method is utilized in the lower model, the amount of CO2 emissions is increasing dramatically with 810000 tons per year because of the conservative property of the typical day analysis method. Neither the low-carbon economy of power system can be reflected by the typical day analysis method nor does the credibility of planning results can be guaranteed. Compared with PSO algorithm which is applied in the upper level model, OPS has a better computing accuracy by further reducing 20000 tons CO2 emissions per year. In addition, from Fig. 4, it can be concluded that the higher proportion of PV power, the better energy conservation and emission reduction can be obtained. That is to say PV power is more excellent than wind power under low-carbon economy. Optimal capacities of wind power and PV power are 3900 MW and 2800 MW respectively and the corresponding proportion of wind and PV capacity is 1.39. However, the present proportion of wind and PV capacity is 4.98 and far larger than the optimal value. Therefore, PV stations should be strongly supported by the government.

The calculation times between different algorithms are presented in Table 4.

In this paper, the average optimization time of TSPS in the lower-level model is about 15 mins, so the total computing time is reduced by 133350 mins by using the bilevel algorithms.

The further research under the case of optimal proportion of wind and PV is conducted (The optimal capacities of wind power and PV power are 3900 MW and 2800 MW) owing to TSPS is applied in the lower-level model. The average curtailment rate of wind and PV power and the average of start-up capacity of thermal power is presented in Fig. 5.

Figure 5 shows that renewable power balance ability off heating period is better than that of heating period because of its better flexibility and load regulation ability. The thermal unit maintenance schedule can be made according to this model, for instance, in the month with smaller start-up capacity of thermal power like September, more units could be arranged for maintenance. Planning and dispatching operation of thermal units can be made in different seasons according to this model.

The operation numbers in various thermal units are presented in Fig. 6. The maintenance scheduling of certain kinds of units can be arranged precisely according to Fig. 6.

5 Conclusions

A novel optimization algorithm based on bilevel optimization under low-carbon economy is applied in this paper to optimize the proportion of wind and PV capacity in a provincial system. The TSPS model is applied in the lower-level model so that both the rationality and credibility of planning results could be improved. The OPS algorithm is applied in the upper-level model so that the efficiency and accuracy of optimization could be improved. Some guidance is given for the optimal proportion of wind and PV capacity power system dispatching as well as the relevant policies made by the government under low-carbon economy.

The future work will be focused on the optimal proportion of wind and PV capacity in the provincial power systems with consideration of the thermal power unit economy.

References

Malla S (2009) CO2 emissions from electricity generation in seven Asia-Pacific and North American countries: a decomposition analysis. Energ Policy 37(1):1–9

Zhang N, Kang CQ, Liu JK et al (2013) Mid-short-term risk assessment of power systems considering impact of external environment. J Mod Power Syst Clean Energ 1(2):118–126

Zhang Y, Yao F, Iu HHC et al (2013) Sequential quadratic programming particle swarm optimization for wind power system operations considering emissions. J Mod Power Syst Clean Energ 1(3):231–240

Chinese Wind Energy Association (2013) China wind power capacity statistic 2013. Chinese Wind Energy Association, Beijing, China (in Chinese)

The global new energy development report 2014. In: 8th China new energy international forum, Beijing, China, 7–8 Jun 2014

Patel MR (2005) Wind and solar power systems: design, analysis and operation, 2nd edn. CRC, Boca Raton, FL, USA

Sarkar S, Ajjarapu V (2011) MW resource assessment model for a hybrid energy conversion system with wind and solar resources. IEEE Trans Sustain Energ 2(4):383–391

Safdarian A, Fotuhi-Firuzabad M, Aminifar F (2012) Compromising wind and solar energies from the power system adequacy viewpoint. IEEE Trans Power Syst 27(4):2368–2376

Liu C, Cao Y, Huang YH et al (2014) An annual wind power planning method based on time sequential simulations. Automat Electr Power Syst 38(11):13–19 (in Chinese)

Hong YY, Lian RC (2012) Optimal sizing of hybrid wind/PV/diesel generation in a stand-alone power system using Markov-based genetic algorithm. IEEE Trans Power Del 27(2):640–647

Xu L, Ruan XB, Mao CX et al (2013) An improved optimal sizing method for wind-solar-battery hybrid power system. IEEE Trans Sustain Energy 4(3):774–785

Das I, Bhattacharya K, Canizares C (2014) Optimal incentive design for targeted penetration of renewable energy sources. IEEE Trans Sustain Energ 5(4):1213–1225

Geem ZW (2012) Size optimization for a hybrid photovoltaic-wind energy system. Int J Electr Power Energ Syst 42(1):448–451

Markvart T (1996) Sizing of hybrid photovoltaic-wind energy system. Solar Energ 57(4):277–281

Kellogg WD, Nehrir MH, Venkataramanan G et al (1998) Generation unit sizing and cost analysis for stand-alone wind, photovoltaic, and hybrid wind/PV systems. IEEE Trans Energ Conver 13(1):70–75

Yang Q, Zhang JH, Liu ZF, et al (2008) A new methodology for optimizing the size of hybrid PV/wind system. In: Proceedings of the 2008 IEEE international conference on sustainable energy technologies (ICSET’08), Singapore, 24-27 Nov 2008, pp 922-927

Xu P, Wang LZ (2014) An exact algorithm for the bilevel mixed integer linear programming problem under these simplifying assumptions. Comput Oper Res 41:309–318

Wang QF, Guan YP, Wang JH (2012) A chance-constrained two-stage stochastic program for unit commitment with uncertain wind power output. IEEE Trans Power Syst 27(1):206–215

GAMS Development Corporation, Washington, DC, USA (2005) GAMS–the solver manuals, version 23.3

Hooke R, Jeeves TA (1961) “Direct search” solution of numerical and statistical problems. J ACM 8(2):212–229

Zhou SL, Mao MQ, Su JH (2011) Short-term forecasting of wind power and non-parametric confidence interval estimation. Proceedings of CSEE 31(25):10–16 (in Chinese)

Ferris MC (2005) MATLAB and GAMS: interfacing and optimization and visualization software. Computer Science Department, University of Wisconsin, Madison, WI, USA

Kennedy J, Eberhart R (1995) Particle swarm optimization. In: Proceedings of the IEEE conference on neural networks, vol 4, Perth, Australia, 27 Nov-1 Dec 1995, pp 1942-1948

Acknowledgments

This work is jointly supported by the research and application of evaluation of priority dispatching of wind/PV generation in multi-levels, State Grid Corporation of China (No. NY71-14-038), Jiangsu Provincial Graduate Education Innovation Project (No. KYLX_0431), the Fundamental Research Funds for the Central Universities (No. 2014B33314) and National Nature Science Foundation of China (No. 51407097). The authors appreciate the anonymous reviewer for the valuable comments, which is helpful to improve the article.

Author information

Authors and Affiliations

Corresponding author

Additional information

CrossCheck date: 4 January 2015

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Yuan, Y., CAO, Y., ZHANG, X. et al. Optimal proportion of wind and PV capacity in provincial power systems based on bilevel optimization algorithm under low-carbon economy. J. Mod. Power Syst. Clean Energy 3, 33–40 (2015). https://doi.org/10.1007/s40565-015-0104-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40565-015-0104-4