Abstract

Electrochemically stable black TiO2 composed of Ti3+ ions and oxygen vacancies is successfully synthesized by a facile and economic sol–gel method followed by calcination in nitrogen atmosphere at 400 °C for 2 h. Several physicochemical techniques are probed to validate the desired state of the obtained material. The material is formed in a pure state with an average size of 10 nm. The electrochemical studies are conducted for its use as negative electrode for Li-ion batteries. At high current rate of 5 C, the electrodes deliver a high discharge capacity of 226 mA h g−1 even after 150 cycles. Similarly, the electrodes also deliver discharge capacities of 197 and 153 mA h g−1 at current rates of 7 C and 10 C, respectively. The robust electrochemical properties of black TiO2 including large specific capacities at high current rates and high stability are ascribed to the formation of defective structure, conductive Ti3+ ions and oxygen vacancies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Low cost and high safety along with large specific capacity are the critical factors for choosing materials as an electrode (cathode or anode) for lithium-ion batteries (LIBs). Hence, it is important to develop a high specific capacity material along with low cost and high safety. It is often observed that materials with high theoretical capacity suffer from low cycling stability [1,2,3,4]. TiO2 (white) is well established as a low-cost material with high safety. The remarkable electrochemical cycling stability of TiO2 makes it more attractive for LIBs. TiO2 is also documented as high-rate anode which operates within the potential window of the most common electrolytes, thus inhibiting the formation of solid–electrolyte interface (SEI) and related gas emission associated with electrolyte decomposition [5, 6].

A limiting factor to its implementation and application would be the high operating potential that makes the energy density of Li-ion battery based on TiO2 negative electrode lower than that featuring graphite anode. Apart from low theoretical specific capacity, it also suffers from high intrinsic resistance (evident from its wide bandgap of 3.2 eV), structural distortion (during Li+ de-/intercalation) and most importantly, formation of passive oxidation layer on the surface when it is annealed in air atmosphere which hinders the kinetics of the Li+ ions [7,8,9].

Many efforts have been made to tackle these shortcomings. Different polymorphs like anatase [10], brookite [5], rutile [11], extensive amorphous TiO2 [12] have been introduced to enhance the electrochemical performance. The research is also focused on synthesizing TiO2 with different morphologies such as nanoparticles (NPs), nanorods (NRs), etc., to improve its electrochemical performance [6, 13, 14]. Recently, black TiO2 nanoparticles (B-TiO2 NPs) have been explored as a solution [8, 9]. B-TiO2 demonstrates narrowed bandgap with unaltered tetravalent Ti. With a decrease in the bandgap, intrinsic resistance is found to decrease [15, 16]. Moreover, B-TiO2 is accompanied by conductive Ti3+ and oxygen vacancies. Oxygen vacancies enhance the interlayer spacing, leading to faster Li+ ions kinetics, and facilitate the reinstitution of host structure during de-/intercalation [17]. Thus, these unique factors make B-TiO2 an attractive contender as negative electrode for LIBs.

Though it has many salient features, surprisingly it has been a less explored negative electrode for LIBs. Several methods including metal reduction, plasma treatment, high-/low-pressure hydrogen treatment have been proposed to synthesize B-TiO2 NPs [18,19,20,21]. However, these methods demand rigorous reaction conditions. Therefore, a facile and economic synthesis method is highly desirable. Herein, we report the synthesis of B-TiO2 NPs by simple and scalable sol–gel method followed by calcination at 400 °C in the nitrogen (N2) atmosphere for 2 h. The obtained B-TiO2 NPs were characterized with several physicochemical techniques and probed as negative electrode for LIBs.

Experimental section

Titanium (IV) butoxide and thiourea were procured from Sigma-Aldrich. Lauryl lactyl lactate (Koplactylate) surfactant was procured from Kumar Organic Products Pvt. Ltd., India. The chemical reagents were used as received without any purification.

Sol–gel synthesis of B-TiO2 NPs

B-TiO2 NPs were synthesized by a simple modified sol–gel method as reported in our earlier work on white TiO2 [22]. A solution composed of 4 mL of ethanol and 0.9 mL of double-distilled (DD) water was named as A. Another solution B was prepared by mixing 0.5 mL of lauryl lactyl lactate, 8 mL of ethanol, 2 mL of titanium butoxide and 0.1 mL of hydrochloric acid. Solution A was then added to solution B and agitated for 5–8 min until gel was developed. It was allowed to age for 12 h at ambient temperature and then dried at 80 °C for 3 h. The solid gel was transferred and subjected to calcination at 400 °C for 2 h in the tubular furnace under nitrogen (N2) atmosphere. The obtained compound was black in color.

Material characterization

Powder X-ray diffraction (PXRD) pattern of B-TiO2 was analyzed using Rigaku SmartLab X-ray diffractometer with monochromatized Cu Kα radiation. The chemical nature of the B-TiO2 was investigated by X-ray photoelectron spectroscopy (XPS) using Al Kα radiation (1.486 keV, Axis Ultra DLD, Kratos Analytical). Raman spectrum of the sample was recorded using 514.5-nm Ar+ laser in HORIBA LabRam HR800. Morphological and structural investigations were carried out using scanning electron microscopy (SEM) [FESEM Carl Zeiss (Oxford instrument)] and transmission electron microscopy (TEM) (FEI Tecnai T20 S-TWIN TEM). Quanta Chrome Nova-1000 surface analyzer was used to record surface area and pore size distribution of the sample.

Electrochemical measurements

Coin cells (CR2032, Hohsen Corporation, Japan) were assembled to investigate the electrochemical properties of B-TiO2 as a negative electrode for LIBs. Lithium (Aldrich) metal was used as both reference and counter electrode. Active material (B-TiO2), carbon black (Super P, Aldrich) and sodium carboxymethyl cellulose (CMC, Aldrich) were mixed in the weight ratio 85:10:5, and a slurry was prepared in a few drops of N-methylpyrrolidinone (NMP, Aldrich). Although CMC is water-soluble, NMP was used to follow the standard practice of electrode formation which tends to avoid water as even PPM level of trapped moisture which can be detrimental to cell performance. The slurry was uniformly coated on a pretreated copper foil before drying it at 110 °C for overnight in a vacuum oven. 1 M LiPF6 dissolved in ethylene carbonate, diethyl carbonate and dimethyl carbonate (2:1:2 v/v) (Chameleon, China) was used as electrolyte, and a porous polypropylene membrane (Celgard 2400) as a separator. The coin cells were fabricated in argon-filled glove box with ~ 1.0 mg cm−2 of active material. Cyclic voltammetry, galvanostatic charge–discharge cycling and rate capability measurements were conducted using Biologic Science BCS-8xx series at 22 ± 1 °C. Electrochemical ac impedance spectroscopy was carried out on the cells in the frequency range of 10 mHz to 100 kHz with an amplitude of 10 mV in three-electrode mode.

Results and discussion

The XRD pattern of B-TiO2 NPs is shown in Fig. 1. All the diffraction peaks in the XRD patterns can be indexed to JCPDS no. 01-073-1764 which corresponds to tetragonal structure of TiO2. XRD pattern confirms the formation of pure anatase phase as no peaks corresponding to any other polymorphous are present. The XRD pattern also reveals that the B-TiO2 NPs are crystalline in nature. The average crystallite size of B-TiO2 is calculated using Debye–Scherrer’s equation and found to be ~ 50 nm:

where D is the average crystallite size (nm), \(\lambda\) is the wavelength of Cu Kα (0.154 nm), \(\beta\) is the full width at half maximum (FWHM) in radian, and \(\theta\) is the Bragg angle. Thus, XRD pattern succeeded in validating the formation of anatase TiO2 but failed to distinguish between white and black TiO2.

XPS is a powerful tool to determine and distinguish the contents of a sample. Figure 2 shows the XPS spectra for survey spectrum (A), Ti 2p (B) and O (C). 459.5 (Ti 2p3/2) and 465.1 (Ti 2p1/2) eV are the characteristic 2p core level XPS peaks of anatase white TiO2 (Fig. S1). These peaks correspond to Ti4+ in TiO2, whereas in case of B-TiO2, a negative shift in binding energy is observed, yielding the centers of the peaks at 458.6 and 464.2 eV. These peaks correspond to the formation of isolated Ti3+ defect structure in TiO2 anatase phase which is stable at room temperature [23,24,25,26,27,28]. Furthermore, formation of Ti3+ is confirmed by convolution of the peaks (Fig. 2b). Annealing the sample at 400 °C in nitrogen flow is accounted for the oxygen vacancies generated in the bulk TiO2−x.

Formation of Ti interstitials and expulsion of oxygen from anion sublattice leaving oxygen vacancies are the chief processes accountable for the formation of high oxygen vacancies in the TiO2−x. Generally, the latter one is extensive than Ti interstitials. The density of carriers, which are regarded as electron donors for TiO2, is enhanced by the generation of oxygen vacancies. With an increase in donor density in the TiO2−x structure, electrical conductivity increases, whereas bandgap energy decreases, yielding visible active property to the material [23,24,25]. We can also observe a tiny peak at 400 eV which corresponds to 1s level of nitrogen (Fig. S1). This can be attributed to the presence of chemisorbed nitrogen. Many authors have exposed this contribution and attributed it to molecularly chemisorbed γ-nitrogen [29,30,31,32,33,34]. Figure 2c shows the XPS spectrum of oxygen. The sample displayed a peak at 529.9 eV which is ascribed to the characteristic peak of Ti–O–Ti [23,24,25,26,27,28]. The peak is broad and slightly asymmetric, and it may be attributed to Ti–O–N and Ti–O–H. Formation of TiN or TiO2–TiN mixed phase can be ruled out as XRD pattern does not show any significant impurity peak. Furthermore, no nitrogen precursor has been used in the synthesis. Therefore, asymmetry of oxygen peak is due to bonding of oxygen with chemisorbed nitrogen and hydrogen [29,30,31,32,33,34]. Thus, XPS spectra reveal the formation Ti3+ ions and oxygen vacancies, causing structural defects in TiO2.

Raman spectroscopy was also carried out on the sample to disclose the formation of B-TiO2. Figure 3 shows the Raman spectrum of B-TiO2 NPs. The peaks at 147 and 638 cm−1 are attributed to Eg modes of vibration. The peaks at 399 and 517 cm−1 are ascribed to B1g modes of vibration [35]. The absence of any other peaks represents the purity of the sample. Further, low intensities of the peaks suggest the formation of anatase B-TiO2 NPs. Morphology of the B-TiO2 NPs was examined by SEM. Figure 4a, b displays SEM images of B-TiO2 NPs. SEM images revealed that B-TiO2 has acquired spongy nature (like partially molten jaggery without much of sharp and clean surface and edges), which is ascribed to the surfactant (lauryl lactyl lactate) used in the synthesis. Lauryl lactyl lactate is an organic compound, which is non-toxic, highly safe, biodegradable, and generally used in the food industries. Among many reagents, lauryl lactyl lactate is implemented in the synthesis of foams. Interestingly, the surfactant effectively participated in the reaction and provided spongy nature to the sample. Figure 4c shows the energy-dispersive X-ray (EDAX) spectrum of B-TiO2 NPs. The EDAX spectrum reveals the presence of titanium and oxygen.

TEM was carried out to further obtain the insight into the morphology of the B-TiO2 NPs. Figure 5a, b depicts low-resolution TEM images of B-TiO2 NPs, which present the dispersion of B-TiO2 NPs. Figure 5c depicts the high-resolution TEM (HRTEM) image of B-TiO2 NPs. From the image, defective surface of TiO2 can be observed confirming the formation of Ti3+ ions and oxygen vacancies. Plane and d spacing values calculated from HRTEM image are coherent with XRD results. The size of B-TiO2 NPs is found to be ~ 10 nm. Figure 5d depicts the selected area electron diffraction (SAED) patterns of B-TiO2 NPs. The SAED pattern is displayed as concentric circles whose d spacing values are consistent with XRD data. Thus, spongy nature, distracted structure and nanosized particles make B-TiO2 an attractive candidate as negative electrode for LIBs.

Surface area and porosity of the material are the two critical points which play a significant role in enhancing the capacity storage and stability of the electrode. Nitrogen (N2) adsorption–desorption measurements were carried out to calculate Brunauer–Emmett–Teller (BET) specific surface area (Fig. 6) and Barrett–Joyner–Halenda (BJH) pore size distribution of B-TiO2 (Fig. 6, inset). B-TiO2 exhibits type IV isotherm with hysteresis loop signifying the mesoporous nature of the sample [36]. The BET specific surface area B-TiO2 is found to be 13 m2 g−1 with average pore size distribution of 2–3 nm. Since we carried out the annealing at 400 °C, we ended up getting high crystallinity and low surface area with mesoporous nature.

Electrochemical performance

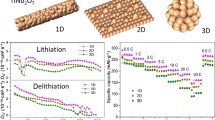

The electrochemical properties of B-TiO2 were evaluated in coin cell configuration at room temperature. Cyclic voltammetry (CV) was implemented as the primary tool to understand the electrochemical redox reactions during charging and discharging. Figure 7 shows the cyclic voltammogram of B-TiO2 in the voltage range 0.1–3.0 V obtained at the sweep rate of 0.1 mV s−1. The first cathodic sweep consists of three peaks at 0.65, 1.67 and 2.36 V. The peak at 2.36 V in the first sweep disappears in the subsequent cycles, indicating the formation of irreversible SEI in the first cycle, and this may be due to extension of stability window of electrolyte down to 0.7–0.8 V vs Li [37,38,39]. The couple of peaks at 0.65 and 1.67 V in the cathodic sweep are assigned to insertion of lithium into TiO2 matrix and to the structure transformation from tetragonal TiO2 to orthorhombic LixTiO2, where x is insertion coefficient. These peaks shift right to 0.75 and 1.75 V in the subsequent cycles, indicating enhanced kinetics after first cycle [10, 12, 40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60]. Insertion mechanism Li+ into TiO2 matrix is further discussed later. The anodic peak at 2.10 V corresponds to delithiation from TiO2 matrix. The overlap of CV curves suggests that the material can uptake and release Li+ with good reversibility.

Overall electrochemical reaction taking place may be illustrated by the following equation:

Figure 8 shows the galvanostatic charge–discharge profile of B-TiO2 at 1 C rate (1 C = 335 mA h g−1), in the potential range 0.1–3.0 V. The first lithiation and delithiation capacities were found to be 575 and 345 mA h g−1, respectively. The excess capacity in the first few cycles is attributed to widening of potential range, defective TiO2 and formation of SEI [39, 57, 61,62,63,64,65,66]. Vereecken et al. demonstrated an increase in the capacity by ~ 30% when the lower potential barrier was dragged from 1.0 to 0.1 V for TiO2. The excess capacity was attributed to widening of potential window, i.e., a large potential difference. They also observed sluggish delithiation kinetics for first few cycles, which was ascribed to excess of Li+ ions present in TiO2 matrix [61]. Harutyunyana et al. showed that high concentration of defects and edges in the electrode matrix is responsible for excess capacity in first few cycles [62]. Similarly, Schuhmann et al. demonstrated that SEI formed in case of TiO2 has high Li-ion transport ability and thereby it enhances the cycle stability of TiO2 [39].

Furthermore, Reddy et al. exclusively carried out electrochemical impedance measurements on TiO2 during charge and discharge processes at different potentials. Reddy group demonstrated that the resistance will decrease as we move from potential 3.0 to 0.05 V (lithiation). However, resistance in the potential window (1.6–2.1 V) where typical redox reaction takes place will be low compared to impedance at different potentials [67,68,69,70,71]. An irreversible capacity loss is generally observed in the first cycle (here 40%) when TiO2 is cycled in the wider potential window and is due to (1) sluggish delithiation kinetics for first few cycles, which is due to excess of Li+ ions trapped in TiO2 matrix; (2) irreversible intercalation/insertion of Li+ ions into the matrix; (3) electrolyte decomposition; and (4) formation of SEI [39, 56, 61,62,63,64,65,66].

The lithium intercalation mechanism can be disintegrated into three parts. Part-1 corresponds to 3.0–1.75 V potential window where voltage drops from OCV to 1.75 V. This range corresponds to intercalation of Li+ ions into tetragonal TiO2 matrix without the nucleation of other phases [10, 12, 40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60]. Part-2 corresponds to plateau at ≈ 1.75 V. In the literature, this plateau is ascribed to formation and coexistence of orthorhombic phase along with tetragonal phase [10, 12, 40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60]. Part-3 extends from 1.75 to 0.1 V. Earlier studies have proven that Li+ insertion in this range depends on the size, morphology and defects of host material [10, 12, 40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60]. Furthermore, it is also illustrated the formation of reversible interfacial lithium storage which holds responsible for excess lithium insertion by means of charge separation [60]. The delithiation curve shows a broad hump at 2.10 V corresponding to removal of Li+ ions from the B-TiO2 matrix. The potential profile is in good agreement with CV results. All the results are coherent with earlier reports [9, 35, 36, 72].

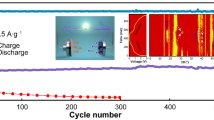

Figure 9 shows the cyclic performance and coulombic efficiency of B-TiO2 over 150 cycles at 1 and 5 C rates. The charge and discharge capacities for second, third and fourth cycles at 1 C were found to be 323 and 327 mA h g−1, 305 and 320 mA h g−1, and 298 and 310 mA h g−1, respectively. After a huge coulombic efficiency (CE) fall in the first cycle, it began to recover from the next cycle, reached about 100% efficiency in the second cycle and remained constant till the end of 150 cycles. At end of 150 cycles, it exhibited charge and discharge capacities of 275 and 283 mA h g−1, respectively. After first five cycles, it displayed excellent stability over 150 cycles by displaying only 0.09% capacity loss per cycle. Furthermore, its cyclic performance was investigated at 5 C to reveal its behavior at high rates. Interestingly, it displayed remarkable stability over 150 cycles by displaying capacity loss of only 0.16% per cycle. On cycling at 5 C rate, the charge and discharge capacities for first three cycles were found to be 508 and 276 mA h g−1, 279 and 260 mA h g−1, and 263 and 254 mA h g−1, respectively. It delivered charge and discharge capacities of 220 and 226 mA h g−1 at the end of 150 cycles.

The applications of B-TiO2 for different rates were investigated to understand memory effect. Figure 10 depicts the rate capability of B-TiO2 at different rates. It exhibited discharge capacities of 394, 350, 307 and 270 mA h g−1 at currents rates of 0.1, 0.2, 0.5 and 1 C, respectively. It exhibited excellent stability and high capacity by delivering high discharge capacities of 197 and 153 mA h g−1 at very high current rates of 7 and 10 C, respectively. The discharge capacity is restored to 392 mA h g−1 when current is reverted to 0.1 C.

The high capacity and excellent stability of the electrode are attributed to the presence of Ti3+ ions and oxygen vacancies. As Ti3+ ions are highly conductive in nature, TiO2 with Ti3+ ions is promoted as a strong contender for negative electrode in LIBs. Meanwhile, oxygen vacancies formed during the generation of Ti3+ ions also favor the lithium storage by providing enhanced interlayer spacing. Thus, Ti3+ ions and oxygen vacancies play a significant role in enhanced Li+ ion storage and excellent stability. It is also worth noting the use of CMC as a binder. The excessive polar functional groups are exploited as excellent chemical bonding agents to bind the active material and current collector together, thereby curtailing the structural destruction during the Li+ ions de-/intercalation. The excellent electrochemical performance of B-TiO2 is also benefited from its nanosize, high surface area, mesoporosity and spongy nature of the electrode material.

The electrochemical impedance spectra (EIS) were recorded after assembly and after 150 cycles at 3.00 V (i.e., delithiated state) to analyze the transport kinetics of B-TiO2 (Fig. 11). The impedance spectrum is represented as Nyquist plots, and it consists of low-frequency linear part and high-frequency semicircles. The diameter of semicircle in Nyquist plot of impedance spectrum is a measure of charge-transfer resistance and SEI layer resistance. The lower-frequency linear spike corresponds to diffusion-limited Warburg element [73, 74]. A lower charge-transfer resistance of 120 Ω is obtained for B-TiO2 cell after 150 cycles, whereas it displayed a high resistance of 230 Ω after assembly. The declined charge-transfer resistance suggests an increase in the kinetics of electron-transfer reaction with cycling.

Conclusion

Black TiO2 NPs were synthesized by a simple surfactant-assisted sol–gel method. The formation of Ti3+ ions and oxygen vacancies were ascertained by XPS studies and were found to be responsible for the formation of black-colored defective TiO2. The synthesized defective B-TiO2 NPs were probed as negative electrode for LIBs. It exhibited discharge capacities of 275 and 220 mA h g−1 at very high current rates of 1 C and 5 C, respectively, even after 100 cycles of charge and discharge. The high specific capacity and excellent stability of B-TiO2 NPs are attributed to the formation of Ti3+ ions and oxygen vacancies. As Ti3+ ions are highly conductive in nature, they enhance the lithium kinetics. The oxygen vacancies which are formed during the generation of Ti3+ ions also favor the lithium storage by providing enhanced interlayer spacing. These are the driving forces for us to implement and investigate B-TiO2 as negative electrode for LIBs. Thus, it is reckoned that defective B-TiO2 can serve as a potential negative electrode for LIBs.

References

Liu, J., Tang, S., Lu, Y., Cai, G., Liang, S., Wang, W., Chen, X.: Synthesis of Mo2N nanolayer coated MoO2 hollow nanostructures as high-performance anode materials for lithium-ion batteries. Energy Environ. Sci. 6, 2691–2697 (2013)

Islam, M., Ali, G., Jeong, M.G., Choi, W.C., Chung, K.Y., Jung, H.G.: Study on the electrochemical reaction mechanism of NiFe2O4 as a high-performance anode for li-ion batteries. ACS Appl. Mater. Interfaces. 9, 14833–14843 (2017)

Patil, S.B., Raghu, M.S., Kishore, B., Nagaraju, G.: Enhanced electrochemical performance of few-layered MoS2-rGO nanocomposite for lithium storage application. J. Mater. Sci. Mater. Electr. (2018). https://doi.org/10.1007/s10854-018-0295-3

Patil, S.B., Kishore, B., Nagaraj, M.K., Nagaraju, G., Velu, U.: Mesoporous MnMoO4 nanorods for enhanced electrochemical performance. ChemistrySelect 3, 7490–7495 (2018)

Armstrong, A.R., Armstrong, G., Canales, J., Bruce, P.G.: Angew. TiO2-B nanowires. Chem. Int. Ed. 43, 2286–2288 (2004)

Armstrong, A.R., Armstrong, G., Canales, J., Garcia, R., Bruce, P.G.: Lithium ion intercalation into TiO2-B nanowires. Adv. Mater. 17, 862–865 (2005)

Ryu, W.H., Nam, D.H., Ko, Y.S., Kim, R.H., Kwon, H.S.: Electrochemical performance of a smooth and highly ordered TiO2 nanotube electrode for li-ion batteries. Electrochim. Acta 61, 19–24 (2012)

Naldoni, A., Allieta, M., Santangelo, S., Marelli, M., Fabbri, F., Cappelli, S., Bianchi, C.L., Psaro, R., Dal Santo, V.: Effect of nature and location of defects on bandgap narrowing of black TiO2 nanoparticles. J. Am. Chem. Soc. 134, 7600–7603 (2012)

Eom, J.Y., Lim, S.J., Lee, S.M., Ryu, W.H., Kwon, H.S.: Black titanium oxide nanoarray electrodes for high rate li-ion microbatteries. J. Mater. Chem. A 3, 11183–11188 (2015)

Wagemaker, M., Kentgens, A.P.M., Mulder, F.M.: Equilibrium lithium transport between nanocrystalline phases in intercalated TiO2 anatase. Nature 418, 397–399 (2002)

Hu, Y.-S., Kienel, L., Guo, Y.-G., Maier, J.: High lithium electroactivity of nanometer-sized rutile-TiO2. Adv. Mater. 18, 1421–1426 (2006)

Sudant, G., Baudrin, E., Larcher, D., Tarascon, J.-M.: Electrochemical lithium reactivity with nanotextured anatase-type TiO2. J. Mater. Chem. 15, 1263–1269 (2005)

Cheng, X.L., Hu, M., Huang, R., Jiang, J.S.: HF-free synthesis of anatase TiO2 nanosheets with largely exposed and clean 001 facets and their enhanced rate performance as anodes of lithium ion battery. ACS Appl. Mater. Interfaces. 6, 19176–19183 (2014)

Liu, H., Li, W., Shen, D., Zhao, D., Wang, G.: Graphite carbon conformal coating of mesoporous TiO2 hollow spheres for high-performance lithium ion battery anodes. J. Am. Chem. Soc. 137, 13161–13166 (2015)

Hu, Y.H.: A highly efficient photocatalyst—hydrogenated black TiO2 for the photocatalytic splitting of water. Angew. Chem. 51, 12410–12412 (2012)

Nowotny, M.K., Bak, T., Nowotny, J.: Electrical properties and defect chemistry of TiO2 single crystal. I. Electrical conductivity. J. Phys. Chem. B 110, 16270–16282 (2006)

Kim, H.S., Cook, J.B., Lin, H., Ko, J.S., Tolbert, S.H., Ozolins, V., Dunn, B.: Oxygen vacancies enhance pseudocapacitive charge storage properties of MoO3−x. Nat. Mater. 16, 454–460 (2017)

Ullattil, S.G., Narendranath, S.B., Pillai, S.C., Periyat, P.: Black TiO2 nanomaterials: a review of recent advances. Chem. Eng. J. 343, 708–736 (2018)

Ma, Y., Wang, X., Jia, Y., Chen, X., Han, H., Li, C.: Titanium dioxide-based nanomaterials for photocatalytic fuel generations. Chem. Rev. 114, 9987–10043 (2014)

Chen, X., Liu, L., Huang, F.: Black titanium dioxide (TiO2) nanomaterials. Chem. Soc. Rev. 44, 1861–1885 (2015)

Kapilashrami, M., Zhang, Y., Liu, Y.-S., Hagfeldt, A., Guo, J.: Probing the optical property and electronic structure of TiO2 nanomaterials for renewable energy applications. Chem. Rev. 114, 9662–9707 (2014)

Phattepur, H., Siddaiah, G.B., Nagaraju, G.: Synthesis and characterisation of mesoporous TiO2 nanoparticles by novel surfactant assisted sol–gel method for the degradation of organic compounds. Periodica Polytech. Chem. Eng. 63, 85–95 (2019)

Cui, H.L., Zhao, W., Yang, C.Y., Yin, H., Lin, T.Q., Shan, Y.F., Xie, Y., Gu, H., Huang, F.Q.: Black TiO2 nanotube arrays for high-efficiency photoelectrochemical water-splitting. J. Mater. Chem. A 2, 8612–8616 (2014)

Chen, X.B., Liu, L., Liu, Z., Marcus, M.A., Wang, W.C., Oyler, N.A., Grass, M.E., Mao, B.H., Glans, P.A., Yu, P.Y., Guo, J.H., Mao, S.S.: Properties of disorder-engineered black titanium dioxide nanoparticles through hydrogenation. Sci. Rep. 3, 1510–1517 (2013)

Ryu, W.H., Lee, Y.W., Nam, Y.S., Youn, D.Y., Park, C.B., Kim, I.D.: Crystalline IrO2-decorated TiO2 nanofiber scaffolds for robust and sustainable solar water oxidation. J. Mater. Chem. A 2, 5610–5615 (2014)

Liu, D.W., Zhang, Y.H., Xiao, P., Garcia, B.B., Zhang, Q.F., Zhou, X.Y., Jeong, Y.H., Cao, G.Z.: TiO2 nanotube arrays annealed in CO exhibiting high performance for lithium ion intercalation. Electrochim. Acta 54, 6816–6820 (2009)

Wang, G.M., Wang, H.Y., Ling, Y.C., Tang, Y.C., Yang, X.Y., Fitzmorris, R.C., Wang, C.C., Zhang, J.Z., Li, Y.: Hydrogen-treated TiO2 nanowire arrays for photoelectrochemical water splitting. Nano Lett. 11, 3026–3033 (2011)

Lu, X.H., Wang, G.M., Zhai, T., Yu, M.H., Gan, J.Y., Tong, Y.X., Li, Y.: Hydrogenated TiO2 nanotube arrays for supercapacitors. Nano Lett. 12, 1690–1696 (2012)

Jagadale, T.C., Takale, S.P., Sonawane, R.S., Joshi, H.M., Patil, S.I., Kale, B.B., Ogale, S.B.: N-Doped TiO2 nanoparticle based visible light photocatalyst by modified peroxide sol–gel method. J. Phys. Chem. C 112, 14595–14602 (2008)

Asahi, R., Morikawa, T., Ohwaki, T., Aoki, K., Taga, Y.: Visible-light photocatalysis in nitrogen-doped titanium oxides. Science 293, 269–271 (2001)

Chen, C., Bai, H., Chang, C.: Effect of plasma processing gas composition on the nitrogen doping status and visible light photocatalysis of TiO2. J. Phys. Chem. C 111(15228), 15235 (2007)

Saha, N.C., Tompkins, H.G.: Titanium nitride oxidation chemistry: an X-ray photoelectron spectroscopy study. J. Appl. Phys. 72, 3072 (1992)

Glaser, A., Surnev, S., Netzer, F.P., Fateh, N., Fontalvo, G.A., Mitterer, C.: Oxidation of vanadium nitride and titanium nitride coatings. Surf. Sci. 601, 1153–1159 (2007)

Gopinath, C.S.: Comment on “Photoelectron spectroscopic investigation of nitrogen-doped titania nanoparticles”. J. Phys. Chem. B 110, 7079–7080 (2006)

Myung, S.T., Kikuchi, M., Yoon, C.S., Yashiro, H., Kim, S.J., Sun, Y.K., Scrosati, B.: Black anatase titania enabling ultra high cycling rates for rechargeable lithium batteries. Energy Environ. Sci. 6, 2609–2614 (2013)

Sunkara, S., Munichandraiah, N., Varma, K.B.R., Shivashankar, S.A.: A sonochemical approach for the synthesis of thermally stable mesoporous microspheres of TiO2 for use as high performance anodes for li-ion batteries. New J. Chem. 40, 7197–7203 (2016)

Madej, E., Ventosa, E., Klink, S., Schuhmann, W., La Mantia, F.: Aging effects of anatase TiO2 nanoparticles in Li-ion batteries. Phys. Chem. Chem. Phys. 16, 7939–7945 (2014)

Nan, Y., Li, S., Li, B., Yang, S.: An artificial TiO2/lithium n-butoxide hybrid SEI layer with facilitated lithium-ion transportation ability for stable lithium anodes. Nanoscale 11, 2194–2201 (2019)

Ventosa, E., Madej, E., Zampardi, G., Mei, B., Weide, P., Antoni, H., Mantia, F.L., Muhler, M., Schuhmann, W.: Solid electrolyte interphase (SEI) at TiO2 electrodes in li-ion batteries: defining apparent and effective SEI based on evidence from X-ray photoemission spectroscopy and scanning electrochemical microscopy. ACS Appl. Mater. Interfaces. 9, 3123–3130 (2017)

Wagemaker, M., van de Krol, R., Kentgens, A.P.M., van Well, A.A., Mulder, F.M.: Two phase morphology limits lithium diffusion in TiO2 (anatase): a Li-7 MAS NMR study. J. Am. Chem. Soc. 123, 11454–11461 (2001)

Leroux, F., Dewar, P.J., Intissar, M., Ouvrard, G., Nazar, L.F.: Study of the formation of mesoporous titania via a template approach and of subsequent Li insertion. J. Mater. Chem. 12, 3245–3253 (2002)

Maier, J.: Defect chemistry and ion transport in nanostructured materials—Part, II. Aspects of nanoionics. Solid State Ionics 157, 327–334 (2003)

Wagemaker, M., Kearley, G.J., van Well, A.A., Mutka, H., Mulder, F.M.: Multiple li positions inside oxygen octahedra in lithiated TiO2 anatase. J. Am. Chem. Soc. 125, 840–848 (2003)

Wagemaker, M., Lutzenkirchen-Hecht, D., van Well, A.A., Frahm, R.: Atomic and electronic bulk versus surface structure: lithium intercalation in anatase TiO2. J. Phys. Chem. B 108, 12456–12464 (2004)

Wagemaker, M., Borghols, W.J.H., Eck, E.R.H., Kentgens, A.P.M., Kearley, G.J., Mulder, F.M.: The influence of size on phase morphology and Li-ion mobility in nano-sized lithiated anatase TiO2. Chem.-Eur. J. 13, 2023–2028 (2007)

Wagemaker, M., Simon, D.R., Kelder, E.M., Schoonman, J., Ringpfeil, C., Haake, U., Lutzenkirchen-Hecht, D., Frahm, R., Mulder, F.M.: A kinetic two-phase and equilibrium solid solution in spinel Li4+xTi5O12. Adv. Mater. 18, 3169–3173 (2006)

Wagemaker, M., Borghols, W.J.H., Mulder, F.M.: Large impact of particle size on insertion reactions. A case for anatase LixTiO2. J. Am. Chem. Soc. 129, 4323–4327 (2007)

Dambournet, D., Belharouak, I., Amine, K.: Tailored preparation methods of TiO2 anatase, rutile, brookite: mechanism of formation and electrochemical properties. Chem. Mater. 22, 1173–1179 (2010)

Pol, V.G., Kang, S.-H., Calderon-Moreno, J.M., Johnson, C.S., Thackeray, M.M.: Autogenic reactions for preparing carbon-encapsulated, nanoparticulate TiO2 electrodes for lithium-ion batteries. J. Power Sources 195, 5039–5043 (2010)

Shin, J.-Y., Samuelis, D., Maier, J.: Sustained lithium-storage performance of hierarchical, nanoporous anatase TiO2 at high rates: emphasis on interfacial storage phenomena. Adv. Funct. Mater. 21, 3464–3472 (2011)

Ortiz, G.F., Hanzu, I., Djenizian, T., Lavela, P., Tirado, J.L., Knauth, P.: Alternative li-ion battery electrode based on self-organized titania nanotubes. Chem. Mater. 21, 63–67 (2009)

Beuvier, T., Richard-Plouet, M., Mancini-Le Granvalet, M., Brousse, T., Crosnier, O., Brohan, L.: TiO2(B) nanoribbons as negative electrode material for lithium ion batteries with high rate performance. Inorg. Chem. 49, 8457–8464 (2010)

Kavan, L.: Electrochemistry of titanium dioxide: some aspects and highlights. Chem. Rec. 12, 131–142 (2012)

Froschl, T., Hörmann, U., Kubiak, P., Kucerova, G., Pfanzelt, M., Weiss, C.K., Behm, R.J., Husing, N., Kaiser, U., Landfester, K., Wohlfahrt-Mehrens, M.: High surface area crystalline titanium dioxide: potential and limits in electrochemical energy storage and catalysis. Chem. Soc. Rev. 41, 5313–5360 (2012)

Berger, T., Monllor-Satoca, D., Jankulovska, M., Lana-Villarreal, T., Gomez, R.: The electrochemistry of nanostructured titanium dioxide electrodes. Chem. Phys. Chem. 13, 2824–2877 (2012)

Borghols, W.J.H., Wagemaker, M., Lafont, U., Kelder, E.M., Mulder, F.M.: Size effects in the Li4+xTi5O12 spinel. J. Am. Chem. Soc. 131, 17786–17792 (2009)

Borghols, W.J.H., Lutzenkirchen-Hecht, D., Haake, U., Chan, W., Lafont, U., Kelder, E.M., van Eck, E.R.H., Kentgens, A.P.M., Mulder, F., Wagemaker, M.: Lithium storage in amorphous TiO2 nanoparticles. J. Electrochem. Soc. 157, A582–A588 (2010)

Ren, Y., Hardwick, L.J., Bruce, P.G.: Lithium intercalation into mesoporous anatase with an ordered 3D pore structure. Angew. Chem. Int. Ed. 49, 2570–2574 (2010)

Guo, Y.-G., Hu, Y.-S., Maier, J.: Synthesis of hierarchically mesoporous anatase spheres and their application in lithium batteries. Chem. Commun. (2006). https://doi.org/10.1039/b605090e

Gentili, V., Brutti, S., Hardwick, L.J., Armstrong, A.R., Panero, S., Bruce, P.G.: Lithium insertion into anatase nanotubes. Chem. Mater. 22, 4468–4476 (2012)

Moitzheim, S., De Gendt, S., Vereecken, P.M.: Investigation of the li-ion insertion mechanism for amorphous and anatase TiO2 thin-films. J. Electrochem. Soc. 166, 1–9 (2019)

Omichi, K., Ramos-Sanchez, G., Rao, R., Pierce, N., Chen, G., Balbuena, P.B., Harutyunyana, A.R.: Origin of excess irreversible capacity in lithium-ion batteries based on carbon nanostructures. J. Electrochem. Soc. 162, A2106–A2115 (2015)

Madian, M., Eychmuller, A., Giebeler, L.: Current advances in TiO2-based nanostructure electrodes for high performance lithium ion batteries. Batteries 4, 7–43 (2018)

Lee, K.H., Song, S.W.: One-step hydrothermal synthesis of mesoporous anatase TiO2 microsphere and interfacial control for enhanced lithium storage performance. ACS Appl. Mater. Interfaces. 3, 3697–3703 (2011)

Yeh, H.L., Tai, S.H., Hsieh, C.M., Chang, B.K.: First-principles study of lithium intercalation and diffusion in oxygen-defective titanium dioxide. J. Phys. Chem. C 122, 19447–19454 (2018)

Wang, J., Polleux, J., Lim, J., Dunn, B.: Pseudocapacitive contributions to electrochemical energy storage in TiO2 (anatase) nanoparticles. J. Phys. Chem. C 111, 14925–14931 (2007)

Cherian, C.T., Reddy, M.V., Magdaleno, T., Sow, C.H., Ramanujachary, K.V., Subba Rao, G.V., Chowdari, B.V.R.: (N, F)-Co-doped TiO2: synthesis, anatase-rutile conversion and li-cycling properties. Cryst. Eng. Comm 14, 978–986 (2012)

Reddy, M.V., Aloysius Chan, T.Y., Adams, S.: Effect of molten salt synthesis temperature on TiO2 and li cycling properties. J. Solid State Electrochem. 22, 429–439 (2018)

Reddy, M.V., Madhavi, S., Subba Rao, G.V., Chowdari, B.V.R.: Metal oxyfluorides TiOF2 and NbO2F as anodes for li-ion batteries. J. Power Sour. 162, 1312–1321 (2006)

Reddy, M.V., Jose, R., Teng, T.H., Chowdari, B.V.R., Ramakrishna, S.: Preparation and electrochemical studies of electrospun TiO2 nanofibers and molten salt method nanoparticles. Electrochim. Acta 55, 3109–3117 (2010)

Reddy, M.V., Sharma, N., Adams, S., Rao, R.P., Peterson, V.K., Chowdari, B.V.R.: Evaluation of undoped and M-doped TiO2, where M = Sn, Fe, Ni/Nb, Zr, V, and Mn, for lithium-ion battery applications prepared by the molten-salt method. RSC Adv. 5, 29535–29544 (2015)

Yan, X., Wang, Z., He, M., Hou, Z., Xia, T., Liu, G., Chen, X.: TiO2 nanomaterials as anode materials for lithium-ion rechargeable batteries. Energy Technol. 3, 801–814 (2015)

Patil, S.B., Kishore, B., Nagaraju, G., Dupont, J.: High capacity MoO3/rGO nanocomposite anode for lithium ion batteries: an intuition into the conversion mechanism of MoO3. New J. Chem. 42, 18569–18577 (2018)

Patil, S.B., Kishore, B., Reddy, V., Nagaraju, G.: Composition of MoO2 nanoparticles with RGO sheets as improved lithium ion battery anode. Chem. Select 3, 13289–13296 (2018)

Acknowledgements

SBP and GN greatly thank BRNS-BARC, DAE (No. 37(2)/14/25/2015/BRNS), Bombay, Govt. of India, for financial sponsorship. Thanks are due to CoE—TEQIP, Director and Principal, Siddaganga Institute of Technology (SIT), Tumakuru, for constant support and encouragement. Thanks to Prof. N. Munichandraiah, Dept. of Inorganic and Physical Chemistry, Indian Institute of Science, Bangalore, for providing glove box facility to assemble the cells.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Patil, S.B., Phattepur, H., Kishore, B. et al. Robust electrochemistry of black TiO2 as stable and high-rate negative electrode for lithium-ion batteries. Mater Renew Sustain Energy 8, 10 (2019). https://doi.org/10.1007/s40243-019-0147-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-019-0147-y