Abstract

We report the synthesis and characterization of Carbon and CdTe quantum dots (QDs), as well as the observed improvement in the power conversion efficiency (PCE) of photovoltaic devices upon the incorporation of the synthesized aforementioned nanostructures. Even though C quantum dots were observed to have a relatively smaller influence on solar cell performance, they are considered to be a more attractive option due to their affordability and minimal impact in the environment that could ultimately promote their widespread utilization on photovoltaic structures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There is a generalized trend to demonstrate higher solar cell efficiency with more affordable devices to promote their widespread utilization. Silicon remains the most widely employed material in solar cell manufacturing. However, one of the main limitations of silicon solar cells is their relatively low capacity to absorb photons near the band gap energy level [1]. In silicon solar cells those high-energy photons represent intrinsic losses. Improving the capture of those photons that are otherwise considered lost could lead to a dramatic increase in the efficiency of photovoltaic structures [2]. One of the options explored involves the utilization of photoluminescent, down-shifting [3] quantum structures to enable the capture of high-energy photons that tend to interact with lattice phonons rather than generate electron–hole pairs [4, 5].

Therefore, we report the utilization of Carbon [6, 7] and CdTe [8] quantum dots [9] for down shifting effects to capture the aforementioned high-energy photons. These nano crystals are obtained from semiconductor materials [10] and are small enough to exhibit quantum effects.

The electrical properties of these materials are intermediate between bulk semiconductor and discrete molecules and are known to exhibit several favorable characteristics comprising (1) significant interactions between the nano crystals and wavelengths near the ultraviolet range of the solar spectrum, (2) an extraordinary photo stability and (3) a strong relationship of the size and shape of the nanoparticle with its emission and absorption spectrum [11]. Due to the anticipated downshifting effects of these nano structures, their utilization in a thin film matrix has the potential to shift the wavelength of the incident radiation into a more favorable solar cell absorption range [12], and achieve an increased power conversion efficiency [13].

Experimental details

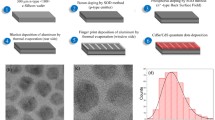

Synthesis of C QDs

The C nanostructures were synthesized employing an alkali-assisted electrochemical fabrication method utilizing graphite rods for both the anode and the cathode [14, 15] while varying the applied current between 10 and 60 mA. The graphite rods employed had a diameter of 5 mm, a separation of anode to cathode of 25.4 mm and were submerged 30 mm in a 100-ml electrolyte solution composed of ethanol and water with a volume ratio of 99.5/.05 to which 0.3 g of NaOH was added. Current was applied for 1 h immediately upon the submersion of the graphite rods within the specified current range. Subsequently, the samples were stored for 48 h at room temperature to stabilize them, and the produced solutions were evaporated until obtaining 5 ml for every 100 ml of quantum dot solution. Upon the completion of the evaporation step the samples were separated employing a silica-gel chromatography column with a 100-ml mixture of petroleum ether and diethyl ether with a volume ratio of 30/70. The final step was to evaporate all the solvents in each vial to increase the C quantum dot concentration (see Fig. 1) [16, 17].

Synthesis of CdTe QDs

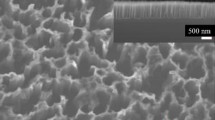

CdTe QDs of measured size between 2 and 18 nm (see Fig. 2) were obtained employing a chemical synthesis scheme. Specifically, 0.0533 g of cadmium acetate dihydrate (Cd (CH3COO)2·2H2O, 99.5 %) was dissolved in 50 ml of deionized (DI) water in a 125-ml Erlenmeyer flask; subsequently 18 µl of thioglycolic acid (TGA, 90 %) was added, and the pH was adjusted with 1 M sodium hydroxide (NaOH) set solution until reaching a value between 10.5 and 11 in the pH scale and stirred for 5 min. Separately, 0.0101 g of potassium tellurite (K2TeO3, 95 %) was dissolved in 50 ml of DI water in a 125-ml Erlenmeyer flask, stirred for 5 min and 0.0101 g K2TeO3 was added to this second solution. Subsequently, the previously prepared solutions were mixed, 0.08 g of sodium borohydride (NaBH4, 99.99 %) was added to the mixture and the reaction was allowed to proceed for 5 min. The mixed solution was then transferred to a single-neck, round-bottom flask that was attached to a Liebig condenser, which was stirred at 500 rpm while being refluxed. During the refluxing time, the flask remained submerged in laboratory oil whose temperature was maintained at 100 °C. QD size and photoluminescent emission wavelength were determined by the refluxing time (15, 30 min, 1, 3, 5, 6, 8 and 12 h) [18, 19].

In order to incorporate the QDs on functional solar cells, they must be dispersed in a matrix. For this purpose, polymers are attractive materials for dispersing the nanoparticles for several reasons including affordability, mechanical flexibility and ease of processing into thin films. Furthermore, most polymers are highly transparent at wavelengths longer than 400 nm; thus, nanocomposites based on nanoparticle dispersion in polymers are a promising option for integrated optical devices. In this effort we selected Polymethylmethacrylate (495 PMMA A2 from Microchem) as the matrix in which to disperse the Carbon and CdTe QDs on the basis of its high transparency (93 %), low fragility, high weather and UV resistance and excellent thermal insulation. Upon nanostructure dispersion, the PMMA + QD thin films were spin cast on the window side of 52 × 38 mm, commercially available polysilicon solar cells (Eco-worthy Company) with thickness of 200 µm.

The dispersion of Carbon QDs in PMMA was obtained by adding to the dried nano crystals produced in the synthesis process previously described 1 ml of PMMA. In the case of the CdTe QDs, 3 ml of the synthesized nanostructures solution was mixed with acetone (volume ratio 1:1) and centrifuged at 10,000 rpm for 10 min to promote sedimentation. Upon removal of the liquid portion with a pipette, 1 ml of PMMA was added to the vial and sonicated for 5 min to disperse the quantum dots.

Spin casting was carried out by starting at 300 rpm for 10 s followed by a set speed of 4000 rpm and holding for 45 s. Upon completion of the spin coating process, the solar cells with the incorporated thin film were annealed at 180 °C for 60 s on a hot plate to allow the evaporation of the solvents. The optical and electrical properties of the photovoltaic devices produced were collected and compared with the data obtained before the application of the PMMA + QDs thin films.

Quantum dot characterization

The size of the synthesized CdTe and Carbon QDs was controlled by the duration of the refluxing step for the former and the applied current in the latter case. Size was monitored by collecting their absorption and photoluminescence spectra. Ostensibly the color of CdTe QDs can be adjusted from green to orange-yellow by the refluxing time. Thus, a refluxing time of 15 min exhibits a characteristic emission peak at 510 nm, which shifts to 585 nm for a refluxing time of 12 h, both collected with an excitation wavelength of 395 nm (see Fig. 3).

Variations in the applied current determine the size of the synthesized carbon nanoparticles such that the colors observed [20, 21], with an excitation with a wavelength of 360 nm, vary from violet (400 nm) to green (550 nm) [22] with the maximum at approximately 420 nm (see Fig. 4) [23]. Fluorescence measurements were carried using an AMINCO-Bowman Series 2 at room temperature.

CdTe QDs solutions exhibit an absorption spectra extending from approximately 450 nm to as much as 600 nm for those samples with the longest refluxing time (see Fig. 5). Carbon QD solutions shows broad UV/Vis absorption with a characteristic curve at 340 nm (see Fig. 6). The UV/Vis absorption spectra were recorded with a UV–VIS-NIR Cary 5000 spectrometer.

Solar cell characterization

Solar cell performance was quantified with an Oriel Sol2A solar simulator under standard testing conditions. Specifically, measurements were collected before and after the deployment of the PMMA + QD layer for the samples of Carbon QDs synthesized with different current values from 10 to 60 mA, and the CdTe QDs were obtained with refluxing times of 15, 30 min, 1, 3, 5, 6, 8 and 12 h, respectively. The external quantum efficiency (EQE) was measured with an Oriel Quantum Efficiency Measurement kit (QE-PV-SI) using a spot size of approximately 2 mm2.

Solar cells with Carbon or CdTe PMMA + QD layers exhibited higher EQE values across the range of interest of the solar spectrum [24] (see Figs. 7 ,8).

Table 1 summarizes the measured Power Conversion Efficiency without and with carbon QDs. The collected measurements indicate that there is a modest but not negligible increase in the PCE when the CQDs are added, for all values of the current employed during QD synthesis.

Table 2 summarizes the measured Power Conversion Efficiency with and without the incorporation of CdTe QDs. The collected measurements indicate that there is a modest but not negligible increase in the PCE when the CdTe QDs are added, regardless of the refluxing time employed during QD synthesis.

Conclusions

The synthesis and characterization of Carbon quantum dots produced with different applied currents (10–60 mA) and CdTe QDs using various refluxing times (15 min–12 h) corroborated the absorption of relatively high energy photons and the emission of lower energy photons in the range of 350–550 nm for carbon QDs and between 480 and 620 nm for CdTe Qds. Ostensibly, the size and the corresponding emission spectra of the aforementioned QDs can be adjusted by varying the current for Carbon and the reflux time for the colloidal chemical synthesis of CdTe. These schemes are considered to be relatively simple, affordable and reproducible methods in both cases.

The experimental results of the incorporation of PMMA thin films with downshifting Carbon CdTe quantum dots on the window side of Poly-Silicon solar cells indicate in all cases a non-negligible increase in the power conversion efficiency (PCE). These results corroborate that the utilization of luminescent down shifting nanoparticles may enable affordable, high-efficiency devices in the near future.

References

Catchpole, K., Polman, A.: Plasmonic solar cells. Opt. Express 16, 21793–21800 (2008)

Reisfeld, R.: New developments in luminescence for solar energy utilization. Opt. Mater. 32(9), 850–856 (2010)

Richards, B.S.: Luminescent layers for enhanced silicon solar cell performance: down-conversion. Sol. Energ. Mat. Sol. Cells 90(9), 1189–1207 (2006)

Hirst, L.C., Ekins-Daukenes, N.J.: Fundamental losses in solar cells. Prog. Photovolt. 19(3), 286–293 (2011)

Ayon, A., Tronco-Jurado, U., Lopez-Delgado, R., Sharma, M., Saucedo-Flores, E., Alvarez-Ramos, E.: Influence of Au/Ag nanostars and CdTe quantum dots on photon manipulation. Paper presented at the Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), 2015 Transducers-2015 18th International Conference on 2015

Wang, Y., Hu, A.: Carbon quantum dots: synthesis, properties and application. J. Mater. Chem. 2(34), 6921–6939 (2014)

Tan, D., Zhou, S., Shimotsuma, Y., Miura, K., Qiu, J.: Effect of UV irradiation on photoluminescence of carbon dots. Opt. Mater. Express 4(2), 213–219 (2015)

Taki, M.: Structural and optical properties of cadmium telluride CdXTe1-Xthin film by evaporate. Int. J. Appl. Innov. Eng. Manage. 2(5), 413–417 (2013)

Hodgson, S.D., Brooks, W.S., Clayton, A.J., Kartopu, G., Barrioz, V., Irvine, S.J.: Enhancing blue photoresponse in CdTe photovoltaics by luminescent down-shifting using semiconductor quantum dot/PMMA films. Nano Energy 2(1), 21–27 (2013)

Trindade, T., O’Brien, P., Pickett, N.L.: Nanocrystalline semiconductors: synthesis, properties, and perspectives. Chem. Mater. 13(11), 3843–3858 (2001)

Saucedo-Flores, E., Ruelas, R., Rangel, V., Tronco, U., Ayón, A.: Modelado del confinamiento y la luminiscencia en nanopartículas de seleniuro y telururo de cadmio. Rev Iberoam Cien 1(7), 113–120 (2014)

Kurtin, J.: Improved solar cell efficiency through the use of an additive nanostructure-based optical downshifter. Contract 303, 275–3000 (2014)

Tronco-Jurado, U.: Modelado, síntesis y caracterización de nanoestructuras luminiscentes de cambio descendente basado en puntos cuánticos de telururo de cadmio aplicado a celdas solares de silicio cristalino. Dissertation, Universidad de Guadalajara (2014)

Li, H., He, X., Huang, H., liu, Y., Lian, S.: Water-soluble fluorescent carbon quantum dots and photocatalyit desingn. Angew. Chem. Int. Edit. 49(26), 4430–4434 (2010)

Zheng, X., Ananthanarayanan, A., Luo, K.Q., Chen, P.: Glowing graphene quantum dots and carbon dots: properties, syntheses, and biological applications. Small 11(14), 1620–1636 (2015)

Zhang, W., Dai, D., Chen, X., Guo, X., Fan, J.: Red shift in the photoluminescence of colloidal carbon quantum dots induced by photon reabsorption. Appl. Phys. Lett. 104(9), 091902 (2014)

Peng, J., Gao, W., Gupta, B.K., Liu, Z., Romero-Aburto, R., Ge, L., Vithayathil, S.A.: Graphene quantum dots derived from carbon fibers. Nano Lett. 12(2), 844–849 (2012)

Wu, S., Dou, J., Zhang, J., Zhang, S.: A simple and economical one-pot method to synthesize high-quality water soluble CdTe QDs. J. Mater. Chem. 22(29), 14573–14578 (2012)

Yuan, Z., Yang, P., Cao, Y.: Time-resolved photoluminescence spectroscopy evaluation of CdTe and CdTe/CdS quantum dots. ISRN Spectrosc. 2012, 1–8 (2012)

Kwon, W., Do, S., Kim, J. H., Jeong, M. S., Rhee, S. W.: Control of photoluminescence of carbon nanodots via surface functionalization using para-substituted anilines. Sci. Rep. 5, 12604 (2012)

Alam, A., Park, B. Y., Ghouri, Z. K., Park, M., Kim, H. Y.: Synthesis of carbon quantum dots from cabbage with down-and up-conversion photoluminescence properties: excellent imaging agent for biomedical applications. Acs Sym. Ser. 17, 3791–3797 (2015)

Bai, J.M., Zhang, L., Liang, R.P., Qiu, J.D.: Graphene quantum dots combined with europium ions as photoluminescent probes for phosphate sensing. Chem-Eur. J. 19(12), 3822–3826 (2013)

Fuyuno, N., Kozawa, D., Miyauchi, Y., Mouri, S., Kitaura, R., Shinohara, H., Matsuda, K.: Size-dependent luminescence properties of chromatographically-separated graphene quantum dots (2013). arXiv: 1311.1684

McIntosh, K.R., Lau, G., Cotsell, N., Hanton, K., Bätzner, D.L., Bettiol, F., Richards, B.S.: Increase in external quantum efficiency of encapsulated silicon solar cells from a luminescent down-shifting layer. Prog. Photovolt. 17(3), 191–197 (2009)

Acknowledgments

We thank the U.S Army Research Office for the financial support provided for this project (Grant W911NF-13-1-0110), and CONACYT for a student fellowships.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Pelayo, E., Zazueta, A., Lopez, R. et al. Silicon solar cell efficiency improvement employing the photoluminescent, down-shifting effects of carbon and CdTe quantum dots. Mater Renew Sustain Energy 5, 5 (2016). https://doi.org/10.1007/s40243-016-0070-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-016-0070-4