Abstract

Polypyrrole is prepared with different molar ratios of dodecylbenzene sulfonic acid (DBSA) (0.1, 0.2, 0.3 and 0.4) by in situ chemical polymerization method. The reaction temperature was 0–5 °C for 24 h. The FTIR spectrum confirmed the attachment of sulfonyl group in the pyrrole structure. The intensity of polypyrrole increased with increase in sulfur content. SEM graphs revealed the granular morphology of the doped polymer surface. DBSA has had strong effect on morphology with formation of aggregated particles at higher concentrations. Higher concentration of DBSA-doped PPy shows higher thermal stability. The promotion of electron from ground state to excited state of polypyrrole is confirmed by UV spectroscopic studies. Various sizes in particle distribution of DBSA-doped PPy were analyzed by a particle size analyzer. Solubility of polypyrrole was determined at room temperature. The solubility and quantity of polypyrrole increased with higher dopant concentration. Current–voltage (I–V) characteristics were carried out over the temperature range 313–343 K, which was found to be linear. The conductivity of doped-PPy showed high conductivity at low concentration of dopant while, conductivity decreased with increasing concentration of DBSA. The higher doping level of DBSA was confirmed by elemental analysis.

Similar content being viewed by others

Introduction

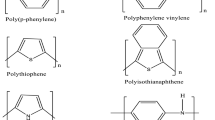

Electrically conducting polymers like polyaniline, polypyrrole and polythiophene are of great interest as a new class of materials in industry during the last two decades, owing to their unique combination of characteristics: electronic, optical, magnetic properties and processing advantage of polymers [1]. Polypyrrole offers tremendous technological potential such as battery electrodes [2], biological sensors [3], corrosion protection [4], microwave shielding [5, 6], e-Textiles and artificial muscles [7] and sensors [8]. PPy can be prepared by electrochemical or chemical methods. Although the electrochemical polymerization of PPy leads to the formation of polymer thin film on working electrode, it is not suitable for mass production. Chemical oxidative polymerization is simple, cheap and fast. It can easily be scaled up. Electrochemically synthesized PPy normally exhibits very poor solubility in all common organic solvents and in water. This limits its processability. To overcome these disadvantages, attempts are made by introducing counter-ions into the polymers backbone. Protonation with an organic acid increases solubility, electronic structure, and crystallinity of PPy [9]. To promote the solubility and processability of PPy, various substituted monomers were proposed to reduce the strong intermolecular interaction between conducting polymer chains in the doped state [10]. But long-chain substituents attached to the monomer ring due to steric interference alters the planarity of the polymer structure. This can be achieved by doping polymer with organic acids such as, dodecylbenzene sulfonic acid (DBSA) and camphor sulfonic acid. The presence of organic sulfonic acid as counter-ion in the polymer strongly affects the conductivity, morphology and thermal stability of bulk PPy [11]. The polymerization parameters, such as solvent [12], temperature, concentration of monomer, supporting electrolyte [13] polymerization time, the dopant concentration and dopant type [14], have strong effect on the polymerization pyrrole.

In the present work, the various molar ratios (0.1, 0.2, 0.3 and 0.4) of DBSA-doped PPy were prepared by in situ chemical polymerization method. The effect of dopant concentration on morphological, thermal, structural, solubility and electrical properties of polypyrrole is investigated.

Experimental

Materials

Pyrrole and dodecylbenzene sulfonic acid (DBSA) (Sigma-Alridch, India) were purified using distillation plant. Ammonium persulphate (APS) was obtained from Loba Chemicals. Methanol and acetone (Merck) were used for the syntheses.

Preparation of DBSA-doped polypyrrole

Polypyrrole was prepared with a molar ratio of DBSA (0.1). First 0.3 mol of pyrrole was dissolved in 500 mL of de-ionized water. After 10 min, 0.06 mol of ammonium persulfate (APS) was prepared in 100 mL de-ionized water and added dropwise into solution mixture. The solution was stirred for 24 h in an ice bath maintained at a constant temperature of 0–5 °C. The solution became dark brown and then 300 mL of methanol was added to the solution to stop the reaction.

The resultant polypyrrole powder was filtered and washed sequentially twice with 100 mL of distilled water, 100 mL of methanol and 100 mL of acetone, and the samples were dried at 30 °C for 12 h in a vacuum oven. The synthesized polypyrrole powder was then stored in a desiccators. For DBSA-doped polypyrrole of molar ratios of 0.2, 03 and 0.4, the same procedure was repeated as above. The quantity of the sample increased with DBSA of higher molar ratio. The polymerization yield of polypyrrole was 6, 12, 17 and 22 g.

Characterization techniques

FTIR analysis was performed in the range of 4,000–400 cm−1 using a Thermo Nicolet V-200 FTIR Spectrometer by KBr pellet technique. A JEOL scanning electron microscope (JSM-5610) was used to study the surface morphology of the polypyrrole powder. The UV-visible spectra of DBSA-doped polypyrrole with different molar ratios were recorded employing a Jasco V-530 dual beam spectrometer. Thermogravimetric analysis of DBSA-doped PPy was recorded in the temperature range of 30–600 °C under nitrogen atmosphere with a heating rate of 10.00 °C/min using NETZSCH STA 449F3Analyzer. Elemental analyses of DBSA-doped polypyrrole samples, prepared at different molar ratios, were tested using a Vario EL III CHNS-11035060 model elemental analyzer. The conductivity of different molar ratios of DBSA-doped polypyrrole was performed by a Kiethly 6571B High Resistance Meter and Electrometer using a four probe-setup (DFP.2 model). The particle size distribution of DBSA-doped PPy was analyzed using a Malvern model No.-500999 instrumental analyzer (USA).

Results and discussion

FTIR spectra of different molar ratios of DBSA-doped polypyrrole

Figure 1 shows the FTIR spectra of DBSA-doped polypyrrole in different molar ratios. N–H symmetric stretching appears at 3,437 cm−1. The peaks at 2,900–2,859 cm−1 correspond to S=O and C–H stretching modes, which indicate the presence of benzenoid ring in the DBSA molecule. The peak at 1,180 cm−1 represents the S=O stretching vibration of sulfonate anions, −SO3 −, which compensate the positive charges in the polypyrrole chains [15]. The peak at 660 cm−1 indicates the characteristic vibrations of DBSA [16]. The peaks at 1,543 and 1,454 cm−1 can be associated with C–N and C–C asymmetric and symmetric ring stretching vibrations, respectively. The peak at 1,028 cm−1 is attributed to C–H deformation and N–H stretching vibration. The broad band at 1,300 cm−1 is attributed to C–H and C–N in-plane deformation vibrations. The bands at 560 cm−1 represent the C–S stretching vibrations. This implies that the sulfonic acid groups were introduced into the polymer backbone. As the molar ratio increases, the intensity also increases. The FTIR spectrum reveals that more DBSA molecules were able to interact with the polypyrrole chains when doped at higher DBSA molar ratios.

SEM images for different molar ratios of DBSA-doped polypyrrole

The SEM images of DBSA-doped polypyrrole with different molar ratios (0.1, 0.2, 0.3 and 0.4) are shown in Fig. 2a–d in the order given. The different molar ratios of DBSA-doped PPy show granular form in each case, though the particle sizes varied due to the molar ratio of dopant. Figure 2a–c shows that the particles are agglomerated. Figure 2d reveals that the 0.4 mol of DBSA has strong effect on the surface morphology, as the particles are aggregated. This aggregation of particles may lead to lower conductivity with increased molar ratio of DBSA. It was observed that the higher molar ratio of DBSA has a strong effect on the DBSA-doped polypyrrole surface.

UV-vis absorption spectrum of different molar ratios of DBSA-doped polypyrrole

Figure 3 shows the UV-vis spectra of DBSA-doped polypyrrole with different molar ratios. The absorption peak at 230 nm reveals the electron transition in the benzenoid rings of DBSA [17]. In Fig. 3a, there are two main absorption peaks at 230 and 280 nm, which correspond to the excitation of the π → π* transition in the benzenoid rings of DBSA. The additional peak at 280 nm shows the presence of pure DBSA. This indicates that the higher sulfonate group introduced into the polymer system may induce more doping of PPy backbone. The sulfonate group could be anionically charged, so that it could stabilize the doped state of the PPy effectively.

Thermogravimetric analysis of DBSA-doped polypyrrole

Figure 4 shows the TGA spectra of polypyrrole with different molar ratios of DBSA. The initial weight of the sample was 9.824 mg. There were 3 stages of major weight losses from 110 to 530 °C. The first weight loss, observed at 110 °C, is due to the loss of water molecules from DBSA-doped polypyrrole. The second weight loss which started at around 244 °C represents the evaporation and degradation of pure DBSA [18–24]. At this stage, the coulombic attraction between DBSA and the backbone of pyrrole is destroyed leading to DBSA evaporation and beginning of degradation process. The third stage of weight loss may be observed within 350–450 °C range.

The sample is shown to degrade above 450 °C and the mass changes are 4.55, 7.28, 17.62 and 25.582 in the order given. The average percentage of weight loss is 55 % with different molar ratios of DBSA-doped PPy. With an increase in molar ratio of DBSA, the rate of weight loss decreases. The peaks are found to be shifted with the addition of dopant molecules. Figure 5 shows DTG curve endothermic peaks at 129, 329 and 429–529 °C. The higher molar ratio of DBSA-doped polypyrrole acquires greater thermal stability.

Elemental analysis of different molar ratios of DBSA-doped polypyrrole

Generally, elemental analysis gives the percentage weight of carbon, hydrogen, nitrogen and sulfur present in the sample which can be used to calculate the stoichiometry of the sample. When organic sulfonic acids are used as dopants, the elemental analysis can be used to estimate the extent of doping in the polymer chain. The experimental values are calculated for different molar ratios of DBSA-doped PPy and they are presented in Table 1. The DBSA molar ratio increases as the N\S ratio decreases. C\N ratios increase with the addition of DBSA. The sulfur content increases with increasing DBSA concentration. Thus, the higher doping level of DBSA-doped polypyrrole is confirmed.

Conductivity measurements for various molar ratios of DBSA-doped polypyrrole

In this arrangement, the samples were sandwiched between the copper electrodes by pressure contact [24]. The voltage, V, was kept constant and the temperature varied from room temperature (313 K) to 343 K. The current values were recorded with increase in temperature. The resistivity at different temperatures was calculated using the relation.

where, F = d/s and I is current, V is voltage, d is thickness of the pellet (2.434 mm), F is correction factor and S is distance between two probes and distance of the probe which was 2 mm. The conductivity was calculated using the relation σ = 1/ρ, where ρ is resistivity; the correction factor depends on the sample geometry, thickness, borders and location of points in the sample. I–V characteristics for various concentration of DBSA-doped polypyrrole are shown in Fig. 6 for 0.1, 0.2, 0.3 and 0.4 while, the thickness of the pellet was 2.434 mm. The current increases with increasing temperature, showing linear behavior. Thermal effects induce lower resistance characteristic, which allows more current passing across the sample.

The conductivity measurement of PPy with various concentration of DBSA is shown in Fig. 7. The various molar ratios of DBSA/PPy from 0.1 to 0.3 led to a greater yield and conductivity of the doped PPy and from 0.4 it began to decrease. By higher amount of DBSA, as depicted in Fig. 2d, there appears segregation of particles in the SEM image. When excess of DBSA was absorbed onto the surface of hydrophobic pyrrole, a so-called protected envelope was formed around the products at higher concentration which prevented further polymerization. So, the conductivity of DBSA-pyrrole decreased with higher molar ratio of DBSA. It is observed that the conductivity of polypyrrole is due to dopant concentration.

Solubility

The solubility of polypyrrole was determined by dissolving it in various organic solvents. One gram of the synthesized polymer was dissolved in 100 mL of m-cresol and kept for 24 h at room temperature [25]. DBSA-doped PPy has long alkyl group and its functional group leads to solubility in all organic solvents [26]. As the concentration of DBSA increases, the solubility of PPy-DBSA also increases. This result is in agreement with the previous assumption that the large dopant reduces inter- and intramolecular interactions by placing itself between the polymer molecules [27]. We observed that the higher concentration of DBSA improves solubility and quantitative yield of polypyrrole.

Particle size analysis of DBSA-doped polypyrrole

The particle size distribution of DBSA-doped polypyrrole is shown in Fig. 8. The different molar ratios of DBSA-doped polypyrrole dispersed in distilled water at 0.1, 0.2, 0.3, and 0.4 molar ratios. The various sizes of the particles were found to be 115, 266, 143 and 209–68 nm for different molar ratios of dopant. The average size of the particles was found to be 200 nm for different molar ratios of DBSA-doped polypyrrole samples. We suggested that the particle size of polypyrrole varies with dopant concentration.

Conclusion

The different molar ratios of DBSA-doped polypyrrole have been prepared by in situ chemical polymerization method. Electrical studies reveal the semiconducting nature of DBSA-doped PPy with linear relation of current and voltage. The conductivity of the doped polypyrrole decreased with increasing molar ratio of the dopant beyond 0.4. The solubility of polypyrrole increased with increasing dopant molar ratio. FTIR study confirms the higher content of dopant and well interaction with the PPy structure. The higher doping enhances thermal stability of PPy. DBSA has a strong effect on the polypyrrole surface and showed granular morphology. The electron transition in the benzenoid rings of DBSA was confirmed by UV spectroscopy. The higher doping level of DBSA was confirmed by elemental analysis.

References

Shaktawat V, Sharma K, Saxena NS (2010) Structural and electrical characterization of protonic acid doped polypyrrole. J Ovonic Res 6:239–245

Kim JH, Sharma AK, Lee YS (2006) Synthesis of polypyrrole and carbon nano-fiber composite for the electrode of electrochemical capacitors. Mater Lett 60:1697–1701

Walkiewicz S, Michalska A, Maksymiuk K (2005) Sensitivity and selectivity of polypyrrole based AC-amperometric sensors for electroinactive ions—frequency and applied potential influence. Electroanalysis 17:1269–1278

Han G, Yuan J, Shi G, Wei F (2005) Electrodeposition of polypyrrole/multiwalled carbon nanotube composite films. Thin Solid Films 474:64–69

Kim MS, Kim HK, Byun SW, Jeong SH, Hong YK, Joo JS, Song KT, Kim JK, Lee CJ, Lee JY (2002) PET fabric/polypyrrole composite with high electrical conductivity for EMI shielding. Synth Met 126:233–239

Yavuz O, Ram MK, Aldissi M, Poddar P, Srikanth H (2005) Polypyrrole composites for shielding applications. Synth Met 151:211–217

Hakansson E, Kaynak A, Lin T, Nahavandi S, Jones T, Hu E (2004) Characterization of conducting polymer coated synthetic fabrics for heat generation. Synth Met 144:21–28

Prissanaroon W, Ruangchuay L, Sirivat A, Schwank J (2000) Electrical conductivity response of dodecylbenzene sulfonic acid-doped polypyrrole films to SO2–N2 mixtures. Synth Met 114:65–72

Zhang X, Zhang J, Wang R, Zhu T, Lin Z (2004) Surfactant-directed polypyrrole/CNT nanocables: synthesis, characterization, and enhanced electrical properties. Chem Phys Chem 5:998–1002

Oh EJ, Jang KS, MacDiarmid AG (2001) High molecular weight soluble polypyrrole. Synth Met 125:267–272

Carrillo I, Sanchez de la Blanca E, Redondo MI, Garcia MV, Gonzalez-Tejera MJ, Fierro JLG, Enciso E (2012) Influence of dopant anions on properties of polypyrrole nano coated poly(styrene-co-methacrylic acid) particles. Synth Met 162:136–142

Tietje-Girault J, Ponce de Leon C, Walsh FC (2007) Electrochemically deposited polypyrrole films and their characterization. Surf Coat Technol 201:6025–6034

Carquigny S, Segut O, Lakard B, Lallemand F, Fievet P (2008) Effect of electrolyte solvent on the morphology of polypyrrole films: application to the use of polypyrrole in pH sensors. Synth Met 158:453–461

Eftekhari A, Kazemzad M, Keyanpour-Rad M (2006) Significant effect of dopant size on nanoscale fractal structure of polypyrrole film. Polym J 38:781–785

Silverstein RM, Bassler GC, Morrill TC (1992) In: Spectroscopic identification of organic compounds. 5th edn, Wiley, p. 129

The Aldrich Library of FTIR spectra (1997) 2:3239

Scherr EM, MacDiarmid AG, Manohar SK, Masters JG, Sun Y, Tang X, Druy MA, Glatkowski PJ, Cajipe VB, Fische JE, Cromack KR, Jozefowicz ME, Ginder JM, McCall RP, Epstein AJ (1991) Polyaniline: oriented films and fibers. Synth Met 41:735–738

Han D, Chu Y, Yang L, Liu Y, Lv Z (2005) Reversed micelle polymerization: a new route for the synthesis of DBSA–polyaniline nanoparticles. Colloid Surf A Physicochem Eng Asp 259:179–187

McCall RP, Ginder JM, Leng JM, Coplin KA, Ye HJ, Epstein AJ, Asturias GE, Manohar SK, Masters JG, Scherr EM, Sun Y, Macdiarmid AG (1991) Photoinduced absorption and erasable optical information storage in polyanilines. Synth Met 41:1329–1332

Haba Y, Segal E, Narkis M, Titelman GI, Siegmann A (1999) Polymerization of aniline in the presence of DBSA in an aqueous dispersion. Synth Met 106:59–66

Haba Y, Segal E, Narkis M, Titelman GI, Siegmann A (2000) Polyaniline–DBSA/polymer blends prepared via aqueous dispersions. Synth Met 110:189–193

Zilberman M, Titelman GI, Siegmann A, Haba Y, Narkis M, Alperstein D (1997) Conductive blends of thermally dodecylbenzene sulfonic acid-doped polyaniline with thermoplastic polymers. J Appl Polym Sci 66:243–253

Chen CH (2002) Thermal studies of polyaniline doped with dodecyl benzene sulfonic acid directly prepared via aqueous dispersions. J Polym Res 9:195–200

Saraswat VK, Singh K, Saxena NS, Kishore V, Sharma TP, Saraswat PK (2006) Composition dependence of the electrical conductivity of Se85-xTe15Sbx (x = 2,4,6,8 and 10) glass at room temperature. Current Appl Phys 6:14–18

Bengaoechea MR, Aliev FM, Pinto NJ (2002) Effects of confinement on the phase separation in emeraldine base polyaniline cast from 1-methyl-2-pyrrolidinone studied via dielectric spectroscopy. J Phys Condens Matter 14:11769

Borkar AD, Umare SS, Gupta MC (2002) Chemical synthesis, characterization and transport properties of copolymer: poly(aniline-co-m-methylaniline). Prog Cryst Growth Charact Mater 44:201–208

Cao Y, Smith P, Heeger AJ (1992) Counter-ion induced processibility of conducting polyaniline and of conducting polyblends of polyaniline in bulk polymers. Synth Met 48:91–97

Acknowledgments

The authors are thankful to sophisticated test and instrumentation center, Cochin (Kerala), and Birla Institute of Technology, Mesra, Ranchi for providing instrumental facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Jayamurgan, P., Ponnuswamy, V., Ashokan, S. et al. The effect of dopant on structural, thermal and morphological properties of DBSA-doped polypyrrole . Iran Polym J 22, 219–225 (2013). https://doi.org/10.1007/s13726-012-0119-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-012-0119-x