Abstract

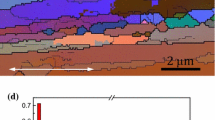

In the present investigation, ultrafine-grained Al alloy was produced from its bulk alloy by cryoforging followed by cryorolling. The bulk Al–Mg–Si alloy, with initial grain size 400 μm, was subjected to solid solution treatment (ST) followed by water quenching at room temperature. The ST treated alloy was subjected to aging at 100 °C for 4 and 8 h prior to cryoforging. The cryoforged alloy was subjected to cryorolling up to 2.4 true strain for producing long sheets. Finally, the deformed alloy was subjected to low temperature aging at 120 °C to improve the tensile properties of the alloys. Microstructure and mechanical properties were evaluated through Vickers hardness testing, tensile testing, and electron back scattered diffraction. The results have shown that combined cryoforging + cryorolling followed by aging led to remarkable improvement in strength (UTS-452 MPa) and ductility (8%). The average grain size of the alloy was found to be 240 nm, with increased fraction of high angle grain boundaries. Low temperature differential scanning calorimetry was used to study thermal behavior of bulk and severely deformed alloy.

Similar content being viewed by others

References

W. Miller, L. Zhuang, J. Bottema, A. Wittebrood, P. De Smet, A. Haszler, A. Vieregge, Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 280(1), 37–49 (2000)

E. Wang, T. Gao, J. Nie, X. Liu, Grain refinement limit and mechanical properties of 6063 alloy inoculated by Al–Ti–C (B) master alloys. J. Alloys Compd. 594, 7–11 (2014)

Y. Birol, Production of Al–Ti–B master alloys from Ti sponge and KBF4. J. Alloys Compd. 440(1–2), 108–112 (2007)

R.Z. Valiev, T.G. Langdon, Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater Sci. 51(7), 881–981 (2006)

A. Zhilyaev, T. Langdon, Using high-pressure torsion for metal processing: fundamentals and applications. Prog. Mater Sci. 53(6), 893–979 (2008)

H.W. Kim, S.B. Kang, N. Tsuji, Y. Minamino, Elongation increase in ultra-fine grained Al–Fe–Si alloy sheets. Acta Mater. 53(6), 1737–1749 (2005)

S. Biswas, S. Suwas, Evolution of sub-micron grain size and weak texture in magnesium alloy Mg–3Al–0.4Mn by a modified multi-axial forging process. Scr. Mater. 66(2), 89–92 (2012)

H. Yu, C. Lu, K. Tieu, X. Liu, Y. Sun, Q. Yu, C. Kong, Asymmetric cryorolling for fabrication of nanostructural aluminum sheets. Sci. Rep. 2, 772 (2012)

K.B. Nie, K.K. Deng, X.J. Wang, F.J. Xu, K. Wu, M.Y. Zheng, Multidirectional forging of AZ91 magnesium alloy and its effects on microstructures and mechanical properties. Mater. Sci. Eng. A 624, 157–168 (2015)

H. Miura, T. Maruoka, X. Yang, J.J. Jonas, Microstructure and mechanical properties of multi-directionally forged Mg–Al–Zn alloy. Scr. Mater. 66(1), 49–51 (2012)

H. Miura, T. Maruoka, J.J. Jonas, Effect of ageing on microstructure and mechanical properties of a multi-directionally forged Mg–6Al–1Zn alloy. Mater. Sci. Eng. A 563, 53–59 (2013)

Y. Wang, T. Jiao, E. Ma, Dynamic processes for nanostructure development in Cu after severe cryogenic rolling deformation. Mater. Trans. 44(10), 1926–1934 (2003)

P.N. Rao, D. Singh, R. Jayaganthan, Mechanical properties and microstructural evolution of Al 6061 alloy processed by multidirectional forging at liquid nitrogen temperature. Mater. Des. 56, 97–104 (2014)

Y. Nakao, H. Miura, T. Sakai, Microstructural evolution and recrystallization behavior in copper multi-directionally forged at 77 K. Adv. Mater. Res. 15–17, 649–654 (2007)

Y. Wang, M. Chen, F. Zhou, E. Ma, High tensile ductility in a nanostructured metal. 419, 912–915 (2002)

D. Singh, P. Nageswara Rao, R. Jayaganthan, Microstructural studies of Al 5083 alloy deformed through cryorolling. Adv. Mater. Res. 585, 376–380 (2012)

E.V. Naidenkin, K.V. Ivanov, E.V. Golosov, Effect of cryorolling on the structure and the mechanical properties of ultrafine-grained nickel. Russ. Metall. 2014(4), 303–307 (2014)

P. NageswaraRao, M. Gopi, R. Jayaganthan, Effect of cryorolling and ageing on microstructure, mechanical properties and corrosion behavior of Al–Cu–Mg–Si alloy. Banaras Met. 19, 19–25 (2014)

Y. Estrin, A. Vinogradov, Extreme grain refinement by severe plastic deformation: a wealth of challenging science. Acta Mater. 61(3), 782–817 (2013)

T. Sakai, H. Miura, X. Yang, Ultrafine grain formation in face centered cubic metals during severe plastic deformation. Mater. Sci. Eng. A 499(1–2), 2–6 (2009)

R.Z. Valiev, R.K. Islamgaliev, I.V. Alexandrov, Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 45(2), 103–189 (2000)

M. Weiss, A.S. Taylor, P.D. Hodgson, N. Stanford, Strength and biaxial formability of cryo-rolled 2024 aluminium subject to concurrent recovery and precipitation. Acta Mater. 61(14), 5278–5289 (2013)

Y.H. Zhao, Y.Z. Guo, Q. Wei, A.M. Dangelewicz, C. Xu, Y.T. Zhu, T.G. Langdon, Y.Z. Zhou, E.J. Lavernia, Influence of specimen dimensions on the tensile behavior of ultrafine-grained Cu. Scr. Mater. 59(6), 627–630 (2008)

S. Cheng, Y.H. Zhao, Y.T. Zhu, E. Ma, Optimizing the strength and ductility of fine structured 2024 Al alloy by nano-precipitation. Acta Mater. 55(17), 5822–5832 (2007)

A.K. Gupta, D.J. Lloyd, S.A. Court, Precipitation hardening processes in an Al–0.4%Mg–1.3%Si–0.25%Fe aluminum alloy. Mater. Sci. Eng. A 301, 140–146 (2001)

G.A. Edwards, K. Stiller, G.L. Dunlop, M.J. Couper, The precipitation sequence in Al–Mg–Si alloys. Acta Mater. 46(11), 3893–3904 (1998)

X. Wang, S. Esmaeili, D.J. Lloyd, The sequence of precipitation in the Al–Mg–Si–Cu alloy AA6111. Metall. Mater. Trans. A 37, 2691–2699 (2006)

A. Gaber, M.A. Gaffar, M.S. Mostafa, E.F.A. Zeid, Precipitation kinetics of Al–1.12 Mg2Si–0.35 Si and Al–1.07 Mg2Si–0.33 Cu alloys. J. Alloys Compd. 429(1–2), 167–175 (2007)

C. Marioara, S. Andersen, J. Jansen, H. Zandbergen, The influence of temperature and storage time at RT on nucleation of the β″ phase in a 6082 Al–Mg–Si alloy. Acta Mater. 51(3), 789–796 (2003)

P.N. Rao, B. Viswanadh, R. Jayaganthan, Effect of cryorolling and warm rolling on precipitation evolution in Al 6061 alloy. Mater. Sci. Eng. A 606, 1–10 (2014)

H.L. Lee, W.H. Lu, S.L.I. Chan, Effect of cold rolling on the aging kinetics of Al composite by differential scanning calorimetric technique. Scr. Metall. Mater. 25(9), 2165–2170 (1991)

Y. Birol, The effect of sample preparation on the DSC analysis of 6061 alloy. J. Mater. Sci. 40, 6357–6361 (2005)

C.S.T. Chang, J. Banhart, Low-temperature differential scanning calorimetry of an Al–Mg–Si alloy. Metall. Mater. Trans. A 42(7), 1960–1964 (2011)

A. Cuniberti, A. Tolley, M.V.C. Riglos, R. Giovachini, Influence of natural aging on the precipitation hardening of an Al–Mg–Si alloy. Mater. Sci. Eng. A 527(20), 5307–5311 (2010)

A. Serizawa, S. Hirosawa, T. Sato, Three-dimensional atom probe characterization of nanoclusters responsible for multistep aging behavior of an Al–Mg–Si alloy. Metall. Mater. Trans. A 39(2), 243–251 (2008)

L. He, H. Zhang, J. Cui, Effects of pre-ageing treatment on subsequent artificial ageing characteristics of an Al–1.01 Mg–0.68Si–1.78Cu alloy. J. Mater. Sci. Technol. 26(2), 141–145 (2010)

L. Cao, P.A. Rometsch, M.J. Couper, Effect of pre-ageing and natural ageing on the paint bake response of alloy AA6181A. Mater. Sci. Eng. A 571, 77–82 (2013)

G.K. Quainoo, S. Yannacopoulos, The effect of cold work on the precipitation kinetics of AA6111 aluminum. J. Mater. Sci. 39(21), 6495–6502 (2004)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hussain, M., Nageswara Rao, P. & Jayaganthan, R. Development of Ultrafine-Grained Al–Mg–Si Alloy Through SPD Processing. Metallogr. Microstruct. Anal. 4, 219–228 (2015). https://doi.org/10.1007/s13632-015-0205-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-015-0205-5