Abstract

The copper-doped gold nanowires (4 nm in diameter) were produced by the novel technique based of laser ablation of Au–Cu alloy inside superfluid helium. The principle of the method is using the quantized vortices as the 1D template for the condensation of the ablation products into thin threads. The nanowires were applied as the catalyst in СО oxidation with oxygen. The activity of Au–Cu nanowires deposited on glass filters was compared with that for monometallic and bimetallic Au and Cu particles (3–8 nm in diameter) deposited on alumina by traditional deposition–precipitation and impregnation techniques. The apparent activation energies of the reaction (Еа) were 95 and 98, 150, and 147 kJ/mol for Au–Cu nanowires and Au–Cu, Au, and Cu particles, respectively. During running-in of the Au–Cu nanowire–based catalyst, Еа decreased to 20 kJ/mol and retained at this level in the subsequent cycles of lowering and raising the reactor temperature.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

For a long time, gold had been regarded as a very stable and catalytically inert metal until Haruta et al. found the surprisingly high activity of supported gold nanoparticles (NPs) for the low-temperature CO oxidation [1]. The recent progress in heterogeneous catalysis by gold resulted in remarkable investigations that demonstrated the high activity of 3–10-nm gold particles in the conversion of bioethanol to synthetic hydrocarbons [2], water gas shift reaction [3, 4], selective hydrogenation of alkynes [5–8], hydrodechlorination of organic molecules [9, 10], and CO oxidation [11–13]. Numerous data on gold catalysis indicate that, apart from the critical particle size (3–5 nm) [1, 14], significant roles for catalytic activity are played by particle shape [13, 15], particle surface chemistry [16, 17], the support nature [10, 18], mutual arrangement of particles, the sign and quantity of the electric charge on the nanoparticle surface [19, 20]. However, the activity of gold nanoparticles is mainly attributed to the high surface curvature [1, 13]. This is supported by the fact that high catalytic activity is exhibited also by gold films provided that they have surface defects with nanometer lateral dimensions [15, 16].

Quasi-one-dimensional (1D) structures, nanowires (NWs) [21, 22], also have a high surface curvature; therefore, it can be expected that gold wires with diameters close to the critical diameter of gold particles (3–5 nm) would also be catalytically active. However, the structural characteristics of nanowires such as the shape and the state of the surface obviously differ from those for particles. Therefore, it appeared of interest to verify the possibility of using nanowires in catalysis in relation to СО oxidation as the test process and to compare the action of nanowires and gold nanoparticles of a similar diameter under the same conditions. Nanowires have not been virtually used as catalysts [23, 24], as it is difficult to manufacture nanowires of small diameter in amounts sufficient for direct measurement of the catalytic action. From this standpoint, unique opportunities are provided by the recently developed method for the synthesis of metal nanowires by laser ablation in superfluid helium (LA) [25, 26], which allows preparation from different metals in exceptionally pure conditions of considerable amounts of nanoweb consisting of single nanowires, interconnected via metallic bonding.

The nanowire thickness and thermal stability depend on the metal thermochemical properties [25, 26]. In particular, the gold wires have diameter of 4 nm and, despite the high melting point of bulk gold (1336 K), decayed into chains of separate nanoclusters already at room temperature [27]. Since this decay is induced by unfreezing the surface atom mobility, the nanowire temperature stability can be improved by doping the major metal by another metal that is readily oxidized in air, as was demonstrated by copper doping of silver [25, 26]. In addition, as compared with other metals, copper seems to be a promising additive to gold due to the synergistic effects detected for supported Au–Cu catalysts in the CO oxidation [28–30].

The purpose of this study was to test the Au–Cu(NW) nanowires as a catalyst and to compare its activity for CO oxidation with that of Au–Cu(NP), Au(NP), and Cu(NP) nanoparticles produced by traditional deposition–precipitation and impregnation methods.

Experimental

Synthesis of catalysts

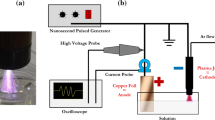

Au–Cu(NW) were produced by LA method inside of liquid helium optical cryostat (Institute of Problems of Chemical Physics of the RAS) pumped out to achieve liquid helium transition to superfluid state. The nanowires were grown from the metal atoms and small clusters embedded into superfluid helium at 1.7 K by laser ablation from the surface of metal targets immersed into liquid helium [25, 26]. The solid-state Nd:LSB diode-pumped (the wavelength is 1.06 μm, the pulse repetition frequency is from 1 to 4 kHz, the pulse energy is 10−4 J, and the pulse duration is 0.4 ns) was used for ablation. A gold–copper alloy (1:1) plate was used as a precursor for the Au–Cu(NW). Carbon-coated grid (CCG) was used as a support in the preparation of the Au–Cu(NW)/CCG samples for transmission electron microscope (TEM) measurements. A glass microporous filter, 0.1 cm thick and 2.1 cm in diameter, was used as a support in the preparation of the Au–Cu(NW)/glass samples for catalytic experiments. In the preparation of Au–Cu(NW)/glass samples, the ablation time was about 30 min. During this period, about 1 × 10−6 mol of the metal was deposited to give a 20–30-nm thick web layer containing Au–Cu nanowires.

Since whole ablated substance was captured to the quantized vortices, eventually forming nanowires, the integral metal ratio in nanowire coincided with that in the alloy being equal to 1:1 in our case. However, the first stage of the metal particles coagulation of leads to their melting. Because the element composition does not correspond to existence of Au/Cu solid solution, the metal in the resulting cluster is separated under cooling into two phases—one, enriched by gold, and second, enriched by copper. It takes place up to the nanocluster size equal approximately to 4 nm. Then, the clusters stuck together by the partial melting at the contact point to form a nanowire. Besides, unlike the large pieces of metal, the contribution of the surface energy to the free energy is very significant in a nanoscale, which leads to additional enrichment of nanowire surface by lighter copper atoms. As a result, in addition to quasi-periodic heterogeneity of the elemental composition along the axis of nanowire, there is heterogeneity in transversal direction. In more detail, this effect has been considered by us for Ag/Cu nanowires with different elemental compositions [22].

Au–Cu (NP), Au(NP), and Cu(NP) nanoparticles were prepared by impregnation and deposition–precipitation as described in [29]. Gamma alumina (Catalyst LLC, S = 160 m2/g, 2-mm grains) was used as a support for particles. Cu(NO3)2 and HAuCl4 (Sigma-Aldrich, 98–99 % pure) were used as precursors. The actual metal content in M(NP)/Al2O3 samples was measured by atomic absorption spectroscopy using a ThermoiCE 3000 AA spectrometer. The gold and copper contents of Au(NP)/Al2O3 and Cu(NP)/Al2O3 samples were 0.1 and 0.05 wt%, respectively. The gold and copper contents of Au–Cu(NP)/Al2O3 were 0.08 and 0.03 wt%, respectively.

TEM measurements

TEM measurements were carried out on a JEOL JEM 2100 F/UHR microscope with 0.1-nm resolution. Au–Cu(NW)/CCG samples were analyzed without any treatment. M(NP)/Al2O3 specimens for TEM analysis were prepared by ultrasonic dispersion of M(NP)/Al2O3 sample in ethanol followed by deposition of a drop of the suspension on a CCG. The assignment of dark spots visible in the images of the M(NP)/Al2O3 specimens to the metal particles was performed by means of electron diffraction X-ray analysis with application of a JED-2300 X-ray spectrometer. The size of particles was calculated as maximum linear size. For each M(NP)/Al2O3 sample, 300 to 380 particles were processed to determine the average particles diameter.

CO oxidation

The pulsed microcatalytic method commonly used, in particular by us, for the catalysts testing [29] was applied for the comparative study of nanoparticle and nanowire catalytic activity. The oxidation of СО with molecular oxygen was performed in a tubular quartz reactor in a pulsed regime. An Au–Cu(NW)/glass sample (one piece, [Au] + [Cu] ≈ 1 × 10−6 mol) or M(NP)/Al2O3 sample (0.2 g, [M] ≈ 1 × 10−6 mol) was placed into the reactor on a Schott filter (S = 0.785 cm2) in such a way as to prevent as fully as possible the gas mixture from bypassing the catalyst. Helium was continuously passed through the reactor under atmospheric pressure at a flow rate of 60 mL/min. In experiments with nanoparticles, the reactor containing the catalyst was maintained at 573 K for 1 h to clean the catalyst surface from the impurities adsorbed from air. The nanowires because of their low thermal stability were not preliminarily heated. Then, the required reactor temperature was established and 1 mL of the gas mixture was injected pulse-wise into the helium flow under atmospheric pressure (CO/O2/He =2:1:97 vol%). The quantitative composition of the flow at the reactor outlet was determined by GC on an LHM-80 gas chromatograph equipped with a thermal conductivity detector and a packed column (Porapak Q, 1 m, id 2 mm). CO conversion was calculated from CO and CO2 peak areas using pre-constructed calibration curves. Ten to 30 successive pulses of the reactant were introduced into the flow every 20 min in order to obtain steady state CO conversion value (α) at each reaction temperature. The thus-measured temperature dependence of the steady state CO conversion far from its limiting value achieved at high temperature reflects the temperature dependence of the catalytic reaction rate [31]. The catalyst performance was determined based on the apparent activation energy [31]. The value of the activation energy was estimated as the slope of the dependence of ln(α) on the 1/RT, were [α] is the steady state CO conversion in 1–40 % range as described in [32].

Results and discussion

Catalyst characterization

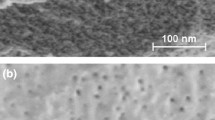

Figure 1 shows typical TEM photomicrographs of the CCG-supported Au–Cu(NW) sample. It can be seen that nanowires as placed on the carbon surface as were hanging as a web in 2-μm CCG holes. According to TEM data, the single Au–Cu(NW) wire diameter is 4 nm, while the average length of a nanowire is about 200 nm. The copper stabilizing influence on gold can be traced in Fig. 2, which shows a TEM image of neat gold nanowires, which, unlike the Au–Cu analogues, decay into the chains of nanoclusters even at 300 K. Considering the nanowires’ temporary contact with the air, the most probable chemical composition for them is (Au–Cu)core–(CuO)shell as it is for nanoparticles of the same composition. The TEM image of Au(NP)/Al2O3 and Cu(NP)/Al2O3 is presented in Figs. 3 and 4, respectively. The gold particle size in the Au(NP)/Al2O3 sample is in the 1- to 11-nm range, the average gold particles size being 5 nm. The copper particle size in a Cu(NP)/Al2O3 sample varies from 1 to 7 nm, the average particles size being 3 nm. The TEM image of the bimetallic Au–Cu(NP)/Al2O3 reference sample is presented in Fig. 5. The average particles size in the bimetallic sample is 8 nm. A study of the surface chemistry for Au(NP)/Al2O3, Cu(NP)/Al2O3, and Au–Cu(NP)/Al2O3 was reported previously [29]. It follows from the XPS and DRIFTS data [29] that copper in Cu(NP)/Al2O3 occurs as CuO; gold in Au(NP)/Al2O3 occurs as Au0; and in Au–Cu(NP)/Al2O3, a large portion of Cu-containing particles are located on the surface of gold particles.

TEM image of the Au nanowires on CCG support at 300 K (unpublished data from our previous study; ref. [27])

CO oxidation

Figure 6 shows the plot for CO conversion versus the number of reaction mixture pulses for the Au–Cu(NW)/glass sample. It can be seen that during reactor heating, the CO conversion on Au–Cu(NW) does not depend on the pulse number. The invariable conversion of CO irrespective of the pulse number is also retained during the reactor cooling. A similar behavior was demonstrated by NP-based reference catalysts. Note that in all experiments, the limiting conversion of СО was 53 ± 5 % and did not change as the reaction temperature was raised. This result implies that during the catalytic experiment, some invariable part of the flow permanently bypasses the catalyst and does not participate in the reaction. However, since this contribution does not depend on temperature, it does not affect the activation energy values.

The curves for the steady state СО conversion versus temperature in the presence of NW- and NP-based catalysts are shown in Fig. 7. During the first heating of the reactor, the efficiency of CO oxidation varies in the following sequence: Au(NP) < Cu(NP) << Au–Cu(NP) < Au–Cu(NW) (Fig. 7, 1 (H)). The activation energy calculated from Fig. 8 is 98, 95, 147, and 150 kJ/mol for Au–Cu(NW), Au–Cu(NP), Cu(NP), and Au(NP), respectively. The dependence of α on T for the Au–Cu(NW) sample after the first heating is shown in Fig. 7 (Au–Cu(NW), 1 (С)). This dependence was recorded during cooling and is characterized by low activation energy of about 30 kJ/mol. The last demonstrates the catalyst’s running-in during the first heating. In the course of Au–Cu(NW) catalyst subsequent heating and cooling cycles, the changes in temperature dependences become weaker (Fig. 7, cf. Au–Cu(NW), 1 (H), 3 (H), and 3 (C)), and in the third cycle, Au–Cu(NW) catalyst reaches the stable operation mode, which has an activation energy of about 20 kJ/mol.

The decrease in the activation energy with time during the catalytic process is usually associated with the modification of the catalyst surface in the reaction. Chemical modification of supported catalysts during CO oxidation was investigated in detail recently [29, 33–35]. It was found that CuO on the surface of copper phase is reduced with CO to give Cu2O. Jernigan and Somorjai reported [35] that the activation energy for CO oxidation in the presence of Cu2O species is lower in comparison with CuO species. The same chemical modification under the influence of reaction conditions can play an important role providing the high catalytic activity of Au–Cu(NW) catalyst, because the surface of the initial Au–Cu(NW) should be covered with CuO. The running-in of the Au–Cu catalyst can also be related to structural changes. According to TEM data, on heating to 723 K, the Au–Cu nanowires are transformed into chains composed of nanoparticles (Fig. 9). Unlike the reference catalysts (Figs. 3, 4, and 5), all the particles in these chains are as close as possible to one another, which facilitate the positive role in the reaction of different particles mutual interaction already observed in [36].

Conclusion

A web consisting of Au–Cu nanowires 4 nm in diameter was synthesized by laser ablation of a gold-copper alloy in the superfluid helium medium. The activity of the Au–Cu nanowires for the СО oxidation with molecular oxygen was detected for the first time. The efficiency of catalytic oxidation of CO varies in the series: Au(NP) < Cu(NP) < <Au–Cu(NP) < Au–Cu(NW), in accordance with the apparent activation energies: 150 < 147 < < 98 < 95 kJ/mol. During the successive heating–cooling cycles, Au–Cu(NW) nanowires are rapidly run-in and reach an operation mode characterized by a constant and low (about 20 kJ/mol) activation energy. The running-in of Au–Cu(NW) nanowires during catalytic operation may be due to both chemical modification of the active surface and decomposition of nanowires into separate nanoparticles occurring in close contact with one another. The possible problem solution is to use the more stable nanowebs made of more refractory metals, e.g., palladium, platinum, and niobium. Subsequently, it is planned to study their catalytic activity in nearest future.

However, there is another possibility. It is shown recently [37] that by using iron-containing platinum nanowires deposited on TiO2 as a catalyst for the reaction of CO oxidation by air, the complete 100 % conversion is achieved already at room temperature. In combination with the results of [38] where 100 % conversion at room temperature for the same reaction has been achieved by using Au nanoparticles on γ-Fe2O3 support as a catalyst, this indicates that for the oxidation of CO by air, the successful catalysis by gold nanoweb can be carried out just at room temperature, when the gold nanowires are quite stable against their decay into a chain of nanoclusters. This means that in reaction of CO oxidation by air catalyzed by nanowires, the temperature of complete conversion may be so low that the nanowebs of most metals would be stable for a long time.

References

Haruta M, Kobayashi T, Sano H, Yamada N (1987) Novel gold catalysts for the oxidation of carbon monoxide at a temperature far below 0°C. Chem Lett 16:405–408

Nikolaev SA, Chistyakov AV, Chudakova MV, Kriventsov VV, Yakimchuk EP, Tsodikov MV (2013) Novel gold catalysts for the direct conversion of ethanol into C3+ hydrocarbons. J Catal 297:296–305

Tabakova T, Ilieva L, Ivanov I, Zanella R, Sobczak JW, Lisowski W, Kaszkur Z, Andreeva D (2013) Influence of the preparation method and dopants nature on the WGS activity of gold catalysts supported on doped by transition metals ceria. Appl Catal B Environ 136–137:70–80

Castaño MG, Reina TR, Ivanova S, Centeno MA, Odriozola JA (2014) Pt vs. Au in water–gas shift reaction. J Catal 314:1–9

McEwan L, Julius M, Roberts S, Fletcher JCQ (2010) A review of the use of gold catalysts in selective hydrogenation reactions. Gold Bull 43:298–306

Hugon A, Delannoy L, Louis C (2008) Supported gold catalysts for selective hydrogenation of 1,3-butadiene in the presence of an excess of alkenes. Gold Bull 41:127–138

Nikolaev SA, Permyakov NA, Smirnov VV, Vasil’kov AY, Lanin SN (2010) Selective hydrogenation of phenylacetylene into styrene on gold nanoparticles. Kinet Catal 51:288–292

Nikolaev SA, Smirnov VV, Podshibikhin VL, Vasil’kov AY (2010) Synergism of the catalytic effect of nanosized gold-nickel catalysts in the reaction of selective acetylene hydrogenation to ethylene. Kinet Catal 51:375–379

Gómez-Quero S, Cárdenas-Lizana F, Keane MA (2013) Unique selectivity in the hydrodechlorination of 2,4-dichlorophenol over hematite-supported Au. J Catal 303:41–49

Smirnov VV, Nikolaev SA, Tyurina LA, Vasil’kov AY (2006) Catalysis of olefin hydrogenation and allylic isomerization by immobilized gold nanoclusters. Pet Chem 46:289–290

Grisel R, Weststrate K-J, Gluhoi A, Nieuwenhuys BE (2002) Catalysis by gold nanoparticles. Gold Bull 35:39–45

Nikolaev SA, Golubina EV, Kustov LM, Tarasov AL, Tkachenko OP (2014) Activity of Au, Ni, and Au-Ni catalysts in the water-gas shift reaction and carbon monoxide oxidation. Kinet Catal 55:311–318

Takei T, Akita T, Nakamura I, Fujitani T, Okumura M, Okazaki K, Huang J, Ishida T, Haruta M (2012) Heterogeneous catalysis by gold. Adv Catal 55:1–126

Cárdenas-Lizana F, Keane MA (2013) The development of gold catalysts for use in hydrogenation reactions. J Mater Sci 48:543–564

Chen M, Goodman DW (2008) Catalytically active gold on ordered titania supports. Chem Soc Rev 37:1860–1870

Chen MS, Goodman DW (2004) The structure of catalytically active gold on titania. Science 306:252–255

Ellert OG, Tsodikov MV, Nikolaev SA, Novotortsev VM (2014) Bimetallic nanoalloys in heterogeneous catalysis of industrially important reactions: synergistic effects and structural organization of active components. Russ Chem Rev 83:718–732

Shi J (2013) On the synergetic catalytic effect in heterogeneous nanocomposite catalysts. Chem Rev 113:2139–2181

Kustov LM (2013) Catalytic properties of supported gold nanoparticles in organic syntheses. Russ Chem Bull 62:869–877

Rostovshchikova TN, Smirnov VV, Kozhevin VM, Yavsin DA, Zabelin MA, Yassievich IN, Gurevich SA (2005) New size effect in the catalysis by interacting copper nanoparticles. Appl Catal A Gen 296:70–79

Messing ME, Hillerich K, Johansson J, Deppert K, Dick KA (2009) The use of gold for fabrication of nanowire structures. Gold Bull 42:172–181

Gordon E, Karabulin A, Matyushenko V, Sizov V, Khodos I (2014) Stability and structure of nanowires grown from silver, copper and their alloys by laser ablation into superfluid helium. Phys Chem Chem Phys 16:25229–25233

Alia SM, Duong K, Liu T, Jensen K, Yan Y (2012) Supportless silver nanowires as oxygen reduction reaction catalysts for hydroxide-exchange membrane fuel cells. ChemSusChem 5:1619–1624

Guo S, Li D, Zhu H, Zhang S, Markovic NM, Stamenkovic VR, Sun S (2013) FePt and CoPt nanowires as efficient catalysts for the oxygen reduction reaction. Angew Chem Int Ed 52:3465–3468

Gordon EB, Karabulin AV, Morozov AA, Matyushenko VI, Sizov VD, Khodos II (2014) Structure and properties of platinum, gold and mercury nanowires grown in superfluid helium. J Phys Chem Lett 5:1072–1076

Gordon EB, Karabulin AV, Matyushenko VI, Sizov VD, Khodos II (2012) The electrical conductivity of bundles of superconducting nanowires produced by laser ablation of metals in superfluid helium. Appl Phys Lett 101:052605(1)–052605(5)

Lebedev V, Moroshkin P, Grobety B, Gordon E, Weis A (2011) Formation of metallic nanowires by laser ablation in liquid helium. J Low Temp Phys 165:166–176

Liu X, Wang A, Wang X, Mou C-Y, Zhang T (2008) Au–Cu alloy nanoparticles confined in SBA-15 as a highly efficient catalyst for CO oxidation. Chem Commun 27:3187–3189

Nikolaev SA, Golubina EV, Krotova IN, Shilina MI, Chistyakov AV, Kriventsov VV (2015) The effect of metal deposition order on the synergistic activity of Au–Cu and Au–Ce metal oxide catalysts for CO oxidation. Appl Catal B Environ 168–169:303–312

Zhang L, Kim HY, Henkelman G (2013) CO oxidation at the Au–Cu interface of bimetallic nanoclusters supported on CeO2(111). J Phys Chem Lett 4:2943–2947

Chorkendorff I, Niemantsverdriet JW (2007) Concepts of modern catalysis and kinetics. Weinheim, Wiley-VCH, 477 p

Kibis LS, Stadnichenko AI, Koscheev SV, Zaikovskii VI, Boronin AI (2012) Highly oxidized palladium nanoparticles comprising Pd4+ species: spectroscopic and structural aspects, thermal stability, and reactivity. J Phys Chem C 116:19342–19348

Duh F-C, Lee D-S, Chen Y-W (2013) Au/CuOx-TiO2 catalysts for CO oxidation at low temperature. Mod Res Catal 2:1–8

Sugano Y, Shiraishi Y, Tsukamoto D, Ichikawa S, Tanaka S, Hirai T (2013) Supported Au–Cu bimetallic alloy nanoparticles: an aerobic oxidation catalyst with regenerable activity by visible-light irradiation. Angew Chem Int Ed 52:5295–5299

Jernigan GG, Somorjai GA (1994) Carbon Monoxide oxidation over three different oxidation states of copper: metallic copper, copper (I) oxide, and copper (II) oxide—a surface science and kinetic study. J Catal 147:567–577

Nesselberger M, Roefzaad M, Hamou RF, Biedermann PU, Schweinberger FF, Kunz S, Schloegl K, Wiberg GKH, Ashton S, Heiz U, Mayrhofer KJJ, Arenz M (2013) The effect of particle proximity on the oxygen reduction rate of size-selected platinum clusters. Nat Mater 12:919–924

Zhu H, Wu Z, Su D, Veith GM, Lu H, Zhang P, Chai S-H, Dai S (2015) Constructing hierarchical interfaces: TiO2-supported PtFe–FeOx nanowires for room temperature CO oxidation. J Am Chem Soc 137:10156–10159

Akita T, Maeda Y, Kohyama M (2015) Low-temperature CO oxidation properties and TEM/STEM observation of Au/γ-Fe2O3 catalysts. J Catal 324:127–132

Acknowledgments

This work was financially supported by Russian Science Foundation (grant № 14-13-00574) and used the equipment of Lomonosov Moscow State University (Program of MSU Development). Nikolaev S.A. expresses his gratitude to RFBR (grant № 13-03-00320, 16-03-00073) for the support in synthesis and characterization of the Au/Al2O3, Au–Cu/Al2O3, and Cu/Al2O3 catalysts.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 15 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Gordon, E.B., Karabulin, A.V., Matyushenko, V.I. et al. Application of Au–Cu nanowires fabricated by laser ablation in superfluid helium as catalysts for CO oxidation. Gold Bull 48, 119–125 (2015). https://doi.org/10.1007/s13404-015-0168-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13404-015-0168-y