Abstract

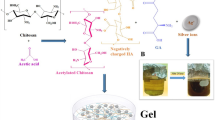

Nanocomposites consisting of silver and solid lipid nanoparticles (SLN) elicit interest for their synergistic effect based enhanced properties in skin hydration. The nanocomposite preparation aims at combining the antimicrobial activity of silver with skin hydration performance of SLN. The nanocomposites designated Ag/SAN (silver/stearic acid nanoparticles), Ag/PAN (silver/palmitic acid nanoparticles) were prepared by incorporating silver nanoparticles into the dispersion of SLN and sonicating for 10 min followed by heating for 1 h at 50 °C in a thermostat. The occlusive property of the two nanocomposites was evaluated in comparison with the pure SLN by adopting de Vringer-de Ronde in vitro occlusion test. The incorporation of silver nanoparticles has improved occlusion factor by 10 % in the case of both composites at SLN concentration of 0.14 mmol. Characterization studies include XRD, DSC, HRSEM, DLS and zeta potential measurement. High resolution scanning electron microscopy (HRSEM) images divulge that the nanoparticles of composite (Ag/SAN) shows halo effect where the hydrophobic stearic acid is oriented at the core and is surrounded by silver nanoparticles while Ag/PAN shows cashew shaped SLN dispersed in silver nanoparticles matrix.

Similar content being viewed by others

Introduction

Since the last three decades, nanotechnology has been impressed practically all the frontier areas of research including cosmetics and pharmaceutics. It has the special form of colloidal drug delivery system which includes Solid Lipid Nanoparticles (SLNs), liposomes, dendrimers, and polymeric nanoparticles. SLN are lipid nanoparticles with solid matrix which has relatively low melting points and some of them are present in foodstuffs and in the human body. It has high specific surface due to their small diameter, spherical shape and favourable zeta potential (Gasco 2007). The stratum corneum (SC) is made up of ceramides, cholesterol, cholesterol esters and free fatty acids in which the percentage of stearic and palmitic acid is 15 % (Ananthapadmanabhan et al. 2013). Fatty acids penetrate the skin effectively and enhance delivery of certain co-applied drugs and cosmetic actives (Golden et al. 1987). Fatty acids are more susceptible to surfactant-induced removal than other lipids necessitating replenishing of stratum corneum lipids. Skin preservation largely depends on incorporation of fatty acids such as stearic acid and palmitic acid into creams and moisturizing body cleansers to minimize their extraction by surfactants and reload lost fatty acids to promote skin barrier preservation (Ananthapadmanabhan et al. 2013). One of the best ways to integrate these fatty acids is in the form of solid lipid nanoparticles since small size ensures a close contact to the stratum corneum and preservation of moisture on the surface. Interesting skin hydration effect is observed when SLNs are incorporated into a moisturizing/day cream. It has been noted that the enhancement of skin hydration effect is due to occlusive property of SLNs (Müller et al. 2002; Wissing and Müller 2002a). Numerous in depth cosmetic and dermatological studies with SLN targeting the skin and incorporation of SLN into topical cosmetic and pharmaceutical preparations, such as creams and gels have been reported (Jenning et al. 2000; Wissing and Müller 2003a; Souto and Müller 2008). SLN possess higher occlusive factor in comparison to nano structured lipid carrier (NLC) of the same lipid content (Souto et al. 2004). It was also observed that an increase in oil content leads to a decrease in the occlusive factor (Teeranachaideekul et al. 2008) thus favouring SLN for skin hydration. Wissing and Müller (2003b) reported that the skin hydration effect of an o/w cream containing SLN has superior skin hydration than a conventional o/w cream. Pardeike et al. reported a significant increase in skin hydration for an NLC incorporated cream compared to conventional cream (Pardeike et al. 2009). The occlusive character of SLN is due to film formation after application on the skin leading to decreased water evaporation (Wissing and Müller 2001a). De Vringer (1997) has demonstrated that nanoparticles of lipids have been found to be 15-folds more occlusive than micro particles. Occlusion can be enhanced by low melting lipids, highly crystalline SLN, decreasing particle size and increase the concentration of the lipids (Wissing et al. 2001; Wissing and Müller 2002b). Generally, the mean particle size of SLN is in the rage of about 40 to 1000 nm (Pardeike et al. 2009). Since SLN combines the advantages of various traditional carriers, such as liposomes and polymeric nanoparticles, it finds application in protecting chemically labile actives and giving the ability to modulate cosmetic active or drug release. Cosmetic actives, like coenzyme Q10 (Müller et al. 2007) ascorbyl palmitate (Üner et al. 2005) tocopherol acetate (Wissing and Müller 2001b) and retinol (vitamin A) (Volkhard Jenning SHG 2001) has proved enhancement of chemical stability due to incorporation into lipid nanocarriers.

In cosmetics and personal care, a new target is to use compounds possessing dual or more properties and recent research is focused on modifying the existing characteristics of a compound by incorporating another ingredient. A survey of literature reveals that SLN are incorporated into creams and lotions owing to their occlusive effect which is responsible for restoring moisture to the stratum corneum. Apart from that SLN are good carriers of chemically labile actives and possess sun blocking efficiency (Lacatusu et al. 2010) due to its particulate nature. In order to take advantage of the antimicrobial activity of silver nanoparticles (Marambio-Jones and Hoek 2010) they are integrated into SLN and the interesting observation of the present study is that it has enhanced the occlusion property of SLN.

Materials and methods

Stearic acid, palmitic acid, ethanol, n-hexane, ethyl acetate and Poly ethylene glycol (PEG) (M. wt 20,000 kDa) were purchased from Merck. AgNO3 was obtained from Qualigen chemicals. TWEEN-80 (Polyoxyethylene derivative of sorbitan mono-oleate) was purchased from Sigma-Aldrich chemicals. The solvents were used after distillation and confirming their melting point for purity. Stearic acid and Palmitic acid were used as such and deionized water was used in all preparations.

Synthesis of silver nanoparticles

Silver nitrate solution (20 mL, 1 mM) was taken in a 250 mL beaker and to this 5 mL of sodium hydroxide was added with continuous stirring. About 3 mL of 3 % solution of PEG (M.wt 20,000) was added drop wise to the above solution and stirred for 5-10 min followed by the drop wise addition of 10 mL of 0.01 M dextrose as reducing agent. The stirring further continued for 5 min and then the beaker containing the solution was heated in a thermostat at 60 °C for 1 h. The solution turned black and was cooled to room temperature and centrifuged at 16,000 rpm (REMI cooling centrifuge) to yield a black precipitate. The silver colloid was washed repeatedly with deionized water and re-dispersed in deionized water by sonication (Pci Ultrasonic bath sonicator, 36 kHz) to give a yellow sol. The sample was designated SN.

Preparation of solid lipid nanoparticles

The SLN were prepared by nano precipitation method developed by Hatem Curt et al. (1992) The organic phase contained various concentrations of stearic acid (0.08, 0.1, 0.12, 0.14 mmol) dissolved in a blend of 18 mL of ethyl acetate and 2 mL of ethanol. The aqueous phase contained specified amount of the emulsifier (TWEEN-80) dissolved in 25 mL deionized water. The organic phase was added drop wise to the aqueous phase with stirring (400 rpm) at room temperature. The mixture immediately became opalescent as a result of the formation of lipid nanoparticles. The suspension was stirred during an additional time of 5–10 min. The organic solvents were removed under reduced pressure and the pH of the cooled dispersion was adjusted to 1.2 by adding 0.1 M hydrochloric acid solution to the precipitated SLN, and the precipitate was then collected by centrifuging at 12,000 rpm. The fine white precipitate was re dispersed in deionized water by sonication. SLN of Palmitic acid of different concentration (0.08, 0.1, 0.12, 0.14 mmol) was also prepared by the above mentioned procedure with the organic phase containing a blend of 18 mL of n-hexane and 2 mL of ethanol. The solid lipid nanoparticles of stearic and palmitic acid are designated SAN and PAN respectively.

Preparation of the nanocomposite

The composites were prepared by mixing 20 mL of the aqueous nanosuspension of the SLN and 2 mL of nanosuspension of silver (10 Wt % of SLN) and sonicating the mixture for 10 min followed by heating in a thermostat at 50 °C for 1 h. The composite was obtained as a nanosuspension after concentration. The composites of silver and stearic acid and silver and palmitic acid were designated as Ag/SAN and Ag/PAN respectively.

In vitro occlusion test

An in vitro occlusion test adapted by de Vringer was used in order to test the skin hydration efficiency of SLN and the composites (De Vringer and De Ronde 1995). Five beakers (100 mL) were filled with 50 mL of water, covered with filter paper (cellulose acetate filter) and sealed. One of the beakers was left as such and 200 mg each of the four samples was applied on the filter surface. The sample was spread evenly with a spatula. The samples were stored at 32 °C and 50–55 % RH for 48 h. The samples were weighed after 6, 24, and 48 h, giving the water loss due to evaporation at each time (water flux through the filter paper). Beaker covered with filter paper but without an applied sample served as standard value. Every experiment was performed in triplicate under constant conditions. The occlusion factor F was calculated according to equation.

where, A is the water loss without sample (standard) B is the water loss with sample.

Characterization studies

Silver nanoparticles in the sol were characterized by measuring the absorption wavelength using a UV–Visible Spectrophotometer (Systronics DBS 2303). Powder X-Ray diffraction (PXRD) analysis of the prepared samples were carried out with a RICHSEIFER powder diffractometer, using nickel filtered copper K-alpha radiations (λ = 1.5461 Å) with a scanning rate of 0.02°. Size and morphology of the particles were studied using HRSEM (FEI quanta FEG 200—HRSEM). The average diameter, polydispersity index (PI) and zeta potential measurements were measured using dynamic light scattering (DLS) using a Malvern Zetasizer nano-ZS (Malvern Instruments, UK). Prior to the measurement, all samples were diluted using ultra-purified water to yield a suitable scattering intensity. Samples were analyzed at 25 °C using the general purpose mode. Thermo grams were recorded with a differential scanning calorimeter (NETZSCH DSC204). Samples were heated at the scanning rate of 3 °C/min over a temperature range between 30 and 200 °C.

Results

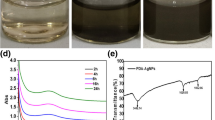

The SLN of palmitic and stearic acids were prepared by nano precipitation method. Silver nanoparticles were prepared by chemical reduction and the nanocomposites were obtained by ultrasound assisted thermal method. The colloidal silver sol was characterized by UV–Visible spectrophotometer that exhibited a typical Surface Plasmon resonance (SPR) peak at 420 nm (Fig. 1a). The morphology of the obtained samples were investigated by HRSEM images. Figure 1b shows the average size of silver nanoparticle about 35 nm. Comparison of HRSEM images of pure SLN and the Ag/SLN composites are as shown in Fig. 2. SEM images of stearic and palmitic acid nanoparticles (Fig. 2a, b) revealed that most of the particles were spherical in shape with an average diameter of 100 and 80 nm respectively. The Ag/SAN sample exhibited a surface morphology different from that of the pure SLN where SLN appeared as a white domain surrounded by silver nanoparticles (Fig. 2c). The hydrophobic SAN appeared to be preferentially oriented to the core with the silver nanoparticles arranged as a loosely organized layer at a small distance from the surface of the nanosphere.

In the other composite Ag/PAN (Fig. 2d) the spherical SLN of palmitic acid was found to be elongated in shape resembling a cashew nut and firmly dispersed in the matrix of silver nanoparticles. To check the chemical composition of the synthesized nanocomposites, energy-dispersive X-Ray (EDX) spectroscopy analysis was performed on the Ag/SLN nanocomposites. The percentage of silver was found to be 41.6 and 61 % of silver in Ag/SAN and Ag/PAN respectively as shown in the EDX spectra (Fig. 3a, b). An adequate characterization of SLN involves determining the size distribution of particles and polydispersity index (PI) in suspension. The average hydrodynamic diameter of the particles in the aqueous suspension of SLN and composites were measured by DLS and are given in Table 1.

It is important that the SLN retain their crystallinity as that of the bulk for them to find application in cosmetics and drug delivery (Wissing et al. 2001). Silver nanoparticles, SAN and Ag/SAN were crystalline as shown from the XRD pattern (Fig. 4) which was in agreement with the literature values of FCC crystal structure of silver (JCPDS Card no. 89-3722) and stearic acid (JCPDS Card No. 09-0618) respectively. The composites revealed peaks at 21.47° and 22.75° corresponding to (110) and (111) diffraction planes of stearic acid respectively. The diffraction Peaks at 44.15° and 64.12° corresponds to (200) and (220) planes of FCC silver respectively. The appearance of two new peaks at 30.88° and 54.81° can be attributed to the formation of AgO and Ag2O corresponding to (021) and (220) plane respectively. The PXRD pattern of the composite Ag/PAN had the typical peaks of FCC silver and palmitic acid (JCPDS Card No. 03-0250) as shown in Fig. 5. Palmitic acid diffraction peaks corresponding to (9 4 1), (2 2 1) and (15 5 0) planes appear at 21.51°, 22.75° and 31.12° respectively. Peaks at 38.27°, 44.57° and 64.23° corresponded to (111), (200) and (220) plane of FCC silver respectively. A peak observed at 55.79° was due to formation of AgO corresponding to (141) plane.

Differential scanning calorimetry (DSC) uses the fact that different lipid modifications possess different melting points and melting enthalpies. The endothermic peak of the pure SLN was at 61.1 °C. However the endothermic peak of the composite Ag/SAN was shifted to 57.7 °C. A similar observation was made in the nanocomposite involving palmitic acid the endothermic peak for Ag/PAN was 56.9 °C which was lower than the melting point of the pure SLN that is 63.6 °C (Fig. 6).

The results obtained from de-Vringer’s occlusion test were given in the form of bar diagram. The composites show consistently more occlusion than pure SLN at 6th, 24th and 48th h. The occlusion factor for pure solid lipid nanoparticle of stearic acid (SAN) is 43.6 % whereas for Ag/SAN it is 48.3 % at the 6th h and at 24th h the occlusion factor is 49.97 and 54.21 % respectively at the lowest concentration of SAN (0.08 mmol). As concentration of SLN in the composite increases the occlusion factor increases and a 10 % increase (53.7) is observed for 0.14 mmol of SAN as compared to the pure SLN at the 6th h and at 48th h the occlusion factor almost remains constant since a thin film has been formed by that time (Fig. 7). Similarly the composite Ag/PAN shows a consistent increase in occlusion factor as concentration of SLN increases in the composite. An increase in the occlusion by 10 % at 24th h was observed in this case (Fig. 8).

Discussion

In general the purpose of composite preparation was to improve existing characteristics and introducing new properties. The nanocomposites Ag/SAN, Ag/PAN were found to have higher occlusion than the pure SLN. The occlusion factor increases with increase in the concentration of SLN in the composite. A 10 % increase was observed at 6th h and 24th h, respectively for the Ag/SAN and Ag/PAN composites. The silver sol exhibited a SPR band in the visible region at 420 nm that strongly suggested the formation of spherical silver nanoparticles and the particle size is in the range of 20–50 nm (Swarnavalli et al. 2015). HRSEM images of Ag/SAN revealed that the silver nanoparticles were self organized to form a loosely organized halo at a small distance from the surface of the SLN nanosphere that suggested a weak attraction between nanoparticles and nanosphere. This type of halo-like structure was reported to stabilize the colloidal suspension (Tohver et al. 2001). However this kind of halo structure was not observed in the nanocomposite Ag/PAN and that may be the reason for lower zeta potential of the same. The percentage of silver present in the nanocomposite was found to be 41.6 and 61 % in Ag/SAN and Ag/PAN respectively (Fig. 3a, b) remaining being carbon, hydrogen and oxygen which indicated that the composite contains the SLN and silver.

The measurement of the zeta potential allowed predictions about the storage stability of colloidal dispersion. In general, particle aggregation was less likely to occur for charged particles (high zeta potential) due to electric repulsion. However, this rule cannot strictly be applied to systems which contain steric stabilizers, because the adsorption of stearic stabilizer will decrease the zeta potential due the shift in the shear plane of the particle. They prevent aggregation of nanoparticles in suspension (Bunjes et al. 2003). The stabilizer TWEEN-80 that is used in the preparations of the samples was known to sterically stabilize the nanoparticles. The pure SLN of stearic acid (SAN) and the composite containing silver nanoparticles (Ag/SAN) were found to have zeta potential of −12.6 Mv and −15.5 Mv respectively. The higher potential of the composite can be attributed to the halo effect which stabilizes the composite. The suspension PAN appeared to be more stable among the suspensions owing to the smallest size (zeta potential +29 Mv). The composite Ag/PAN has a zeta potential of 13.5 Mv that indicated lower stability for the composite compared to the pure SLN. However The zeta potential values of all the nano suspension indicated (Table 1) moderate stability of the suspensions with limited flocculation (Bunjes et al. 2003).

The physical states of the SLN of stearic acid, palmitic acid were understood via the characteristic melting or transformation endotherms upon heating. Stearic acid nanoparticles (SAN) and palmitic acid nanoparticles (PAN) exhibited a well defined endothermic peak at a temperature lower than the melting point of the bulk samples. Both the composites melted at a temperature lower than pure SLN. Lowering of melting point up to 5 °C while moving to nano regime for SLN has been reported (Heurtault et al. 2003). The lowering of m.pt may improve application of the cream on skin easier and hence makes the composite suitable to be included in a topical application.

De Vringer’s occlusion test demonstrated that SLN of palmitic acid exhibited a slight increase in the occlusion factor than SLN of stearic acid at 6th, 24th and 48th h that may be due to smaller size of the nanoparticles of palmitic acid. It has been reported that the particles in the nanometer range exhibited two to three times more occlusion than micro particles (Wissing and Müller 2003a). The in vitro test has also shown higher occlusion factor of the nanocomposites containing higher concentration of SLN. This can be attributed to quick film formation which may be due to the nano size, crystalline state and absence of other lipid modification as seen from the HRSEM, XRD and DSC measurements respectively. Earlier work suggested that SLN would be forming films of densely packed spheres and under the pressure of application the spheres form a coherent film (Wissing and Müller 2001a). It has been shown in vitro that the occlusion factor of SLN depends strongly on crystallinity and size (Wissing et al. 2001). The ease with which the film is formed and the pore size on the films affects the occlusion factor. The smaller the particles more will be the surface area and hence adhesion is improved. Adhesion resulted in quick film formation. It was reported that the SLN less than 200 nm have shown complete film formation when examined under SEM (Wissing and Müller 2001b). From HRSEM images of the composites, it was obvious that Ag nanoparticles were adsorbed on the surface of SLN which may prevent pore formation or reduce the size of pores on the film surface. This might have led to uniform film formation which reduced water evaporation to a greater extent in the composites. Among the pure SLN and nanocomposites Ag/SAN exhibited highest occlusion factor at all concentrations which may be attributed the stability of the composite which might have resulted from the halo effect produced in the Ag/SAN.

Conclusion

Pure SLN of stearic and palmitic acid and nanocomposites of SLN containing silver nanoparticles were prepared characterized and its occlusion property tested in vitro. The nanocomposites were stable and their crystallinity was intact as suggested by zeta potential and DSC measurements respectively. Among the pure SLN, palmitic acid nanoparticles exhibited better occlusion which may be attributed to smaller size. Both the composites were found to exhibit enhanced occlusion compared to the pure SLN’s. An increase of occlusion factor by 10 % was observed at 6th and 24th h for Ag/SAN and Ag/PAN respectively when the concentration of SLN is 0.14 mmol in the composite. This may be due to the incorporation of silver nanoparticles into the SLN which helps in quick film formation with smaller pores on the film surface. The better occlusion property exhibited by Ag/SAN may be attributed to the halo effect which was known to increase the stability of suspensions containing nanoparticles of different sizes. However the weight percentage of silver nanoparticles in the sample was kept constant at 10 % by weight of SLN. There is lot of scope for future work that will be focused on incorporating the composites into a day cream and study its occlusive and sunscreen effect in vitro and in vivo.

References

Ananthapadmanabhan KP, Mukherjee S, Chandar P (2013) Stratum corneum fatty acids: Their critical role in preserving barrier integrity during cleansing. Int J Cosmet Sci 35:337–345. doi:10.1111/ics.12042

Bunjes H, Koch MHJ, Westesen K (2003) Influence of emulsifiers on the crystallization of solid lipid nanoparticles. J Pharm Sci 92:1509–1520. doi:10.1002/jps.10413

De Vringer T (1997) Topical preparation containing a suspension of solid lipids particles. European patent EP0786251A2, 30 July 1997

De Vringer T, De Ronde HAG (1995) Preparation and structure of a water-in-oil cream containing lipid nanoparticles. J Pharm Sci 84:466–472. doi:10.1002/jps.2600840415

Fessi C, Devissaguet J-P, Puisieux F, Thies C (1992) Process for the preparation of dispersible colloidal systems of a substance in the form of nanoparticles. US patent US5118528 A, 2 June 1992

Gasco MR (2007) Lipid nanoparticles: perspectives and challenges. Adv Drug Deliv Rev 59:377–378. doi:10.1016/j.addr.2007.05.004

Golden GM, McKie JE, Potts RO (1987) Role of stratum corneum lipid fluidity in transdermal drug flux. J Pharm Sci 76:25–28

Heurtault B, Saulnier P, Pech B et al (2003) Physico-chemical stability of colloidal lipid particles. Biomaterials 24:4283–4300. doi:10.1016/S0142-9612(03)00331-4

Jenning V, Gysler A, Schäfer-Korting M, Gohla SH (2000) Vitamin A loaded solid lipid nanoparticles for topical use: Occlusive properties and drug targeting to the upper skin. Eur J Pharm Biopharm 49:211–218. doi:10.1016/S0939-6411(99)00075-2

Lacatusu I, Badea N, Murariu A et al (2010) Effect of UV sunscreens loaded in solid lipid nanoparticles: a combinated spf assay and photostability. Mol Cryst Liquid Cryst 523:247/[819]–259/[831]. doi:10.1080/15421401003719928

Marambio-Jones C, Hoek EMV (2010) A review of the antibacterial effects of silver nanomaterials and potential implications for human health and the environment. J Nanopart Res 12:1531–1551. doi:10.1007/s11051-010-9900-y

Müller RH, Radtke M, Wissing SA (2002) Solid lipid nanoparticles (SLN) and nanostructured lipid carriers (NLC) in cosmetic and dermatological preparations. Adv Drug Deliv Rev 54:131–155. doi:10.1016/S0169-409X(02)00118-7

Müller RH, Petersen RD, Hommoss A, Pardeike J (2007) Nanostructured lipid carriers (NLC) in cosmetic dermal products. Adv Drug Deliv Rev 59:522–530. doi:10.1016/j.addr.2007.04.012

Pardeike J, Hommoss A, Müller RH (2009) Lipid nanoparticles (SLN, NLC) in cosmetic and pharmaceutical dermal products. Int J Pharm 366:170–184. doi:10.1016/j.ijpharm.2008.10.003

Souto EB, Müller RH (2008) Cosmetic features and applications of lipid nanoparticles (SLN®, NLC®). Int J Cosmet Sci 30:157–165. doi:10.1111/j.1468-2494.2008.00433.x

Souto EB, Wissing SA, Barbosa CM, Müller RH (2004) Development of a controlled release formulation based on SLN and NLC for topical clotrimazole delivery. Int J Pharm 278:71–77. doi:10.1016/j.ijpharm.2004.02.032

Swarnavalli GCJ, Dinakaran S, Raman N et al (2015) Bio inspired synthesis of monodispersed silver nano particles using Sapindus emarginatus pericarp extract—study of antibacterial efficacy. J Saudi Chem Soc. doi:10.1016/j.jscs.2015.03.004

Teeranachaideekul V, Boonme P, Souto EB et al (2008) Influence of oil content on physicochemical properties and skin distribution of Nile red-loaded NLC. J Control Release 128:134–141. doi:10.1016/j.jconrel.2008.02.011

Tohver V, Smay JE, Braem A et al (2001) Nanoparticle halos: a new colloid stabilization mechanism. Proc Natl Acad Sci USA 98:8950–8954. doi:10.1073/pnas.151063098

Üner M, Wissing SA, Yener G, Müller RH (2005) Solid lipid nanoparticles (SLN) and nanostructured lipid carriers (NLC) for application of ascorbyl palmitate. Pharmazie 60:577–582

Volkhard Jenning SHG (2001) Encapsulation of retinoids in solid lipid nanoparticles (SLN). J Microencapsul 18:149–158. doi:10.1080/02652040010000361

Wissing SA, Müller RH (2001a) Solid lipid nanoparticles (SLN)—a novel carrier for UV blockers. Pharmazie 56:783–786

Wissing SA, Müller RH (2001b) A novel sunscreen system based on tocopherol acetate incorporated into solid lipid nanoparticles. Int J Cosmet Sci 23:233–243. doi:10.1046/j.1467-2494.2001.00087.x

Wissing SA, Müller RH (2002a) Solid lipid nanoparticles as carrier for sunscreens: in vitro release and in vivo skin penetration. J Control Releas 81:225–233. doi:10.1016/S0168-3659(02)00056-1

Wissing SA, Müller RH (2002b) The influence of the crystallinity of lipid nanoparticles on their occlusive properties. Int J Pharm 242:377–379. doi:10.1016/S0378-5173(02)00220-X

Wissing SA, Müller RH (2003a) Cosmetic applications for solid lipid nanoparticles (SLN). Int J Pharm 254:65–68. doi:10.1016/S0378-5173(02)00684-1

Wissing SA, Müller RH (2003b) The influence of solid lipid nanoparticles on skin hydration and viscoelasticity - In vivo study. Eur J Pharm Biopharm 56:67–72. doi:10.1016/S0939-6411(03)00040-7

Wissing S, Lippacher A, Müller R (2001) Investigations on the occlusive properties of solid lipid nanoparticles (SLN). J Cosmet Sci 52:313–324

Acknowledgments

We gratefully acknowledge the facilities provided by Sophisticated Analytical Instrumentation Facility (SAIF), IIT Madras, Central Instrumentation Facility (CIF), Pondicherry University and University of Madras, Guindy Campus Chennai. We also thank Dr. John Philip, Head, Material Science Division, IGCAR, Kalpakkam, Chennai for zeta potential measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Cynthia Jemima Swarnavalli, G., Dinakaran, S. & Divya, S. Preparation and characterization of nanosized Ag/SLN composite and its viability for improved occlusion. Appl Nanosci 6, 1065–1072 (2016). https://doi.org/10.1007/s13204-016-0522-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-016-0522-2