Abstract

This work deals with the development of an efficient method for the removal of a MG (malachite green) dye from aqueous solution using polyaniline (PANI)–Nickel ferrite (NiFe2O4) magnetic nanocomposite. It is successfully synthesised in situ through self polymerisation of monomer aniline. Adsorptive removal studies are carried out for water soluble MG dye using PANI–Nickel ferrite magnetic nanocomposite in aqueous solution. Different parameters like dose of adsorbent, contact time, different initial conc., and pH have been studied to optimise reaction condition. It is concluded that adsorptive removal by PANI–Nickel ferrite magnetic nanocomposite is an efficient method for removing a MG dye from aqueous solution than work done before. The optimum conditions for the removal of the dye are initial concentration 30 mg l−1, adsorbent dose 5gm l−1 and pH 7. The adsorption capacity is found 4.09 mg g−1 at optimum condition 30 mg l−1. The adsorption followed pseudo-second-order kinetics. The experimental isotherm is found to fit with Langmuir equation. The prepared adsorbent is characterised by techniques SEM, EDS, XRD and VSM.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water pollution by dyes has been a worldwide problem. Colour is the first contaminant to be recognised in wastewater. Dyes are used in different industries such as paper, plastics, food cosmetics, leather, pharmaceutical dyestuffs textiles etc. to colour the product. As a result considerable amount of colour water is generated (Ezgi et al. 2008). Even small quantities of dyes can colour huge water bodies, which influences aesthetic merit and decreases light penetration needed for photosynthesis. Furthermore many dyes are toxic or carcinogenic (Akl et al. 2013). The cationic dye like Malachite green caused carcinogenic symptoms. Culp (2002). A wide range of method has been developed for the removal of synthetic dyes from water and wastewater to decrease their impact on environment. Adsorption is very known method in the world. Adsorption using low-cost adsorbents is an effective and affordable method for water purification. The process of adsorption has an edge over the other method due to its sludge free clean operation and completely removed dyes even from the diluted solution (Azhar et al. 2005).

Adsorption using low-cost adsorbents is an effective and affordable method for water purification. Many attempts have been made by researchers for dye removal using various non-conventional adsorbent materials. (Tavallali and Daneshyar 2012; God bole and Sawant 2006; Hammed and Ahmed 2009). Now a days polyaniline (PANI) has attracted much attention because of its unique properties and advantages. It has easy way to prepare due to good environmental stability. It exists in various oxidation states. So PANI is frequently used for the removal of dyes from contaminated wastewater. Polyaniline-functionalised magnetic nanoparticles has been used for the removal of toxic dye from wastewater (Mahto et al. 2014).

The present investigation report is a new, simple and fast method for removal and recovery of a MG dye using PANI–NiFe2O4 magnetic nanocomposite as an adsorbent. The main objective of the present work is to solve the problem of dyes industry wastewater pollution.

Experimental

Materials and methods

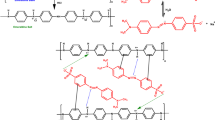

The structure of Malachite green (as shown in Fig. 1), NiCl2, FeCl3.6H2O, monomer aniline, Distilled water, Ammonium per-sulphate (NH4)2S2O8. The water soluble MG dye which has M.F. C23H25N2Cl, M.W. 364.91 g mole−1, M.P.112 °C and PANI–NiFe2O4 is used as an adsorbent. All chemicals and reagents were of analytical grade purity. The structure of dye is presented in Fig. 1. The stock solution 1,000 mg l−1. of dye was prepared in double distilled water. In 50 ml of dye solution of the desired concentration, of a different adsorbent dose is added and stirred with magnetic stirrer. At specific time interval suitable aliquot of the sample is withdrawn and analysed after centrifugation. The changes of dye concentration are determined by UV–visible double beam spectrophotometer (systronics model-2203) at λ max 618 nm in our laboratory.

Preparation of PANI–NiFe2O4 nanocomposite

Synthesis of NiFe2O4 nanoparticles

NiFe2O4 nanoparticles were synthesized according to the following procedures: 1.0 g of Nickel chloride (NiCl2.6H2O) (5 mmol) in 5 ml of deionised water and 1.63 g of ferric chloride (FeCl3.6H2O) (6 mmol) in 5 ml of deionised water were mixed at room temperature. The above mixture was dropped into 200 ml aqueous ammonia solution (0.6 M) in 20 min with vigorous stirring. The pH values of the reaction mixture were kept in the range of 11–12 with the addition of a concentrated ammonium hydroxide solution. The resulting nanoparticles were separated by centrifugation at 2,800 rpm for 10 min, and then these nanoparticles were calcinated in muffle furnace for 4 h at 400 °C.

Synthesis of PANI–NiFe2O4 nanocomposite

PANI–NiFe2O4 nanocomposite was synthesized via self-assembly method using ammonium persulfate APS is used as an oxidant without the addition of organic dopants or surfactants. During the synthesis process, it is as followed: 0.64 mol l−1 aniline monomer into polymerization vessel containing 1 g. NiFe2O4 in 100 ml of 1.14 mol l−1 H2SO4 acid solution at room temperature and magnetic stirring for 8 h. Then 50 ml (1 M) of ammonium per-sulphate (NH4)2S2O8 was added to the above mixture reaction. Resulting precipitate was collected by filtration then washed with deionised water and methanol three times, respectively. The product was dried in oven at 70 °C for 24 H to obtain black-green powder of PANI–NiFe2O4 nanocomposite (Patil and Shrivastava 2014).

Results and discussion

SEM analysis

The PANI–NiFe2O4 nanocomposites are analysed by SEM before and after adsorption of Malachite green dye is shown in the Fig. 2a, b, respectively. It show SEM micrographs of PANI–NiFe2O4. Figure. 2a shows surface texture, colour and porosity on PANI–NiFe2O4. It has homogeneous surface, microspores and mesopores as seen from its surface micrographs. It is black-green in colour, Fig. 2b shows adsorption of MG dye on PANI–NiFe2O4 surface. The cluster of a MG dye is shown on the surface of adsorbent. The MG dye is adsorbed in microspores and mesopores of adsorbent PANI–NiFe2O4 Fig. 2b.

XRD analysis

The XRD diagram of PANI–NiFe2O4 is as shown in Fig. 3 .It shows main peak at 30.290° and subsidiary peak at 37.323°, 66.250°. It shows match scan with JCPDS-PDF NO-00-044-1485 at radiation of 1.54 A°.The high intensity of peaks indicates the highly crystalline nature of PANI–NiFe2O4.The average particle size of PANI–NiFe2O4 is estimated by Scherrer formula is 28 nm.

Electron dispersive X-Ray spectroscopy (EDS) analysis

EDS can be used to find the chemical composition of materials down to a spot size of a few microns, and to create element composition maps over a much broader raster area. Together, these capabilities provide fundamental compositional information for a wide variety of materials. From the analysis it is known that PANI–NiFe2O4. nanocomposite consists of exact elemental composition of specific element like Ni–1.55 %, Fe–2.15 %, N–15.63 %, O–22.02 %, C–57.19 % etc. as shown in the (Fig. 4). As PANI–NiFe2O4 is conducting material therefore it needs to coat with gold (Au) metal.

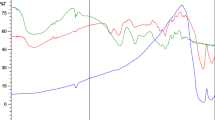

VSM analysis

Vibrating sample magnetometer (VSM) is widely used for study of magnetic nature of adsorbent. The magnetic property of PANI–NiFe2O4 and NiFe2O4 was analysed at R.T by VSM (Vibrating sample magnetometer) at applied field of 20,000 gauss. The NiFe2O4 nanoparticles show the value of saturation magnetisation is 4.6 emu g−1. It is shown in the curve (a) of the Fig. 5. The PANI–NiFe2O4 nanocomposite the value of saturation magnetisation (Ms) is 3.7 emu g−1, which is lower than NiFe2O4. It is shown in the curve (b) of the Fig. 5. So this magnetisation curve of the sample shows a weak ferromagnetic behaviour, with hysteresis. The magnetic property of nanocomposite is dependent on the sample shape, crystallinity; therefore it can be adjusted to obtain optimum property.

Parametric studies

The adsorptive removal of MG is studied at λ max 618 nm. The optimum condition for removal of dyes is 30 mg l−1. pH 7, PANI–NiFe2O4, 5gm l−1. The results obtained during this study are as shown in the Figs. (6, 7, 8, 9).

Effect of adsorbent dose

The effect of adsorbent dose on the removal of MG dye is studied. The percentage removal of a MG dye by PANI–NiFe2O4 nanocomposite at different adsorbent doses 2–5gm l−1 for 30–90 mg l−1 of dye conc. is studied as shown in the (Fig. 6). Adsorptive removal of MG increases rapidly from 71.2 to 95.3 % with an increasing amount from 2 to 5gm l−1 of PANI–NiFe2O4 nanocomposite. As the number of active sites for the adsorption increases, removal of MG also increases is as shown in the (Fig. 6). It is also observed that, as the conc. of dye increases from 30 to 90 mg l−1. % removal of dye decreases from 95.2 to 67.1 % for adsorbent dose 5 gm l−1.

Effect of pH

The role of pH on the adsorptive removal of MG is studied in the pH range 0–10 at dye concentration 30 mg l−1 and PANI–NiFe2O4 concentration 5gm l−1. It is observed that the rate of adsorption increases with an increase in pH up to 7 is as shown in the (Fig. 7). As the pH increases up to 7, MG cation adsorbed on surface of PANI/NiFe2O4. At pH 7 maximum adsorption takes place because PANI amine group has easily available lone pair for the formation of bond with MG dye. At low pH cationic dye becomes more acidic in nature therefore adsorption efficiency is low. When the pH increases 7 onwards, the MG dye becomes anionic, so dye molecule is repelled by lone pair electron of PANI–NiFe2O4, therefore surface would result in reduction in efficiency of adsorption of MG dye.

Effect of contact time

The effect of contact time and initial dye concentration on percentage removal of MG dye is shown in Figs. 6 and 8. It is studied that the rate of dye removal is faster in first 60 min after that decreases gradually, then it attains equilibrium at 210 min and after that it remains constant. The percent removal at equilibrium decreases from 95.53 to 67.1 % as dye concentration is increased from 30 to 90 mg l−1 for 5 gm l−1 adsorbent dose. The amount of dye adsorbed qt (mg g−1) increases from 4.09 to 8.62 mg g−1 for dye conc.30 mg l−1 to 90 mg l−1 as shown in Fig. 9.

Adsorption kinetics study

The adsorption kinetics gives the idea about mechanism of adsorption, from which efficiency of process estimated.

Pseudo-first order

The integrated form of equation is

where qe and qt are the amounts of dye adsorbed (mg g−1) on PANI–NiFe2O4 at equilibrium and at time t (min) respectively, while K1 is the rate constant calculated from the slope of the plot log (qe−qt) Vs time is as shown in (Fig. 10). The linear relationship of the plot for 30,60,90 mg l−1.dye concentration indicates invalidity of equation. These calculated K1 and correlation coefficient r2 values are shown in Table 1. The correlation coefficient r2 for the plots are not in linearity, the calculated qe values from first-order kinetics plots are very small as compared to experimental qe values (as shown in Table 1). This shows that the pseudo-first-order kinetic model is not applicable to predict the adsorption kinetics of a MG dye on PANI–NiFe2O4 nanocomposite.

Pseudo-second order

Adsorption kinetics is explained by second order model is represented by equation.

where K2 is rate constant for second order adsorption (g mg−1min−1), while k2 and qe are determined from slope and intercept of plot t/qt Vs t (Fig. 11). The linear plot with correlation coefficient (r2) 0.997–0.998 (as shown in Table 1). It shows a good correlation to the qe (Expt). From this results concluded that adsorption belongs to the second order kinetics model.

Isotherm study

Freundlich isotherm

The Freundlich isotherm is an equation used to describe heterogeneous systems and can be expressed in its logarithmic form as Eq.(3).The Freundlich adsorption isotherm equation is applied for a MG dye.

where qe is the amount of dye adsorbed (mg g−1) and Ce is the equilibrium concentration of dye in solution (mg l−1).The Kf and n are the constants involved in factors affecting adsorption process. The linear plot of log qe vs log Ce shows Freundlich adsorption. In adsorption Kf value increases the quantity of dye adsorbed onto the surface of PANI–NiFe2O4 also increases (Fig. 12).The slope 1/n ranging between 0 and 1 is the measure of adsorption extent or surface becomes heterogeneous as its value gets closer to zero. The values of 1/n are between 0.210 and 0.467 for 30–90 mg l−1 dye conc. and adsorbent dose 5 gm l−1. Its value is not much closer to one therefore its fails for chemisorption. The calculated R2,Kf and 1/n values are presented in Table 2.

Langmuir isotherm

It explains adsorption on homogeneous site. It has been successful for the explanation of monolayer adsorption. The linear form of Langmuir equation is given as:

where Ce is the equilibrium concentration (mg l−1), qe is the amount of dye adsorbed at equilibrium (mg g−1) and Qo (mg g−1) is the monolayer coverage capacity, b is Langmuir isotherm constant (l mg−1). The values of Qo and b are calculated from the slope and intercepts of the linear plots of Ce/qe Vs Ce. It is shown in the (Fig. 13) calculated Qo and b values are presented in Table 2. The Langmuir adsorption predict the monolayer coverage of dye on PANI–NiFe2O4 nanocomposite. The dimensionless constant is called equilibrium parameter (RL).

where b is the Langmuir constant, Ci is the initial dye concentration (mg l−1). When the rule 1 ≥ RL ≥ 0 is obeyed, Langmuir isotherm becomes favourable. The correlation coefficient of r2 values for Langmuir isotherm is very closer to linearity value one is shown in Table 2. Langmuir isotherms are fit well to experimental data.

Comparison of the results with traditional adsorbent

In these adsorption experiments, good comparable results are obtained as compared to other removal traditional methods using low-cost adsorbent. In these experiments, adsorbent does not get recovered and reused. (God bole and Sawant 2006).In the present MG adsorbed by PANI–NiFe2O4 adsorbent was dissolved in methanol, MG dye were easily desorbed by methanol solvent molecules. For reusability of PANI–NiFe2O4 were further separated it from the methanol solution using external magnet. As the PANI- NiFe2O4 was sufficiently magnetic therefore it was easily separated and reused, recycled repeatedly for number of times.

Conclusions

PANI–NiFe2O4 nanocomposite is successfully synthesised in situ through self polymerisation of monomer aniline. Adsorptive removal of MG dye using adsorbent dose (PANI–NiFe2O4) is successfully carried. The adsorption rate increased significantly by increasing amount of adsorption dose, while with an increasing dye concentration adsorption rate decreases. Neutral pH condition is found, which significantly affects the dye adsorption efficiency of MG dye is 95.2 % and after elution the concentration of dye is 30 mg l−1. The present article confirms PANI–NiFe2O4 can be used adsorbent for the removal of a MG dye from aqueous solution. The amount of adsorbed dye is found from 2.3 to 4.09(mg g−1) increased with an increase contact time and increase in initial dye concentration with an increasing adsorbent dose. The rate of adsorption is found to confirm the pseudo-second-order kinetics with good correlation with R2 values. Langmuir isotherm model is found to fit with experimental.

References

Akl MA, Youssuf AM, Al-Awadhi MM (2013) Adsorption of acid dyes on to bentonite and surfactant modified bentonite. J Anal Bio anal Tech 4:4

Azhar SS, Liew AG, Subardy D, Hafiz KF, Hatim I (2005) Dye removal from aqueous solution by using adsorption on treated sugarcane Bagass. Am J Appl Sci 2:9

Culp SJ (2002) Mutagen city and carcinogenicity in relation to DNA adduct formation in rats fed leucomalachite green. Mutat Res 506–507:55–63

Ezgi A, Mufith B, Mustafa Y (2008) Removal of a calyx(4) arene-based polymer for water soluble carcinogenic direct azo dyes & aromatic amines. J Hazard Mater 162:960–966

God bole PT, Sawant AD (2006) Removal of malachite green from aqueous solutions using immobilised saccharamyces cerevisiae. J Sci & Ind Res 65:440–442

Hammed BH, Ahmed AA (2009) Batch adsorption of methylene blue from aqueous solution by garlic pee & agricultural west by material biomass. J Hazard Mater 164:870–875

Mahto TK, Chowdhuri AR, Sahu SK (2014) Polyaniline-functionalised magnetic nanoparticles for the removal of toxic dye from wastewater. J Appl Polym Sci 131:19

Patil MR, Shrivastava VS (2014) Photocatalytic degradation of carcinogenic methylene blue by using polyaniline-nickel ferrite Nano-composite. Pelagia Res Libr 5(2):8–17

Tavallali H, Daneshyar A (2012) Fast removal and recovery of congo red by modified iron oxide magnetic nanoparticles. Int J Chem Tech Res 4(3):1174–1177

Acknowledgments

Authors are gratefully acknowledged to the Director UDCT, Jalgaon (M.S) for SEM, EDS & XRD studies and are also thankful to Director of I.I.T. Madras for VSM studies. Authors are also thankful to the Principal of G.T.Patil College, Nandurbar for providing necessary laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Patil, M.R., Shrivastava, V.S. Adsorption of malachite green by polyaniline–nickel ferrite magnetic nanocomposite: an isotherm and kinetic study. Appl Nanosci 5, 809–816 (2015). https://doi.org/10.1007/s13204-014-0383-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-014-0383-5