Abstract

A new adsorbent was fabricated via grafting polyethyleneimine (PEI) on activated carbon (AC) to remove anionic amaranth from water. X-ray photoelectron spectroscopy and Fourier transform infrared spectroscopy were used to characterize the grafting process of PEI. The adsorption behavior of the anionic amaranth (AM) on the modified AC is further evaluated by adjusting pH, the modified AC dosage, contact time and the initial AM concentration. AM adsorption was dramatically dependent of solution pH and the optimum pH is 1.08. The adsorption rate was very high within 20 min and equilibrium was achieved at 180 min. The maximum adsorption amount of AM on the modified AC is 72.68 mg/g at pH 1.08. Compared with the unmodified AC, the adsorption efficiency on the modified AC was dramatically increased from 29.9 to 97%. An electrostatic interaction mechanism was proposed in the acidic solution. The adsorption isotherms were consistent with the Langmuir model and the obtained kinetic data were in accordance with a pseudo-second order adsorption behavior for the modified AC.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Currently, amaranth (AM) is extensively used in food, textile, wood and leather industries. Large amount of wastewater containing AM is discharged into bodies of water (Gupta et al. 2012a; Gupta and Nayak 2012). The wastewater is harmful because AM causes serious health problems to humans and animals, such as cancer, anaphylaxis and respiratory problems (Gupta et al. 2012c, 2013). Thus, it is necessary to remove AM from wastewater.

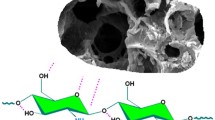

Several methods have been used to remove AM from wastewaters, such as ion exchange, flocculation, degradation, adsorption and membrane filtration (Akil et al. 2015; Mohammadtaghi et al. 2014; Gupta et al. 2011b, 2012b, 2015; Saleh and Gupta 2011, 2012a, b, 2014; Mittal et al. 2010a; Saravanan et al. 2013a, b, c, d, e, f, 2015a, b, c, d, 2016). Among these methods, solid-phase adsorption is very convenient and effective. The solid-phase adsorbents include activated carbon (AC), alumina and polymer, etc. (Gupta et al. 2011a; Gupta and Saleh 2013; Khani et al. 2010; Karthikeyan et al. 2012; Saravanan et al. 2014a, b, c; Saleh and Gupta 2012c). AC is becoming increasingly popular in dealing with the dye-bearing wastewater due to the advantages of easy operation, cost-effectiveness and high efficiency (Mohd et al. 2010; Gupta et al. 1998; Devaraj et al. 2016; Rajendran et al. 2016; Mittal et al. 2009a, 2010b; Jain et al. 2003). However, most of the researches focused on commercial activated carbons. The commercial AC still has some shortcomings, such as weak hydrophilic property, relatively low sorption capacity and low selectivity (Rafatullah et al. 2013; Gupta 2004; Ahmaruzzaman and Gupta 2011). Therefore, some researches modified the surface of AC by introducing polymer matrix to further improve the sorption capacity and selectivity. The reactive black 5 was removed by AC modified with cationic surfactant (Heibati et al. 2014). AC functionalized with cationic surfactant was one of the most powerful adsorbent for the dye removal. The cationic surfactant was directly attached on AC via cationic exchange (Mohammadi et al. 2011; Mittal et al. 2009b). Recently, more studies have focused on modifying AC via electrostatic adsorption. However, electrostatic interaction is easily destroyed by other factors, such as pH. So, it is necessary to overcome the disadvantages via surface grafting.

In this study, we modified AC with polyethyleneimine (PEI) via surface grafting to remove AM from water. The effect of pH, the modified AC dosage, the initial concentration and the contact time were evaluated. Adsorption kinetics and isotherms were also studied.

Materials

Commercially granular AC was used as the starting material. Branched polyethyleneimine (PEI) and amaranth (AM) were obtained from Aladdin Chemical Reagent Co., Ltd. HNO3, anhydrous tetrahydrofuran (THF) and thionyl chloride were purchased from Sinopharm Chemical Reagent Co., Ltd. Deionized water was utilized for preparing all solutions throughout the experiments.

Modification of activated carbon

8 g of AC was first oxidized by 150 mL of concentrated HNO3 (69 wt% HNO3) at 85 °C for 30 h. After filtration, the solid was washed with deionized water five times and dried in a vacuum oven to give AC-COOH. In the second step, 5.6 g of the oxidized AC was treated with 80 mL concentrated thionyl chloride at 75 °C for 48 h. The mixture was separated by filtration. THF was used to wash the solid. Subsequently the solid was dried in a vacuum oven to give AC-COCl (3.5 g). Finally, 3.5 g of the chlorinated carbon was refluxed for 48 h in anhydrous THF solution containing branched polyethyleneimine (1.2 mg/mL). After filtration, the obtained solid was washed with deionized water and dried under vacuum, defined to AC-PEI (4.1 g).

Adsorption experiments

Adsorption experiments were implemented on a shaker with a vibrating speed of 240 rpm, using 15 mL centrifugal tube. The effects of the parameter including pH, the modified AC dosage, the contact time and the initial AM concentration on the removal were evaluated. After adsorbed, the samples were filtered and the filtrate was analyzed at 520 nm by a UV-2401 spectrophotometer (Japan). The adsorption amounts (Q) and efficiency (R) of AM on the modified AC were obtained from the following equations:

where m (g) represents the dosage of AC-PEI and V (L) is the volume of AM solution. C b and C a (mg/L) are the concentration of AM before and after adsorption, respectively. All experiments were repeated three times for data analysis.

Characterization

X-ray photoelectron spectroscopy (XPS) was recorded using an ESCALab220I-XL (VG Scientific, UK). The binding energies were referenced to the C1s line at 284.6 eV from adventitious carbon. The Fourier transform infrared (FT-IR) spectroscopy was obtained between 400 and 4000 cm−1 using a FT-IR spectrometer (Irprestige-21, Japan) with a resolution of 4 cm−1.

Results and discussion

Characterization of the modified activated carbon

The FTIR spectra of AC-COOH and AC-PEI are presented in Fig. 1. The spectra of AC-COOH showed a broad peak between 3200 and 3600 cm−1, coming from –OH groups. The peaks of C=O and C–O in AC-COOH appeared at 1710 and 1240 cm−1, respectively, which came from −COO− groups in carboxyl AC. The C–H bond vibrations at 2937 and 2778 cm−1 appeared after modification with PEI. The successful modification of AC with PEI was also confirmed by the vibration absorptions at 1441 and 1580 cm−1, ascribed to the stretching vibration of C–N–H.

The surface modifications were further ascertained by XPS. The spectra of AC-COOH revealed carbon and oxygen peaks at 284.7 eV (C1s) and 530.9 eV (O1s), respectively (Fig. 2). After modification by PEI, the nitrogen peak at 398.2 eV was observed. The C1s spectra of AC-COOH and AC-PEI are shown in Fig. 3. The C1s spectra of the AC-COOH were curve-fitted to two peaks with bond energies at 284.9 and 289.4 eV for the C–C species and the O–C=O species, respectively. However, compared to AC-COOH, AC-PEI exhibited two new peaks at 288.1 and 285.8 eV corresponding to O=C–N and C–N species. These further demonstrated that PEI was grafted on the AC surface.

Adsorption

Effect of pH

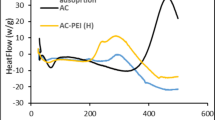

pH is a key factor that influences adsorption process when AC-PEI was used as a sorbent. The experiments were carried out in solutions containing 150 mg/L AM, 2 mg/mL AC-PEI with a contact time of 240 min. Figure 4a presented the influence of pH on the adsorption amount from 1.08 to 12.7 at 298 K. The adsorption amount decreased with increasing pH values. The maximum adsorption amount is 72.68 mg/g when the initial pH of AM solution is 1.08. When pH increases, the adsorption amount decreases and then presents an increasing trend in the pH value range of 11.2–12.7. This suggests that AC-PEI was high-efficiency adsorbent for AM under acidic conditions. The reason could be explained as the changes of surface charge of the adsorbent. At low pH value, the surface of AC-PEI is positively charged due to the protonation of the amine and imino groups (–NH2 and –NH–), while the anionic AM are still negatively charged. The electrostatic attraction between the protonated adsorbent and the anionic AM enhances the adsorption capacity (Royer et al. 2009). Therefore, the mechanisms of adsorption can be considered as the electrostatic interactions between the AC-PEI surface and the AM anions. On the other hand, the adsorption efficiency of AM increased with increasing pH from 11 to 12. This was because the surface of AC-PEI was covered with OH– groups in strong basic condition. The mechanism is anion exchange in this situation. Hence, the pH of aqueous solution significantly influenced the adsorption behavior of AC-PEI for AM.

We also compared the adsorption capacity of AM on AC and AC-PEI (Fig. 4b) at pH = 1.08. After adsorbed by AC and AC-PEI, the residual concentration of AM is 117.1 and 5.5 ppm, respectively. The adsorption efficiency was dramatically increased from 29.9 to 97%. The result showed that attachment of polyethyleneimine onto activated carbon enhanced markedly the removal ratio of AM from water.

Effect of initial AM concentration

Effect of the initial AM concentration on the adsorption performance was studied by adding AC-PEI (2 mg/mL) to different concentrations of AM solution (80, 120, 150, 180, 200, 250 and 300 mg/L) at pH 1.08. The results showed that the adsorbed amount of AM first increases with the increasing initial AM concentration and then tends to level off (Fig. 5). This is attributed to the higher mass transfer driving force at high initial AM concentration, and finally the adsorption reached saturation (Özacar 2003).

Effect of AC-PEI dosage

The effect of AC-PEI dosage on the adsorption was studied at initial AM concentration (150 mg/L) and pH (1.08). Figure 6 illustrated the effect of the AC-PEI dosage (0.5, 1, 2, 3, 4, 5, 6, 7, 8, 9 and 10 mg/mL) for AM adsorption. The removal percent of AM enhances from 34.72 to 99.49% with the increase of AC-PEI dosage from 0.5 to 4 mg/mL and then remains invariant at higher dosage. The increase of the removal efficiencies could be due to that the quantity of active adsorption points increased with increasing the dose of adsorbent.

Effects of contact time

In order to investigate the effect of contact time, 2 mg/mL AC-PEI was added to the AM solutions (150 mg/L) in pH = 1.08 (Fig. 7). Figure 7 shows a rapid uptake of AM within the first 50 min, indicating a high affinity between the AC-PEI surfaces and AM molecules. Then, the adsorption rate decreased until reaching the equilibrium (180 min), due to the intraparticle diffusion of AM molecules. After 4 h, the AM adsorption capacity with initial AM concentrations of 150 mg/L is 72.68 mg/g. Rapid increasing of the capacity at initial contact time can be attributed to that many active adsorption sites are available; then the capacity remains invariant, which was possibly due to the mutually exclusive of the AM molecules on AC-PEI. Yao and coauthors had also observed that the removal efficiency of dye by multi-walled carbon nanotubes increased with increasing contact time and finally reached equilibrium (Yao et al. 2010).

Adsorption isotherms

Adsorption isotherms express the relationship between the adsorbed amount on the adsorbent and the residue concentration in solution. The isotherm data of AM on AC-PEI at pH 1.08 and 298 K were fitted by Langmuir and Freundlich models. The Langmuir model assumed that the monolayer adsorption occurs on a homogeneous surface (Yao et al. 2015). The Langmuir isotherm equation was followed:

where C e (mg/L), q e (mg/g) and K e (L/mg) are the equilibrium concentration of AM, the equilibrium adsorption capacity and the equilibrium constant, respectively. q m (mg/g) is the maximum adsorption amount.

The Freundlich isotherm supposed that a multilayer adsorption occurs on a heterogeneous substrate. The Freundlich isotherm equation was followed:

where K F and n are Freundlich constants. Figure 8 showed the Langmuir and Freundlich isotherms. K L, q 0, K F and n were calculated from two isotherms and the results of this analysis were listed in Table 1. The square of the correlation coefficient (R 2) are also tabulated in Table 1. The R 2 (0.9998) of Langmuir model is bigger than that of Freundlich model (0.6885), suggesting that Langmuir model is reliable. Moreover, a dimensionless factor, called separation factor (R L), associated with Langmuir isotherm is investigated to study the viability of adsorption on AC-PEI, which are expressed:

where C 0 (mg/L) is the initial AM concentration and K L (L/mg) is Langmuir constant. The value of R L indicates the type of the isotherm: irreversible (R L = 0), favorable (0 < R L < 1), linear (R L = 1), unfavorable (R L > 1). The R L of AM adsorption onto AC-PEI is in between 0.0032 and 0.0119, showing a favorable adsorption of AM. According to Fig. 8, the maximum adsorption capacity of AM is 80.65 mg/g. The adsorption capacity of AM and other results reported in literature were listed in Table 2, which showed that the AC-PEI are an efficient sorbent. Thus the AC-PEI sorbent will show great potential in the field of adsorption of AM.

Adsorption kinetics

For further exploring the adsorption mechanisms, adsorption kinetic was evaluated at 298 K and pH 1.08. The Lagergren pseudo-first-order and pseudo-second-order kinetic models were used to study the experimental date. These two kinetic equations can be expressed as follows:

where q e and q t (mg/g) represent the adsorption amount at equilibrium and any time (h), respectively. k 1 (h−1) is the pseudo-first-order model rate constant and k 2 (g/mg/h) is the rate constant of the pseudo-second-order model.

The calculated kinetic parameters and the correlation coefficients (R 2) were presented in Table 3. The R 2 (0.9994) of the pseudo-second-order model is bigger than that of the pseudo-first-order model. Therefore, the adsorption of AM onto AC-PEI follows the pseudo-second-order model and the chemisorption is the rate limiting step.

The Weber–Morris intraparticle diffusion kinetic model was also used to study the steps involved during adsorption, which is expressed as

where k i (mg/g−1 h−1/2) is the intraparticle diffusion rate constant, and c (mg/g) is a constant that gives idea about the thickness of the boundary layer. i.e., larger the value of C the greater is the boundary layer effect. Figure 9c presents the multi-linear plots. It suggests that the sorption process includes three steps. The first straight portion represents the stage of external mass transfer, and at the second step AM entered the pores of the adsorbents and were adsorbed on the internal surface of the AC-PEI and the last is attributed to the intraparticle diffusion (Liu et al. 2015).

Conclusion

In this work, we fabricated a new adsorbent via grafting polyethyleneimine on activated carbon (AC) to enhance the selective removal of AM from water. The modified activated carbon was characterized by FTIR and XPS. The effect of parameters including pH, initial AM concentration, AC-PEI dosage and contact time were also investigated. The optimum adsorption condition is pH = 1.08 and the contact time is 180 min. The adsorption capacity of AM onto AC-PEI at 298 K is 72.68 mg/g. This is higher than the adsorption capacity of AM onto the unmodified AC. The electrostatic interaction between AC-PEI and AM is the driving motivation in the acidic solution. AM adsorption on AC-PEI was accordance with the pseudo-second-order kinetics model and the equilibrium data are well consistent with the Langmuir models. The adsorbents containing amino-group will be beneficial to the removal of anionic organic pollutants from polluted water.

References

Ahmaruzzaman M, Gupta VK (2011) rice husk and its ash as low-cost adsorbents in water and wastewater treatment. Ind Eng Chem Res 50(24):13589–13613

Akil AS, Hamidah MS, Chuo SC, Asma K, Waseem AW, Rajeev K, Mohd R (2015) Recent advances in new generation dye removal technologies: novel search for approaches to reprocess wastewater. RSC Adv 5(39):30801–30818

Ali HA, Egzar HK, Kamal NM, Abdulsaheb N, Mashkour MS (2013) Removal of amaranth dye from aqueous solution using pomegranate peel. IJBAS-IJENS 13(04):57–64

Chowdhury S, Saha TK (2016) Removal of amaranth (AR) onto puffed rice in aqueous solution. IJOAR 4(3):2320–9186

Devaraj M, Saravanan R, Deivasigamani RK, Gupta VK, Gracia F, Jayadevan S (2016) Fabrication of novel shape Cu and Cu/Cu2O nanoparticles modified electrode for the determination of dopamine and paracetamol. J Mol Liq 221:930–941

Guerrero-Coronilla I, Morales-Barrera L, Villegas-Garrido TL, Cristiani-Urbina E (2014) Biosorption of amaranth dye from aqueous solution by roots, leaves, stems and the whole plant of E. crassipes. Environ Eng Manag J 13(8):1917–1926

Gupta VK (2004) Adsorbents for water treatment: development of low-cost alternatives to carbon. Encycl Surf Colloid Sci 2004 Update Supplement 5, 1

Gupta VK, Nayak A (2012) Cadmium removal and recovery from aqueous solutions by novel adsorbents prepared from orange peel and Fe2O3 nanoparticles. Chem Eng J 180:81–90

Gupta VK, Saleh TA (2013) Sorption of pollutants by porous carbon, carbon nanotubes and fullerene—An overview. Environ Sci Pollut R 20(5):2828–2843

Gupta VK, Srivastava SK, Mohan D, Sharma S (1998) Design parameters for fixed bed reactors of activated carbon developed from fertilizer waste for the removal of some heavy metal ions. Waste Manag 17(8):517–522

Gupta VK, Agarwal S, Saleh TA (2011a) Synthesis and characterization of alumina-coated carbon nanotubes and their application for lead removal. J Hazard Mater 185(1):17–23

Gupta VK, Jain R, Nayak A, Agarwal S, Shrivastava M (2011b) Removal of the hazardous dye-tartrazine by photodegradation on titanium dioxide surface. Mater Sci Eng C 31(5):1062–1067

Gupta VK, Ali I, Saleh TA, Nayak A, Agarwal S (2012a) Chemical treatment technologies for waste-water recycling-an overview. Rsc Adv 2(16):6380–6388

Gupta VK, Jain R, Mittal A, Saleh TA, Nayak A, Agarwal S, Sikarwar S (2012b) Photo-catalytic degradation of toxic dye amaranth on TiO2/UV in aqueous suspensions. Mater Sci Eng C 32(1):12–17

Gupta VK, Mittal A, Jhare D, Mittal J (2012c) Batch and bulk removal of hazardous colouring agent Rose Bengal by adsorption techniques using bottom ash as adsorbent. Rsc Adv 2(22):8381–8389

Gupta VK, Kumar R, Nayak A, Saleh TA, Barakat MA (2013) Adsorptive removal of dyes from aqueous solution onto carbon nanotubes: a review. Adv Colloid Interface Sci 193–194:24–34

Gupta VK, Nayak A, Agarwal S (2015) Bioadsorbents for remediation of heavy metals: current status and their future prospects. Environ Eng R 20(1):001–018

Heibati B, Rodriguez-Couto S, Amrane A, Rafatullah M, Hawari A, Al-Ghouti MA (2014) Uptake of reactive black 5 by pumice and walnut activated carbon: chemistry and adsorption mechanisms. J Ind Eng Chem 20(5):2939–2947

Jain AK, Gupta VK, Bhatnagar A, Suhas (2003) A comparative study of adsorbents prepared from industrial wastes for removal of dyes. Sep Sci Technol 38(2):463–481

Karthikeyan S, Gupta VK, Boopathy R, Titus A, Sekaran G (2012) A new approach for the degradation of high concentration of aromatic amine by heterocatalytic Fenton oxidation: kinetic and spectroscopic studies. J Mol Liq 173:153–163

Khani H, Rofouei MK, Arab P, Gupta VK, Vafaei Z (2010) Multi-walled carbon nanotubes-ionic liquid-carbon paste electrode as a super selectivity sensor: application to potentiometric monitoring of mercury ion(II). J Hazard Mater 183(1–3):402–409

Liu Y, Zeng G, Tang L, Cai Y, Pang Y, Zhang Y (2015) Highly effective adsorption of cationic and anionic dyes on magnetic Fe/Ni nanoparticles doped bimodal mesoporous carbon. J Colloid Interface Sci 448:451–459

Mittal A, Kaur D, Malviya A, Mittal J, Gupta VK (2009a) Adsorption studies on the removal of coloring agent phenol red from wastewater using waste materials as adsorbents. J Colloid Interface Sci 337(2):345–354

Mittal A, Mittal J, Malviya A, Gupta VK (2009b) Adsorptive removal of hazardous anionic dye “Congo red” from wastewater using waste materials and recovery by desorption. J Colloid Interface Sci 340(1):16–26

Mittal A, Mittal J, Malviya A, Gupta VK (2010a) Removal and recovery of Chrysoidine Y from aqueous solutions by waste materials. J Colloid Interface Sci 344(2):497–507

Mittal A, Mittal J, Malviya A, Kaur D, Gupta VK (2010b) Decoloration treatment of a hazardous triarylmethane dye, light green SF (yellowish) by waste material adsorbents. J Colloid Interface Sci 342(2):518–527

Mohammadi N, Khani H, Gupta VK, Amereh E, Agarwal S (2011) Adsorption process of methyl orange dye onto mesoporous carbon material-kinetic and thermodynamic studies. J Colloid Interface Sci 362(2):457–462

Mohammadtaghi V, Mohd R, Babak S, Ahmad ZA, Mahamad HI, Kok BT, Zahra G, Parisa A (2014) Application of chitosan and its derivatives as adsorbents for dye removal from water and wastewater: a review. Carbohydr Polym 113:115–130

Mohd R, Othman S, Rokiah H, Anees A (2010) Adsorption of methylene blue on low-cost adsorbents: a review. J Hazard Mater 177(1):70–80

Özacar M (2003) Phosphate adsorption characteristics of alunite to be used as a cement additive. Cem Concr Res 33:1583–1587

Rafatullah M, Ahmad T, Ghazali A, Sulaiman O, Danish M, Hashim R (2013) Oil palm biomass as a precursor of activated carbons: a review. Crit Rev Environ Sci Technol 43(11):1117–1161

Rajendran S, Khan MM, Gracia F, Qin JQ, Gupta VK, Arumainathan S (2016) Ce3+-ion-induced visible-light photocatalytic degradation and electrochemical activity of ZnO/CeO2 nanocomposite. Sci Rep 6:31641

Royer B, Cardoso NF, Lima EC, Vaghetti JCP (2009) Applications of Brazilian pine-fruit shell in natural and carbonized forms as adsorbents to removal of methylene blue from aqueous solutions—Kinetic and equilibrium study. J Hazard Mater 164:1213–1222

Saleh TA, Gupta VK (2011) Functionalization of tungsten oxide into MWCNT and its application for sunlight-induced degradation of rhodamine B. J Colloid Interface Sci 362(2):337–344

Saleh TA, Gupta VK (2012a) Column with CNT/magnesium oxide composite for lead(II) removal from water. Environ Sci Pollut R 19(4):1224–1228

Saleh TA, Gupta VK (2012b) Photo-catalyzed degradation of hazardous dye methyl orange by use of a composite catalyst consisting of multi-walled carbon nanotubes and titanium dioxide. J Colloid Interface Sci 371(1):101–106

Saleh TA, Gupta VK (2012c) Synthesis and characterization of alumina nano-particles polyamide membrane with enhanced flux rejection performance. Sep Purif Technol 89:245–251

Saleh TA, Gupta VK (2014) Processing methods, characteristics and adsorption behavior of tire derived carbons: a review. Adv Colloid Interface 211:93–101

Saravanan R, Gupta VK, Narayanan V, Stephen A (2013a) Comparative study on photocatalytic activity of ZnO prepared by different methods. J Mol Liq 181:133–141

Saravanan R, Gupta VK, Prakash T, Narayanan V, Stephen A (2013b) Synthesis, characterization and photocatalytic activity of novel Hg doped ZnO nanorods prepared by thermal decomposition method. J Mol Liq 178:88–93

Saravanan R, Joicy S, Gupta VK, Narayanan V, Stephen A (2013c) Visible light induced degradation of methylene blue using CeO2/V2O5 and CeO2/CuO catalysts. Mater Sci Eng C 33:4725–4731

Saravanan R, Karthikeyan S, Gupta VK, Sekaran G, Narayanan V, Stephen A (2013d) Enhanced photocatalytic activity of ZnO/CuO nanocomposite for the degradation of textile dye on visible light illumination. Mater Sci Eng C 33:91–98

Saravanan R, Karthikeyan N, Gupta VK, Thirumal E, Thangadurai P, Narayanan V, Stephen A (2013e) ZnO/Ag nanocomposite: an efficient catalyst for degradation studies of textile effluents under visible light. Mater Sci Eng C 33:2235–2244

Saravanan R, Thirumal E, Gupta VK, Narayanan V, Stephen A (2013f) The photocatalytic activity of ZnO prepared by simple thermal decomposition method at various temperatures. J Mol Liq 177:394–401

Saravanan R, Gupta VK, Mosquera E, Gracia F (2014a) Preparation and characterization of V2O5/ZnO nanocomposite system for photocatalytic application. J Mol Liq 198:409–412

Saravanan R, Gupta VK, Narayanan V, Stephen A (2014b) Visible light degradation of textile effluent using novel catalyst ZnO/γ-Mn2O3. J Taiwan Inst Chem Eng 45:1910–1917

Saravanan R, Prakash T, Gupta VK, Stephen A (2014c) Tailoring the electrical and dielectric properties of ZnO nanorods by substitution. J Mol Liq 193:160–165

Saravanan R, Gracia F, Khan MM, Poornima V, Gupta VK, Narayanan V, Stephen A (2015a) ZnO/CdO nanocomposites for textile effluent degradation and electrochemical detection. J Mol Liq 209:374–380

Saravanan R, Gupta VK, Mosquera E, Gracia F, Narayanan V, Stephen A (2015b) Visible light induced degradation of methyl orange using β-Ag0.333V2O5 nanorod catalysts by facile thermal decomposition method. J Saudi Chem Soc 19(5):521–527

Saravanan R, Khan MM, Gupta VK, Mosquera E, Gracia F, Narayanan V, Stephen A (2015c) ZnO/Ag/Mn2O3 nanocomposite for visible light-induced industrial textile effluent degradation, uric acid and ascorbic acid sensing and antimicrobial activity. Rsc Adv 5:34645–34651

Saravanan R, Khan MM, Gupta VK, Mosquera E, Gracia F, Narayanan V, Stephen A (2015d) ZnO/Ag/CdO nanocomposite for visible light-induced photocatalytic degradation of industrial textile effluents. J Colloid Interface Sci 452:126–133

Saravanan R, Sacari E, Gracia F, Khan MM, Mosquera E, Gupta VK (2016) Conducting PANI stimulated ZnO system for visible light photocatalytic degradation of coloured dyes. J Mol Liq 221:1029–1033

Yao Y, Xu F, Chen M, Xu Z, Zhu Z (2010) Adsorption behavior of methylene blue on carbon nanotubes. Bioresour Technol 101:3040–3046

Yao T, Guo S, Zeng C, Wang C, Zhang L (2015) Investigation on efficient adsorption of cationic dyes on porous magnetic polyacrylamide microspheres. J Hazard Mater 292:90–97

Acknowledgements

The authors are grateful for the financial support from the National Natural Science Foundation (No. 51464024) and Applied Basic Research Projects in Yunnan Province (2013FB096).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Fu, L., Zhang, G., Wang, S. et al. Modification of activated carbon via grafting polyethyleneimine to remove amaranth from water. Appl Water Sci 7, 4247–4254 (2017). https://doi.org/10.1007/s13201-017-0557-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13201-017-0557-x