Abstract

In this work, silica fume (SF) is used as a solid-phase extractor for extraction of Zn(II) and Cd(II) from aqueous solutions. Characterization of SF is performed by Fourier transform infrared, X-ray diffraction, transmission and scanning electron microscopy. The optimum experimental conditions for the two metal ions are investigated using batch and column techniques. The maximum adsorption capacity values are found to be 54.13 and 121.28 mg g−1 at the optimum pH 6.0 and 8.0 for Zn(II) and Cd(II), respectively. The equilibrium data are analyzed using the Langmuir, Freundlich, and Temkin isotherms by nonlinear regression analysis. Also, the kinetics analysis revealed that the overall adsorption process is successfully fitted with the pseudo-second-order model. The method is applied for determination of the target metal ions in pharmaceutical and environmental samples using square-wave anodic stripping voltammetry. The limit of detection (LOD) values are 0.102 and 1.43 × 10−3 mg L−1 for Zn(II) and Cd(II), respectively. The percentage recovery values are 98.8–100.5 % which indicate the success of the proposed method for determination of Zn(II) and Cd(II) without interfering effects.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

One of the major concerns of environmental and health sciences is the preservation of human nutrition from the heavy metal ions contamination (Rajabi et al. 2014). Cadmium as one of these heavy metal ions reaches the food chain through various geogenic and anthropogenic activities. The sources of this metal are food, drinking water, and air (Amin and Gouda 2012). Cd(II) accumulation in rice and its subsequent transfer to the human food chain are a major environmental issue. Rice soils have been affected by Cd(II) accumulation derived from fertilizer and manure application, mine tailings, and refining plants. Also, water pollution with Cd(II) may arise from industrial discharges and mining wastes. Excessive intake of cadmium into the human body is detrimental to human health, causing serious diseases such as high blood pressure, kidney damage, destruction of testicular tissue, brain damage, and poisoning. Therefore, development of remediation methods for Cd-contaminated rice soils and water has become an urgent task to ensure food safety (Bolan et al. 2013). However, at trace concentrations, some of heavy metals are essential and have a great benefit to the human body. Zinc is one of these ions which has a fundamental role in the structure and function of numerous proteins, including metalloenzymes, transcription factors, and hormone receptors. The widespread role of Zn(II) in metabolism is also accentuated by its occurrence in all tissues, organs, and fluids of the human body (DeMartino et al. 2010). Moreover, its deficiency might lead to several disorders such as growth retardation, diarrhea, immunity depression, eye and skin lesions, malfunction of wound healing, and other skin diseases (Scherz and Kirchhoff 2006). In addition, the use of Zn(II) has increased exponentially due to its presence in every area of modern consumerism: from construction materials to cosmetics, medicines to processed foods, and appliances to personal care products (Pérez-Quintanilla et al. 2009; Yu and Li 2011). The extensive utilization and application of zinc in various industrial and commercial activities necessitate its accurate analytical determination and recovery for regulating and minimizing its discharge into the environment from the view point of safety (Sharma et al. 2013). So, the development of new methods for quantifying trace metals has been required and challenged. One of widely used and fast emerging preconcentrative separation techniques for this purpose is the solid-phase extraction (SPE) due to its advantages (Daniel et al. 2006). So far, different SP-extractors were used for determination of Cd(II) and Zn(II) from different real samples (Rajabi et al. 2014; Behbahani et al. 2013, 2014; Barciela-Alonso et al. 2014; Jamshidi et al. 2011; Ghaedi et al. 2013a, b, d, e; Shakerian et al. 2012). An efficient solid-phase extractor should consist of a stable and insoluble porous matrix having suitable active groups that interact with heavy metal ions (Fang et al. 2005). Therefore, silica fume (SF) was chosen as SP-extractor for this purpose because of its characteristics: has specific high surface area, composed of ultra-fine solid, amorphous glassy spheres of SiO2 and it is great negatively charged particles. Furthermore, SF has been shown to strongly bind heavy metal ions via surface complexation (Li et al. 2011).

With the best of our knowledge, there are no studies that have been reported on using silica fume as SP-extractor for the determination of neither Zn(II) nor Cd(II). So, the objective of this work was to develop method using SF which considered as a simple, cheap, available adsorbent and has been used without modification process for extraction of Zn(II) and Cd(II) from aqueous solutions using batch and column techniques. The developed method has been applied for determination of Zn(II) and Cd(II) in pharmaceutical and environmental samples.

Experimental

Apparatus

Square-wave adsorptive anodic stripping voltammetric (SWAdSV) technique was carried out using AMEL Model 433 TRACE ANALYSER involving three-electrode system consisted of a hanging mercury dropping electrode (HMDE) as a working electrode, an Ag/AgCl with saturated KCl as a reference electrode, and a platinum wire as a counter electrode. A magnetic stirrer and stirring bar provided the convective transport during the pre-concentration. The peak heights were automatically or manually measured using the ‘tangent fit’ capability of the instrument. The pH measurements were made with Accumet® Model 825 pH meter (Germany). The infrared spectrum of SF before and after adsorption of metal ion was obtained using FT-IR (410 JASCO, Japan). The particle size and surface morphology of the adsorbent were characterized using transmission electron microscopy (JEM100CX11 JEOL, Japan) and scanning electron microscopy (JSM-5400 LV JEOL, Japan). The crystal structure of the adsorbents was studied using X-ray diffractometer (JSX-60 PA JEOL, Japan). Wrist Action mechanical shaker Model 75 (manufactured by Burrell Corporation Pittsburgh, PA, USA) for shaking process.

Reagents and solutions

Silica fume (SF) was provided from the Ferrosilicon Company, Edfo, Egypt. It contains 93.0 % SiO2 and has a surface area of about 20,000 m2 kg−1. All solutions were prepared using doubly distilled water (DDW). ZnCl2, CdCl2·H2O, Cd(NO3)2·4H2O, KCl, NaCl, CaCl2, CuCl2·5H2O, NiSO4·7H2O, MnCl2, KNO3, HNO3, HClO4, H2O2, and ethylene diamine tetra acetic acid (EDTA) were analytical grade from Merck (Darmstadt, Germany). ACS reagents HCl, NH4OH, NH4Cl, and NaOH which were used for justifying the pH values were obtained from Aldrich Chemical Company (Milwaukee, WI, USA). Samples of drinking tap-water (DTW), mineral drinking-water (MDW), ground water (GW), and distilled water (DW) were collected from Minia City, Egypt. Rice and chocolate samples were purchased from local market in Minia city. Calcitron and Vita zinc capsules were collected from pharmaceutical samples from EIMC united pharmaceuticals and Egyptian international pharmaceutical industries company, respectively.

Analytical procedures

Batch adsorption method

The effect of pH, shaking time, amount of adsorbent, and isotherms of adsorption were tested and evaluated by batch method. The percentage extraction of CdCl2.H2O and ZnCl2 using SF was determined in triplicate under static conditions. A definite amount of SF was added to a certain volume of 0.1 M of each metal ion. The pH adjustment by using 1.0 M HCl and 0.1 M NaOH for Zn(II) at pH range 2.0–6.0, while 1.0 M HCl and ammonia buffer were used for Cd(II) where the pH ranged from 2.0 to 8.0. Then the total volume was completed to 50.0 mL by DDW in a 100-mL measuring flask. This mixture was automatically shaken for 30 min at room temperature to attain equilibrium. The adsorbent was separated by filtration; the residual metal ion concentration in the filtrate was determined by complexometric EDTA titration (Soliman and Ahmed 2009). The recovery of both Zn(II) and Cd(II) was calculated as follows:

where C i is the initial concentration of metal ion and C f is its final concentration.

Fixed bed column adsorption method

A glass mini column of 30 cm length and 2 cm internal diameter was used. A small piece of cotton was placed at the bottom of the column and above the known quantity of SF adsorbent. Cd(II) and Zn(II) solutions with initial concentration of 0.001 M were allowed to flow downward through the column at a specific flow rate. Samples were collected from the outlet of the column at different time intervals and analyzed for metal ion concentration. The experiment was terminated when the concentration of each metal ion at the outlet of the column equals the initial concentration of both Cd(II) and Zn(II).

Study the effect of foreign ions and ionic strength on the uptake of Zn(II) and Cd(II)

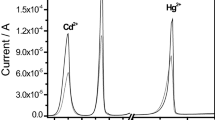

In order to study the selectivity of the target metal ions in presence of interfering ions, the procedure was performed in presence of alkaline K(I), alkaline earth Ca(II), and transition metals Cu(II), Ni(II), and Mn(II). An aliquot of 50.0 mL containing each of the interfering ion and the target metal ion (either Cd(II) and Zn(II)) with molar ratio 1:1, 2:1, 5:1, 10:1, 50:1, and 100:1, respectively, was shaken with definite weights of SF (50.0 and 100.0 mg for Cd(II) and Zn(II), respectively) at the optimum conditions; then this mixture was filtrated. The concentrations of each Zn(II) and Cd(II) were determined using SWAdSV technique. Different standard additions of ZnCl2 were spiked into a solution containing 10.0 mL of 0.1 M KCl and aliquot of the filtrate to determine Zn(II) at E acc. = −1.3 V and t acc. = 30 s. Also, the concentration of Cd(II) was determined by spiking different additions of Cd(NO3)2 into 10.0 mL of 0.1 M KNO3 and aliquot of the filtrate at E acc. = −0.9 V and t acc.= 30 s. Also, to investigate the effect of ionic strength on the extraction of Zn(II) and Cd(II), several experiments were performed with different NaCl concentrations (0.0–1.0 M) while keeping other experimental parameters constant. The concentrations of each Zn(II) and Cd(II) were determined also using SWAdSV technique as described above.

Batch mode desorption

Desorption measurements were conducted in order to explore the feasibility of recovering the metal ion and the adsorbent. Thus, 1.0 g of each Cd(II)-SF and Zn(II)-SF phase was mixed with excess (0.1 M EDTA) solution and shaken for 60 min. The mixture was left overnight, then filtrated, and washed with DDW in order to remove the residues of EDTA. Each treated phase was dried well to reuse for next experiment under the same conditions of batch method at the optimum pH values for extraction of both Cd(II) and Zn(II).

Preparation of Calcitron and Vita zinc capsules extract to determine Zn(II) ions

The whole content of one capsule for each drug was accurately weighed, transferred to a 50-mL volumetric flask, and dissolved in DDW. The solution was stirred for 30 min and then filtrated, and the residue was completed to 50.0 mL with DDW. 0.5 mL of the stock solution was taken, completed to 50.0 mL with DDW and shaken with 100.0 mg of SF after adjusting the pH to 6.0. The concentrations of Zn(II) in each capsule and after extraction by SF were determined using SWAdSV by standard additions method as described above.

Preparation of environmental samples to determine Cd(II) ions

Rice sample

20.0 g of rice sample was accurately weighed in quartz crucible. 10.0 mL of concentrated sulfuric acid was added and evaporated to near dryness; then 10.0 mL of nitric acid (1:1, v/v %) was added and evaporated to dryness. To the previous, concentrated hydrogen peroxide was added drop by drop untill the solution gets clear and evaporated to dryness. DDW was added for washing to remove the excess hydrogen peroxide. The residue was then cooled, transferred into a 50-mL volumetric flask, and diluted with DDW (Abbasi et al. 2011). Different volumes of the stock rice sample solution were taken and completed to 50.0 mL by DDW (the pH of solutions was adjusted to 8.0 for Cd(II) extraction). These solutions were shaken with 50.0 mg of SF for 30 min and then filtrated. The concentrations of Cd(II) in samples before and after extraction by SF were determined via SWAdSV by standard additions method as described above.

Chocolate sample

A 20.0 g of tablet chocolate sample was ashed in quartz crucible for 4 h on a hot plate, and the charred material was transferred to furnace for overnight heating at 450 °C. The residue was cooled and treated with 10.0 mL concentrated nitric acid and 3.0 mL 30 % H2O2 then kept in furnace for 2 h at the same temperature so that no organic compound traces are left. The final residue was treated with 0.5 mL concentrated hydrochloric acid and 1.0–2.0 mL 70 % perchloric acid and evaporated to fumes, so that all the cadmium metal changes to cadmium ions (Ghaedi et al. 2013e). The solid residue was dissolved in water and filtered and by keeping the pH at 8.0 made up to 25 mL by addition of NH4OH and HCl. Then the procedure was applied, and Cd(II) concentrations in the final solutions were determined by SWAdSV.

Water samples

Different water samples were used such as drinking tap-water (DTW), ground water (GW), mineral drinking-water (MDW), and distilled water (DW) were collected and stored in cleaned polyethylene bottles. GW was filtered before the analysis. 50.0 mg of SF was conditioned with 50.0 mL of water sample spiked with 1.0 and 2.0 mg L−1 of Cd(II) after adjusting the pH samples to the optimum pH value and shaken for 30 min. 25.0 mL of each filtrate was taken and determined via SWAdSV by standard additions method as described above.

Results and discussion

Characterization of SF

Silica fume was characterized before and after adsorption of metal ions by means of Fourier transform infrared (FT-IR), X-ray diffraction (XRD), transmission electron microscopy (TEM), and scanning electron microscopy (SEM). FT-IR spectrum of SF in (Fig. 1) showed the strongest absorbance bands at 1123, 806, and 483 cm−1, characteristic of condensed silica (Kota et al. 1997). The two bands at 1123 and 806 cm−1 were attributed to asymmetric stretching and symmetric stretching of \(\upupsilon\)(Si–O–Si), respectively (Moenke 1974). A broad and strong overlapped band at around 3444 cm−1 was due to the stretching vibration of \(\upupsilon\)(O–H) (Mostafa et al. 2001). The presence of these functional groups contributed to the strong binding between SF and the target metal ions. After adsorption of both Cd(II) and Zn(II), the band at 3444 cm−1 shifted to 3436 cm−1, and the intensity of \(\upupsilon\)(Si–O–Si) bands decreased.

XRD pattern of SF showed its amorphous structure, exhibiting only a very broad scattering peak in the range between 12° and 40° (Fig. 2a). After adsorption of Cd(II), the peak of Cd(II) appeared at 22° as illustrated in Fig. 2b. Also, the peak related to Zn(II) in (Fig. 2c) can be appeared at 74° (Behbahani et al. 2014). The appearance of these peaks which attributed to the target metal ion confirmed the adsorption process on SF surface.

The TEM images of SF before and after adsorption of metal ions are outlined in Fig. 3a–c. As shown in these images, the SF is nearly spherical in shape, and the average size of its particles is about 0.157 micron (Fig. 3a). After adsorption of Cd(II), the particles are gathered and their size ranged from 0.113 to 0.185 micron, Fig. 3b. On the other hand, in the case of Zn(II), the particle size recorded range from 0.065 to 0.189 micron (Fig. 3c). These results support the adsorption of Zn(II) and Cd(II) ions onto silica fume adsorbent.

SEM micrographs were displayed to clarify the change in morphological features of SF before and after metal ion adsorption. The microphotographs (Fig. 4a) showed that individual SF spheres agglomerate to form larger particles. After adsorption of Cd(II), the particles become larger in size (Fig. 4b), but after adsorption of Zn(II) (Fig. 4c), the particles of SF decrease in size. All of these changes support the adsorption process of both Cd(II) and Zn(II) on SF surface.

Batch adsorption

Effect of pH

Distribution of SF charge has significant role on the removal and interaction of various metal ions with adsorbent. The specified pH is known as zero point of charge, adsorbent surface is neutral, and the prominent mechanism for solute transfer is the diffusion into the adsorbent micro- and meso-pores (Ghaedi et al. 2015). At pH above this value, the surface becomes negative, and the positive ions attracted on the surface according to electrostatic attraction. The estimated value of pH at point of zero charge (4.2) shows the high tendency of these cationic species for strong adsorption on the SF phase.

The effect of pH on Zn(II) and Cd(II) adsorption was examined in the pH range 2.0–8.0 using 50.0 mg of SF (Fig. 5a). At lower pH values (2.0–4.0), the percentage extraction of both Cd(II) and Zn(II) decreased significantly due to the protonation of the hydroxyl moiety of SF and the competition between protons and metal ions for binding with the proposed phase (Ghaedi et al. 2013c). At pH ≥ 5.0, the percentage extraction of the two metal ions gradually increases. At pH 5.0 and 6.0, the percentage extraction values of Zn(II) were 23.4 and 74.47 %, and metal capacities were 24.75 and 54.13 mg g−1. At pH > 6.0, the metal capacity values decreased as Zn(II) precipitated in the form of zincate (ZnO) and/or zinc hydroxides (Deliyanni et al. 2007). For Cd(II), the percentage of extraction increased from 71.39 to 98.31 % and metal capacities from 76.71 to 121.28 mg g−1 at pH range 5.0–8.0. At higher pH values (>8.0), Cd(II) usually precipitated and formed Cd(OH)2 species (Lv et al. 2005). Finally, pH values of 6.0 and 8.0 were chosen for Zn(II) and Cd(II), respectively, as optimum pH value.

Effect of adsorbent amount

The amount of adsorbent is important parameter for the extraction of metal ion. As shown in Fig. 5b, increasing weights of SF from 10.0 to 50.0 mg increased the % extraction of Cd(II) from 78.61 to 98.3 %. Also, increasing weights from 10.0 to 100.0 mg increased the % extraction of Zn(II) from 65.4 to 95.0 %. This increase in extraction percentage might have been attributed to the fact that increasing the adsorbent dose provided a greater surface area or more adsorption sites for the metal ions (Rengaraj and Moon 2002). Additional increases in the amounts of SF used from 150.0 to 300.0 mg and from 100.0 to 300.0 mg for Zn(II) and Cd(II), respectively, did not significantly affect the extraction percentage of the two metal ions due to the saturation of the adsorbent surface by these ions.

Effect of extraction time

The adsorption capacity of SF toward Zn(II) and Cd(II) as a function of time was studied (Fig. 5c). Increasing the time from 10 to 30 min increased the uptake of Zn(II) and Cd(II) from 41.07 and 112.89 to 54.13 and 121.28 mg g−1, respectively, and reached equilibrium. So, for Zn(II) and Cd(II), 30 min was chosen as the equilibrium time of extraction. The data obtained were further used to evaluate the kinetic parameters of the adsorption process.

Adsorption kinetics

The adsorption kinetics is one of the most important characteristics, which represents the adsorption efficiency of the samples (Ye et al. 2010). The kinetics data obtained from batch experiments have been analyzed using the pseudo-first order and pseudo-second order. The first-order equation of Lagergren (Lagergren et al. 1898) is expressed as

where q t and q e (mg g−1) are the amounts of metal ions adsorbed per unit weight of the adsorbent at time t and equilibrium, respectively, and k 1 (min−1) is the pseudo-first-order rate constant of the adsorption process. The kinetic plots were drawn, and the adsorption rate constant (k 1 = 0.067 and 0.20) and adsorption capacity (q e = 5.96 and 62.66 mg g−1) of Zn(II) and Cd(II) using SF, respectively, were calculated from the slope and intercepts of plots of log (q e − q t ) versus ‘t.’ The calculated q e values were far lower than the corresponding experimental values, implying that the adsorption process has not fully followed the pseudo-first-order adsorption rate expression.

The pseudo-second-order kinetic rate equation (Wu et al. 2001) is based on the assumption that the adsorption follows the second-order chemisorption. The linear form can be written as Eq. (2):

where k 2 (g mg−1 min−1) is the second-order rate constant of adsorption. In the linear plots of t/q t against t, q e and k 2 were evaluated for Zn(II) and Cd(II) from slopes and intercepts as shown in Fig. 6. The calculated adsorption capacity values of Zn(II) and Cd(II) equal 54.95 and 122.85 mg g−1, respectively, were more consistent with the experimental values (54.13 and 121.28 mg g−1) of the predicted adsorption capacity, r 2 = 0.999 and 0.999. Therefore, the option exercised in favor of the pseudo-second-order model better represents the adsorption kinetics and thus supports the assumption behind the model. This suggests that the adsorption may be the rate-limiting step involving valence forces through sharing or exchange of electrons between adsorbate and adsorbent (Taty-Costades et al. 2003; Ho and McKay 1999).

Adsorption isotherm

The effect of Zn(II) and Cd(II) concentrations on the adsorption capacities was examined using the batch procedure at optimum conditions for extraction. The adsorption characteristics of the two metal ions on SF, experimental data, were evaluated using well-known adsorption isotherm models of Freundlich, Langmuir, and Temkin. The two linearized forms of Langmuir and Freundlich isotherms were described by the following equation:

where q e (mg g−1) is the amount of solute sorbed on the surface of adsorbent, C e (mg L−1) is the solution equilibrium concentration of metal ion, q max. (mg g−1) is the maximum amount of metal ion which is taken up by the adsorbent, K L (L mg−1) is Langmuir adsorption constant, K f (mg g−1) is Freundlich constant, and n is the heterogeneity factor which represents the bond distribution. K L and q max. can be calculated from the intercept and slope of the linear plot, 1/q e versus 1/C e in Langmuir isotherm curve of Zn(II) and Cd(II) adsorption on SF. The K L values were 0.764 and 0.268 while q max. values were 212.77 and 314.47 mg g−1 with r2 = 0.9142 and 0.9130 for Zn(II) and Cd(II), respectively. On the other hand, K f and 1/n can be calculated from the intercept and slope of the plot, log q e vs. log C e (Fig. 7) in Freundlich isotherm curve. The K f values were 5.188 × 104 and 1684.23 × 104, and 1/n values were 0.67 and 0.938 for Zn(II) and Cd(II). The values of r 2 were 0.995 and 0.978 for Zn(II) and Cd(II), respectively, which indicate that the Freundlich isotherm fits the experimental data better than the Langmuir model for adsorption studies of Zn(II) and Cd(II) on SF adsorbent.

The heat of the adsorption and the adsorbent–adsorbate interaction were evaluated using Temkin isotherm model (Temkin and Pyzhev 1940) which is given by the following equation

where B 1 is the Tempkin constant related to heat of the adsorption (J mol−1), T is the absolute temperature (K), R is the universal gas constant (8.314 J mol−1 K−1), and KT is the equilibrium binding constant (L mg−1). The values of the Tempkin constants and the correlation coefficient (r 2 = 0.975) are lower than the Freundlich value. Therefore, the Tempkin isotherm represents a worse fit of experimental data (Roosta et al. 2014) than the Langmuir isotherm, but the Freundlich isotherm provides the best correlation for the experimental data.

Column study

Effect of bed height

To investigate the effect of bed height on the breakthrough curve of Zn(II) and Cd(II) ions adsorption onto SF phase, other parameters such as the inlet concentration, flow rate, and pH were kept constant. For T = 298 K, flow rate = 1.0 mL min−1, C in = 0.001 M, and pH 6.0 for Zn(II) and 8.0 for Cd(II), it was observed that an increase in column height from 0.2 to 0.5 cm leads to an increase of the volume treated due to high contact time and an increase in breakpoint time. The steepness of the breakthrough curves is a strong function of the bed height (Fig. 8a, b).

Effect of flow rates

The rate of the flow of model solutions through the column is one of the factors affecting the time needed for the determination of the amount of metal ions and is directly related to the time needed for the contact of the solution with the adsorbent, thereby providing information about the adsorption rate of the complexes on the sorbent (Bulut et al. 2007). Therefore, the effect of the flow rate on the uptake of Zn(II) and Cd(II) using SF was investigated under the optimum conditions. The results for different solution flow rates are shown for fixed bed height and inlet adsorbate concentration in Fig. 9a, b. When the flow rate increased from 1.0 to 5.0 mL min−1, the breakthrough curve became steeper and the breakpoint time decreased. The reason for this decrease is probably due to insufficient contact of the metal ions and the adsorbent in order to reach equilibrium.

Selectivity studies

In order to study the selectivity of the target metal ions in presence of interfering ions, the procedure was performed in presence of alkaline, alkaline earth, and transition metals. These metal ions often accompany Zn(II) and Cd(II) in real samples. The anodic adsorptive stripping voltammetry of Zn(II) and Cd(II) was investigated by the addition of the interfering ion to the solution containing both metals at the optimum conditions. The results of this study are summarized in Table 1. These results obtained that co-existing ions had no obvious influence on the extraction of Zn(II) and Cd(II). Thus, the two metal ions can be determined in different and complicated matrices.

Effect of ionic strength

In order to investigate the effect of ionic strength on the extraction of Zn(II) and Cd(II), several experiments were performed with different NaCl concentrations (0.0–1.0 M) while keeping other experimental parameters constant. The concentrations of both Zn(II) and Cd(II) were determined through SWAdSV using standard additions method. The results confirmed that salt addition had no significant effect on the extraction process.

Desorption and regeneration

Studies of desorption are important in order to regenerate the phase and recover the metal ions. In fact, regeneration using acid or base treatment as ion-exchangers is not adequate for SF phase because acid or base treatment may increase the chance of hydrolysis of the bound complexing agent (Soliman and Ahmed 2009). It was selected to use another strong complexing agent such as EDTA to back extract of Zn(II) and Cd(II) from the metal chelate formed SF phase in the regeneration process. It was observed that the result of extraction percentage determined after the second extraction was similar to extraction percentage found in the first one for both the two metal ions.

Analysis of real samples

Pharmaceutical samples

Due to the importance of analysis of Zn(II) in trace levels, separation and enrichment of trace Zn(II) in complex matrix should be considered. So, to verify the applicability of the proposed method, it has been applied to analysis of Zn(II) in pharmaceuticals, Calcitron, and Vita zinc capsules, as shown in Table 2. Known concentration of Zn(II) (0.5 mg L−1) was spiked into the drug samples solutions, and the concentrations of Zn(II) in both solutions were tested using standard additions method via SWAdSV technique. The limit of detection (LOD) value of Zn(II) was 0.102 mg L−1. The recovery values were 99.9 and 100.0 % for Vita zinc and Calcitron capsules, respectively.

Rice and chocolate samples

To evaluate the ability of the developed method for analysis of real samples with different matrices containing various amounts of the target metal ion, the method has been used for analysis of Cd(II) in rice and chocolate samples solutions. The accuracy was checked by spiking of known concentration of 1.0 mg L−1 of Cd(II) into the two samples solutions. The technique SWAdSV tested using standard additions method was used for the determination of Cd(II) in these samples solutions. The calculated recovery values were higher than 99.0 % confirming the accuracy and high sensitivity of the procedure and the absence of matrix effects, Table 3. The limit of detection (LOD) was calculated to be 1.43 × 10−3 mg L−1 for Cd(II).

Water samples

Also, the developed method has been applied for Cd(II) determination in water samples: drinking tap-water (DTW), ground water (GW), mineral drinking-water (MDW), and distilled water (DW). Analytical recovery was assessed for two concentration levels, after spiking different aliquots of 1.0 and 2.0 mg L−1 of Cd(II) into water samples. The concentrations of Cd(II) were determined using SWAdSV technique by standard additions method. Results obtained are listed in Table 3. This procedure presents high sensitivity and high recovery values between 99.0 and 100.5 %.

Analytical features

The method validation should be investigated in order to check the accuracy and precision of the new proposed extraction method. The results exhibited fairly good analytical performance as expressed by the acceptable accuracy, repeatability, and sensitivity. Table 4 showed the obtained results which demonstrated the validity of the used SF phase for determination of the spiked ultra-trace amount of Cd(II) and Zn(II).

Comparison with other solid-phase extraction methods

Extraction and determination of Zn(II) and Cd(II) using SF were compared with the other solid-phase extraction methods and other complicated adsorbents used for their extraction. From the results in Table 5, SF showed great adsorptive ability toward Zn(II) and Cd(II) than the other adsorbents. Furthermore, it illustrated an alternative procedure to technique such as SWAdSV for determination of Zn(II) and Cd(II) at trace levels.

Conclusion

A simple, fast, and selective solid-phase extraction procedure, based on SF, for the determination of Zn(II) and Cu(II) has been developed. Compared with other solid phases, SF has the advantages of simple, high-capacity factor, and low limit of detection. This method can selectively separate Zn(II) and Cd(II) from other metal ions. The sorption of Zn(II) and Cd(II) on SF phase was fitted well with Freundlich model with r 2 = 0.995 and 0.978 along with fast kinetics obeying pseudo-second-order type and r 2 = 0.999 and 0.999 for Zn(II) and Cd(II), respectively. Also, the proposed method has been applied to determine Zn(II) and Cd(II) in pharmaceutical and environmental samples, respectively, with high recovery values and no matrix interference.

References

Abbasi S, Khodarahmiyan K, Abbasi F (2011) simultaneous determination of ultra-trace amounts of lead and cadmium in food samples by adsorptive stripping voltammetry. Food Chem 128:245–257

Amin AS, Gouda AA (2012) Utility of solid phase spectrophotometry for the modified determination of trace amounts of cadmium in food samples. Food Chem 132:518–524

Bagheri A, Behbahani M, Amini MM et al (2012) Simultaneous separation and determination of trace amounts of Cd(II) and Cu(II) in environmental samples using novel diphenylcarbazide modified nanoporous silica. Talanta 89:455–461

Barciela-Alonso MC, Plata-García V, Rouco-López A et al (2014) Ionic imprinted polymer based solid phase extraction for cadmium and lead pre-concentration/determination in seafood. Microchem J 114:106–110

Behbahani M, Bagheri A, Amini MM et al (2013) Application of multiwalled carbon nanotubes modified by diphenylcarbazide for selective solid phase extraction of ultra traces Cd(II) in water samples and food products. Food Chem 141:48–53

Behbahani M, Salarian M, Bagheri A et al (2014) Synthesis, characterization and analytical application of Zn(II)-imprinted polymer as an efficient solid-phase extraction technique for trace determination of zinc ions in food samples. J Food Compos Anal 34:81–89

Bolan NS, Makino T, Kunhikrishnan A et al (2013) Chapter four—cadmium contamination and its risk management in rice ecosystems. Adv Agron 119:183–273

Bulut VN, Gundogdu A, Duran C et al (2007) A multi-element solid-phase extraction method for trace metals determination in environmental samples on Amberlite XAD-2000. J Hazard Mater 146:155–163

Daniel S, Praveen RS, Rao TP (2006) Ternary ion-association complex based ion imprinted polymers (IIPs) for trace determination of palladium(II) in environmental samples. Anal Chim Acta 570:79–87

Deliyanni E, Peleka E, Matis K (2007) removal of zinc ion from water by sorption onto iron-based nanodsorbent. J Hazard Mater 141:176–184

DeMartino MG, Macarovscha GT, Cadore S (2010) The use of zincon for preconcentration and determination of zinc by flame atomic absorption spectrometry. Anal Methods 2:1258–1262

Fang GZ, Tan J, Yan XP (2005) An ion-imprinted functionalized silica gel sorbent prepared by a surface imprinting technique combined with a sol–gel process for selective solid-phase extraction of cadmium(II). Anal Chem 77:1734–1739

Ghaedi M, Tavallali H, Shokrollahi A et al (2009) Flame atomic absorption spectrometric determination of zinc, nickel, iron and lead in different matrixes after solid phase extraction on sodium dodecyl sulfate (SDS)-coated alumina as their bis (2-hydroxyacetophenone)-1, 3-propanediimine chelates. J Hazard Mater 166:1441–1448

Ghaedi M, Montazerozohori M, Nazari E et al (2013a) Functionalization of multiwalled carbon nanotubes for the solid-phase extraction of silver, cadmium, palladium, zinc, manganese and copper by flame atomic absorption spectrometry. Hum Exp Toxicol 32:687–697

Ghaedi M, Montazerozohori M, Rahimi N et al (2013b) Chemically modified carbon nanotubes as efficient and selective sorbent for enrichment of trace amount of some metal ions. J Ind Eng Chem 19:1477–1482

Ghaedi M, Montazerozohori M, Sajedi M et al (2013c) Comparison of novel sorbents for preconcentration of metal ions prior to their flame atomic absorption spectrometry determination. J Ind Eng Chem 19:1781–1787

Ghaedi M, Mortazavi K, Montazerozohori M et al (2013d) Flame atomic absorption spectrometric (FAAS) determination of copper, iron and zinc in food samples after solid-phase extraction on Schiff base-modified duolite XAD 761. Mater Sci Eng 33:2338–2344

Ghaedi M, Niknam K, Zamani S et al (2013e) Silica chemically bonded N-propyl kriptofix 21 and 22 with immobilized palladium nanoparticles for solid phase extraction and preconcentration of some metal ions. Mater Sci Eng C 33:3180–3189

Ghaedi M, Mazaheri H, Khodadoust S et al (2015) Application of central composite design for simultaneous removal of methylene blue and Pb2+ ions by walnut wood activated carbon. Spectrochim Acta Part A Mol Biomol Spectrosc 135:479–490

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465

Jamshidi M, Ghaedi M, Mortazavi K et al (2011) Determination of some metal ions by flame-AAS after their preconcentration using sodium dodecyl sulfate coated alumina modified with 2-hydroxy-(3-((1-H-indol 3-yle)phenyl) methyl) 1-H-indol (2-HIYPMI). Food Chem Toxicol 49:1229–1234

Kota HR, Ronin V, Forssberg E (1997) High performance energetically modified portland blast-furnace cements. Int Congr Chem Cem 3:1–9

Lagergren S, Kungliga S, Ventenkapsakademiens HB (1898) About the theory of so-called adsorption of soluble substances. Kungliga Svenska Vetenskapsakademiens Handlinger 24:1–39

Li Y, Li T, Jin Z (2011) Stabilization of Fe0 nanoparticles with silica fume for enhanced transport and remediation of hexavalent chromium in water and soil. J Environ Sci 23:1211–1218

Lv L, Hor M, Su F et al (2005) competitive adsorption of Pb2+, Cu2+ and Cd2+ ions on microporous titanosilicate ETS-10. J Colloid Interface Sci 287:178–184

Moenke HHW (1974) Silica the three-dimentional silicates, borosilicates and beryllium silicates. In: Farmer CV (ed) The Infrared Spectra of Minerals. Adlard & Son, New York p 365

Mostafa NY, El-Hemaly SAS, Al-Wakeel EI et al (2001) Characterization and evaluation of the pozzolanic activity of Egyptian industrial by-products I: Silica fume and dealuminated kaolin. Cem Concr Res 31:467–474

Pérez-Quintanilla D, Sánchez A, del Hierro I et al (2009) Preconcentration of Zn(II) in water samples using a new hybrid SBA-15-based material. J Hazard Mater 166:1449–1458

Rajabi M, Mohammadi B, Asghari A et al (2014) Nano-alumina coated with SDS and modified with salicylaldehyde-5-sulfonate for extraction of heavy metals and their determination by anodic stripping voltammetry. J Ind Eng Chem 20:3737–3743

Rengaraj S, Moon S (2002) kinetics of adsorption of Co(II) removal from water and wastewater by ion exchange resins. Water Res 36:1783–1793

Roosta M, Ghaedi M, Shokri N et al (2014) Optimization of the combined ultrasonic assisted/adsorption method for the removal of malachite green by gold nanoparticles loaded on activated carbon: experimental design. Spectrochim Acta Part A Mol Biomol Spectrosc 118:55–65

Scherz H, Kirchhoff E (2006) Trace elements in foods: zinc contents of raw foods—a comparison of data originating from different geographical regions of the world. J Food Compos Anal 19:420–433

Shakerian F, Dadfarnia S, Shabani AMH (2012) Synthesis and application of nano-pore size ion imprinted polymer for solid phase extraction and determination of zinc in different matrices. Food Chem 134:488–493

Sharma RK, Aditi P, Anil K et al (2013) Chemically modified silica gel with 1-f4-[(2-hydroxy benzylidene) amino] phenylgethanone: synthesis, characterization and application as an efficient and reusable solid phase extractant for selective removal of Zn(II) from mycorrhizal treated fly-ash samples. J Environ Sci 25:1252–1261

Soliman EM, Ahmed SA (2009) Selective separation of silver(I) and mercury(II) ions in natural water samples using alumina modified thiouracil derivatives as new solid phase extractors. Int J Environ Anal Chem 89:389–406

Taty-Costades VC, Fauduest H, Porte C et al (2003) Removal of Cd(II) and Pb(II) from aqueous solutions, by adsorption onto sawdust of Pinus sylvestris. J Hazard Mater 105:121–142

Temkin MJ, Pyzhev V (1940) Recent modifications to Langmuir isotherms. Acta Physiochimica URSS 1:217–222

Vellaichamy S, Palanivelu K (2011) Preconcentration and separation of copper, nickel and zinc in aqueous samples by flame atomic absorption spectrometry after column solid-phase extraction onto MWCNTs impregnated with D2EHPA-TOPO mixture. J Hazard Mater 185:1131–1139

Wu FC, Tseng RL, Juang RS (2001) Kinetic modeling of liquid-phase adsorption of reactive dyes and metal ions on chitosan. Water Res 35:613–618

Ye H, Zhu Q, Du D (2010) Adsorptive removal of Cd(II) from aqueous solution using natural and modified rice husk. Bioresour Technol 101:5175–5179

Yu JX, Li TH (2011) Distinct biological effects of different nanoparticles commonly used in cosmetics and medicine coatings. Cell Biosci 1:19–27

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Ahmed, S.A., Gaber, A.A.A. & Rahim, A.M.A. Application of silica fume as a new SP-extractor for trace determination of Zn(II) and Cd(II) in pharmaceutical and environmental samples by square-wave anodic stripping voltammetry. Appl Water Sci 7, 677–688 (2017). https://doi.org/10.1007/s13201-015-0281-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13201-015-0281-3