Abstract

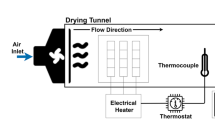

The investigation of an economical and efficient drying method for chilli is beneficial because it could provide a means of overcoming the drawbacks of traditional drying methods: high operating power and long drying time, which result in a decrease in the quality of the chilli. This study involved the design and development of a combined infrared and hot air laboratory-scale rotary dryer, which consists of three operating modes: hot air, infrared, and combined infrared and hot air. Drying experiments were conducted at five different temperatures (50, 55, 60, 65, and 70 °C). The drying behavior produced with the three operating modes was evaluated. The best mode was determined based on the parameters for evaluating the quality of chilli, the power consumption, and the retention time. The results indicate that the optimal overall drying performance for chilli was achieved at 70, 65, 50 °C drying temperatures in hot air, combined, and IR mode, respectively. A positive correlation was observed between retention time and power consumption with the hot air and the combined modes, while a negative correlation was identified in the IR mode.

Similar content being viewed by others

References

Abukhaiifeh H, Dhib R, Fayed M (2003) Model predictive control of an infrared-dryer. IEEE, 0-7803-7939-X/03, 340–344

Akintunde TYT, Afolabi TJ, Akintunde BO (2005) Influence of drying methods on drying of bell-pepper (Capsicum annuum). J Food Eng 68:439–442

Akpinar EK, Bicer Y, Yildiz C (2003) Thin layer drying of red pepper. J Food Eng 59:99–104

Das I, Das SK, Bal S (2004) Drying performance of a batch type vibration aided infrared dryer. J Food Eng 64:129–133

Das I, Das SK, Bal S (2009) Drying kinetics of high moisture paddy undergoing vibration-assisted infrared (IR) drying. J Food Eng 95:166–171

Datta AK, Ni H (2002) Infrared and hot-air-assisted microwave heating of foods for control of surface moisture. J Food Eng 51(4):355–364

Drewnowski A, Henderson SA, Levine A, Hann C (1999) Taste and food preferences as predictors of dietary practices in young women. Public Health Nutr 2:513–519

Erbay Z, Icier F (2010) A review of thin layer drying of foods: theory, modeling, and experimental results. Crit Rev Food Sci Nutr 50:441–464

Garau MC, Simal S, Femenia A, Rossello C (2006) Drying of orange skin: drying kinetics modeling and functional properties. J Food Eng 75:288–295

Goksu EI, Sumnu G, Esin A (2005) Effect of microwave on fluidized bed drying of macaroni beads. J Food Eng 66:463–468

Hebbar HU, Vishwanathan KH, Ramesh MN (2004) Development of combined infrared and hot air dryer for vegetables. J Food Eng 65:557–563

Ibrahim D (2006) Thin-layer drying behavior of mint leaves. J Food Eng 74:370–375

Kaleemullah S, Kailappan R (2005) Drying kinetics of red chillies in a rotary dryer. Biosyst Eng 92:15–23

Kaleemullah S, Kailappan R (2006) Modelling of thin-layer drying kinetics of red chillies. J Food Eng 76:531–537

Kim DY, Rhee CO, Shin SC (1982) Changes in colour of red pepper during drying and milling. J Korean Agri Chem Soc 25:1–7

Krokida MK, Karathanos VT, Maroulis ZB, Marinos- Kouris D (2003) Drying kinetics of some vegetables. J Food Eng 59:391–403

Maskan M (2000) Microwave/air and microwave finish drying of banana. J Food Eng 44:71–78

Maskan M (2001) Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying. J Food Eng 48:177–182

Mihindukulasuriya SDF, Jayasuriya HPW (2013) Mathematical modeling of drying characteristics of chilli in hot air oven and fluidized bed dryers. Agric Eng Int CIGR J 15:154–166

Praveen Kumar DG, Hebbar HU, Ramesh MN (2006) Suitability of thin layer models for infrared hot air-drying of onion slices. LWT Food Sci Technol 39:700–705

Sadasivam S, Manickam A (1997) Biochemical methods. New Age International (p) Ltd, New Delhi

Sandu C (1986) Infrared radiative drying in food engineering: a process analysis. Biotechnol Prog 2:109–119

Senadeera W, Bhandari BR, Young G, Wijesinghe B (2003) Influence of shapes of selected vegetable materials on drying kinetics during fluidized bed drying. J Food Eng 58:277–283

Sogi DS, Shivhare US, Garg SK, Bawa AS (2003) Water sorption isotherm and drying characteristics of tomato seeds. Biosyst Eng 84:297–301

Togrul ET, Dursun P (2003) Modelling of drying kinetics of single apricot. J Food Eng 58:23–32

Umesh H, Vishwanathan KH, Ramesh MN (2004) Development of combined infrared and hot air dryer for vegetables. J Food Eng 65:557–563

Acknowledgments

This research was supported by the Norwegian Centre for International Cooperation in Higher Education. The experiments were conducted in Asian Institute of Technology, Bangkok, Thailand.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mihindukulasuriya, S.D.F., Jayasuriya, H.P.W. Drying of chilli in a combined infrared and hot air rotary dryer. J Food Sci Technol 52, 4895–4904 (2015). https://doi.org/10.1007/s13197-014-1546-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-014-1546-9