Abstract

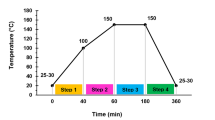

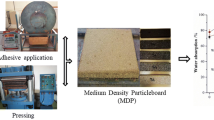

The aim of this research was to evaluate the potential of using castor husk as raw material for particleboard production un/mixed with pine wood considering anatomical, physical and chemical characteristics. The particleboards were produced with five different levels of castor husk content (0, 25, 50, 75 and 100 %) in association to pinewood. The adhesive urea formaldehyde and paraffin content were applied at 8 and 1 %, respectively. The particleboards were pressed under a pressure of 3.92 MPa and 160 °C of temperature for 8 min. Properties of castor husks particleboards such as density, modulus of rupture, modulus of elasticity, water absorption (2 and 24 h) and thickness swelling (2 and 24 h) were investigated. There were no statistical differences between the densities of the particleboards. The castor husk particleboards produced with 75 and 100 % had lower mechanical strength. In general, the addition of castor husk particles in particleboards improved their physical properties; although the thickness swelling for all samples met the requirements stipulated by EN 312 standard. Overall, mechanical strength of particleboards decreased with higher castor husk content. Castor husk may be added up to 50 % to pine wood in order to produce particleboards suitable for internal applications. The study concluded that it is feasible to produce particleboards with castor husk in combination to pinewood for production of particleboards.

Similar content being viewed by others

Abbreviations

- ABNT:

-

Associação brasileira de normas técnicas

- ANOVA:

-

Analysis of variance

- ANSI:

-

American National Standards Institute

- ASTM:

-

American Society for Testing and Materials

- CEN:

-

European Committee for Standardization

- FAO:

-

Food and Agriculture Organization of the United Nations

- IB:

-

Internal bond

- MOR:

-

Modulus of rupture

- MOE:

-

Modulus of elasticity

- TS:

-

Thickness swelling

- UFLA:

-

Federal University of Lavras

- WA:

-

Water absorption

References

ABNT: Associação brasileira de normas técnicas. NBR 13999: Papel, cartão, pastas celulósicas e madeira - Determinação do resíduo (cinza) após a incineração a 525°C. Rio de Janeiro (2003)

ABNT: Associação brasileira de normas técnicas. NBR 14810- Chapas de madeira aglomerada (2002)

ABNT: Associação brasileira de normas técnicas. NBR 14853: Madeira - Determinação do material solúvel em etanol-tolueno e em diclorometano e em acetona. Rio de Janeiro (2010)

ABNT: Associação brasileira de normas técnicas. NBR 7989: Pasta celulósica e madeira - Determinação de lignina insolúvel em ácido. Rio de Janeiro (2010)

ABNT: Associação brasileira de normas técnicas. NBR 11941: madeira – determinação da densidade básica. Rio de Janeiro (2003)

ASTM D-1037: Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials(2006)

CEN: European Committee for Standardization. EN 312: Particleboards—specifications (2003)

DIN: Normen fur Holzfaserplaten Spanplatten Sperrholz. DIN 52362: Testing of Wood Chipboards Bending Test, Determination of Bending Strength (1982)

FAO: Food and Agriculture Organization of The United Nations. http://faostat3.fao.org/browse/Q/QC/E (2015). Accessed 21 Mar 2016

Gomes, F.H.T.: Chemical-Bromatological Composition and In Situ Degradation of Co-products Nutrients from Castor and Physic Nut Biodiesel Production. Monograph (Graduation in Agronomy). Federal University of Ceará (2007)

Grigoriou, A., Ntalos, G.A.: The potencial use of Ricinus communis L. (Castor) stalks as a lignocellulosic resource of particleboards. Ind. Crops Prod. 13, 209–218 (2002)

Guler, C., Buyuksari, U.: Effect of production parameters on the physical and mechanical properties of particleboards made from peanut (Arachis hypogaea L.) husk. BioResources 6, 5027–5036 (2011)

Hardell, H.L., Nilvebrant, N.O.: A rapid method to discrimination between free and esterified fatty acids by pyrolytic methylation using tetramethyl ammonium acetate or hydroxide. J. Anal. Appl. Pyrol. 52, 1–14 (1999)

Iwakiri, S.: Painéis de madeira reconstituída. UFPR, Curitiba (2005)

Maloney, T.M.: Modern Particleboard and Dry-Process Fiberboard Manufacturing. Miller Freeman, San Francisco (1993)

Mani, S., Tabil, L.G., Sokhansanj, S.: Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 30, 648–654 (2006)

Melo, R.R., Santini, E., José, H., Clovis, R., Martins, S.D.: Propriedades físico-mecânicas de painéis aglomerados produzidos com diferentes proporções de madeira e casca de arroz. Ciência Florestal 19, 449–460 (2009)

Mendes, R.F., Mendes, L.M., Guimarães Júnior, J.B., Mori, F.A., César, A.A.S.: Effect of the incorporation of coffee husks on the physico-mechanical properties of Eucalyptus urophylla S.T. Blake particleboards. Ciênc. Agrotec. 34, 610–617 (2010)

Mendes, R.F., Mendes, L.M., Guimarães Júnior, J.B., Santos, R.C., César, A.A.S.: Efeito da associação de bagaço de cana, do tipo e do teor de adesivo na produção de painéis aglomerados. Ciência Florestal 22, 161–170 (2012)

Mendes, R.F., Mendes, L.M., Mendonça, L.L., Guimarães Júnior, J.B., Mori, F.A.: Qualidade de painéis aglomerados homogêneos produzidos com a madeira de clones de Eucalyptus Urophylla. Cerne 20, 329–336 (2014)

Morais, S.A.L., Nascimento, E.A., Melo, D.C.: Análise da madeira de Pinus oocarpa parte I – estudo dos constituintes macromoleculares e extrativos voláteis. Rev. Árvore. 29, 461–470 (2005)

Neutelings, G.: Lignin variability in plant cell walls: contribution of new models. Plant Sci. 181, 379–386 (2011)

Shrirame, H.Y., Panwar, N.L., Bamniya, B.R.: Biodiesel from castor oil—a green energy option. Low Carbon Econ. 2, 1–6 (2011)

Sakagami, H., Kushida, T., Oizumi, T., Nakashima, H., Makino, T.: Distribution of lignin-carbohydrate complex in plant kingdom and its functionality as alternative medicine. Pharmacol. Ther. 128, 91–105 (2010)

Samson, A.B., Hans-Wolf, R.: Fibers of coffee husk and hulls for the production of particleboard. Mater. Struct. 43, 1049–1060 (2010)

Scatolino, M.V., Silva, D.W., Mendes, R.F., Mendes, L.M.: Maize cob utilization for production of particleboard. Ciência Agrotecnologia 37, 330–337 (2013)

Sekaluvu, L., Tumutegyereize, P., Kiggundu, N.: Investigation of factors affecting the production and properties of maize cob-particleboards. Waste Biomass Valoriz. 5, 27–32 (2014)

Severino, L.S., Auld, D.L.: A framework for the study of the growth and development of castor plant. Ind. Crops Prod. 46, 25–38 (2013)

Severino, L.S., Freire, M.A.O., Lucena, A.M.A., Vale, L.S.: Sequential defoliations influencing the development and yield components of castor plants (Ricinus communis L.). Ind. Crops Prod. 32, 400–404 (2010)

Silva, D.W., Farrapo, C.L., Ribeiro, D.P., Mendes, R.F., Mendes, L.M., Scolforo, J.R.S.: MDP com partículas de eucalipto e palha de milho. Sci. For. 43, 853–862 (2015)

Sweet, M.S., Winandy, J.E.: The influence of degree of polymerization (DP) of cellulose and hemicellulose on the strength loss of fire-retardant-treated wood. Holzforschung 53, 311–317 (1999)

Teodoro, R., Raabe, J., Silva, D.W., Mendes, R.F., Tonoli, G.H.D.: Functionally graded MDP panels using bamboo particles. Key Eng. Mater. 668, 39–47 (2016)

Vijaya, K.P., Ramakrishna, Y.S., Rao, B.V.R., Victor, U.S., Srivastava, N.N., Subba Rao, A.V.M.: Influence of moisture, thermal and photoperiodic regimes on the productivity of castor beans (Ricinuscommunis L.). Agric. Forest Meteorol. 88, 279–289 (1997)

Youngquist, J.A., English, B.E., Scharmer, R.C., Chow, P., Shook, S.R.: Literature review on use of nonwoodplant fibers for building materials and panels. General Technical Report FPL–GTR-80 (1994)

Acknowledgments

The authors thank to the Fundação de Amparo à Pesquisa do Estado de Minas Gerais – FAPEMIG, Coordenacão de Aperfeiçoamento de Pessoa de Nível Superior – CAPES, Conselho Nacional de Desenvolvimento Científico e Tecnológico – CNPq, Brazilian Research Network in Lignocellulosic Composites and Nanocomposites – RELIGAR and PPGBiomat – Programa de Pós Graduação em Engenharia de Biomateriais.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, D.W., Scatolino, M.V., do Prado, N.R.T. et al. Addition of Different Proportions of Castor Husk and Pine Wood in Particleboards. Waste Biomass Valor 9, 139–145 (2018). https://doi.org/10.1007/s12649-016-9742-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9742-7