Abstract

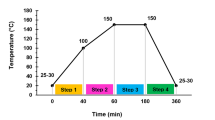

The use of agricultural residues in association with wood for panel production has potential to increase value, promote the adequate disposal and ensure adequate panel properties. The aim of the present study was to evaluate the potential of coconut husk in association with Pinus oocarpa wood in the production of medium-density particleboard (MDP) panels. The experimental design consisted of four percentages of Pinus oocarpa substituted with coconut husk (25, 50, 75 and 100%) and a control condition consisting of only pinus wood. The panels were produced with a nominal density of 650 kg m−3; relation face/core/face ratio of 20:60:20; 11% and 7% urea–formaldehyde adhesive (based on the weight of the particles) on the faces and in the core, respectively; and specific pressing cycle of 3.92 MPa at 160 °C with an 8 min press time. The properties of the moisture content; thickness swelling after water immersion for 2 and 24 h; water absorption after water immersion for 2 and 24 h; internal bond; and the modulus of rupture and elastic modulus in static bending were evaluated. Increasing the amount of coconut husk in the MDP panels significantly improved water absorption properties after 2 and 24 h (WA2h and WA24h), screw holding and thickness swelling after water immersion for 2 h (TS2h), increased thickness swelling property after water immersion for 24 h (TS24h), and decreased the modulus of rupture (MOR), elastic modulus (MOE) in static bending and internal bond. The use of coconut fibers provided an improvement in the physical and thermal properties of MDP panels, and although the increase in the amount of coconut fibers reduces the mechanical properties, all treatments met the values determined by standards, being allowed to state that it is possible to produce MDP panels only with coconut fibers.

Graphic Abstract

Similar content being viewed by others

References

González-García, S., Ferro, F.S., Silva, D.A.L., Feijoo, G., Lahr, F.A.R., Moreira, M.T.: Cross-country comparison on environmental impacts of particleboard production in Brazil and Spain. Resour. Conserv. Recycle 150, 104434 (2019). https://doi.org/10.1016/j.resconrec.2019.104434

Ciannamea, E.M., Stefani, P.M., Ruseckaite, R.A.: Medium-density particleboards from modified rice husks and soybean protein concentrate-based adhesives. Bioresour. Technol. 101, 818–825 (2010). https://doi.org/10.1016/j.biortech.2009.08.084

Li, B., Zheng, Y., Pan, Z., Hartsough, B.: Improved properties of medium-density particleboard manufactured from saline Creeping Wild Rye and HDPE plastic. Ind. Crops Prod. 30, 65–71 (2009). https://doi.org/10.1016/j.indcrop.2009.01.006

Factfish: Particle Board, Production Volume (cu. Meters) - for All Countries

Akgül, M., Çamlibel, O.: Manufacture of medium density fiberboard (MDF) panels from rhododendron (R. ponticum L.) biomass. Build. Environ. 43, 438–443 (2008). https://doi.org/10.1016/j.buildenv.2007.01.003

de Lima Mesquita, A., Barrero, N.G., Fiorelli, J., Christoforo, A.L., De Faria, L.J.G., Lahr, F.A.R.: Eco-particleboard manufactured from chemically treated fibrous vascular tissue of acai (Euterpe oleracea. Mart) Fruit: a new alternative for the particleboard industry with its potential application in civil construction an furniture. Ind. Crops Prod. 112, 644–651 (2018). https://doi.org/10.1016/j.indcrop.2017.12.074

Iwakiri, S., Shimizu, J., Silva, J.C., Del Menezzi, C.H.S., Puehringher, C.A., Venson, I., Larroca, C.: Produção de painéis de madeira aglomerada de Grevillea robusta A. Cunn. ex R. Br. Rev. Árvore. 28, 883–887 (2004). https://doi.org/10.1590/S0100-67622004000600013

Mo, X., Hu, J., Sun, X.S., Ratto, J.A.: Compression and tensile strength of low-density straw-protein particleboard. Ind. Crops Prod. 14, 1–9 (2001). https://doi.org/10.1016/S0926-6690(00)00083-2

Wang, D., Sun, X.S.: Low density particleboard from wheat straw and corn pith. Ind. Crops Prod. 15, 43–50 (2002). https://doi.org/10.1016/S0926-6690(01)00094-2

Mo, X., Cheng, E., Wang, D., Sun, X.S.: Physical properties of medium-density wheat straw particleboard using different adhesives. Ind. Crops Prod. 18, 47–53 (2003). https://doi.org/10.1016/S0926-6690(03)00032-3

Maldas, D., Kokta, B.V.: Studies on the preparation and properties of particle boards made from bagasse and PVC: II. Influence of the addition of coupling agents. Bioresour. Technol. 35, 251–261 (1991). https://doi.org/10.1016/0960-8524(91)90122-Z

Ntalos, G.A., Grigoriou, A.H.: Characterization and utilisation of vine prunings as a wood substitute for particleboard production. Ind. Crops Prod. 16, 59–68 (2002). https://doi.org/10.1016/S0926-6690(02)00008-0

Almeida, R.R., Del Menezzi, C.H.S., Teixeira, D.E.: Utilization of the coconut shell of babaçu (Orbignya sp.) to produce cement-bonded particleboard. Bioresour. Technol. 85, 159–163 (2002). https://doi.org/10.1016/S0960-8524(02)00082-2

Brígida, A.I.S., Calado, V.M.A., Gonçalves, L.R.B., Coelho, M.A.Z.: Effect of chemical treatments on properties of green coconut fiber. Carbohydr. Polym. 79, 832–838 (2010). https://doi.org/10.1016/j.carbpol.2009.10.005

Lomelí-Ramírez, M.G., Kestur, S.G., Manríquez-González, R., Iwakiri, S., de Muniz, G.B., Flores-Sahagun, T.S.: Bio-composites of cassava starch-green coconut fiber: Part II—Structure and properties. Carbohydr. Polym. 102, 576–583 (2014). https://doi.org/10.1016/j.carbpol.2013.11.020

Freire, A.L., de Araújo Júnior, C.P., de Freitas Rosa, M., de Almeida Neto, J.A., de Figueirêdo, M.C.: Environmental assessment of bioproducts in development stage: the case of fiberboards made from coconut residues. J. Clean. Prod. 153, 230–241 (2017). https://doi.org/10.1016/j.jclepro.2017.03.100

Brainer, M.S.D.P.: Produção de coco: O nordeste é destaque nacional. Cad. Setorial ETENE. 61, 1–25 (2018)

van Dam, J.E., van den Oever, M.J., Teunissen, W., Keijsers, E.R., Peralta, A.G.: Process for production of high density/high performance binderless boards from whole coconut husk. Ind. Crops Prod. 19, 207–216 (2004). https://doi.org/10.1016/j.indcrop.2003.10.003

Rios, P.D., Ferreira, G.P., Vieira, H.C., Grubert, W., da Cunha, A.B., Brand, M.A.: Avaliação do potencial da madeira de Pinus patula Schltdl. & Cham para a produção de painéis de madeira aglomerada. Sci. For. (2016). https://doi.org/10.18671/scifor.v44n110.22

Nemli, G., Kalaycıoğlu, H., Alp, T.: Suitability of date palm (Phoenix dactyliferia) branches for particleboard production. Holz als Roh- und Werkst. 59, 411–412 (2001). https://doi.org/10.1007/s00107-001-0257-x

Treusch, O., Tröger, F., Wegener, G.: Einfluss von Rohdichte und Bindemittelmenge auf das Rohdichteprofil von einschichtigen Spanplatten. Holz als Roh- und Werkst. 62, 474–475 (2004). https://doi.org/10.1007/s00107-004-0510-1

Borysiuk, P., Jenczyk-Tolloczko, I., Auriga, R., Kordzikowski, M.: Sugar beet pulp as raw material for particleboard production. Ind. Crops Prod. 141, 111829 (2019). https://doi.org/10.1016/j.indcrop.2019.111829

ANSI A 208-1: Mat-formed wood particleboard: Specification. National Particleboard Association (1993)

Büyüksarı, Ü.: Surface characteristics and hardness of MDF panels laminated with thermally compressed veneer. Compos. Part B Eng. 44, 675–678 (2013). https://doi.org/10.1016/j.compositesb.2012.01.087

Olorunnisola, A.O.: Effects of husk particle size and calcium chloride on strength and sorption properties of coconut husk–cement composites. Ind. Crops Prod. 29, 495–501 (2009). https://doi.org/10.1016/j.indcrop.2008.09.009

NBR-11941: Madeira – determinação da densidade básica (2003)

Mendes, J.F., Martins, J.T., Manrich, A., Neto, A.R., Pinheiro, A.C.M., Mattoso, L.H.C., Martins, M.A.: Development and physical-chemical properties of pectin film reinforced with spent coffee grounds by continuous casting. Carbohydr. Polym. 210, 92–99 (2019). https://doi.org/10.1016/j.carbpol.2019.01.058

ABNT: Madeira - Determinação do material solúvel em etanol-tolueno e em diclorometano e em acetona (ABNT NBR 14853) (2010)

Rebenfeld, L.: The Chemistry of Wood. B. L. Browning. Science 80-(142), 1564–1564 (1963). https://doi.org/10.1126/science.142.3599.1564-a

White, C.A.: Wood and cellulosics. In: Kennedy, J.F., Phillips, G.O., Williams, P.A. (eds.) Industrial Utilization Biotechnology Structure and Properties. Ellis Horwood, Chichester (1987)

ASTM D- 1037: Standard methods of evaluating of wood-base fiver and particles materials (2016)

DIN 52362: Testing of wood chipboards bending test, determination of bending strength (1982)

ANSI A208.1: American National Standard. Particle board (1999)

ABNT NBR 14810-2: Medium density particleboards Part 2: Requirements and test methods (2018)

ABNT: Desempenho térmico de edificações Parte 2: método de cálculo da transmitância térmica, da capacidade térmica, do atraso térmico e do fator solar de elementos e componentes de edificações (2005)

Lertwattanaruk, P., Suntijitto, A.: Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Constr. Build. Mater. 94, 664–669 (2015). https://doi.org/10.1016/j.conbuildmat.2015.07.154

Pereira, T.G., Silva, D.W., Eugênio, T.M., Scatolino, M.V., de Carvalho Terra, I.C., Fonseca, C.S., Bufalino, L., Mendes, R.F., Mendes, L.M.: Coconut fibers and quartzite wastes for fiber-cement production by extrusion. Mater. Today Proc. (2020). https://doi.org/10.1016/j.matpr.2020.01.394

Fiorelli, J., Gomide, C.A., Lahr, F.A., Nascimento, M.F., de Lucca Sartori, D., Ballesteros, J.E., Bueno, S.B., Belini, U.L.: Physico-chemical and anatomical characterization of residual lignocellulosic fibers. Cellulose 21, 3269–3277 (2014). https://doi.org/10.1007/s10570-014-0398-9

Cravo, J.C.M., de Lucca Sartori, D., Mármol, G., Schmidt, G.M., de Carvalho Balieiro, J.C., Fiorelli, J.: Effect of density and resin on the mechanical, physical and thermal performance of particleboards based on cement packaging. Constr. Build. Mater. 151, 414–421 (2017). https://doi.org/10.1016/j.conbuildmat.2017.06.084

Mendes, R.F., Mendes, L.M., Abranches, R.A.S., Santos, R.C., Guimarães, J.B.J.: Painéis aglomerados produzidos com bagaço de cana em associação com madeira de eucalipto. Sci. For. 38, 285–295 (2010)

Fiorelli, J., Galo, R.G., Castro Junior, S.L., Belini, U.L., Lasso, P.R.O., Savastano, H.: Multilayer particleboard produced with agroindustrial waste and amazonia vegetable fibres. Waste Biomass Valoriz. 9, 1151–1161 (2018). https://doi.org/10.1007/s12649-017-9889-x

Kelly, M.W.: Critical literature review of relationships between processing parameters and physical properties of particleboard. US Department of Agriculture Forest Service, Forest Products Laboratory, Madison (1977)

Maloney, T.M.: Modern Particleboard & Dry-Process Fiberboard Manufacturing. Miller Freeman Publication, San Fransico (1993)

Junior, J.B., Mendes, L.M., Mendes, R.F., Guimarães, B.M., de Melo, R.R.: Efeito do Teor da Parafina nas Propriedades Físico-Mecânicas de Painéis Aglomerados de Pinus oocarpa. Rev. Ciência da Madeira - RCM. 4, 72–82 (2013). https://doi.org/10.12953/2177-6830.v04n01a06

Silva, D.W., Scatolino, M.V., Prado, N.R., Mendes, R.F., Mendes, L.M.: Addition of different proportions of castor husk and pine wood in particleboards. Waste Biomass Valoriz. 9, 139–145 (2018). https://doi.org/10.1007/s12649-016-9742-7

Adhikary, K.B., Pang, S., Staiger, M.P.: Long-term moisture absorption and thickness swelling behaviour of recycled thermoplastics reinforced with Pinus radiata sawdust. Chem. Eng. J. 142, 190–198 (2008). https://doi.org/10.1016/j.cej.2007.11.024

Fiorelli, J., Bueno, S.B., Cabral, M.R.: Assessment of multilayer particleboards produced with green coconut and sugarcane bagasse fibers. Constr. Build. Mater. 205, 1–9 (2019). https://doi.org/10.1016/j.conbuildmat.2019.02.024

Jonoobi, M., Grami, M., Ashori, A., Ebrahimi, G.: Effect of ozone pretreatment on the physical and mechanical properties of particleboard panels made from bagasse. Measurement 94, 451–455 (2016). https://doi.org/10.1016/j.measurement.2016.08.019

312-4., E.: Particleboards - specifications. Part 4. Requirements for load-bearing boards for use in dry condidtions (2003)

Iwakiri, S., Olandoski, D.P., Leonhardt, G., Brand, M.A.: Produção de chapas de madeira compensada de cinco espécies de pinus tropicais. Ciência Florest. 11, 71 (2001). https://doi.org/10.5902/198050981656

Fiorelli, J., Curtolo, D.D., Barrero, N.G., Savastano Jr., H., Pallone, E.M., Johnson, R.: Particulate composite based on coconut fiber and castor oil polyurethane adhesive: an eco-efficient product. Ind. Crops Prod. 40, 69–75 (2012). https://doi.org/10.1016/j.indcrop.2012.02.033

Asasutjarit, C., Hirunlabh, J., Khedari, J., Charoenvai, S., Zeghmati, B., Shin, U.C.: Development of coconut coir-based lightweight cement board. Constr. Build. Mater. 21, 277–288 (2007). https://doi.org/10.1016/j.conbuildmat.2005.08.028

Acknowledgements

The authors thank the National Council for Scientific and Technological Development—CNPq (Grant # 141823/2017-8), Fundação de Amparo à Pesquisa do estado de Minas Gerais (FAPEMIG) and Si Group Crios Adesivos S/A.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Narciso, C.R.P., Reis, A.H.S., Mendes, J.F. et al. Potential for the Use of Coconut Husk in the Production of Medium Density Particleboard. Waste Biomass Valor 12, 1647–1658 (2021). https://doi.org/10.1007/s12649-020-01099-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01099-x