Abstract

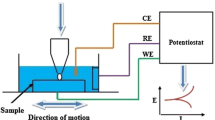

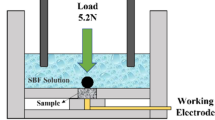

The corrosion resistance behavior of TA2 pure titanium processed by tungsten inert gas (TIG) welding was investigated in artificial saliva solution at 37 °C. By metallographic examination, electrochemical measurement technology, and electrochemical impedance spectroscopy (EIS), the corrosion resistance of the base metal (BM), heat-affected zone (HAZ), and weld metal (WM) were investigated. Metallographic examination experiments show that welding process would cause the growth of grain size. In addition, phase change happens in the HAZ and WM. The change of grain size and phase would influence the generation of the original passive film. The electrochemical tests show that the BM, HAZ, and WM are all equipped with good corrosion resistance. The welded joint shows a better corrosion resistance than the original TA2. It is shown that the BM with the lowest corrosion potential and the biggest corrosion current has a worse corrosion resistance than WM as well as HAZ. Silver (Ag) nanoparticles can be distributed on the WM zone of Ti uniformly. The WM zone of Ti with Ag coating considerably enhances the antibacterial activity of Ti implants.

Similar content being viewed by others

References

Xu TC, Peng XD, Jiang JW, Chen J, Yi HY. Progress in welding of titanium alloy and dissimilar materials. Chin J Rare Met. 2013;38(4):711.

Wang H, Fan YJ, Li L, Chen ZH, Yang HB, Cao JM. Influence of drawing deformation on microstructure of TC4 wire after welding. Chin J Rare Met. 2013;37(3):506.

Kim MG. Fatigue properties on the failure mode of a dental implant in a simulated body environment. Met Mater Int. 2011;17(5):705.

Peng J, Zhou CY, Dai Q, He XH, Tang ZX, Du YQ. Strain rate sensitivity of commercially pure titanium TA2 at room temperature and revising of hollomon empirical formula, Rare Met Mat Eng. 2013;42(3):483.

Wang Q, Zhang PZ, Wei DB, Wang RN, Chen XH, Wang HY. Microstructure and corrosion resistance of pure titanium surface modified by double-glow plasma surface alloying. Mater Design. 2013;1402:49.

Qi YL, Deng J, Hong Q, Zeng LY. Electron beam welding, laser beam welding and gas tungsten arc welding of titanium sheet. Mater Sci Eng A. 2000;280(1):177.

Cvetkovic RP, Popovic O, Burzic M, Jovicic R, Macura SK, Buyukyildirim G. The effect of welding process and shielding atmosphere on the AlMg4.5Mn weld metal properties. Int J Mater Res. 2013;104(1):18.

Blasco-Tamarit E, Igual-MunOz A, GarcIA AntON J, Garciacarc DM. Galvanic corrosion of titanium coupled to welded titanium in LiBr solutions at different temperatures. Corros Sci. 2009;51(5):1095.

Atapour M, Fathi MH, Shamanian M. Corrosion behavior of Ti–6Al–4V alloy weldment in hydrochloric acid. Mater Corros. 2012;63(2):134.

Orsi IA, Raimundo LB, Bezzon OL, Nóbilo MA, Kuri SE, Rovere CA, Pagnano VO. Evaluation of anodic behavior of commercially pure titanium in tungsten inert gas and laser welds. J Prosthodont. 2011;20(8):628.

Cai Z, Shafer T, Watanabe I, Nunn ME, Okabe T. Electrochemical characterization of cast titanium alloys. Biomaterials. 2003;24(2):213.

Stern M, Geary AL. Electrochemical polarization I. A theoretical analysis of the shape of polarization curves. J Electrochem Soc. 1957;104(1):56.

Buddery A, Kelly P, Drennan J, Dargusch M. The effect of contamination on the metallurgy of commercially pure titanium welded with a pulsed laser beam. J Mater Sci. 2010;46(8):2726.

Shukla AK, Balasubramaniam R, Bhargava S. Properties of passive film formed on CP titanium, Ti–6Al–4 V and Ti–13.4Al–29Nb alloys in simulated human body conditions. Intermetallics. 2005;13(6):631.

González JEG, Mirza-Rosca JC. Study of the corrosion behavior of titanium and some of its alloys for biomedical and dental implant applications. J Electroanal Chem. 1999;471(2):109.

Hodgson AWE, Mueller Y, Forster D, Virtanen S. Electrochemical characterisation of passive films on Ti alloys under simulated biological conditions. Electrochim Acta. 2002;47(12):1913.

Menini R, Dion MJ, So SKV, Gauthier M, Lefebvre LP. Surface and corrosion electrochemical characterization of titanium foams for implant applications. J Electrochem Soc. 2006;153(1):B13.

Fonseca C, Barbosa MA. Corrosion behaviour of titanium in biofluids containing H2O2 studied by electrochemical impedance spectroscopy. Corros Sci. 2001;43(3):547.

Chang YY, Huang HL, Lai CH, Hsu JT, Shieh TM, Wu AYJ, Chen CL. Analyses of antibacterial activity and cell compatibility of titanium coated with a Zr–C–N film. PloS One. 2013;8(2):e56771.

Kronstrom M, Svenson B, Hellman M, Persson GR. Early implant failures in patients treated with Branemark system titanium dental implants, a retrospective study. Int J Oral Maxillofac Implants. 2001;16(2):201.

Huang HL, Chang YY, Weng JC, Chen YC, Lai CH, Shieh TM. Anti-bacterial performance of zirconia coatings on titanium implants. Thin Solid Films. 2013;528:151.

Wang X, Wang G, Liang J, Cheng J, Ma W, Zhao Y. Staphylococcus aureus adhesion to different implant surface coatings: an in vitro study. Surf Coat Technol. 2009;203(22):3454.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 81070871).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, YP., Li, CY. & Zhang, LY. Corrosion resistance and antibacterial activity of different zones in TA2 weldment by TIG welding. Rare Met. 39, 1449–1456 (2020). https://doi.org/10.1007/s12598-014-0395-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0395-z