Abstract

This work deals with the modeling of the material flow in Friction Stir Welding (FSW) processes using particle tracing method. For the computation of particle trajectories, three accurate and computationally efficient integration methods are implemented within a FE model for FSW process: the Backward Euler with Sub-stepping (BES), the 4-th order Runge–Kutta (RK4) and the Back and Forth Error Compensation and Correction (BFECC) methods. Firstly, their performance is compared by solving the Zalesak’s disk benchmark. Later, the developed methodology is applied to some FSW problems providing a quantitative 2D and 3D view of the material transport in the process area. The material flow pattern is compared to the experimental evidence.

Similar content being viewed by others

Notes

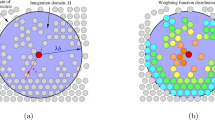

In the present work, the bins algorithm is used [29].

References

Thomas WM, Nicholas ED, Needham JC, Murch MG, Temple-Smith P, Dawes CJ (1991) Friction-stir butt welding. GB Patent No. 9125978.8, International Patent No. PCT/GB92/02203

Mishra RS, Ma ZY (2005) Friction Stir Welding and processing. Mater Sci Eng R 50:1–78

London B, Mahoney M, Bingel B, Calabrese R, Waldron D (2001) Experimental methods for determining material flow in friction stir welds. The third International symposium on Friction Stir Welding, Kobe, Japan, 27–28 September

Reynolds AP (2008) Flow visualization and simulation in FSW. Scr Mater 58:338–342

Seidel TU, Reynolds AP (2001) Visualization of the material flow in AA2195 Friction Stir Welds using a marker insert technique. Metall Mater Trans A32:2879–2884

Colligan K (1999) Material flow behaviour during Friction Stir Welding of aluminium. Weld J 78:229–237

Guerra M, Schmids C, McClure JC, Murr LE, Nunes AC (2003) Flow patterns during Friction Stir Welding. Mater Charact 49:95–101

Dickerson T, Shercliff HR, Schmidt H (2003) A weld marker technique for flow visualization in Friction Stir Welding. 4th International Symposium on Friction Stir Welding, Park City, Utah, USA, 14–16 May

Kallgren T, Jin L-Z, Sandstrom R (2008) Material flow during Friction Stir Welding of copper. 7th International Friction Stir Welding symposium, Awaji Island, Japan, 20–22 May

Johnson R, Threadgill P (2003) Friction Stir Welding of magnesium alloys. Magnes Technol

Ouyang J, Yarrapareddy E, Kovacevic R (2006) Microstructural evolution in the friction stir welded 6061 aluminum alloy (T6-temper condition) to copper. J Mater Process Technol 172:110–122

Abdollah-Zadeh A, Saeid T, Sazgari B (2008) Microstructural and mechanical properties of friction stir welded aluminum/copper lap joints. J Alloys Comp 460:535–538

Buffa G, Fratini L, Micari F, Shivpuri R (2008) Material flow in FSW of T-joints: experimental and numerical analysis. Int J Metal Form 1(1):1283–1286

Buffa G, Ducato A, Fratini L (2011) Numerical procedure for residual stresses prediction in Friction Stir Welding. Finite Elem Anal Des 47(4):470–476

Alfaro I, Racineux G, Poitou A, Cueto E, Chinesta F (2009) Numerical simulation of Friction Stir Welding by natural element methods. Int J Metal Form 2(4):225–234

Guerdoux S, Fourment L (2009) A 3D numerical simulation of different phases of Friction Stir Welding. Model Simul Mater Sci Eng 17:075001

Feulvarch E, Roux J-C, Bergheau J-M (2013) A simple and robust moving mesh technique for the finite element simulation of Friction Stir Welding. J Comput Appl Math 246:269–277

Chiumenti M, Cervera M, Agelet de Saracibar C, Dialami N (2013) Numerical modeling of Friction Stir Welding processes. Comput Methods Appl Mech Eng 254:353–369

Dialami N, Chiumenti M, Cervera M, Agelet de Saracibar C (2013) An apropos kinematic framework for the numerical modelling of Friction Stir Welding. Comput Struct 117:48–57

Agelet de Saracibar C, Chiumenti M, Cervera M, Dialami N, Seret A (2014) Computational modeling and sub-grid scale stabilization of incompressibility and convection in the numerical simulation of Friction Stir Welding processes. Arch Comput Methods Eng 21(1), Accepted

Bussetta P, Dialami N, Boman R, Chiumenti M, Agelet de Saracibar C, Cervera M, Ponthot J-P (2013) Comparison of a fluid and a solid approach for the numerical simulation of Friction Stir Welding with a non-cylindrical pin, Steel research international, accepted

Brezzi F, Fortin M (1991) Mixed and hybrid finite element methods. Springer, New York

Agelet de Saracibar C, Chiumenti M, Valverde Q, Cervera M (2006) On the orthogonal subgrid scale pressure stabilization of finite deformation J2 plasticity. Comput Methods Appl Mech Eng 195:1224–1251

Cervera M, Chiumenti M, Valverde Q, Agelet de Saracibar C (2003) Mixed linear/linear simplicial elements for incompressible elasticity and plasticity. Comput Methods Appl Mech Eng 192:5249–5263

Chiumenti M, Valverde Q, Agelet de Saracibar C, Cervera M (2004) A stabilized formulation for incompressible plasticity using linear triangles and tetrahedral. Int J Plast 20:1487–1504

Chiumenti M, Valverde Q, Agelet de Saracibar C, Cervera M (2001) A stabilized formulation for incompressible elasticity using linear displacement and pressure interpolations. Comput Methods Appl Mech Eng 191:5253–5264

Agelet de Saracibar C, Cervera M, Chiumenti M (1999) On the formulation of coupled thermoplastic problems with phase-change. Int J Plast 15:1–34

Cervera M, Agelet de Saracibar C, Chiumenti M (1999) Thermo-mechanical analysis of industrial solidification processes. Int J Numer Methods Eng 46:1575–1591

Cormen TH, Leiserson CE, Rivest RL (1990) Introduction to algorithms, 1st edn. MIT Press and McGraw-Hill. ISBN 0-262-03141-8

Dupont T, Liu Y-J (2002) Back and forth error compensation and correction methods for removing errors induced by uneven gradients of the level set function. J Comput Phys 183:83–116

Osher S, Fedkiw R (2002) Level set methods and dynamic implicit surfaces. Springer-Verlag, New York

Osher S, Sethian J (1988) Fronts propagating with curvature-dependent speed: algorithms based on Hamilton-Jacobi formulations. J Comput Phys 79:12–49

Zalesak ST (1979) Fully multidimensional flux-corrected transport. J Comput Phys 31:335–362

Reynolds AP (2000) Visualisation of material flow in autogenous friction stir welds. Sci Technol Weld Join 5(2):120–124

Santiago D, Lombera G, Urquiza S, Agelet de Saracibar C, Chiumenti M (2010) Modelado termomecánico del proceso de Friction Stir Welding utilizando la geometría real de la herramienta. Rev Int Métodos Numéricos para Cálculo Diseño Ing 26(4):293–303

Acknowledgments

This work was supported by the European Research Council under the Advanced Grant: ERC-2009-AdG “Real Time Computational Mechanics Techniques for Multi-Fluid Problems”. The authors are also thankful for the financial support of the Spanish Ministerio de Educación y Ciencia (PROFIT programme) within the project CIT-020400–2007-82.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dialami, N., Chiumenti, M., Cervera, M. et al. Material flow visualization in Friction Stir Welding via particle tracing. Int J Mater Form 8, 167–181 (2015). https://doi.org/10.1007/s12289-013-1157-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-013-1157-4