Abstract

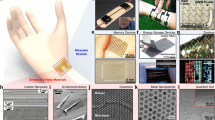

Silicon nanowire (SiNW) fabrics are of great interest for fabricating high-performance multifunctional wearable sensors. However, it remains a big challenge to fabricate high-quality SiNW fabrics in a simple and efficient manner. Here we report, for the first time, one-step growth of large-area SiNW fabrics for multifunctional wearable sensors, by using a massive metal-assisted chemical vapor deposition (CVD) method. With bulk Sn as a catalyst source, numerous millimeter-long SiNWs grow and naturally interweave with each other, forming SiNW fabrics over 80 cm2 in one experiment. In addition to intrinsic electronic properties of Si materials, the SiNW fabrics also feature high flexibility, good tailorability and light weight, rendering them ideal for fabricating multifunctional wearable sensors. The prototype sensors based on the SiNW fabrics could effectively detect various stimuli including temperature, light, strain and pressure, with outstanding performance among reported multifunctional sensors. We further demonstrate the integration of the prototype sensors onto the body of a robot, enabling its perception to various environmental stimuli. The ability to prepare high-quality SiNW fabrics in a simple and efficient manner will stimulate the development of wearable devices for applications in portable electronics, Internet of Things, health care and robotics.

Similar content being viewed by others

References

Wang, S. H.; Xu, J.; Wang, W. C.; Wang, G. J. N.; Rastak, R.; Molina-Lopez, F.; Chung, J. W.; Niu, S. M.; Feig, V. R.; Lopez, J. et al. Skin electronics from scalable fabrication of an intrinsically stretchable transistor array. Nature2018, 555, 83–88.

Choi, S.; Han, S. I.; Jung, D.; Hwang, H. J.; Lim, C.; Bae, S.; Park, O. K.; Tschabrunn, C. M.; Lee, M.; Bae, S. Y. et al. Highly conductive, stretchable and biocompatible Ag–Au core–sheath nanowire composite for wearable and implantable bioelectronics. Nat. Nanotechnol.2018, 13, 1048–1056.

Seyedin, S.; Zhang, P.; Naebe, M.; Qin, S.; Chen, J.; Wang, X. G.; Razal, J. M. Textile strain sensors: A review of the fabrication technologies, performance evaluation and applications. Mater. Horiz.2019, 6, 219–249.

Wang, C. Y.; Xia, K. L.; Wang, H. M.; Liang, X. P.; Yin, Z.; Zhang, Y. Y. Advanced carbon for flexible and wearable electronics. Adv. Mater.2019, 31, 1801072.

Hu, Y. G.; Zhao, T.; Zhu, P. L.; Zhang, Y.; Liang, X. W.; Sun, R.; Wong, C. P. A low-cost, printable, and stretchable strain sensor based on highly conductive elastic composites with tunable sensitivity for human motion monitoring. Nano Res.2018, 11, 1938–1955.

Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X. M. Fiber-based wearable electronics: A review of materials, fabrication, devices, and applications. Adv. Mater.2014, 26, 5310–5336.

Yetisen, A. K.; Qu, H.; Manbachi, A.; Butt, H.; Dokmeci, M. R.; Hinestroza, J. P.; Skorobogatiy, M.; Khademhosseini, A.; Yun, S. H. Nanotechnology in textiles. ACS Nano2016, 10, 3042–3068.

Li, X. T.; Hu, H. B.; Hua, T.; Xu, B. G.; Jiang, S. X. Wearable strain sensing textile based on one-dimensional stretchable and weavable yarn sensors. Nano Res.2018, 11, 5799–5811.

Liu, X.; Tang, C.; Du, X. H.; Xiong, S.; Xi, S. Y.; Liu, Y. F.; Shen, X.; Zheng, Q. B.; Wang, Z. Y.; Wu, Y. et al. A highly sensitive graphene woven fabric strain sensor for wearable wireless musical instruments. Mater. Horiz.2017, 4, 477–486.

Zhang, M. C.; Wang, C. Y.; Wang, H. M.; Jian, M. Q.; Hao, X. Y.; Zhang, Y. Y. Carbonized cotton fabric for high-performance wearable strain sensors. Adv. Funct. Mater.2017, 27, 1604795.

Wang, C. Y.; Li, X.; Gao, E. L.; Jian, M. Q.; Xia, K. L.; Wang, Q.; Xu, Z. P.; Ren, T. L.; Zhang, Y. Y. Carbonized silk fabric for ultrastretchable, highly sensitive, and wearable strain sensors. Adv. Mater.2016, 28, 6640–6648.

Yang, Z.; Pang, Y.; Han, X. L.; Yang, Y. F.; Ling, J.; Jian, M. Q.; Zhang, Y. Y.; Yang, Y.; Ren, T. L. Graphene textile strain sensor with negative resistance variation for human motion detection. ACS Nano2018, 12, 9134–9141.

Liu, M. M.; Pu, X.; Jiang, C. Y.; Liu, T.; Huang, X.; Chen, L. B.; Du, C. H.; Sun, J. M.; Hu, W. G.; Wang, Z. L. Large-area all-textile pressure sensors for monitoring human motion and physiological signals. Adv. Mater.2017, 29, 1703700

Someya, T.; Kato, Y.; Sekitani, T.; Iba, S.; Noguchi, Y.; Murase, Y.; Kawaguchi, H.; Sakurai, T. Conformable, flexible, large-area networks of pressure and thermal sensors with organic transistor active matrixes. Proc. Natl. Acad. Sci. USA2005, 102, 12321–12325.

Hua, Q. L.; Sun, J. L.; Liu, H. T.; Bao, R. R.; Yu, R. M.; Zhai, J. Y.; Pan, C. F.; Wang, Z. L. Skin-inspired highly stretchable and conformable matrix networks for multifunctional sensing. Nat. Commun.2018, 9, 244.

Hsu, P. C.; Liu, X. G.; Liu, C.; Xie, X.; Lee, H. R.; Welch, A. J.; Zhao, T.; Cui, Y. Personal thermal management by metallic nanowire-coated textile. Nano Lett.2015, 15, 365–371.

Liao, X. Q.; Liao, Q. L.; Zhang, Z.; Yan, X. Q.; Liang, Q. J.; Wang, Q. Y.; Li, M. H.; Zhang, Y. A highly stretchable ZnO@fiber-based multifunctional nanosensor for strain/temperature/UV detection. Adv. Funct. Mater.2016, 26, 3074–3081.

Xiao, P.; Mao, J.; Ding, K.; Luo, W. J.; Hu, W. D.; Zhang, X. J.; Zhang, X. H.; Jie, J. S. Solution-processed 3D RGO–MoS2/pyramid Si heterojunction for ultrahigh detectivity and ultra-broadband photodetection. Adv. Mater.2018, 30, 1801729.

Hosticka, B. J.; Brockherde, W.; Hammerschmidt, D. Silicon sensor systems. In Smart Sensor Interfaces. Huijsing, J. H.; Meijer, G. C. M; Springer: Boston, MA, 1997; pp 99–111.

Hull, R. Properties of Crystalline Silicon; INSPEC, the Institution of Electrical Engineers: London, 1999.

Chockla, A. M.; Harris, J. T.; Akhavan, V. A.; Bogart, T. D.; Holmberg, V. C.; Steinhagen, C.; Mullins, C. B.; Stevenson, K. J.; Korgel, B. A. Silicon nanowire fabric as a lithium ion battery electrode material. J. Am. Chem. Soc.2011, 133, 20914–20921.

Xu, Z.; Sun, H. Y.; Zhao, X. L.; Gao, C. Ultrastrong fibers assembled from giant graphene oxide sheets. Adv. Mater.2013, 25, 188–193.

Koziol, K.; Vilatela, J.; Moisala, A.; Motta, M.; Cunniff, P.; Sennett, M.; Windle, A. High-performance carbon nanotube fiber. Science2007, 318, 1892–1895.

Heo, K.; Cho, E.; Yang, J. E.; Kim, M. H.; Lee, M.; Lee, B. Y.; Kwon, S. G.; Lee, M. S.; Jo, M. H.; Choi, H. J. et al. Large-scale assembly of silicon nanowire network-based devices using conventional microfabrication facilities. Nano Lett.2008, 8, 4523–4527.

Wang, H.; Wang, J. T.; Cao, Z. X.; Zhang, W. J.; Lee, C. S.; Lee, S. T.; Zhang, X. H. A surface curvature oscillation model for vapour–liquid–solid growth of periodic one-dimensional nanostructures. Nat. Commun.2015, 6, 6412.

Wang, H.; Zhang, X. H.; Meng, X. M.; Zhou, S. M.; Wu, S. K.; Shi, W. S.; Lee, S. Bulk preparation of Si-SiOx hierarchical structures: high-density radially oriented amorphous silica nanowires on a single-crystal silicon nanocore. Angew. Chem., Int. Ed.2005, 44, 6934–6937.

Zhang, B. C.; Wang, H.; He, L.; Zheng, C. J.; Jie, J. S.; Lifshitz, Y.; Lee, S. T.; Zhang, X. H. Centimeter-long single-crystalline Si nanowires. Nano Lett.2017, 17, 7323–7329.

Moutanabbir, O.; Isheim, D.; Blumtritt, H.; Senz, S.; Pippel, E.; Seidman, D. N. Colossal injection of catalyst atoms into silicon nanowires. Nature2013, 496, 78–82.

Allen, J. E.; Hemesath, E. R.; Perea, D. E.; Lensch-Falk, J. L.; Li, Z. Y.; Yin, F.; Gass, M. H.; Wang, P.; Bleloch, A. L.; Palmer, R. E. et al. High-resolution detection of Au catalyst atoms in Si nanowires. Nat. Nanotechnol.2008, 3, 168–173.

Norton, P.; Brandt, J. Temperature coefficient of resistance for p- and n-type silicon. Solid-State Electron.1978, 21, 969–974.

Kim, J.; Lee, M.; Shim, H. J.; Ghaffari, R.; Cho, H. R.; Son, D.; Jung, Y. H.; Soh, M.; Choi, C.; Jung, S. et al. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun.2014, 5, 5747.

Wu, M. H.; Liu, K. H.; Wang, W. L.; Sui, Y.; Bai, X. D.; Wang, E. G. Ultralong aligned single-walled carbon nanotubes on flexible fluorphlogopite mica for strain sensors. Nano Res.2012, 5, 443–449.

Milne, J. S.; Rowe, A. C. H.; Arscott, S.; Renner, C. Giant piezoresistance effects in silicon nanowires and microwires. Phys. Rev. Lett.2010, 105, 226802.

Li, R. Y.; Si, Y.; Zhu, Z. J.; Guo, Y. J.; Zhang, Y. J.; Pan, N.; Sun, G.; Pan, T. R. Supercapacitive iontronic nanofabric sensing. Adv. Mater.2017, 29, 1700253.

Ge, J.; Sun, L.; Zhang, F. R.; Zhang, Y.; Shi, L. A.; Zhao, H. Y.; Zhu, H. W.; Jiang, H. L.; Yu, S. H. A stretchable electronic fabric artificial skin with pressure-, lateral strain-, and flexion-sensitive properties. Adv. Mater.2016, 28, 722–728.

Kim, S. J.; Song, W.; Yi, Y.; Min, B. K.; Mondal, S.; An, K. S.; Choi, C. G. High durability and waterproofing rGO/SWCNT-fabric-based multifunctional sensors for human-motion detection. ACS Appl. Mater. Interfaces2018, 10, 3921–3928.

Ho, D. H.; Sun, Q. J.; Kim, S. Y.; Han, J. T.; Kim, D. H.; Cho, J. H. Stretchable and multimodal all graphene electronic skin. Adv. Mater.2016, 28, 2601–2608.

Yao, S. S.; Zhu, Y. Wearable multifunctional sensors using printed stretchable conductors made of silver nanowires. Nanoscale2014, 6, 2345–2352.

Lipomi, D. J.; Vosgueritchian, M.; Tee, B. C. K.; Hellstrom, S. L.; Lee, J. A.; Fox, C. H.; Bao, Z. A. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol.2011, 6, 788–792.

Park, J.; Kim, M.; Lee, Y.; Lee, H. S.; Ko, H. Fingertip skin–inspired microstructured ferroelectric skins discriminate static/dynamic pressure and temperature stimuli. Sci. Adv.2015, 1, e1500661.

Acknowledgements

This work was supported by the Major Research Plan of the National Natural Science Foundation of China (No. 91833303), the Foundation for Innovation Research Groups of the National Natural Science Foundation of China (No. 51821002), the National Natural Science Foundation of China (Nos. 51672180 and 51802208), the Natural Science Foundation of Jiangsu Province (No. BK20160309), Postdoctoral Research Foundation of China (Nos. 2016M601880 and 2017T100396), Collaborative Innovation Center of Suzhou Nano Science and Technology, the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), and the 111 Project.

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Zhang, BC., Jie, JS., Shao, ZB. et al. One-step growth of large-area silicon nanowire fabrics for high-performance multifunctional wearable sensors. Nano Res. 12, 2723–2728 (2019). https://doi.org/10.1007/s12274-019-2505-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-019-2505-6