Abstract

Biodiesel is one of the most popular prospective alternative fuels and can be obtained from a variety of sources. Waste frying oil is one such source along with the various raw vegetable oils. However, some specific technical treatments are required to improve certain fuel properties such as viscosity and calorific value of the biodiesel being obtained from waste cooking oil methyl ester (WCOME). Various treatments are applied depending on the source and therefore the composition of the cooking oil. This research investigated the performance of WCOME as an alternative biofuel in a four-stroke direct injection diesel engine. An 8-mode test was undertaken with diesel fuel and five WCOME blends. The best compromise blend in terms of performance and emissions was identified. Results showed that energy utilization factors of the blends were similar within the range of the operational parameters (speed, load and WCOME content). Increasing biodiesel content produced slightly more smoke and NOx for a great majority of test points, while the CO and THC emissions were lower.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Alternative fuel resources will play an important role in replacing the dwindling world supply of fossil fuels. Increasing industrialization and mechanization has led to a steep rise in the demand for fossil fuel. As a result, limited reserves and environmental degradation have mandated the search for alternative fuels (He et al. 2010), which are gaining worldwide acceptance as a partial solution to the problems of environmental degradation, energy security, import restrictions, rural employment and agricultural economy. Generally, different ratios of biodiesel are blended with fossil fuel for use in diesel engines, which are recognized for energy generation and are a power source providing higher efficiency and ruggedness in the field of transportation. One of the biodiesel sources is waste cooking oil methyl ester (WCOME). WCOME presents a twofold gain, as it can provide benefits both as an environmental strategy for municipalities as well as for the safeguarding of human health due to the lowered gas emissions. Arslan (2011) and Hamasaki et al. (2001) stated that biodiesel could be used as an alternative fuel instead of existing conventional diesel engines without requiring any modifications. Compared to conventional fossil diesel fuel, biodiesel provides significant reductions in particulate matter (PM) emissions (Canakci and Van Gerpen 2003; Lapuerta et al. 2008; Tat 2003), carbon monoxide (CO) emissions (Mittelbach and Tritthart 1988) and total hydrocarbon (THC) emissions (Payrı et al. 2005). The performance of biodiesel-fueled engines is better than that of diesel-fueled engines in terms of thermal efficiency, brake-specific energy consumption, and smoke opacity, wear of vital components and exhaust emissions for an entire range of operations (Agarwal and Das 2001). These findings are supported by researchers who observed similar behavior for all biodiesel blends with fuel of various origins (Cetinkaya et al. 2005; Felizardo et al. 2006; Mangesh and Dalai 2006; Ulusoy et al. 2004). Gopal et al. (2014) have observed that there is significant reduction in CO, unburned HC and smoke emissions for biodiesel and its blends compared to diesel fuel. However, NOx emission of WCO biodiesel is marginally higher than of petroleum diesel.

Many studies have been conducted on the use of alternative input products such as rape seed and soybean WCOME in the production of biodiesel for use in diesel engines (Altıparmak et al. 2007; Felizardo et al. 2006; Kaplan et al. 2006; Mangesh and Dalai 2006; Nachid et al. 2015; Selvan and Nagarajan 2013; Ulusoy et al. 2004, 2016). The performance and smoke results obtained from an electricity generator engine operating on WCOME showed that the smoke reduction, compared to that of conventional diesel fuel, was around 60% for B100 (100% biodiesel) and around 25% for B20 (20% biodiesel) (Cetinkaya and Karaosmanoglu 2005). Dorado et al. (2003) conducted an 8-mode test using waste olive oil in a four-stroke, three-cylinder, direct injection, 34 kW engine and results showed that 8.6% reduction in CO2, a 58.9% reduction in CO and a 57.7% reduction in SO2 emissions. However, increases of 8.5% and 32% were observed in specific fuel consumption and NOx emissions, respectively. Murillo et al. (2007) tested a four-stroke diesel outboard engine running on conventional diesel, conventional diesel blended with 10%, 30% and 50% biodiesel derived from WCOME and pure biodiesel. The biodiesel blends proved to be environmentally friendly alternatives to conventional diesel fuel. They noticed reductions in power of approximately 5% with B10 and B30, and 8% with B50 and B100. Despite the positive performance tendencies of WCOME mentioned above, contradictory results have also been reported. Lin et al. (2007) found sharp increases in both NOx and particulate emissions when WCOME was used.

In this study, we investigated the performance of WCOME as an alternative biofuel in a four-stroke, four-cylinder, direct injection diesel engine. The test was carried out in compliance with ISO 8178-C1 8-modes test cycle as commonly applied for off-road engine applications. Emission results, besides the engine characteristics, are reported as instantaneous pollutant concentrations (in ppm or %) and cumulative values determined based on weighted average modal pollutant values in g/kW-h.

2 Materials and methods

2.1 Test fuel

Diesel fuel (D2) and a set of blends of diesel with WCOME were used in this research. D2 was used as the reference fuel. The WCOME–diesel blends included B10, B20, B30, B40 and B50 (according to WCOME, %). Test fuel specifications are shown in Table 1.

The experiments were carried out in the Research and Development department of the Türk Traktör ve Ziraat Makineleri Co. in Turkey. Throughout the tests, WCOs from industrial sources in the Marmara region were used. To eliminate the effects of fuel composition on the measured emission levels, low-sulfur diesel fuel (maximum sulfur content 50 ppm) was used as a reference fuel in the experiments.

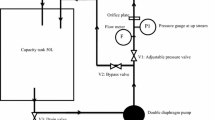

2.2 Experimental setup

The engine test laboratory provided a complete system for measuring all parameters relating to diesel engine performance and exhaust gas emissions analyses. The experimental system consisted of an AC dynamometer and a HORIBA MEXA-7100D emission measuring system. A HORIBA MDLT-1300 partial-flow mini-dilution tunnel was used for PM measurement. Figure 1 gives a schematic layout of the experimental system used. Descriptions of the test devices are given in Table 2, and the engine specifications are summarized in Table 3.

2.3 Test methods

The engine was run for a preliminary period until the cooling water and oil reached stable temperatures. This stabilization typically took 30 min. After warming up, the test conditions were set and the engine was allowed to reach a steady state before any data were taken. Emissions were measured according to the regulatory test procedures necessary to verify and ensure compliance with the required standards. In many countries, including the USA, the EU and Japan, for off-road engine applications, those procedures are carried out in accordance with the ISO 8178-C1 standard specified in the 97/68/EC directive. This standard requires a sequence of steady-state 8-mode tests performed on an engine dynamometer. Each mode represents a combination of different speed and load conditions with different weighting factors. This test cycle was intended to create repeatable emission measurement conditions and to correspond to the simulation of a real driving condition for a given application.

Prior to each test, the particulate tunnel and sampling system were conditioned at 55–60 °C to ensure that any unburned deposits resulting from running at light load were burned off and that defined conditions were repeatable from test to test.

Exhaust emissions were normally measured for each test mode on a volume basis. The exhaust emissions tests were calculated as a weighted average. The final emission results were stated in g/kW-h (grams of pollutant per unit of mechanical energy delivered by the engine). Test modes and weighting factors for this test cycle are given in Table 4. The average integrated value for the test cycle was determined by means of the weighting factor for each mode.

3 Results and discussion

A set of typical performance curves showed that apart from the percentage of WCOME in the blends, there was no unusual difference in the performance indicators, except for the emission parameters.

The power curves are given in Fig. 2. Both figures in Fig. 2 show very small fluctuations in the torque and power values for different blends at different loads. These fluctuations seem to be arbitrary and can be considered as experimental uncertainties.

The specific fuel consumption curves in Fig. 3 show an obvious increase with increasing WCOME content, which is a natural consequence of the decreasing calorific value of the blends. However, the energy efficiency of the blends relative to that of the diesel fuel, i.e., the energy utilization factor, was a more reliable measure for comparison of the combustion performance of the fuels. The energy utilization factor (relative energy efficiency) is defined as the overall efficiency of the blend fuel divided by the overall efficiency of the diesel fuel (ηei/ηed). In Table 5, the energy utilization factors of the blends are given at the defined operational modes. The changes in the energy utilization factor seem to be a function of load rather than engine speed and WCOME content. Despite the exceptions at a few points, it can generally be concluded that the energy utilization factor decreased with increasing load, as was expected.

One of the most interesting results was that the utilization factor decreased from B10 to B20, then began to increase and reached the greatest value at B50. There were almost no exceptions to this case at any speed–load combination. In Table 5, the relative energy efficiencies (ηei/ηed) of the blends are given at the defined operational modes.

The test engine was tested under the steady-state 8-mode ISO 8178 test cycle. Emission levels at various engine speeds–loads and fuel blends were observed in terms of filter smoke number (FSN), CO, THC, NOx emissions and PM.

As shown in Fig. 4, the smoke emission increased with increasing load and with decreasing speed (at the same load). However, the positive effect of increasing WCOME content on smoke emissions was more prominent at higher loads and lower speeds.

Besides some contradicting conclusions reported in various references (Jeong et al. 2006; De Almeida et al. 2002), we observed a slight decrease in NOx emissions with increasing WCOME content for all loads and speeds, as shown in Fig. 5. These results of this study were in good agreement with the results reported by Yücesu and Ilkiliç (2006), Rakopoulos et al. (2006) and Fan et al. (2008), who similarly reported that the NOx emission of biodiesel blends decreased when the percentage of biodiesel in the blend increased. This decrease, despite the higher oxygen content of blends with higher biodiesel content, might be attributed to lower heat release and thus the temperature rose due the lower calorific value of WCOME. But we need to express the conclusion that there are many different factors contradictorily affecting the NOx release with increasing biodiesel content of the blends and their effects are not definitely dominating so that it is possible to get contradicting results in different studies depending on the various experimental atmosphere and physical conditions of test equipment, especially the combustion chamber of the engine.

For all WCOME contents, however, NOx emission increased with increasing engine load up to 75%, but thereafter remained nearly constant. This increase is definitely a result of higher energy release, and thus, temperature increases with increasing fuel/air ratio.

Plots of CO concentration (Fig. 6) showed that almost regardless of load and speed, a minimum value of CO appeared between B10 and B20 and there was a stable and continuous increase above B20, except relatively unstable appearance at 100% load. Another important result was that in 50%–75% load band there was not a remarkable change in CO emissions, while it increased considerably at extremes of 10% and 100% (10% is not reported for 1800 rpm). All these results showed that increasing oxygen content in the combustion atmosphere, either by an increase in excess air coefficient (decreasing load) or oxygen content of the fuel, results in a decrease in CO concentration up to some extent, but later this trend is reversed and CO concentration increased most probably regarding the extra dilution effect of oxygen.

The curves in Fig. 7 show that the type of fuel had no significant effect on CO2 emission. The CO2 emission was an obvious function of load, and as the load increased, the CO2 emission increased significantly. If we compare variation in CO2 with that of CO for a specific fuel, we see that in terms of combustion efficiency the 50%–75% load band is the best, i.e., [CO]/[CO2] is the smallest, regardless of the fuel type.

Hydrocarbon emission in internal combustion engines is a function of both oxygen available in the combustion atmosphere and temperature; higher oxygen concentration and temperature reduce the HC emissions. Figure 8 shows that at 1800 rpm THC is the smallest with the B10 blend and increases remarkably as the WCOME content increases for a specific load. Since oxygen content increases with increasing biodiesel content, that means this increase in HC is not dominated by oxygen concentration but should be a result of a remarkable decrease in temperature. This conclusion confirms well that the decrease in NOx emissions with increase in WCOME content, as shown in Fig. 5, can be attributed to a decrease in combustion temperature at the same load (but for all loads). But similar confirmation of THC emissions with NOx emissions cannot be made for the effect of increasing load. If THC emissions were dominated purely by temperature, increase in NOx emissions with increasing load in Fig. 5 should have resulted with decreasing THC emissions. But this effect is not distinguishable for 1800 rpm as shown in Fig. 8. This means at 1800 rpm, a possible effect of temperature increase in THC with increasing load, which should be to decrease THC emissions, is compensated by decrease in oxygen concentration with increasing load and there is almost no significant change.

At 2800 rpm, an increase in CO concentration with increasing WCOME content at all loads is not as sharp as it is at 1800 rpm and it shows a clear turn after B40. Also, unlike 1800 rpm results, there is a substantial decrease in THC emissions with increasing load with some exceptions between 10% and 50% after B20. This means the thermo-chemical effect of an increase in engine speed is very prominent on THC emissions. The combined effect of increasing load and speed and hence increasing the temperature results in a decrease in THC values.

Figure 9 shows the weighted cumulative 8-mode THC and PM emission results for conventional diesel fuel and various blends. Results showed a clear reduction in PM emissions and an increase in THC emissions as the amount of WCOME increased in the blend. Using B50 fuel, the reduction in PM emissions reached 40%, while an increase of 53% in THC was observed under the same conditions.

The results for NOx and CO emissions for diesel fuel and various blends from the same 8-mode test are presented in Fig. 10. It is obvious from Fig. 10 that cumulative NOx emissions did not show a meaningful variation with content of the blend, while CO emissions show a stable decrease with decreasing WCOME content and stabilized almost at the same value between B10 and B20.

4 Conclusion

Although WCOME is of a slightly different nature and of a lower quality than various other vegetable oil methyl esters, the results of the tests presented above show that it exhibits very good performance. At a majority of the test points, the relative energy efficiencies of the blends are greater than unity. This research confirms the common conclusion of biodiesel studies that, if WCOME content cannot be kept high enough due to the shortage of sources, then 10% is the best blend ratio in terms of energy efficiency. Blends with WCOME content yielded much better emission results than the diesel fuel, and this advantage increased with increasing WCOME content in terms of smoke and NOx emissions. However, only the B10 blend carried the same advantage in terms of both CO and THC emissions. So only the emission results with B10 were better than those with diesel fuel almost under all operational conditions. The blends with higher WCOME content yielded worse or at best equal CO and THC emissions, except for CO values at several points at full load.

References

Agarwal AK, Das LM. Biodiesel development and characterization for use as a fuel in compression ignition engines. Trans ASME. 2001;123(2):440–7. https://doi.org/10.1115/1.1364522.

Altıparmak D, Keskin A, Koca A, Guru M. Alternative fuel properties of tall oil fatty acid methyl ester–diesel fuel blends. Biores Technol. 2007;98(2):241–6. https://doi.org/10.1016/j.biortech.2006.01.020.

Arslan R. Emission characteristics of a diesel engine using waste cooking oil as biodiesel fuel. Afr J Biotech. 2011;10(19):3790–4. https://doi.org/10.5897/AJB10.2202.

Canakci M, Van Gerpen JH. Comparison of engine performance and emissions for petroleum diesel fuel, yellow grease biodiesel and soybean oil biodiesel. Trans ASAE. 2003;46(4):937–44. https://doi.org/10.13031/2013.13948.

Cetinkaya M, Karaosmanoglu F. A new application area for used cooking oil originated biodiesel generators. Energy Fuels. 2005;19(2):645–52. https://doi.org/10.1021/ef049890k.

Cetinkaya M, Ulusoy Y, Tekin Y, Karaosmanoğlu F. Engine and winter road test performances of used cooking oil originated biodiesel. Energy Convers Manag. 2005;46(7–8):1279–91. https://doi.org/10.1016/j.enconman.2004.06.022.

De Almeida SC, Belchior CR, Nascimento MV, dos SR Vieira L, Fleury G. Performance of a diesel generator fuelled with palm oil. Fuel. 2002;81(16):2097–102. https://doi.org/10.1016/S0016-2361(02)00155-2.

Dorado M, Ballesteros E, Arnal J, Gomez J, Lopez F. Exhaust emissions from a diesel engine fueled with transesterified waste olive oil. Fuel. 2003;82:1311–5. https://doi.org/10.1016/S0016-2361(03)00034-6.

Fan X, Wang X, Chen F, Geller DP, Wan JP. Engine performance test of cottonseed oil biodiesel. Open Fuels Energy Sci J. 2008;1:40–5.

Felizardo P, Correia MJN, Raposo I, Mendes JF, Berkemeier R, Bordado JM. Production of biodiesel from waste frying oils. Waste Manag. 2006;26(5):487–94. https://doi.org/10.1016/j.wasman.2005.02.025.

Gopal KN, Pal A, Sharma S, Samanchi C, Sathyanarayanan K, Elango T. Investigation of emissions and combustion characteristics of a CI engine fueled with waste cooking oil methyl ester and diesel blends. Alex Eng J. 2014;53(2):281–7. https://doi.org/10.1016/j.aej.2014.02.003.

Hamasaki K, Kinoshita E, Tajima H, Takasaki K, Morita D. Combustion characteristics of diesel engines with waste vegetable oil methyl ester. In: The fifth international symposium on diagnostics and modeling of combustion in internal combustion engines. (COMODIA 2001). 2001.

He C, Ge Y, Tan J, You K, Han X, Wang J. Characteristics of polycyclic aromatic hydrocarbons emissions of diesel engine fueled with biodiesel and diesel. Fuel. 2010;89:2040–6. https://doi.org/10.1016/j.fuel.2010.03.014.

Jeong GT, Oh YT, Park DH. Emission profile of rapeseed methyl ester and its blend in a diesel engine. Appl Biochem Biotechnol. 2006;129(1–3):165–78.

Kaplan C, Arslan R, Surmen A. Performance characteristics of sunflower methyl esters as biodiesel. Energy Sources. 2006;28(8):751–5. https://doi.org/10.1080/009083190523415.

Lapuerta M, Agudelo JR, Rodriguez-Fernandez J. Diesel particulate emissions from used cooking oil biodiesel. Bioresour Technol. 2008;99:731–40. https://doi.org/10.1016/j.biortech.2007.01.033.

Lin Y, Wu YG, Chang CT. Combustion characteristics of waste oil produced biodiesel/diesel fuel blends. Fuel. 2007;86:1772–80. https://doi.org/10.1016/j.fuel.2007.01.012.

Mangesh GK, Dalai KA. Waste cooking oil-an economical source for biodiesel: a review. Ind Eng Chem Res. 2006;45(9):2901–13. https://doi.org/10.1021/ie0510526.

Mittelbach M, Tritthart P. Diesel fuel derived from vegetable oils, III. Emission tests using methyl esters of used frying oil. J Am Oil Chem Soc. 1988;65(7):1185–7.

Murillo S, Mı´guez JL, Porteiro J, Granada E, Mora´n JC. Performance and exhaust emissions in the use of biodiesel in outboard diesel engines. Fuel. 2007;86:1765–71. https://doi.org/10.1016/j.fuel.2006.11.031.

Nachid M, Ouanji F, Kacimi M, Liotta LF, Ziyad M. Biodiesel from Moroccan waste frying oil: the optimization of transesterification parameters impact of biodiesel on the petrodiesel lubricity and combustion. Int J Green Energy. 2015;12(8):865–72. https://doi.org/10.1080/15435075.2014.888660.

Payri F, Macian V, Arregle J, Tormos B, Martinez JL. Heavy-duty diesel engine performance and emission measurements for biodiesel (from cooking oil) blends used in the ECOBUS project. SAE paper, 2005-01-2205. https://doi.org/10.4271/2005-01-2205.

Rakopoulos CD, Antonopoulos KA, Rakopoulos DC, Hountalas DT, Giakoumis EG. Comparative performance and emissions study of a direct injection diesel engine using blends of diesel fuel with vegetable oils or bio-diesels of various origins. Energy Convers Manag. 2006;47(18):3272–87. https://doi.org/10.1016/j.enconman.2006.01.006.

Selvan T, Nagarajan G. Combustion and emission characteristics of a diesel engine fuelled with biodiesel having varying saturated fatty acid composition. Int J Green Energy. 2013;10:952–65. https://doi.org/10.1080/15435075.2012.732157.

Tat ME. Investigation of oxides of nitrogen emissions from biodiesel-fueled engines. Ph.D. thesis, Iowa State University. 2003. http://lib.dr.iastate.edu/rtd/922.

Ulusoy Y, Tekin Y, Cetinkaya M, Karaosmanoğlu F. The engine tests of biodiesel from used frying oil. Energy Sources. 2004;26:927–93. https://doi.org/10.1080/00908310490473219.

Ulusoy Y, Arslan R, Kaplan C, Bolat A, Cedden H, Kaya A, Gunc G. An investigation of engine and fuel system performance in a diesel engine operating on waste cooking oil. Int J Green Energy. 2016;13(1):40–4. https://doi.org/10.1080/15435075.2014.909360.

Yücesu HS, Ilkiliç C. Effect of cotton seed oil methyl ester on the performance and exhaust emission of a diesel engine. Energy Sources Part A. 2006;28(4):389–98. https://doi.org/10.1080/009083190927877.

Author information

Authors and Affiliations

Corresponding author

Additional information

Edited by Xiu-Qin Zhu

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Ulusoy, Y., Arslan, R., Tekin, Y. et al. Investigation of performance and emission characteristics of waste cooking oil as biodiesel in a diesel engine. Pet. Sci. 15, 396–404 (2018). https://doi.org/10.1007/s12182-018-0225-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12182-018-0225-2