Abstract

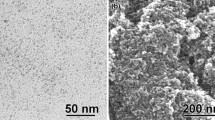

Nano-sized ceramic powders with weaker aggregation of Nd 3 +-doped yttrium aluminum garnet (YAG:Nd 3 +) were synthesized via co-microemulsion and microwave heating. This method provides a limited small space in a micelle for the formation of nano-sized precursors. It also requires a very short heating time, thus reducing energy consumption in comparison with conventional solid-state sintering processes. As a result, small-sized particles with narrow size distribution, weaker aggregation and high purity were obtained. Powder X-ray diffraction results revealed that the structure of pure YAG:Nd 3 +nanoparticles was cubic garnet. Transmission electron microscopy results indicated that the synthesized particles were almost spherical with average diameters of 40 and 80 nm. The luminescent properties of YAG:Nd 3 +were investigated through PL. Under excitation at 488 nm, YAG:Nd 3 +nano-sized ceramic powders showed main emission bands of 1045–1080 nm because of 4 F 3/2 → 4 I 11/2 transitions that are identical to those observed for a single YAG:Nd 3 +crystal.

Similar content being viewed by others

References

Braun M M and Pilon L 2006 Thin Solid Films 496 505

Capek I 2004 Adv. Colloid Interf. Sci. 110 49

Caponetti E, Martino D C, Saladino M L and Leonelli C 2007 Langmuir 23 3947

Dexter D L and Schulman J A 1954 J. Chem. Phys. V22(N6) 1063

Fedyk R, Hreniak D, Łojkowski W, Strȩk W, Matysiak H, Grzanka E, Gierlotka S and Mazur P 2007 Opt. Mater. 29 1252

Hreniak D and Strek W 2002 J. Alloy Compd 341 183

Hreniak D, Fedyk R, Bednarkiewicz A, Strȩk W and Łojkowski W 2007 Opt. Mater. 29 1244

Hreniak D, Strek W, Głuchowski P, Fedyk R and Łojkowski W 2008 J. Alloys Compd 451 549

Ikesue A, Furusato I and Kamata K 1995 J. Am. Ceram. Soc. 78 225

Katelnikovas A, Barkauskas J, Ivanauskas F, Beganskiene A and Kareiva A 2007 J. Sol–Gel Sci. Technol. 41 193

Kshida T, Marcos H M and Geusic J E 1968 Phys. Rev. 167 289

Li X, Liu H, Wang J, Cui H, Zhang X and Han F 2004 Mater. Sci. Eng. A-Struct. 379 347

Lu J, Prabhu M, Xu J, Ueda K, Yagi H, Yanagitani T and Kaminskii A 2000a Jpn J. Appl. Phys. 39 1048

Lu J, Prabhu M, Xu J, Ueda K, Yagi H, Yanagitani T and Kaminskii A 2000b Appl. Phys. Lett. 77 3707

Lu J, Ueda K, Yagi H, Yanagitani T and Akiyama Y 2002 J. Alloys Compd 341 220

Pang Q, Shi J, Liu Y, Xing D, Gong M and Xu N 2003 Mater. Sci. Eng. B-Solid 103 57

Pang Q, Shi J and Gong M 2007 J. Am. Ceram. Soc. 90 3943

Panneerselvam M, Subanna G N and Rao K J 2001 J. Mater. Res. 16 2773

Pillai V, Kumar P and Shah D O 1992 J. Magn. Magn. Mater. 116 L299

Pradhan A K, Zhang K and Loutts G B 2004 Mater. Res. Bull. 39 1291

Rabinovitch Y, Bogicevic C, Karolak F, Ttard D and Dammak H 2008 J. Mater. Process Tech. 199 314

Sekino T and Sogabe Y 1993 Rev. Laser Eng. 21 827

Skita M, Haneda H and Yanagitani T 1991 J. Appl. Phys. 69 3709

Strek W, Bednarkiewicz A, Hreniak D, Mazur P and Lojkowski W 2007 J. Lumin. 122123 70

Vaidhyanathan B and Binner J G 2003 J. Mater. Sci. 41 5954

Vaqueiro P and Lopequea M A 1997 Chem. Mater. 9 2836

Veith M and Mathur S 1999 J. Mater. Chem. 9 3069

Wang S, Xu Y, Lu P, Xu C and Cao W 2006 Mater Sci. Eng. B-Solid 127 203

Zhang X L, Liu D, Sang Y H, Liu H and Wang J Y 2010 J. Alloys Compd 502 206

Zhang X L, Liu D, Liu H, Wang J Y, Qin H M and Sang Y H 2011 J. Rare Earths 29 585

Acknowledgments

This research was supported by grants from the National Science Foundation of China (Grant No. 21363027) and the Natural Science Foundation of Guangxi Province (No. 2011GXNSFA018060) and the Project Sponsored by the Scientific Research Foundation of GuangXi University (Grant No. XGZ130765).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

JUN, H., QI, P., XIA, L. et al. Luminescence properties of YAG:Nd 3+nano-sized ceramic powders via co-microemulsion and microwave heating. Bull Mater Sci 36, 1191–1194 (2013). https://doi.org/10.1007/s12034-013-0598-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-013-0598-1