Abstract

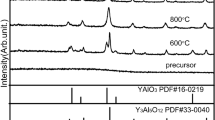

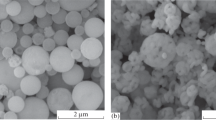

Nano Ce-doped yttrium aluminum garnet (YAG:Ce) phosphor precursor was synthesized using the urea precipitation method, and dispersed submicron YAG:Ce phosphor was prepared using the molten salt method, with fine particle NaCl acting as the salt source. The effects of NaCl particle size on the mixing homogeneity of raw materials, particle morphology, dispersity, and luminescent properties of YAG phosphor were investigated. We found that the mixing homogeneity improved dramatically with a fine (2 µm) NaCl particle. Agglomeration and sintering of the phosphor were significantly reduced, and 200 nm dispersed YAG phosphor can be obtained at 1000 °C. The YAG phosphor obtained with fine NaCl salt also exhibits excellent luminous performance. The YAG phosphor blue light absorption ratio is 38%, and the internal quantum efficiency is 93%. The internal quantum efficiency is superior to YAG phosphors synthesized using commercial large-particle NaCl. These findings provide a new idea for preparing dispersed inorganic powder with fine particle size using the molten salt method.

Similar content being viewed by others

References

W.W. Holloway Jr., M. Kestigian, J. Opt. Soc. Am. (1917–1983) 59, 60–63 (1969)

X. Su, J. Zhou, G. Bai, J. Zhang, P. Zhao, J. Ceram. Int. 42, 17497–17502 (2016)

V. Tucureanu, A. Matei, A.M. Avram, J. Opto-Electron. Rev. 23, 239–251 (2015)

R. Kasuya, T. Isobe, H. Kuma, J. Alloys Compd. 412(2006), 820–823

D. Chen, W. Xiang, X. Liang, J. Zhong, H. Yu, M. Ding, H. Lu, Z. Ji, J. Euro. Ceram. Soc. 35, 859–869 (2015)

Y. Zhou, D. Chen, W. Tian, Z. Ji, J. Am. Ceram. Soc. 98, 2445–2450 (2015)

B.H. King, J.W. Halloran, J. Am. Ceram. Soc. 78, 2141–2148 (1995)

T.A. Parthasarathy, T.I. Mah, K. Keller, J. Am. Ceram. Soc 75, 1756–1759 (1992)

S.C. Huang, J.K. Wu, W.J. Hsu, H.H. Chang, H.Y. Hung, Int. J. Appl. Ceram. Technol. 6, 465–469 (2009)

S.A. Hassanzadeh-Tabrizi, E. Taheri-Nassaj, H. Sarpoolaky, J. Alloys Compd. 456, 282–285 (2008)

F. Qiu, X. Pu, J. Li, X. Liu, Y. Pan, J. Ceram. Int. 31, 663–665 (2005)

L. Wang, F. Zhao, M. Zhang, T. Hou, Z. Li, J. Alloys Compd. 661, 148–154 (2016)

Y. You, L. Qi, X. Li, W. Pan, J. Ceram. Int. 39, 3987–3992 (2013)

J. Cho, K. Jung, Y.J. Chankang, RSC Adv. 5, 8345–8350 (2015)

H.L. Sang, H.Y. Koo, M.L. Su, C.K. Yun, J. Ceram. Int. 36, 611–615 (2010)

Xd Zhang, H. Liu, J.Y. Wang, X. Li, W. He, J. Alloys Compd. 372, 300–303 (2004)

P. Ramanujam, B. Vaidhyanathan, J. Binner, S. Ghanizadeh, C. Spacie, J. Supercrit. Fluids 107, 433–440 (2015)

R. Fazli, M. Fazli, Y. Safaei-Naeini, F. Golestani-Fard, A. Mirhabibi, J. Ceram. Int. 38, 5363–5368 (2012)

A.R. Kamali, D.J. Fray, J. Ceram. Int. 40, 1835–1841 (2014)

X. Wang, J.H. Li, Q.R. Shen, P.L. Shi, J. Ceram. Int. 40, 15313–15317 (2014)

L. Liu, G. Feng, G. Hu, J. Liu, J. Adv. Powder Technol. 25, 219–225 (2014)

Y. Li, H. Ye, H. Liu, Asian J. Chem. 10, 4491–4494 (2012)

C. Wu, A. Luo, G. Du, X. Qin, W. Shi, J. Mater. Sci. Semicond. Process. 16, 679–685 (2013)

W. Liu, G. Hu, K. Du, J. Surf. Coat. Int. 216, 267–272 (2013)

X. Du, S. Zhao, Y. Liu, Z. Peng, Y. Cao, J. Appl. Phys. A 116, 1963–1969 (2014)

J.L. Wu, G. Gundiah, A.K. Cheetham, J. Chem. Phys. Lett. 441, 250–254 (2007)

L. Gan, Z.Y. Mao, F.F. Xu, Y.C. Zhu, X.J. Liu, J. Ceram. Int. 40, 5067–5071 (2014)

Acknowledgements

This work was supported by the Natural Science Foundation for Distinguished Young Scholar of the Jiangsu Province (BK20160073).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, L., Dong, Y., Shao, Q. et al. Preparation of dispersed submicron YAG:Ce3+ phosphors via the molten salt method. J Mater Sci: Mater Electron 29, 5761–5767 (2018). https://doi.org/10.1007/s10854-018-8547-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-8547-9