Abstract

The objective of this work was to study the effect of container orientation on heat transfer during reciprocation agitation thermal processing of cans filled with liquid particulate mixtures. A vertical steam retort, retrofitted with a mechanism to provide horizontal reciprocation of containers, was used in this study. Cans of size 307 × 409, filled with 30 % (v/v) Nylon particles in a Newtonian fluid (100 % glycerin), were placed inside the reciprocating cage with longer axis in one of the three possible orientations viz. horizontal along axis of reciprocation (HA), horizontal perpendicular to axis of reciprocation (HP), or vertical (V). Reciprocation frequency (1–4 Hz) and amplitude (5–25 cm), and container headspace (2–12 mm) were varied according to a full factorial experimental design, and heat transfer coefficients and process times associated with each orientation were calculated. Additional experiments were also carried out in still mode to study the effect of container orientation in static processing mode. Results showed that for the static mode, HA and HP provided more rapid heating than V. For agitation processing, HA provided more rapid heat transfer followed by HP and then V, respectively. Reciprocation frequency and amplitude affected the heat transfer significantly (p < 0.05) in all orientations, while headspace was significant only for HA. An agitation intensity (AI) parameter was defined based on reciprocation frequency and amplitude. An AI value of 3.0 g was found sufficient for HA cans, while HP and V cans required a higher AI of 6.0 g for optimum heat transfer. This study could be used in designing of reciprocation thermal processes with optimal heat transfer delivery.

Similar content being viewed by others

References

Boz, Z., & Erdogdu, F. (2013). Evaluation of two-dimensional approach for computational modelling of heat and momentum transfer in liquid containing horizontal cans and experimental validation. Food and Bioproducts Processing, 91, 37–45.

Deniston, M. F., Hassan, B. H., & Merson, R. L. (1987). Heat transfer coefficients to liquids with food particles in axially rotating cans. Journal of Food Science, 52, 962–979.

Dhayal, P., Chhanwal, N., & Anandharamakrishnan, C. (2013). Heat transfer analysis of sterilization of canned milk using computational fluid dynamics simulations. Journal of Food Science and Engineering, 3, 571–583.

Dimou, Α., Stoforos, N. G., & Yanniotis, S. (2014). Effect of particle orientation during thermal processing of canned peach halves: a CFD simulation. Foods, 3, 304–317.

Dwivedi, M., & Ramaswamy, H. S. (2010). Comparison of heat transfer rates during thermal processing under end-over-end and axial modes of rotation. LWT - Food Science and Technology, 43, 350–360.

Erdogdu, F., & Tutar, M. (2011). Velocity and temperature field characteristics of water and air during natural convection heating in cans. Journal of Food Science, 76, 119–129.

Farid, M., & Ghani, A. G. (2004). A new computational technique for the estimation of sterilization time in canned food. Chemical Engineering and Processing, 43, 523–531.

Garrote, R. L., Silva, E. R., Roa, R. D., & Bertone, R. A. (2006). Heat transfer coefficients to canned green peas during end-over-end sterilisation. International Journal of Food Science and Technology, 41, 1016–1022.

Ghani, A. G., Farid, M. M., & Chen, X. D. (2002). Numerical simulation of transient temperature and velocity profiles in a horizontal can during sterilization using computational fluid dynamics. Journal of Food Engineering, 51, 77–83.

Ghani, A. G., Farid, M. M., & Zarrouk, S. J. (2003). The effect of can rotation on sterilization of liquid food using computational fluid dynamics. Journal of Food Engineering, 57, 9–16.

Hassan, H. F., Ramaswamy, H. S., & Dwivedi, M. (2012). Overall and fluid-to-particle heat transfer coefficients associated with canned particulate non-Newtonian fluids during free bi-axial rotary thermal processing. International Journal of Food Engineering, 8, 1556–3758.

Incropera, F. P., & DeWitt, D. P. (2000). Fundamentals of heat and mass transfer (4th ed.). New York: Wiley.

James, P. W., Hughes, J. P., Jones, T. E. R., & Tucker, G. S. (2006). Numerical simulations of non-isothermal flow in off-axis rotation of a can containing a headspace bubble. Chemical Engineering Research and Design, 84, 311–318.

Joseph, S. J., Speers, R. A., & Pillay, V. (1996). Effect of head space variation and heat treatment on the thermal and rheological properties of nonagitated, conduction-heated materials. LWT - Food Science and Technology, 29, 556–560.

Kannan, A., & Gourisankar Sandaka, P. C. (2008). Heat transfer analysis of canned food sterilization in a still retort. Journal of Food Engineering, 88, 213–228.

Lenz, M. K., & Lund, D. B. (1978). The lethality-fourier number method: heating rate variations and lethality confidence intervals for forced-convection heated foods in containers. Journal of Food Process Engineering, 2, 227–271.

Meng, Y., & Ramaswamy, H. S. (2007a). System variables affecting heat transfer in a canned particle in Newtonian fluid system during end-over-end rotation. LWT - Food Science and Technology, 40, 1240–1245.

Meng, Y., & Ramaswamy, H. S. (2007b). Effect of system variables on heat transfer to canned particulate non-Newtonian fluids during end-over-end rotation. Food and Bioproducts Processing, 85, 34–41.

Mohamed, I. O. (2007). Determination of an effective heat transfer coefficients for can headspace during thermal sterilization process. Journal of Food Engineering, 79, 1166–1171.

Ramaswamy, H. S., & Dwivedi, M. (2011). Effect of process variables on heat-transfer rates to canned particulate Newtonian fluids during free bi-axial rotary processing. Food and Bioprocess Technology, 4(1), 61–79.

Ramaswamy, H. S., & Grabowski, S. (1996). Influence of entrapped air on the heating behavior of a model food packaged in semi-rigid plastic containers during thermal processing. LWT - Food Science and Technology, 29, 82–93.

Ramaswamy, H. S., Abbatemarco, C., & Sablani, S. S. (1993). Heat transfer rates in a canned food model as influenced by processing in an end-over-end rotary steam/air retort. Journal of Food Processing and Preservation, 17, 269–286.

Sablani, S. S., & Ramaswamy, H. S. (1996). Particle heat transfer coefficients under various retort operating conditions with end-over-end rotation. Journal of Food Process Engineering, 19, 403–424.

Sablani, S. S., & Ramaswamy, H. S. (1999). End-over-end agitation processing of cans containing liquid particle mixtures. Influence of continuous versus oscillatory rotation. Journal of Food Science and Technology, 5, 385–389.

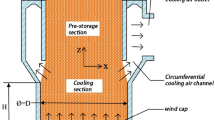

Singh, A. P., Singh, A., & Ramaswamy, H. S. (2015a). Modification of a static steam retort for evaluating heat transfer under reciprocation agitation thermal processing. Journal of Food Engineering, 153, 63–72.

Singh, A., Singh, A. P., & Ramaswamy, H. S. (2015b). A refined methodology for evaluation of heat transfer coefficients in canned particulate fluids under rapid heating conditions. Food and Bioproducts Processing, doi:10.1016/j.fbp.2015.02.005.

Singh, A., Singh, A. P., & Ramaswamy, H. S. (2015c). Computational techniques used in heat transfer studies on canned liquidparticulate mixtures – A review, Trends in Food Science & Technology. Trends in Food Science & Technology, doi:10.1016/j.tifs.2015.02.001.

Stoforos, N. G., & Merson, R. L. (1990). Estimating heat transfer coefficients in liquid/particulate canned foods using only liquid temperature data. Journal of Food Science, 55, 478–483.

Stoforos, N. G., & Merson, R. L. (1991). Measurement of heat transfer coefficients in rotating liquid/particulate systems. Biotechnology Progress, 7, 267–271.

Sun, G., Hewitt, G.F., Wadekar, VV., & Hewitt, G.F. (1994). Heat transfer in horizontal slug flow. Institute of Chemical Engineers, 271–276.

Varma, M. N., & Kannan, A. (2006). CFD studies on natural convective heating of canned food in conical and cylindrical containers. Journal of Food Engineering, 77, 1024–1036.

Walden, R., & Emanuel, J. (2010). Developments in in-container retort technology: the Zinetec Shaka process. In C. J. Doona, K. Kustin, & F. E. Feeherry (Eds.), Case studies in novel food processing technologies: innovation in processing, packaging, and predictive modeling (pp. 359–406). Cambridge: Woodhead Publishing Ltd.

Weng, Z., Hendrickx, M., Maesmans, G., & Tobback, P. (1992). The use of a time temperature integrator in conjunction with mathematical modeling for determining liquid/particle heat transfer coefficients. Journal of Food Engineering, 16, 197–241.

Acknowledgments

This research was partially supported by funds from the Natural Sciences and Engineering Research Council (NSERC) of Canada.

Conflicts of Interest

The authors declare no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, A.P., Ramaswamy, H.S. Effect of Can Orientation on Heat Transfer Coefficients Associated with Liquid Particulate Mixtures During Reciprocation Agitation Thermal Processing. Food Bioprocess Technol 8, 1405–1418 (2015). https://doi.org/10.1007/s11947-015-1500-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-015-1500-5