Abstract

The burgeoning field of high-entropy alloys (HEAs) is underpinned by two foundational concepts, and early research has been motivated by several hypotheses known as “core effects.” The field is now entering its teenage years, and sufficient data have been collected to evaluate these hypotheses and to take a fresh look at the foundational concepts. Although recent assessments have concluded that two of the four HEA hypotheses are not supported by available data, new studies are already coming online to extend these analyses, and new interpretations are inspiring new directions for research within the field. This article gives an up-to-date evaluation of the HEA “core effects” and proposes “nonlinear alloys” as a new strategy to embrace the founding concept of compositional and microstructural vastness.

Similar content being viewed by others

Introduction

High-entropy alloys (HEAs) are entering their teenage years—a time of transition, growth, and an increasing maturity that broadens activities and goals. Robust activity in the formative years has spurred vibrant growth. From an initial focus on single-phase, solid solution microstructures in alloys with five or more principal elements, the field has expanded to include both single-phase and multiphase microstructures containing solid solution phases (SS), intermetallic compounds (IMs), or both, in alloys with as few as three principal elements. The field now incorporates ionic and covalent compounds such as oxides, borides, carbides, and nitrides—not only as a major microstructural constituent but also as the only constituent. Single-phase intermetallic alloys for functional applications are also included. This broader range of compositions, microstructures, and materials is captured in the term “complex concentrated alloys” (CCAs).

The HEA field has already produced a rich dataset against which founding concepts can be evaluated and new theories can be formulated to stimulate future research. The objective of this article is to provide such an assessment. We discuss the two foundational concepts that launched the HEA field and focus on an evaluation of the four HEA “core effects.” Recent assessments have already appeared in the literature;1,2 here we emphasize new data that have come to light since these earlier papers were published and new interpretations that are emerging.

Two Foundational Ideas

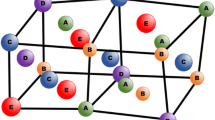

Most new fields are launched by a single major idea, the HEA field has two. The first foundational concept is “to investigate the unexplored central region of multicomponent alloy phase space.”3 This idea focuses on the vast space away from the apexes and edges of multicomponent phase diagrams. This idea places no restrictions on the number or concentrations of elements in the alloys or on the number or types of phases in the microstructures. The second foundational concept is to favor SS phases over IM compounds by controlling the configurational entropy in complex alloys.4,5,6,7,8 A composition-based definition gives HEAs as any alloy with five or more principal elements with atom fractions between 0.05 and 0.35, and an alternative definition gives an HEA as any alloy with an ideal configurational entropy ≥1.5R, where R is the gas constant. Both HEA definitions require a minimum of five principal elements. Since a common motivation is to favor SS phases with “simple” (BCC, FCC, or HCP) crystal structures, HEAs are often assumed to be limited to single-phase SS microstructures even though neither definition sets these requirements.

This second concept has captured the imagination, has motivated most of the work, and has given the field its name. This concept is formalized by the first of four core effects that have been proposed to describe anticipated behaviors of HEAs. These core effects provide hypotheses that can now be evaluated using the wealth of published data.

Four Core Effects

The four HEA core effects are high configurational entropy, sluggish diffusion, lattice distortion, and the cocktail effect. The first three give testable hypotheses, and the fourth is an evocative phrase inspired by Ref. 9 that has helped to launch the field. All four are discussed below.

The High-Entropy Hypothesis

The high-entropy hypothesis proposes that increased configurational entropy in equimolar or near-equimolar alloys with ≥5 elements may noticeably favor single-phase SS microstructures with simple (BCC, FCC, HCP) crystal structures over competing IM compounds. The high-entropy hypothesis generally considers configurational entropy only and uses the Boltzmann equation (S = kln(N)) to model the configurational entropy, S, of an ideal solution of N elements, each at the equimolar concentration. k is Boltzmann’s constant. One approach to evaluating this hypothesis is to consider the fractions of reported HEA microstructures containing only SS, only IM, or both SS + IM phases. This approach implicitly assumes that the alloys studied—and the microstructures produced—represent a random sampling of all HEA systems. However, reported HEAs do not give a random sampling of the hundreds of millions of potential HEA alloy bases, and two recent evaluations have taken a more critical look at reported microstructures.1,2 One of these assessments2 describes six biases in HEA studies: (I) Alloys are usually studied in the as-cast condition; (II) elements and alloys are not randomly selected; (III) studied alloys often have low mixing enthalpies; (IV) contiguity of phase fields in multidimensional phase space; (V) incomplete microstructure characterization; and (VI) inconsistent classification of SS phases. The three most significant biases (I, II, and V) are briefly described as follows.

It is well known that the as-cast condition can produce nonequilibrium microstructures. Analysis of 46 alloys that have been characterized in both as-cast and annealed conditions shows that annealing decreases the number of alloys with only SS phases; increases the number of alloys with both SS + IM phases; decreases the number of single-phase alloys; and increases the number of microstructures with ≥3 phases.2 Roughly 70% of HEAs in the literature are characterized in the as-cast condition, thus giving a clear bias toward solid solutions and a smaller number of phases.

The HEA field is motivated by the study of single-phase SS microstructures, and so elements and alloys are chosen to produce these microstructures and are not selected at random. There is a remarkable focus in the HEA literature on alloys using four or more elements from the palette of Ti, V, Cr, Mn, Fe, Co, Ni, Cu, and Al. Called “3d transition metal HEAs,” this single-alloy family accounted for essentially 100% of the alloys studied through the end of 2010, and it still accounted for about 85% of the alloys studied by the end of 2015. None of these nine elements have the HCP structure at their melting temperature (T m), and so it is not surprising that none of the 3d transition metal HEAs have the HCP structure. Five of these nine elements have the BCC structure at their T m (Ti, V, Cr, Mn, and Fe), but the remaining four elements are FCC and are used more frequently in 3d transition metal HEAs (see Table III in Ref. 2). Thus, it is also not surprising that SS phases in 3d transition metal HEAs most commonly have an FCC structure (see Fig. 10 in Ref. 2). In fact, a direct relationship is shown between the crystal structures of the elements used to produce a set of alloys and the frequency with which SS phases with the same crystal structure are produced. This structure in–structure out (SISO) principle gives a simple, intuitive approach for understanding the types of crystal structures in HEAs by considering the uneven frequency with which different atoms are used in HEAs.2 Alloy datasets that use more FCC elements show more FCC phases, and datasets that use more BCC or HCP elements show more phases with these crystal structures.

This bias also extends to the groupings of elements used to produce alloys. Co, Cr, Fe, and Ni are by far the most commonly used elements in HEAs, and the trinity of Cr-Fe-Ni appeared in 82% of the 3d transition metal HEAs and in nearly 75% of all reported HEAs by the end of 2015. An extended FCC SS phase field is very well known in concentrated Cr-Fe-Ni alloys (austenitic stainless steels and nickel solid solution alloys, some of which also use Mn or Co as principle elements). An overwhelming focus on a group of elements already known to form an extended FCC SS phase thus biases the number of reported HEA microstructures toward this same result. There is nothing wrong with the underlying motivation or the bias it produces, but care is required in evaluating the results. The alloys made to date cannot be considered a random dataset, and the trends observed are not likely to represent the possibilities of the field as a whole.

Finally, superlattice peaks in HEAs seem to be suppressed when using standard x-ray diffraction (XRD) techniques, making it more difficult to distinguish between IM and SS phases. Quite often, microstructures reported to contain only SS phases when using XRD are found to also contain IM phases when using TEM diffraction.1,2

These three biases, and the remaining three discussed in detail elsewhere,2 all have the same effect of increasing the likelihood of reporting microstructures with SS rather than with IM phases and of reducing the actual number of phases. Thus, a simple counting of reported phases is not sufficient to evaluate the high-entropy hypothesis, and more systematic studies coupled with new tools are needed. A classic, systematic experimental study has replaced elements, one at a time, in the well-known “Cantor” alloy, CoCrFeMnNi.10 The substituted atoms have essentially the same radii and electronegativities as the atoms replaced, so that the new alloys should remain a single-phase SS if entropy is controlling the phase selection. Nevertheless, only the initial alloy was a single-phase SS. It was concluded that entropy alone does not control the formation of SS phases, and that both entropy and enthalpy must be considered together.10

Two computational studies explore a vastly broader range of alloys than has been studied experimentally.11,12 Using two different methods for predicting the phases present, both studies come to the same conclusion that increasing the number of constituents, N, decreases the probability of producing single-phase SS microstructures. This is exactly opposite the trend suggested by the high-entropy hypothesis. The physical interpretation of this finding is that the configurational entropy of an alloy cannot be varied independently of other thermodynamic terms such as enthalpy. Increasing N may increase the configurational entropy of an HEA, but it also has direct consequences for the mixing enthalpies of SS phases and for formation enthalpies of IM phases, H IM. From the Boltzmann equation, configurational entropy increases slowly with N (as ln(N)), whereas the number of binary systems increases much more quickly (as (N/2)(N − 1)). Increasing N thus increases the possibility that a pair of atoms will have sufficiently large, negative H IM to outcompete configurational entropy.

The ability for IM compounds with sufficiently negative H IM to overcome configurational entropy was anticipated by the pioneer of the HEA field. In one of the first HEA publications, it was stated that configurational entropy could favor ideal solid solutions over IM compounds “except for those with very large heats of formation, such as strong ceramic compounds: oxides, carbides, nitrides, and silicides.”8 The formation enthalpies of selected carbides, nitrides, silicides, and borides are plotted in Fig. 1 with a histogram of 1055 H IM values, showing that many IM compounds are more stable than ceramic compounds. These highly stable IM compounds are thus likely to outcompete SS phases.

Histograms of 1176 solid solution enthalpies of mixing (H SS) estimated by the Miedema method from Ref. 13 (solutions with H, B, C, N, O, P, and S are excluded in this analysis), and 1055 formation enthalpies for metal–metal and metal–semimetal compounds (H IM) from Refs. 14,15,16,17,18,19,20,21 and assessed for accuracy in Ref. 22. H IM values are often more negative than formation enthalpies of selected borides, carbides, nitrides, and silicides, supporting the early insight that H IM may often overwhelm configurational entropy

Taken as a whole, these considerations support the conclusion that configurational entropy alone does not play a dominant role in forming single-phase SS microstructures with simple crystal structures. Both experimental and computational studies show that entropy and enthalpy must be considered together. Both entropy and enthalpy depend sensitively on alloy constitution, and increasing N increases entropy and increases the possibility of forming an IM compound with H IM sufficiently negative to overcome entropy. The crystal structures of the elements used, and the frequency with which elements are used, also influences the phases found in a family of alloys.

Sluggish Diffusion Hypothesis

Sluggish diffusion was proposed as an HEA core effect as early as 2006,23 but the first diffusion study was not published until 2013.24 Observations that inspired the sluggish diffusion hypothesis included the presence of nanocrystals in as-cast material, elevated recrystallization temperatures, and formation of nanocrystals or amorphous materials in sputter-deposited thin films.23 Assessments of data published prior to 2015 concluded that the sluggish diffusion hypothesis was not supported.1,2 Nevertheless, additional data are becoming available that refine and extend the seminal work by Tsai et al. in 2013. A discussion of these more recent results is given here.

Beke and Erdélyi reanalyze the earlier data using a modified form of the diffusion equation where the temperature, preexponential term (D 0), and the activation enthalpy are all normalized by the arithmetic mean of the liquidus and solidus temperatures.25 This new analysis reconfirms the results of Tsai et al.24

Measuring diffusion in alloys with three or more elements is extremely challenging, and the initial work by Tsai et al. assumed that interdiffusion was equal to tracer diffusion to simplify analysis. Dąbrowa et al. overcome this assumption by using the Darken–Manning analysis coupled with Levenberg–Marquardt or genetic algorithm optimization methods.26 In addition to reanalyzing the data from Tsai et al., new diffusion data were generated in Al-Co-Cr-Fe-Ni alloys. The new analysis of the original data from Tsai et al. gives tracer diffusion coefficients that are essentially equal to the interdiffusion coefficients first reported in Ref. 24. Both analyses give essentially identical D 0 and activation enthalpies for Cr diffusion. Nevertheless, for Co and Mn, the tracer analysis gives activation enthalpies that are about 6% less negative and D 0 values that are about 4 times smaller than the interdiffusion analysis. In Fe and Ni, the differences are even greater—the tracer diffusion analysis gives activation enthalpies that are up to 20% less negative and D 0 terms that are 30–130 times smaller. The Co, Cr, Fe, and Ni tracer diffusion data from CoCrFeMn0.5Ni and Al-Co-Cr-Fe-Ni alloys are the same order of magnitude, but there are important differences in D 0 and activation enthalpies, especially for Co and Ni.

Cross-diffusion is the phenomenon in which a concentration gradient of one element induces or alters the flux of another element.27 This occurs when the presence of one element changes the chemical potential of other elements in the alloy.28 Tsai et al. assumed that cross terms are negligible to facilitate analysis, and Kulkarni and Chauhan evaluate interdiffusion in CoCrFeNi to explore this assumption.29 The Dayananda-Sohn analysis is used to extract the (N − 1)2 interdiffusion coefficients. The main interdiffusion coefficients in CoCrFeNi were found to be the same order of magnitude as the quasi-binary interdiffusion coefficients reported by Tsai et al. in CoCrFeMn0.5Ni. Nonetheless, Kulkarni and Chauhan clearly show that interdiffusion cross-terms can be important and cannot be neglected.

All of the studies discussed measure interdiffusion. Vaidya et al. measure tracer diffusion coefficients in CoCrFeNi and CoCrFeMnNi using the 63Ni isotope.30 The data for 63Ni tracer diffusion in CoCrFeMnNi are essentially identical to the quasi-binary interdiffusion coefficients reported for Ni in CoCrFeMn0.5Ni, validating the earlier work. Vaidya et al. also provide the first experimental data for grain boundary diffusion in HEAs.

From this larger body of work, a consensus is emerging that diffusion and interdiffusion coefficients decrease with increasing N as long as the comparison is done using normalized homologous temperatures, T m/T, rather than 1/T.24,25,30 The temperature of comparison matters, however. Tracer diffusion coefficients in CoCrFeNi and CoCrFeMnNi are equal at 80% T m, and extrapolation to lower T m/T suggests that diffusion in CoCrFeNi will be more rapid than in CoCrFeMnNi.30 It is also becoming established that interdiffusion cross-terms are important and cannot be ignored. As a result, diffusion of a given species can be accelerated or retarded in the presence of a third element, and effects such as “uphill” diffusion (atomic flux “up” the concentration gradient) are observed.26

A mechanistic view of diffusion in HEAs is still evolving. Chemical and thermodynamic considerations can retard (for negative deviations from ideal solutions) or accelerate (for positive deviations from ideal solutions) interdiffusion.29 Increasing the number of components seems to give more negative activation enthalpies as long as the comparison is made using T m/T.24,30 At the same time, reported D 0 values differ by 4 orders of magnitude26,30 and must be considered. These differences may originate from a trapping effect that can alter the correlation factor between atomic jumps25 or from differences in diffusion entropy30 that come from the strain produced at the diffusional saddle point and from local vibrational changes associated with the introduction of a vacancy.28 Local chemical ordering may have an important effect on the diffusional entropy.30 The trends in D 0 and activation enthalpy offset each other, reducing the influence of N on the overall rate of diffusion or interdiffusion.

There is still no consensus on the validity of the sluggish diffusion hypothesis. HEA diffusion is actually faster than in simpler alloys (N = 2–4) when plotting against 1/T, but the opposite trend is observed when comparing against T m/T.2,25,30 Comparisons using T m/T have a solid physical basis with good support31 and are preferred, thus, apparently favoring the sluggish diffusion hypothesis. Support for the hypothesis is only found, however, when HEA diffusion is compared against a small number of elements and simpler alloys.24,25,30 In these studies, HEA diffusion is slower than any of the other materials chosen for comparison, supporting the conclusion that HEA diffusion is “anomalously” or “exceptionally” sluggish. On the other hand, comparison with a wider set of elements and alloys gives a different result.

Figure 2 plots diffusion data for CoCrFeMn0.5Ni with curves for three elements (Co, Fe, Ni) and three simpler alloys. The data are taken from Ref. 24 and are extrapolated to T m/T = 1. Figure 2 also shows a much broader range of diffusion data at T m for 11 FCC elements and 12 different FCC binary alloy systems and dozens of unique compositions.31 The elemental diffusion extends just over 2 orders of magnitude (large pink oval at T m/T = 1), and the small gray oval at T m/T = 1 shows the range of reported HEA diffusion coefficients extrapolated from Ref. 24. An expanded view shows the specific diffusion ranges for the elements and binary systems reported in Ref. 31. This comparison shows that HEA diffusion is slower than average but not the slowest compared with other FCC elements and alloys. Specifically, diffusion in two elements (Pb, Pt) and four binary alloys [Cr-Ni, Ni-W, Cu-Pt, and Ni-Cu (not shown in Fig. 2)] is as slow or slower than in CoCrFeMn0.5Ni at T m/T = 1. This comparison shows that the sluggish diffusion hypothesis is supported if “sluggish” means slower than average. It is not supported if “sluggish” means slower than any other material of the same crystal structure. The words, “anomalous,” “unusual,” or “exceptional” suggest the latter and are not supported by the data available.

Diffusion data for Ni in CoCrFeMn0.5Ni (solid gray circles and solid black line) as a function of inverse homologous temperature, T m/T, taken from Ref. 24 and extrapolated to T m/T = 1. The range of diffusion coefficients for 11 FCC elements and 12 binary alloys is shown at T m by the large pink bubble, and the range in diffusion coefficients for the five elements in CoCrFeMn0.5Ni is shown at T m by the smaller gray bubble at T m/T = 1. The specific diffusion ranges for elements and binary FCC alloys are shown within an expanded view of the larger pink bubble at T m (data taken from Ref. 31). Diffusion in the CoCrFeMn0.5Ni HEA is slower than the typical FCC metal or alloy, but it is not the slowest. Two FCC elements for which data are available (Pt, Pb) and 4 FCC binary alloys (Cr-Ni, Ni-W, Cu-Pt, and Ni-Cu (not shown in Fig. 2)) have diffusion rates as slow or slower than the CoCrFeMn0.5Ni HEA at T m/T = 1

Increasing the number of constituents in an alloy may not only cause diffusion to become sluggish (slower than average), it may also lower T m relative to the constituent elements. These effects are coupled and cannot be separated. For the limited diffusion data currently available, the lower T m seems to have a stronger influence because diffusion appears faster in HEAs than in their constituent elements and simpler alloys when comparison is not normalized by T m. Thus, from a practical perspective where an alloy must resist diffusion at a given application temperature, the “sluggish” diffusion (slower than average compared with other alloys of the same crystal structure at their respective melting temperatures) of HEAs may often be overcome by the lower melting temperature of the HEA.

Lattice Distortion Hypothesis

The lattice distortion hypothesis states that the different sizes of the principal elements will cause atomic level strains with important consequences that include decreasing x-ray diffraction intensity;7,23,32 increasing hardness;23,32 reducing electrical and thermal conductivity;23,32 and reducing the temperature dependence of these properties.23,32 In the extreme, it is proposed that the crystalline lattice will collapse to an amorphous structure.23 Of the three HEA core effects that give a testable hypothesis, the lattice distortion effect has received by far the least amount of systematic study. This may stem from the difficulty in defining the local lattice strain, which requires a reference lattice against which local atom positions can be compared. HEAs do not have a well-defined reference lattice needed to determine these local strains. It is also very difficult to measure the local lattice strains (or, more correctly, local atomic displacements from the “average” lattice points). One approach uses lattice fringes traced on fast Fourier transform images from high-resolution TEM photographs to measure lattice strains.33 This technique shows local distortions, but the atomic interpretation and the consequences of these distortions are not yet clear. Atomic displacement parameters (ADPs) can also be obtained from single-crystal diffraction,33 but the displacements are averaged and do not give atomically local variations.

Attempts to evaluate the influence of lattice distortion are most frequently based on the δr term that gives the composition-weighted average of the difference in elemental radii, r.34 This approach has some success and reasonably separates SS from amorphous alloys, especially when used with the enthalpy of mixing35 or other parameters.36 Nevertheless, δr gives a single value for an entire alloy, but local distortions depend on the size of the atom occupying a given site and the sizes of atoms in the first shell surrounding that site, which can vary considerably throughout a structure.

It is physically reasonable to accept that HEA lattices are distorted, and so future studies are needed to determine how much distortion occurs, to evaluate local variations in distortion, and to establish the effect of these distortions on properties. Current experimental and modeling tools (lattice fringes, ADPs, δr parameter) are likely to give new insights, especially when combined. The effect of lattice distortions thus far seems to have been limited to exploring the boundary between crystalline and amorphous structures, and future studies are needed to evaluate the effects on other properties such as diffraction intensity and strengthening. Such studies need to isolate other influences on the properties being measured. For example, diffraction intensity depends on atomic cross sections and strengthening is influenced by stacking fault energies and the shear moduli of constituent atoms. All of these properties depend sensitively on alloy constitution, and so isolating the effect of lattice distortion is expected to be a major challenge.

The Cocktail Effect

The idea of “multi-metallic cocktails” was published before the first HEA paper, and it was used to describe three distinct materials: bulk metallic glasses (BMGs), “gum” metals, and HEAs.9 A clear definition of the cocktail effect is not given in that publication, but the idea was initially intended to mean “a pleasant, enjoyable mixture” and later came to mean a synergistic mixture where the end result is unpredictable and greater than the sum of the parts.37 This synergy and unpredictability is a cornerstone of many eccentric and exciting materials. In addition to BMGs, gum metals, and HEAs, these unusual materials also include alloys with a near-zero coefficient of thermal expansion, quasi-crystals, photo-voltaic materials, and thermo-electric compounds. The cocktail effect is not a testable hypothesis, but it nevertheless has had a profound influence on the HEA field. This simple, evocative phrase has motivated new research and has inspired new thoughts. It reminds us to remain open to the intoxicating possibilities that may yet be found in the vast and still unexplored regions of alloy space. In a discipline built on knowledge, it reminds us of the excitement of the unexplored, the unexpected, and the yet unknown.

Discussion

The HEA field has two founding concepts, and the early years have focused on exploring the role of configurational entropy. Although it has been found that configurational entropy alone does not dominate phase selection in HEAs, the community has nevertheless shown that configurational entropy must be considered on equal terms with mixing and formation enthalpies. When considered together with enthalpy, compositional engineering can produce deliberate configurational disorder capable of altering phase transformations and giving new phases. This result has been shown most directly in high-entropy oxides.38 This new perspective overturns many decades of neglect, where enthalpies have been the primary focus and the role of configurational entropy has never been systematically evaluated in phase selection. Establishing the role of configurational entropy as an adjustable parameter in phase engineering gives a more balanced, mature perspective that is a major success from the early HEA years.

The second HEA foundational concept—exploring the vast unknown central regions of complex compositions and microstructures—has barely been scratched and remains a major motivation for research in the “teenage years.” This continues a trend seen in the early years. From a strong initial focus on a single alloy family based on 3d transition metals, work in more recent years has exploded to include six completely new alloy bases.2 An initial emphasis on single-phase SS microstructures has grown to include single-phase IM microstructures; single-phase oxides, borides, nitrides and carbides; and multiphase microstructures with any number of SS, IM, and/or ceramic phases. Finally, the field has expanded to explore not only structural but also functional materials.2 The groundwork has thus been laid during the HEA formative years to embrace the compositional and microstructural vastness offered by CCAs.

New alloy bases built from new and unexpected combinations of elements are a key component to exploring the foundational concept of vastness. These new alloys will be inspired by scientific phenomena (such as solid solution hardening or lattice distortion) or an exceptional balance of useful properties, such as high-temperature strength, high specific strength, or thermo-electric performance. The first generation of HEAs in the formative years represent intuitive, “linear” combinations of similar elements, such as 3d transition metal alloys, refractory metal alloys, low-density alloys, precious metal alloys, and 4f transition metal alloys. Like an elemental mutation in a genetic algorithm, the next generation will explore “nonlinear alloys” built from unexpected combinations of elements. As one example from the HEA formative years, Al is frequently used, even in alloy bases where it is an obvious outsider. Specifically, an alloy with a high T m need not contain only elements with high T m, and it can include one or two elements of moderate or even low T m. The use of Al or Si in high-temperature structural alloys is a well-known case-in-point for conventional Ti-based and Ni-based alloys. Additions of 3d transition metals (several of which are base elements in conventional high-temperature alloys) as principal elements in refractory metal CCAs with high T m is another obvious extension of this “nonlinear alloying” concept that has not yet been tried. In functional materials, the iso-structure substitution approach only considers elements that form the same crystal structure as the desired compound, but HEA results show that other elements can be used. Expanding this idea, nonlinear alloys can be explored broadly, intentionally, and systematically to tap into the full potential of the vastness concept. Element selection cannot be done randomly, and must be guided by the best computational and experimental tools available.

Summary

Four core effects are linked to the HEA field, giving three testable hypotheses: the high-entropy hypothesis, the sluggish diffusion hypothesis, and the lattice distortion hypothesis. Sufficient data have been collected in the HEA formative years to evaluate two of these hypotheses. Data from several sources and different types of evaluations all conclude that configurational entropy alone does not play a dominant role in forming single-phase, solid-solution (SS) microstructures with simple crystal structures. A main reason for this result is that the alloying strategy used to increase configurational entropy (increasing the number of principle elements, N) also introduces new enthalpy terms that must be considered and may overcome S. Although the high-entropy hypothesis is not supported, it has nevertheless had a major positive influence by showing that, when considered jointly with enthalpy terms, configurational disorder can be engineered to produce new phases with unusual and useful properties.

Increasing N gives a modest decrease in the diffusion rate, D, relative to simpler alloys when compared at the same inverse homologous temperature, T m/T Nevertheless, increasing N also generally decreases T m. As a result, D in HEAs is higher than in simpler alloys when compared at the same T. The decrease in D at a given T m/T is small, and it is usually overcome by the influence of N on T m. Thus, decreasing T m is a dominant effect that cannot be ignored or separated from the influence of N on D. We conclude that the sluggish diffusion hypothesis is supported only if the following two conditions are met: Comparison is done at the same T m/T, and “sluggish” means slower than average but not unusually or exceptionally slow (that is, slower than any other element/alloy with the same crystal structure). Supporting this conclusion, several FCC elements and binary alloys have D at T m as slow or slower than D in FCC HEAs. As an important caveat, HEA diffusion data are extremely limited and more data are needed.

Controlled, systematic studies of lattice distortion are still missing, and this is a direction for future research. The cocktail effect is different from the other core effects because it is not an hypothesis, but it has nevertheless had a substantial influence on the community.

The founding concept of compositional and microstructural vastness has hardly been explored and remains a potent motivation for exploration in “the teenage years” of the field. The intentional, systematic pursuit of “nonlinear alloys” is suggested as a keystone for studies exploring the vastness concept in the next generation. New models, new knowledge, and new computational and experimental tools are required to support these new directions.

References

E.J. Pickering and N.G. Jones, Int. Mater. Rev. 61, 183 (2016).

D.B. Miracle and O.N. Senkov, Acta Mater. 122, 448 (2017).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213 (2004).

T.K. Chen, T.T. Shun, J.-W. Yeh, and M.S. Wong, Surf. Coat. Technol. 188–189, 193 (2004).

C.-Y. Hsu, J.-W. Yeh, S.-K. Chen, and T.-T. Shun, Metall. Mater. Trans. A 35A, 1465 (2004).

P.-K. Huang, J.-W. Yeh, T.-T. Shun, and S.-K. Chen, Adv. Eng. Mater. 6, 74 (2004).

J.-W. Yeh, S.-K. Chen, J.-W. Gan, S.-J. Lin, T.-S. Chin, T.-T. Shun, C.-H. Tsau, and S.-Y. Chang, Metall. Mater. Trans. A 35A, 2533 (2004).

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, and S.-Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

S. Ranganathan, Curr. Sci. 85, 1404 (2003).

F. Otto, Y. Yang, H. Bei, and E.P. George, Acta Mater. 61, 2628 (2013).

O.N. Senkov, J.D. Miller, D.B. Miracle, and C. Woodward, Nat. Commun. 6, 6529 (2015).

M.C. Troparevsky, J.R. Morris, P.R.C. Kent, A.R. Lupini, and G.M. Stocks, Phys. Rev. X 5, 011041 (2015).

A. Takeuchi and A. Inoue, Intermetallics 18, 1779 (2010).

R. Hultgren, R.L. Orr, P.D. Anderson, and K.K. Kelley, Selected Values of Thermodynamic Properties of Metals and Alloys (New York: Wiley, 1963).

F.R. de Boer, B. Boom, W.C.M. Mattens, A.R. Miedema, and A.K. Niessen, Cohesion in Metals: Transition Metal Alloys (Amsterdam: The Netherlands, Elsevier Science Publishers, 1989).

C. Colinet, J. Alloys Compd. 225, 409 (1995).

S. Fries and T. Jantzen, Thermochim. Acta 314, 23 (1998).

Q. Guo and O.J. Kleppa, J. Alloys Compd. 269, 181 (1998).

Q. Guo and O.J. Kleppa, J. Alloys Compd. 321, 169 (2001).

P. Franke, D. Neuschutz, and W. Martienssen, eds., Landolt-Bornstein Numerical Data and Functional Relationships in Science and Technology: Group IV: Physical Chemistry (Berlin: Springer-Verlag, 2002).

O. Kubaschewski, C.B. Alcock, and P.J. Spencer, Materials Thermochemistry, 6th ed. (Oxford: Pergamon Press, 1993).

D.B. Miracle, J.D. Miller, O.N. Senkov, C. Woodward, M.D. Uchic, and J. Tiley, Entropy 16, 494 (2014).

J.-W. Yeh, Ann. Chim. Sci. Mater. 31, 633 (2006).

K.-Y. Tsai, M.-H. Tsai, and J.-W. Yeh, Acta Mater. 61, 4887 (2013).

D.L. Beke and G. Erdélyi, Mater. Lett. 164, 111 (2016).

J. Dabrowa, W. Kucza, G. Cieslak, T. Kulik, M. Danielewski, and J.-W. Yeh, J. Alloys Compd. 674, 455 (2016).

V.K. Vanag and I.R. Epstein, Phys. Chem. Chem. Phys. 11, 897 (2009).

P.G. Shewmon, Diffusion in Solids (New York: McGraw-Hill Book Co., 1963).

K. Kulkarni and G.P.S. Chauhan, AIP Adv. 5, 097162 (2015).

M. Vaidya, S. Trubel, B.S. Murty, G. Wilde, and S.V. Divinski, J. Alloys Compd. 688, 994 (2016).

A.M. Brown and M.F. Ashby, Acta Metall. 28, 1085 (1980).

B.S. Murty, J.-W. Yeh, and S. Ranganathan, High-Entropy Alloys (Oxford: Butterworth-Heinemann, 2014).

Y. Zou, S. Maiti, W. Steurer, and R. Spolenak, Acta Mater. 65, 85 (2014).

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Adv. Eng. Mater. 10, 534 (2008).

S. Guo, Q. Hu, C. Ng, and C.T. Liu, Intermetallics 41, 96 (2013).

X. Yang and Y. Zhang, Mater. Chem. Phys. 132, 233 (2012).

S. Ranganathan, Personal communication (Bangalore: Indian Institute of Science, 2015).

C.M. Rost, E. Sachet, T. Borman, A. Moballegh, E.C. Dickey, D. Hou, J.L. Jones, S. Curtarolo, and J.-P. Maria, Nat. Commun. 6, 8485 (2015).

Acknowledgements

The author gratefully acknowledges support from the Air Force Research Laboratory, Materials and Manufacturing Directorate.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miracle, D.B. High-Entropy Alloys: A Current Evaluation of Founding Ideas and Core Effects and Exploring “Nonlinear Alloys”. JOM 69, 2130–2136 (2017). https://doi.org/10.1007/s11837-017-2527-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2527-z