Abstract

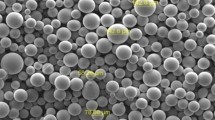

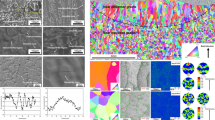

In this work, a near-beta Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloy was fabricated by selective laser melting (SLM), and the microstructure evolution together with the mechanical properties was studied. The as-fabricated alloy showed columnar β grains spreading over multiple layers and paralleling to the building direction. The distinct microstructure of as-fabricated alloy was composed of near-β (more than 98.1 %) with a submicron cellular structure. Different SLM processing parameters such as hatch spacing could affect the microstructure of as-fabricated alloy, which could thus further significantly affect the mechanical properties of as-fabricated alloy. In addition, the as-fabricated alloy with the distinct microstructure exhibits yield strength of 818 MPa combined with elongation of more than 19 %, which shows that SLM is a potential technology for manufacturing near-beta titanium components.

摘要

本文采用选择性激光熔融法制备了Ti-5Al-5Mo-5V-1Cr-1Fe 近β钛合金, 并研究了Ti-5Al-5Mo5V-1Cr-1Fe 合金在打印过程的组织演变和力学性能。Ti-5Al-5Mo-5V-1Cr-1Fe 合金组织为近β钛合金 (相含量大于98.1%)且在β晶粒内部存在大量亚微米级的晶胞组织, β柱状晶平行于构建方向。扫描间 距、扫描功率等选择性激光熔融工艺参数显著影响Ti-5Al-5Mo-5V-1Cr-1Fe 合金的微观组织和力学性 能。制备的Ti-5Al-5Mo-5V-1Cr-1Fe 合金屈服强度为818 MPa, 伸长率超过19%, 表明选择性激光熔 融法是一种有潜力的近β钛零件制造技术。

Similar content being viewed by others

References

GU D D, MEINERS W, WISSENBACH K, POPRAWE R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms [J]. International Materials Reviews, 2012, 57(3): 133–164. DOI: https://doi.org/10.1179/1743280411Y.0000000014.

DUTTA B, FROES F H. Additive manufacturing of titanium alloys [M]. Oxford: Butterworth-Heinemann Elsevier, 2016. DOI: https://doi.org/10.1016/B978-0-12-804782-8.00005-7.

LI Neng, HUANG Shuai, ZHANG Guo-dong, QIN Ren-yao, LIU Wei, XIONG Hua-ping, SHI Gong-qi, BLACKBURN J. Progress in additive manufacturing on new materials: A review [J]. Journal of Materials Science & Technology, 2019, 35(2): 242–269. DOI: https://doi.org/10.1016/j.jmst.2018.09.002.

STOLT R, ELGH F. Introducing design for selective laser melting in aerospace industry [J]. Journal of Computational Design and Engineering, 2020, 7(4): 489–497. DOI: https://doi.org/10.1093/jcde/qwaa042.

LIU Min, LIU Shi-chao, CHEN Wei, CHEN Chao, LV Yaping, ZHANG Xiao-yong, LEI Peng-fei, LIN Yong-cheng, ZHOU Ke-chao. Effect of trace lanthanum hexaboride on the phase, grain structure, and texture of electron beam melted Ti6Al-4V [J]. Additive Manufacturing, 2019, 30: 100873. DOI: https://doi.org/10.1016/j.addma.2019.100873.

ZHANG Qi, LIANG Zheng-long, CAO Miao, LIU Zi-fan, ZHANG An-feng, LU Bing-heng. Microstructure and mechanical properties of Ti6Al4V alloy prepared by selective laser melting combined with precision forging [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(5): 1036–1042. DOI: https://doi.org/10.1016/S1003-6326(17)60121-3.

GUO Kuai-kuai, LIU Chang-sheng, CHEN Sui-yuan, DONG Huan-huan, WANG Si-yu. High pressure EIGA preparation and 3D printing capability of Ti-6Al-4V powder [J]. Transactions of Nonferrous Metals Society of China, 2020, 30(1): 147–159. DOI: https://doi.org/10.1016/S1003-6326(19)65187-3.

THIJS L, VERHAEGHE F, CRAEGHS T, HUMBEECK J V, KRUTH J P. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V [J]. Acta Materialia, 2010, 58(9): 3303–3312. DOI: https://doi.org/10.1016/j.actamat.2010.02.004.

ZHAO Xiao-li, LI Shu-jun, ZHANG Man, LIU Yan-dong, SERCOMBE T B, WANG Shao-gang, HAO Yu-lin, YANG Rui, MURR L E. Comparison of the microstructures and mechanical properties of Ti-6Al-4V fabricated by selective laser melting and electron beam melting [J]. Materials & Design, 2016, 95: 21–31. DOI: https://doi.org/10.1016/j.matdes.2015.12.135.

NEIKTER M, WORACEK R, MAIMAITIYILI T, SCHEFFZÜK C, STROBL M, ANTTI M L, ÅKERFELDT P, PEDERSON R, BJERKÉN C. Alpha texture variations in additive manufactured Ti-6Al-4V investigated with neutron diffraction [J]. Additive Manufacturing, 2018, 23: 225–234. DOI: https://doi.org/10.1016/j.addma.2018.08.018.

YU Han-chen, YANG Jing-jing, YIN Jie, WANG Ze-min, ZENG Xiao-yan. Comparison on mechanical anisotropies of selective laser melted Ti-6Al-4V alloy and 304 stainless steel [J]. Materials Science and Engineering A, 2017, 695: 92–100. DOI: https://doi.org/10.1016/j.msea.2017.04.031.

RAFI H K, KARTHIK N V, GONG Hai-jun, STARR T L, STUCKER B E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting [J]. Journal of Materials Engineering and Performance, 2013, 22(12): 3872–3883. DOI: https://doi.org/10.1007/s11665-013-0658-0.

YANG Jing-jing, YU Han-chen, YIN Jie, GAO Ming, WANG Ze-min, ZENG Xiao-yan. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting [J]. Materials & Design, 2016, 108: 308–318. DOI: https://doi.org/10.1016/j.matdes.2016.06.117.

MISHRA A K, KUMAR A. Numerical and experimental analysis of the effect of volumetric energy absorption in powder layer on thermal-fluidic transport in selective laser melting of Ti6Al4V [J]. Optics & Laser Technology, 2019, 111: 227–239. DOI: https://doi.org/10.1016/j.optlastec.2018.09.054.

CHEN Cai-yan, GU Dong-dong, DAI Dong-hua, DU Lei, WANG Rui, MA Cheng-long, XIA Mu-jian. Laser additive manufacturing of layered TiB2/Ti6Al4V multi-material parts: Understanding thermal behavior evolution [J]. Optics & Laser Technology, 2019, 119: 105666. DOI: https://doi.org/10.1016/j.optlastec.2019.105666.

ATTAR H, LÖBER L, FUNK A, CALIN M, ZHANG L C, PRASHANTH K G, SCUDINO S, ZHANG Y S, ECKERT J. Mechanical behavior of porous commercially pure Ti and Ti-TiB composite materials manufactured by selective laser melting [J]. Materials Science and Engineering A, 2015, 625: 350–356. DOI: https://doi.org/10.1016/j.msea.2014.12.036.

ATTAR H, BÖNISCH M, CALIN M, ZHANG L C, ZHURAVLEVA K, FUNK A, SCUDINO S, YANG C, ECKERT J. Comparative study of microstructures and mechanical properties of in situ Ti-TiB composites produced by selective laser melting, powder metallurgy, and casting technologies [J]. Journal of Materials Research, 2014, 29(17): 1941–1950. DOI: https://doi.org/10.1557/jmr.2014.122.

LI Zhen, TIAN Xiang-jun, TANG Hai-bo, WANG Hua-ming. Low cycle fatigue behavior of laser melting deposited TC18 titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(9): 2591–2597. DOI: https://doi.org/10.1016/S1003-6326(13)62772-7.

LIU C M, WANG H M, TIAN X J, TANG H B, LIU D. Microstructure and tensile properties of laser melting deposited Ti-5Al-5Mo-5V-1Cr-1Fe near β titanium alloy [J]. Materials Science and Engineering A, 2013, 586: 323–329. DOI: https://doi.org/10.1016/j.msea.2013.08.032.

LIU Y J, WANG H L, LI S J, WANG S G, WANG W J, HOU W T, HAO Y L, YANG R, ZHANG L C. Compressive and fatigue behavior of beta-type titanium porous structures fabricated by electron beam melting [J]. Acta Materialia, 2017, 126: 58–66. DOI: https://doi.org/10.1016/j.actamat.2016.12.052.

QIU Chun-lei, RAVI G A, ATTALLAH M M. Microstructural control during direct laser deposition of a β-titanium alloy [J]. Materials & Design, 2015, 81: 21–30. DOI: https://doi.org/10.1016/j.matdes.2015.05.031.

XIE Le-chun, GUO Hao-jie, SONG Yan-li, LIU Chang, WANG Zhong-qi, HUA Lin, WANG Li-qiang, ZHANG Laichang. Effects of electroshock treatment on microstructure evolution and texture distribution of near-β titanium alloy manufactured by directed energy deposition [J]. Materials Characterization, 2020, 161: 110137. DOI: https://doi.org/10.1016/j.matchar.2020.110137.

MANTRI S A, BANERJEE R. Microstructure and microtexture evolution of additively manufactured β-Ti alloys [J]. Additive Manufacturing, 2018, 23: 86–98. DOI: https://doi.org/10.1016/j.addma.2018.07.013.

SCHWAB H, PALM F, KÜHN U, ECKERT J. Microstructure and mechanical properties of the near-beta titanium alloy Ti-5553 processed by selective laser melting [J]. Materials & Design, 2016, 105: 75–80. DOI: https://doi.org/10.1016/j.matdes.2016.04.103.

QIU Chun-lei, LIU Qi. Multi-scale microstructural development and mechanical properties of a selectively laser melted beta titanium alloy [J]. Additive Manufacturing, 2019, 30: 100893. DOI: https://doi.org/10.1016/j.addma.2019.100893.

LIU Y J, LI S J, WANG H L, HOU W T, HAO Y L, YANG R, SERCOMBE T B, ZHANG L C. Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting [J]. Acta Materialia, 2016, 113: 56–67. DOI: https://doi.org/10.1016/j.actamat.2016.04.029.

VRANCKEN B, THIJS L, KRUTH J P, VAN HUMBEECK J. Microstructure and mechanical properties of a novel β titanium metallic composite by selective laser melting [J]. Acta Materialia, 2014, 68: 150–158. DOI: https://doi.org/10.1016/j.actamat.2014.01.018.

CHEN Wei, CHEN Chao, ZI Xu-hui, CHENG Xiao-fan, ZHANG Xiao-yong, LIN Yong-cheng, ZHOU Ke-chao. Controlling the microstructure and mechanical properties of a metastable β titanium alloy by selective laser melting [J]. Materials Science and Engineering A, 2018, 726: 240–250. DOI: https://doi.org/10.1016/j.msea.2018.04.087.

LIU Y J, ZHANG Y S, ZHANG L C. Transformation-induced plasticity and high strength in beta titanium alloy manufactured by selective laser melting [J]. Materialia, 2019, 6: 100299. DOI: https://doi.org/10.1016/j.mtla.2019.100299.

ZHOU Li-bo, YUAN Tie-chui, TANG Jian-zhong, HE Jian-jun, LI Rui-di. Mechanical and corrosion behavior of titanium alloys additively manufactured by selective laser melting-A comparison between nearly β titanium, α titanium and α+β titanium [J]. Optics & Laser Technology, 2019, 119: 105625. DOI: https://doi.org/10.1016/j.optlastec.2019.105625.

IVASISHIN O M, MARKOVSKY P E, MATVIYCHUK Y V, SEMIATIN S L, WARD C H, FOX S. A comparative study of the mechanical properties of high-strength β-titanium alloys [J]. Journal of Alloys and Compounds, 2008, 457(1, 2): 296–309. DOI: https://doi.org/10.1016/j.jallcom.2007.03.070.

SINGH P, PUNGOTRA H, KALSI N S. On the characteristics of titanium alloys for the aircraft applications [J]. Materials Today: Proceedings, 2017, 4(8): 8971–8982. DOI: https://doi.org/10.1016/j.matpr.2017.07.249.

BOYER R R. An overview on the use of titanium in the aerospace industry [J]. Materials Science and Engineering A, 1996, 213(1, 2): 103–114. DOI: https://doi.org/10.1016/0921-5093(96)10233-1.

AHMED T, RACK H J. Phase transformations during cooling in α+β titanium alloys [J]. Materials Science and Engineering A, 1998, 243(1, 2): 206–211. DOI: https://doi.org/10.1016/S0921-5093(97)00802-2.

BANERJEE D, WILLIAMS J C. Perspectives on titanium science and technology [J]. Acta Materialia, 2013, 61(3): 844–879. DOI: https://doi.org/10.1016/j.actamat.2012.10.043.

WEISS I, SEMIATIN S L. Thermomechanical processing of beta titanium alloys—An overview [J]. Materials Science and Engineering A, 1998, 243(1, 2): 46–65. DOI: https://doi.org/10.1016/S0921-5093(97)00783-1.

MOISEYEV V N. Titanium alloys: Russian aircraft and aerospace application [M]. Boca Raton: CRC Press, 2005: 75–77. DOI: https://doi.org/10.1201/9781420037678.

XU W, BRANDT M, SUN S, ELAMBASSERIL J, LIU Q, LATHAM K, XIA K, QIAN M. Additive manufacturing of strong and ductile Ti-6Al-4V by selective laser melting via in situ martensite decomposition [J]. Acta Materialia, 2015, 85: 74–84. DOI: https://doi.org/10.1016/j.actamat.2014.11.028.

NI Mang, CHEN Chao, WANG Xiao-jun, WANG Peng-wei, LI Rui-di, ZHANG Xiao-yong, ZHOU Ke-chao. Anisotropic tensile behavior of in situ precipitation strengthened Inconel 718 fabricated by additive manufacturing [J]. Materials Science and Engineering A, 2017, 701: 344–351. DOI: https://doi.org/10.1016/j.msea.2017.06.098.

CARROLL B E, PALMER T A, BEESE A M. Anisotropic tensile behavior of Ti-6Al-4V components fabricated with directed energy deposition additive manufacturing [J]. Acta Materialia, 2015, 87: 309–320. DOI: https://doi.org/10.1016/j.actamat.2014.12.054.

ZHANG Ming-kang, YANG Yong-qiang, WANG Di, XIAO Ze-feng, SONG Chang-hui, WENG Chang-wei. Effect of heat treatment on the microstructure and mechanical properties of Ti6AUV gradient structures manufactured by selective laser melting [J]. Materials Science and Engineering A, 2018, 736: 288–297. DOI: https://doi.org/10.1016/j.msea.2018.08.084.

HOZOORBAKHSH A, ISMAIL M I S, AZIZ N B A. A computational analysis of heat transfer and fluid flow in high-speed scanning of laser micro-welding [J]. International Communications in Heat and Mass Transfer, 2015, 68: 178–187. DOI: https://doi.org/10.1016/j.icheatmasstransfer.2015.08.013.

LE T N, LO Y L. Effects of sulfur concentration and Marangoni convection on melt-pool formation in transition mode of selective laser melting process [J]. Materials & Design, 2019, 179: 107866. DOI: https://doi.org/10.1016/j.matdes.2019.107866.

LUO Lei, MAO Xiao-nan, YANG Guan-jun, NIU Rong-rong. Brief Introduction for BT22 titanium alloy [J]. Material & Heat Treatment, 2009, 38(14): 14–16. DOI: https://doi.org/10.14158/j.cnki.1001-3814.2009.14.038. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project(2019B010943001) supported by Key-area Research and Development Program of Guangdong Province, China; Project(2020) supported by the Fund of State Key Laboratory of Powder Metallurgy, Central South University, China

Contributors

CHEN Chao provided the concept and edited the draft of manuscript. HUANG Hua-long conducted the literature review and wrote the first draft of the manuscript. LI Dan and LIU Shi-chao analyzed the measured data. LI Rui-di, ZHANG Xiao-yong, and ZHOU Ke-chao edited the draft of manuscript. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Huang, Hl., Li, D., Chen, C. et al. Selective laser melted near-beta titanium alloy Ti-5Al-5Mo-5V-1Cr-1Fe: Microstructure and mechanical properties. J. Cent. South Univ. 28, 1601–1614 (2021). https://doi.org/10.1007/s11771-021-4720-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4720-z

Key words

- selective laser melting

- Ti-5Al-5Mo-5V-1Cr-1Fe

- near-β and β-titanium alloy

- cellular structure

- precipitation