Abstract

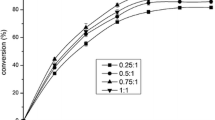

Biodiesel is conventionally produced by alkaline-catalyzed transesterification, which requires high-purity oils. However, low-quality oils can be used as feedstocks for the production of biodiesel by enzyme-catalyzed reactions. The use of enzymes has several advantages, such as the absence of saponification side reactions, production of high-purity glycerol co-product, and low-cost downstream processing. In this work, biodiesel was produced from lipase-catalyzed hydrolysis of waste cooking oil (WCO) followed by esterification of the hydrolyzed WCO (HWCO). The hydrolysis of acylglycerols was carried out at 30 °C in salt-free water (WCO/water ratio of 1:4, v/v) and the esterification of HWCO was carried out at 40 °C with ethanol in a solvent-free medium (HWCO/ethanol molar ratio of 1:7). The hydrolysis and esterification steps were carried out using immobilized Thermomyces lanuginosus lipase (TLL/WCO ratio of 1:5.6, w/w) and immobilized Candida antarctica lipase B (10 wt%, CALB/HWCO) as biocatalysts, respectively. The hydrolysis of acylglycerols was almost complete after 12 h (ca. 94 %), and in the esterification step, the conversion was around 90 % after 6 h. The purified biodiesel had 91.8 wt% of fatty acid ethyl esters, 0.53 wt% of acylglycerols, 0.003 wt% of free glycerol, viscosity of 4.59 cP, and acid value of 10.88 mg KOH/g. Reuse hydrolysis and esterification assays showed that the immobilized enzymes could be recycled five times in 10-h batches, under the conditions described above. TLL was greatly inactivated under the assay conditions, whereas CALB remained fully active. The results showed that WCO is a promising feedstock for use in the production of biodiesel.

Similar content being viewed by others

References

Ranganathan SV, Narasimhan SL, Muthukumar K (2008) An overview of enzymatic production of biodiesel. Bioresour Technol 99:3975–3981

Patil PD, Gude VG, Reddy HK, Muppaneni T, Deng S (2012) Biodiesel production from waste cooking oil using sulfuric acid and microwave irradiation process. J Environ Protec 3:107–113

Tan T, Lu J, Nie K, Deng L, Wang F (2010) Biodiesel production with immobilized lipase: a review. Biotechnol Adv 28:628–634

Ma F, Hanna MA (1999) Biodiesel production: a review. Bioresour Technol 70:1–15

Canakci M, Gerpen JV (2001) Biodiesel production from oils and fats with high free fatty acids. Am Soc Agric Eng 44:1429–1436

Ting W-J, Huang C-M, Nair GR, Wu W-T (2008) An enzymatic/acid-catalyzed hybrid process for biodiesel production from soybean oil. J Chin Inst Chem Eng 39:203–210

Kaieda M, Samukawa T, Matsumoto T, Ban K, Kondo A, Shimada Y, Noda H, Nomoto F, Ohtsuka K, Izumoto E, Fukuda H (1999) Biodiesel fuel production from plant oil catalyzed by Rhizopus oryzae lipase in a water-containing system without an organic solvent. J Biosci Bioeng 88:627–631

Aguieiras ECG, Cavalcanti-Oliveira ED, Castro AM, Langone MAP, Freire DMG (2014) Biodiesel production from Acrocomia aculeata acid oil by (enzyme/enzyme) hydroesterification process: use of vegetable lipase and fermented solid as low-cost biocatalysts. Fuel 135:315–321

Hernández-Martín E, Otero C (2008) Different enzyme requirements for the synthesis of biodiesel: Novozym® 435 and Lipozyme® TL IM. Bioresour Technol 99:277–286

Watanabe Y, Nagao T, Nishida Y, Takagi Y, Shimada Y (2007) Enzymatic production of fatty acid methyl esters by hydrolysis of acid oil followed by esterification. J Am Oil Chem Soc 84:1015–1021

Talukder MdMR, Wu JC, NgM Fen, Melissa YLS (2010) Two-step lipase catalysis for production of biodiesel. Biochem Eng J 49:207–212

Talukder MdMR, Wu JC, Chua LP-L (2010) Conversion of waste cooking oil to biodiesel via enzymatic hydrolysis followed by chemical esterification. Energy Fuel 24:2016–2019

Cavalcanti-Oliveira ED, Silva PR, Ramos AP, Aranda DAG, Freire DMG (2011) Study of soybean oil hydrolysis catalyzed by Thermomyces lanuginosus lipase and its application to biodiesel production via hydroesterification. Enzym Res. doi:10.4061/2011/618692

de Sousa JS, Cavalcanti-Oliveira ED, Aranda DAG, Freire DMG (2010) Application of lipase from the physic nut (Jatropha curcas L.) to a new hydrid (enzyme/chemical) hydroesterification process for biodiesel production. J Mol Catal B Enzym 65:133–137

Soares D, Pinto AF, Gonçalves AG, Mitchell DA, Krieger N (2013) Biodiesel production from soybean soapstock acid oil by hydrolysis in subcritical water followed by lipase-catalyzed esterification using a fermented solid in a packed-bed reactor. Biochem Eng J 81:15–23

Lotero E, Liu Y, Lopez DE, Suwannakarn K, Bruce DA, Goodwin JG (2005) Synthesis of biodiesel via acid catalysis. Ind Eng Chem Res 44:5353–5363

Salis A, Svensson I, Monduzzi M, Solinas V, Adlercreutz P (2003) The atypical lipase B from Candida antarctica is better adapted for organic media than typical lipase from Thermomyces lanuginosa. Biochim Biophys Acta 1646:145–151

AOCS Official Method Cd 3-25: Saponification value - revised 2013 (2013) In: Firestone D (ed) Official methods and recommended pratices of the AOCS, 6th edn. (3rd Printing). AOCS Press, Urbana.

AOCS Official Method Ca 5a-40: free fatty acids - revised 2012 (2013) In: Firestone D (ed) Official methods and recommended pratices of the AOCS, 6th edn. (3rd Printing). AOCS Press, Urbana.

AOCS Official Method Ca 2c-25: moisture and volatile matter air oven method -reapproved 2009 (2013) In: Firestone D (ed) Official methods and recommended pratices of the AOCS, 6th edn. (3rd Printing). AOCS Press, Urbana.

AOCS Official Method Ce 2-66: preparation of methyl esters of fatty acids - reapproved 2009 (2013) In: Firestone D (ed) Official methods and recommended pratices of the AOCS, 6th edn. (3rd Printing). AOCS Press, Urbana.

ISO 5508 (1990) Animal and vegetable fats and oils—analysis by gas chromatography of methyl esters of fatty acid. International Standard, Switzerland

EN 14103 (2011) Fat and oil derivatives—fatty acid methyl esters (FAME)—determination of ester and linolenic acid methyl ester contents

ASTM D6584 (2013) Standard test method for determination of total monoglycerides, total diglycerides, total triglycerides, and free and total glycerol in B-100 biodiesel methyl esters by gas chromatography. ASTM International, 2013

Freire PCM, Mancini-Filho J, Ferreira TAPC (2013) Major physical and chemical changes in oils and fats used for deep frying: regulation and effects on health. Rev Nutr 26:353–368

Rodrigues RC, Volpato G, Wada K, Ayub MAS (2008) Enzymatic synthesis of biodiesel from transesterification reaction of vegetable oils and short chain alcohols. J Am Oil Chem Soc 85:925–930

Lipase enzymes (2016) Novozymes, Denmark. http://www.novozymes.com/en/solutions/pharmaceuticals/biocatalysis/lipase-enzymes. Acessed 21 Sep 2016.

Du W, Xu Y-Y, Liu D-H, Li Z-B (2005) Study of acyl migration in immobilized lipozyme TL-catalyzed transesterification of soybean oil for biodiesel production. J Mol Catal B-Enzym 37:68–71

Fernandez-Lafuente R (2010) Lipase from Thermomyces lanuginosus: uses and prospects as an industrial biocatalyst. J Mol Catal B Enzym 62:197–212

Lima LN, Oliveira GC, Rojas MJ, Castro HF, Da Rós PCM, Mendes AA, Giordano RLC, Tardioli PW (2015) Immobilization of Pseudomonas fluorescens lipase on hydrophobic supports and application in biodiesel synthesis by transesterification of vegetable oils in solvent-free systems. J Ind Microbiol Biotechnol 42:523–535

Shimada Y, Watanabe Y, Sugihara A, Tominaga Y (2002) Enzymatic alcoholysis for biodiesel fuel production and application of the reaction oil processing. J Mol Catal B Enzym 17:133–142

Nie K, Xie F, Wang F, Tan T (2006) Lipase catalyzed methanolysis to produce biodiesel: optimization of the biodiesel production. J Mol Catal B Enzym 43:142–147

ANP Resolution No. 14 of 11/05/2012. National agency of petroleum, natural gas and biofuels (ANP), Brazil. http://nxt.anp.gov.br/nxt/gateway.dll/leg/resolucoes_anp/2012/maio/ranp%2014%20-%202012.xml. Accessed 24 Feb 2015

Acknowledgments

The authors are grateful for the financial support provided by the São Paulo Research Foundation (FAPESP, grant #2011/23194-0), National Council for Scientific and Technological Development (CNPq), and Improvement Commission of Higher Level Personnel (CAPES).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

About this article

Cite this article

Vescovi, V., Rojas, M.J., Baraldo, A. et al. Lipase-Catalyzed Production of Biodiesel by Hydrolysis of Waste Cooking Oil Followed by Esterification of Free Fatty Acids. J Am Oil Chem Soc 93, 1615–1624 (2016). https://doi.org/10.1007/s11746-016-2901-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-016-2901-y