Abstract

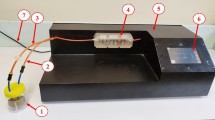

Presented work addresses the development and application of artificial olfactory (e-nose) as an efficient nondestructive handheld system to extract quality attributes of variety of orange cultivars at various cultivated lands. An ARM-9 (S3C2440 controller) based advance embedded electronic nose system has been developed for on-site odor acquisition, processing and ripeness level prediction for various orange cultivars. Developed handheld electronic nose system is light weight, low power, and easy operable to every consumer. Various statistical multivariate data analysis techniques (PCA, LDA, QDA, and KNN) implementation on electronic nose measurements helped estimating optimal harvest dates for various orange cultivars. Developed handy system has been optimized in the sense of selectivity, sensitivity of gas sensors using the implementation of temperature control for heating element of the gas sensors. Various temperature, humidity models also have been developed to improve the performance of developed system in different environmental conditions. Data acquisition process has been performed using developed system for 100 orange samples have two different cultivars (mandarin and sweet orange). Extracted parameters have been subjected towards supervised Levenberg–Marquardt back-propagation algorithm to training and testing of developed handheld electronic nose system to predict quality parameters of oranges. A good correlation has been found between developed handheld electronic nose system signals and quality attributes indicators and it shows that system can successfully detect and predict various quality parameters of orange samples. Results of developed handheld electronic nose system have been validated with commercial standard electronic nose Alpha Fox 3000 system and it has been observed that efficiency varies around 94 ± 0.3 %.

Similar content being viewed by others

References

C. Li, Sensor fusion models to integrate electronic nose and surface acoustic wave sensor for apple quality evaluation (The Pennsylvania State University, State College, 2006)

Hongmei Zhang, Jun Wang, Evaluation of peach quality attributes using an electronic nose. Sens. Mater 21, 419–431 (2009)

M.L.A.T.M. Hertog et al. Non-destructive techniques and quality models for the supply chain: a review. XXVII International Horticultural Congress-IHC2006: International Symposium on the Role of Postharvest Technology in the 768 (2006)

S. Saevels et al., Electronic nose as a non-destructive tool to evaluate the optimal harvest date of apples. Postharvest Biol Technol 30(1), 3–14 (2003)

S. Saevels et al., An electronic nose and a mass spectrometry-based electronic nose for assessing apple quality during shelf life. Postharvest Biol Technol 31(1), 9–19 (2004)

A.H. Gomez et al., Discrimination of storage shelf-life for mandarin by electronic nose technique. LWT-Food Sci Technol 40(4), 681–689 (2007)

S. Zampolli et al., An electronic nose based on solid state sensor arrays for low-cost indoor air quality monitoring applications. Sens. Actuators B 101(1), 39–46 (2004)

H. Guohua et al., Study of peach freshness predictive method based on electronic nose. Food Control 28(1), 25–32 (2012)

Simon M. Scott, David James, Zulfiqur Ali, Data analysis for electronic nose systems. Microchim. Acta 156(3-4), 183–207 (2006)

E.Z. Panagou et al., Table olives volatile fingerprints: Potential of an electronic nose for quality discrimination. Sens. Actuators B 134(2), 902–907 (2008)

H. Zhang et al., Evaluation of peach quality indices using an electronic nose by MLR, QPST and BP network. Sens. Actuators B 134(1), 332–338 (2008)

L.P. Pathange et al., Non-destructive evaluation of apple maturity using an electronic nose system. Journal of Food Engineering 77(4), 1018–1023 (2006)

A.H. Abdullah et al. Hand-held electronic nose sensor selection system for basal stamp rot (BSR) disease detection. Third IEEE International Conference on Intelligent Systems, Modelling and Simulation (ISMS), 2012

C.-J. Du, D.-W. Sun, Learning techniques used in computer vision for food quality evaluation: a review. J. Food Eng. 72(1), 39–55 (2006)

J. Brezmes et al., Correlation between electronic nose signals and fruit quality indicators on shelf-life measurements with pinklady apples. Sens. Actuators B 80(1), 41–50 (2001)

J.P. Santos, M. Aleixandre, C. Cruz, Hand held electronic nose for VOC detection. Chem. Eng. 30 (2012). doi:10.3303/CET1230031

A.H. Gómez et al., Electronic nose technique potential monitoring mandarin maturity. Sens. Actuators B 113(1), 347–353 (2006)

J. Brezmes et al., Evaluation of an electronic nose to assess fruit ripeness. Sens. J., IEEE 5(1), 97–108 (2005)

S.N. Jha et al., Quality parameters of mango and potential of non-destructive techniques for their measurement—a review. J. Food Sci. Technol. 47(1), 1–14 (2010)

C. Di Natale et al., Sorting of apricots with computer screen photoassisted spectral reflectance analysis and electronic nose. Sens. Actuators B 119(1), 70–77 (2006)

S. Benedetti et al., Electronic nose as a non-destructive tool to characterise peach cultivars and to monitor their ripening stage during shelf-life. Postharvest Biol. Technol. 47(2), 181–188 (2008)

A.Z. Berna et al., Relating sensory analysis with electronic nose and headspace fingerprint MS for tomato aroma profiling. Postharvest Biol. Technol. 36(2), 143–155 (2005)

H. Yu et al., Quality grade identification of green tea using the eigenvalues of PCA based on the E-nose signals. Sens. Actuators B 140(2), 378–382 (2009)

H. Yu et al., Identification of green tea grade using different feature of response signal from E-nose sensors. Sens. Actuators B 128(2), 455–461 (2008)

R.N. Bleibaum et al., Comparison of sensory and consumer results with electronic nose and tongue sensors for apple juices. Food Qual. Prefer. 13(6), 409–422 (2002)

B.G. Kermani, S.S. Schiffman, H.T. Nagle, Performance of the Levenberg–Marquardt neural network training method in electronic nose applications. Sens. Actuators B 110(1), 13–22 (2005)

M. Padilla et al., Drift compensation of gas sensor array data by orthogonal signal correction. Chemometr. Intell. Lab. Syst. 100(1), 28–35 (2010)

H. Zhang et al., Application of electronic nose and statistical analysis to predict quality indices of peach. Food Bioprocess Technol. 5(1), 65–72 (2012)

G. Hui et al., Winter jujube (Zizyphus jujuba Mill.) quality forecasting method based on electronic nose. Food Chem. 170, 484–491 (2015)

Bo Zhou, Jun Wang, Use of electronic nose technology for identifying rice infestation by Nilaparvata lugens. Sens. Actuators B 160(1), 15–21 (2011)

H. Guohua et al., Fuji apple storage time predictive method using electronic nose. Food Anal. Methods 6(1), 82–88 (2013)

Bo Zhou, Jun Wang, Discrimination of different types damage of rice plants by electronic nose. Biosyst. Eng. 109(4), 250–257 (2011)

L. Wei, H. Guohua, Kiwi fruit (Actinidia chinensis) quality determination based on surface acoustic wave resonator combined with electronic nose. Bioengineered 6(1), 53–61 (2015)

Q. Dong et al., A novel bioelectronic nose based on brain–machine interface using implanted electrode recording in vivo in olfactory bulb. Biosens. Bioelectron. 49, 263–269 (2013)

H. Guohua et al., Study of grass carp (Ctenopharyngodon idellus) quality predictive model based on electronic nose. Sens. Actuators B 166, 301–308 (2012)

D. Wang et al., Characterization of a modified surface acoustic wave sensor used in electronic nose for potential application in breath diagnosis. Sens. Lett. 9(2), 884–889 (2011)

Acknowledgments

Author is grateful to CSIR-CEERI, Director Dr. Chandra Shekhar for providing an opportunity to develop such kind of project in CSIR-CEERI as well as allowing us to publish this work. Thanks are due to AEG team members who helped us in successful completion of and installation of Handheld E-Nose food quality detection system.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srivastava, S., Sadisatp, S. Development of a low cost optimized handheld embedded odor sensing system (HE-Nose) to assess ripeness of oranges. Food Measure 10, 1–15 (2016). https://doi.org/10.1007/s11694-015-9270-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-015-9270-3