Abstract

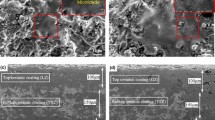

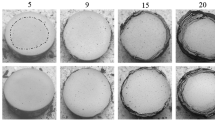

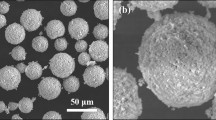

The infiltration of molten CMAS in thermal barrier coatings (TBCs) at high temperature is significantly affected by the microstructure of the ceramic coating. Enhancing the bonding ratio between splats can reduce the interconnected pores and suppress the infiltration of the molten CMAS into the coating. In this study, a dual-layered (DL) TBC with the dense 8YSZ on the top of the conventional porous 8YSZ was proposed to enhance CMAS corrosion of atmospheric plasma-sprayed YSZ. The dense YSZ coating with improved lamellar bonding was deposited at a higher deposition temperature. The microstructure of the coatings before and after CMAS attack test was characterized by scanning electron microscopy. It was clearly revealed that by adjusting the microstructure and applying a dense ceramic layer with the improved interface bonding on the top of porous TBC, the infiltration of CMAS into porous YSZ coating can be effectively suppressed. Moreover, by designing DL TBCs, the thermal conductivity of the TBC system exhibits a limited increase. Thus with the design of DL structure, the TBCs with high CMAS corrosion resistance and low thermal conductivity can be achieved.

Similar content being viewed by others

References

N.P. Padture, M. Gell, and E.H. Jordan, Thermal Barrier Coatings for Gas-Turbine Engine Applications, Science, 2002, 296, p 280-284

C.U. Hardwickre and Y.C. Lau, Advances in Thermal Spray Coatings for Gas Turbines and Energy Generation: A Review, J. Therm. Spray Technol., 2013, 22(5), p 564-576

A. Feuerstein, J. Knapp, T. Taylor, A. Ashary, A. Bolcavage, and N. Hitchman, Technical and Economical Aspects of Current Thermal Barrier Coating Systems for Gas Turbine Engines by Thermal Spray and EBPVD, A Review, J. Therm. Spray Technol., 2008, 17(2), p 199-213

R. McPherson, A Model for the Thermal Conductivity of Plasma-Sprayed Ceramic Coatings, Thin Solid Films, 1984, 112, p 89-95

R. McPherson, A Review on Microstructure and Properties of Plasma Sprayed Ceramic Coatings, Surf. Coat. Technol., 1989, 39-40, p 173-181

R. McPherson, The Relationship Between the Mechanism of Formation, Microstructure and Properties of Plasma-Sprayed Coatings, Thin Solid Films, 1981, 83, p 297-310

A.G. Evans, M.Y. He, and J.W. Hutchinson, Mechanics-Based Scaling Laws for the Durability of Thermal Barrier Coatings, Prog. Mater. Sci., 2001, 46, p 249-271

A.G. Evans, D.R. Mumm, J.W. Hutchinson, G.H. Meier, and F.S. Pettit, Mechanisms Controlling the Durability of Thermal Barrier Coatings, Prog. Mater. Sci., 2001, 46, p 505-553

S. Kramer, J. Yang, and C. Levi, Thermochemical Interaction of Thermal Barrier Coatings with Molten CaO-MgO-Al2O3-SiO2 (CMAS) Deposits, J. Am. Ceram. Soc., 2006, 89, p 3167-3175

C. Mercer, S. Faulhaber, A.G. Evans, and R. Darolia, A Delamination Mechanism for Thermal Barrier Coatings Subject to Calcium-Magnesium-Alumino-Silicate (CMAS) Infiltration, Acta Mater., 2005, 53, p 1029-1039

L.H. Gao, H.B. Guo, S.K. Gong, and H.B. Xu, Plasma-Sprayed La2Ce2O7 Thermal Barrier Coatings Against Calcium-Magnesium-Alumina-Silicate Penetration, J. Eur. Ceram. Soc., 2014, 34, p 2553-2561

B.S. Senturk, H.F. Garces, A.L. Ortiz, G. Dwivedi, S. Sampath, and N.P. Padture, CMAS-Resistant Plasma Sprayed Thermal Barrier Coatings Based on Y2O3-Stabilized ZrO2 with Al3+ and Ti4+ Solute Additions, J. Therm. Spray Technol., 2014, 23(4), p 708-715

W.H. Li, H.Y. Zhao, X.H. Zhong, L. Wang, and S.Y. Tao, Air Plasma-Sprayed Yttria and Yttria Stabilized Zirconia Thermal Barrier Coatings Subjected to Calcium-Magnesium-Alumino-Silicate (CMAS), J. Therm. Spray Technol., 2014, 23(6), p 975-983

R.A. Pidani, R.S. Razavi, R. Mozafarinia, and H. Jamali, Improving the Hot Corrosion Resistance of Plasma Sprayed Ceria-Yttria Stabilized Zirconia Thermal Barrier Coatings by Laser Surface Treatment, Mater. Des., 2014, 57, p 336-341

R. Ghasemi, R.S. Razavi, R. Mozafarinia, H. Jamali, M.H. Oghaz, and R.A. Pidani, The Influence of Laser Treatment on Hot Corrosion Behavior of Plasma-Sprayed Nanostructured Yttria Stabilized Zirconia Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2014, 34, p 2013-2021

P. Mohan, B. Yao, T. Patterson, and Y.H. Sohn, Electrophoretically Deposited Alumina as Protective Overlay for Thermal Barrier Coatings Against CMAS Degradation, Surf. Coat. Technol., 2009, 204, p 797-801

T. Liu, E.J. Yang, C.X. Li, and C.-J. Li, Splat Interface Bonding Formation During Plasma Spraying of LZO Coating, Mater. Res. Innov., 2014, 18, p 973-978

S. Hao, C.-J. Li, and G.J. Yang, Influence of Deposition Temperature on the Microstructures and Properties of Plasma-Sprayed Al2O3 Coatings, J. Therm. Spray Technol., 2010, 20, p 160-169

Y.Z. Xing, C.-J. Li, Q. Zhang, C.X. Li, and G.J. Yang, Influence of Microstructure on the Ionic Conductivity of Plasma-Sprayed Yttria-Stabilized Zirconia Deposits, J. Am. Ceram. Soc., 2008, 91, p 3931-3936

S.L. Zhang, C.X. Li, C.-J. Li, Z.H. Han, and G.J. Yang, Scandia-Stabilized Zirconia Electrolyte with Improved Interlamellar Bonding by High-Velocity Plasma Spraying for High Performance Solid Oxide Fuel Cells, J. Power. Sour., 2013, 232, p 123-131

A. Kulkarni, Z. Wang, T. Nakamura, S. Sampath, A. Goland, H. Herman, J. Allen, J. Ilavsky, G. Long, J. Frahm, and R.W. Steinbrech, Comprehensive Microstructural Characterization and Predictive Property Modeling of Plasma-Sprayed Zirconia Coatings, Acta Mater., 2003, 51, p 2457-2475

G.J. Yang, C.X. Li, S. Hao, Y.Z. Xing, E.J. Yang, and C.-J. Li, Critical Bonding Temperature for the Splat Bonding Formation during Plasma Spraying of Ceramic Materials, Surf. Coat. Technol., 2013, 235, p 841-847

J. Wu, H.B. Guo, Y.Z. Gao, and S.K. Gong, Microstructure and Thermo-Physical Properties of Yttria Stabilized Zirconia Coatings with CMAS Deposits, J. Eur. Ceram. Soc., 2011, 31, p 1881-1888

R.A. Miller, J.L. Smialek, and P.G. Garlick, Phase Stability in Plasma-Sprayed, Partially Stabilized Zirconia-Yttria, Adv. Ceram., 1981, 3, p 241-253

W.J. Parker, R.J. Jenkins, C.P. Butler, and G.L. Abbott, Flash Method of Determining Thermal Diffusivity, Heat Capacity and Thermal Conductivity, J. Appl. Phys., 1961, 32, p 1679-1684

X.Q. Cao, R. Vassen, and D. Stoever, Ceramic Materials for Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2004, 24, p 1-10

N. Markocsan, P. Nylen, J. Wigren, X.H. Li, and A. Tricoire, Effect of Thermal Aging on Microstructure and Functional Properties of Zirconia-Base Thermal Barrier Coatings, J. Therm. Spray Technol., 2009, 18(2), p 160-169

R. Bolot, J.H. Qiao, G. Bertrand, P. Bertrand, and C. Coddet, Effect of Thermal Treatment on the Effective Thermal Conductivity of YPSZ Coatings, Surf. Coat. Technol., 2010, 205, p 1034-1038

R. Dutton, R. Wheeler, K.S. Ravichandran, and K. An, Effect of Heat Treatment on the Thermal Conductivity of Plasma-Sprayed Thermal Barrier Coatings, J. Therm. Spray Technol., 1999, 9(2), p 204-209

G. Bertrand, P. Bertrand, P. Roy, C. Rio, and R. Mevrel, Low Conductivity Plasma Sprayed Thermal Barrier Coating Using Hollow psz Spheres: Correlation Between Thermophysical Properties and Microstructure, Surf. Coat. Technol., 2008, 202, p 1994-2001

C.-J. Li, Y. Li, G.J. Yang, and C.X. Li, A Novel Plasma-Sprayed Durable Thermal Barrier Coating with a Well-Bonded YSZ Interlayer Between Porous YSZ and Bond Coat, J. Therm. Spray Technol., 2012, 21, p 383-390

E. Bakan, D.E. Mack, G. Mauer, R. Mucke, and R. Vassen, Porosity-Property Relationships of Plasma-Sprayed Gd2Zr2O7/YSZ Thermal Barrier Coatings, J. Am. Ceram. Soc., 2015. doi:10.1111/jace.13611

G.J. Yang, Z.L. Chen, C.X. Li, and C.J. Li, Microstructural and Mechanical Property Evolutions of Plasma-Sprayed YSZ Coating During High-Temperature Exposure: Comparison Study Between 8YSZ and 20YSZ, J. Therm. Spray Technol., 2013, 22(8), p 1294-1302

Acknowledgments

The present project is supported by the National Basic Research Program (Grant No. 2012CB625100) and National Natural Science Foundation (Grant No. 51171144). The authors are grateful for the support of the European Program Marie Curie IPACTS (No. 268696).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, T., Yao, SW., Wang, LS. et al. Plasma-Sprayed Thermal Barrier Coatings with Enhanced Splat Bonding for CMAS and Corrosion Protection. J Therm Spray Tech 25, 213–221 (2016). https://doi.org/10.1007/s11666-015-0345-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0345-9