Abstract

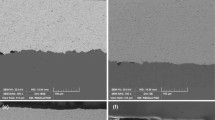

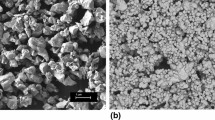

Tribomechanical properties of nanostructured coatings deposited by suspension high velocity oxy-fuel (S-HVOF) and conventional HVOF (Jet Kote) spraying were evaluated. Nanostructured S-HVOF coatings were obtained via ball milling of the agglomerated and sintered WC-12Co feedstock powder, which were deposited via an aqueous-based suspension using modified HVOF (TopGun) process. Microstructural evaluations of these hardmetal coatings included transmission electron microscopy, x-ray diffraction, and scanning electron microscopy equipped with energy dispersive x-ray spectroscopy. The nanohardness and modulus of the coated specimens were investigated using a diamond Berkovich nanoindenter. Sliding wear tests were conducted using a ball-on-flat test rig. Results indicated that low porosity coatings with nanostructured features were obtained. High carbon loss was observed, but coatings showed a high hardness up to 1000 HV2.9N. S-HVOF coatings also showed improved sliding wear and friction behavior, which were attributed to nanosized particles reducing ball wear in three-body abrasion and support of metal matrix due to uniform distribution of nanoparticles in the coating microstructure.

Similar content being viewed by others

References

P. Fauchais, G. Montavon, R.S. Lima, and B.R. Marple, Engineering a New Class of Thermal Spray Nano-based Microstructures from Agglomerated Nanostructured Particles, Suspension and Solutions: An Invited Review, J. Phys. D, 2011, 44, p 093001

J. Oberste Berghaus, B. Marple, and C. Moreau, Suspension Plasma Spraying of Nanostructured WC-12Co Coatings, J. Therm. Spray Technol., 2006, 15(4), p 676-681

V. Chawla, B.S. Sidhu, D. Puri, and S. Prakash, State of Art: Plasma Sprayed Nanostructured Coatings: A Review, Mater. Forum, 2008, 32, p 137-143

Z.Z. Fang, X. Wang, T. Ryu, K.S. Hwang, and H.Y. Sohn, Synthesis, Sintering, and Mechanical Properties of Nanocrystalline Cemented—A Review, Int. J. Refract. Met. Hard Mater., 2009, 27(2), p 288-299

L.-M. Berger, Comprehensive Hard Materials, Hardmetals, Vol 1, V. Sarin, D. Mari, L. Llanes, and C. Nebel, Ed., Elsevier, Amsterdam, 2014, p 479-514

V. Stoica, R. Ahmed, T. Itsukaichi, and S. Tobe, Sliding Wear Evaluation of HIPed Thermal Spray Cermet Coatings, Wear, 2004, 257(11), p 1103-1124

S. Stewart, R. Ahmed, and T. Itsukaichi, Rolling Contact Fatigue of Post-treated WC-NiCrBSi Thermal Spray Coatings, Surf. Coat. Technol., 2005, 190(2-3), p 171-189

R. Ahmed and M. Hadfield, Mechanisms of Fatigue Failure in Thermal Spray Coatings, J. Therm. Spray Technol., 2002, 11(3), p 333-349

Š. Houdková, F. Zahálka, M. Kašparová, and L.-M. Berger, Comparative Study of Thermally Sprayed Coatings Under Different Types of Wear Conditions for Hard Chromium Replacement, Tribol. Lett., 2011, 43(2), p 139-154

F.-L. Toma, L.-M. Berger, C.C. Stahr, T. Naumann, and S. Langner, Microstructures and Functional Properties of Suspension-Sprayed Al2O3 and TiO2 Coatings: An Overview, J. Therm. Spray Technol., 2010, 19(1-2), p 262-274

V. Bonache, M.D. Salvador, J.C. García, E. Sánchez, and E. Bannier, Influence of Plasma Intensity on Wear and Erosion Resistance of Conventional and Nanometric WC-Co Coatings Deposited by APS, J. Therm. Spray Technol., 2011, 20(3), p 549-559

E. Sánchez, E. Bannier, M.D. Salvador, V. Bonache, J.C. García, J. Morgiel, and J. Grzonka, Microstructure and Wear Behavior of Conventional and Nanostructured Plasma-Sprayed WC-Co Coatings, J. Therm. Spray Technol., 2010, 19(5), p 964-974

G. Bolelli, V. Cannillo, L. Lusvarghi, R. Rosa, A.V. Wanhuk, B. Choib, R. Dey, C. Weyant, and S. Sampath, Functionally Graded WC-Co/NiAl HVOF Coatings for Damage Tolerance, Wear and Corrosion Protection, Surf. Coat. Technol., 2012, 206(8-9), p 2585-2601

H. Chen, G. Gou, M. Tu, and Y. Liu, Research on the Friction and Wear Behavior at Elevated Temperature of Plasma-Sprayed Nanostructured WC-Co Coatings, J. Mater. Eng. Perform., 2010, 19(1), p 1-6

H.L. de Villiers Lovelock, Powder/Processing/Structure Relationship in WC-Co Thermal Spray Coatings: A Review of the Published Literature, J. Therm. Spray Technol., 1998, 7(3), p 357-373

S. Stewart and R. Ahmed, Contact Fatigue Failure Modes in Hot Isostatically Pressed WC-12%Co Coatings, Surf. Coat. Technol., 2003, 172(2-3), p 204-216

V. Stoica and R. Ahmed, Influence of Vacuum Heat Treatment on Sliding Wear of Thermal Spray Cermet Coatings, Surf. Coat. Technol., 2005, 199(1), p 7-21

V. Stoica, R. Ahmed, and S. Tobe, Wear of Hot Isostatically Pressed (HIPed) Thermal Spray Cermet Coatings, J. Therm. Spray Technol., 2004, 13(1), p 93-107

P. Chivavibul, M. Watanabe, S. Kuroda, and K. Shinoda, Effects of Carbide Size and Co Content on the Microstructure and Mechanical Properties of HVOF-Sprayed WC-Co Coatings, Surf. Coat. Technol., 2007, 202(3), p 509-521

J. He and J.M. Schoenung, Nanostructured Coatings, Mater. Sci. Eng. A, 2002, 336, p 274-319

R. Ahmed, N.H. Faisal, A.M. Paradowska, M.E. Fitzpatrick, and K.A. Khor, Neutron Diffraction Residual Strain Measurements in Nanostructured Hydroxyapatite Coatings for Orthopaedic Implants, J. Mech. Behav. Biomater., 2011, 4(8), p 2043-2054

F. Tarasi, “Suspension Plasma Sprayed Alumina-Yttria Stabilized Zirconia Nanocomposite Thermal Barrier Coatings-Formation and Roles of the Amorphous Phase,” Ph.D. Thesis, Concordia University, 2010

P. Fauchais and G. Montavon, Latest Developments in Suspension and Liquid Precursor Thermal Spraying, J. Therm. Spray Technol., 2010, 19(1-2), p 226-239

P. Fauchais and A. Vardelle, Innovative and Emerging Processes in Plasma Spraying: From Micro-to Nanostructured Coatings, J. Phys. D, 2011, 44, p 194011

A.S.M. Ang and C.C. Berndt, A Review of Testing Methods for Thermal Spray Coatings, Int. Mater. Rev., 2014, 59(4), p 179-223

M. Couto, S. Dosta, M. Torrell, J. Fernández, and J.M. Guilemany, Cold Spray Deposition of WC-17 and 12Co Cermets onto Aluminum, Surf. Coat. Technol., 2013, 235, p 54-61

J.M. Guilemany, S. Dosta, J. Nin, and J.R. Miguel, Study of the Properties of WC-Co Nanostructured Coatings Sprayed by High-Velocity Oxy Fuel, J. Therm. Spray Technol., 2005, 14(3), p 405-413

Z.-G. Ban and L.L. Shaw, Characterization of Thermal Sprayed Nanostructured WC-Co Coatings Derived from Nanocrystalline WC-18wt.%Co Powders, J. Therm. Spray Technol., 2003, 12, p 112-119

F.-L. Toma, L.-M. Berger, S. Scheitz, S. Langner, C. Rödel, A. Potthoff, V. Sauchuk, and M. Kusnezoff, Comparison of the Microstructural Characteristics and Electrical Properties of Thermally Sprayed Al2O3 Coatings from Aqueous Suspensions and Feedstock Powders, J. Therm. Spray Technol., 2012, 21(3-4), p 480-488

L.-M. Berger, F.-L. Toma, and A. Potthoff, Thermal Spraying with Suspensions—An Economic Spray Process, Therm. Spray Bull., 2013, 6(2), p 98-101

F.-L. Toma, L.-M. Berger, S. Langner, and T. Naumann, Suspension Spraying-The Potential of a New Spray Technology, Therm. Spray Bull., 2010, 3(1), p 24-29

A. Killinger, M. Kuhn, and R. Gadow, High-Velocity Suspension Flame Spraying (HVSFS), a New Approach for Spraying Nanoparticles with Hypersonic Speed, Surf. Coat. Technol., 2006, 201(5), p 1922-1929

A. Killinger, R. Gadow, A. Rempp, and A. Manzat, Advanced Ceramic Tribological Layers by Thermal Spray Routes, Adv. Sci. Technol., 2010, 66, p 106-119

K. Korpiola, “High Temperature Oxidation of Metal, Alloy and Cermet Powders in HVOF Spraying Process,” Dissertation, Helsinki University of Technology, 2006

N.H. Faisal, J.A. Steel, R. Ahmed, and R.L. Reuben, The Use of Acoustic Emission (AE) to Characterise Vickers Indentation Behaviour of HVOF Thermally Sprayed WC-12%Co Coatings, J. Therm. Spray Technol., 2009, 18(4), p 525-535

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7, p 1564-1583

S. Osawa, T. Itsukaichi, and R. Ahmed, Influence of Powder Size and Strength on HVOF Spraying—Mapping the Onset of Spitting, Advancing the Science and Applying the Technology, International Thermal Spray Conference, FL, USA, 2003, p 819-824

S. Thiele, K. Sempf, K. Jaenicke-Roessler, L.-M. Berger, and J. Spatzier, Thermophysical and Microstructural Studies on Thermally Sprayed Tungsten Carbide-Cobalt Coatings, J. Therm. Spray Technol., 2011, 20(1-2), p 358-365

C. Verdon, A. Karimi, and J.-L. Martin, A Study of High Velocity Oxy-Fuel Thermally Sprayed Tungsten Carbide Based Coatings. Part 1: Microstructures, Mater. Sci. Eng., 1998, A246(1-2), p 11-24

D.A. Stewart, P.H. Shipway, and D.G. McCartney, Microstructural Evolution in Thermally Sprayed WC-Co Coatings: Comparison Between Nanocomposite and Conventional Starting Powders, Acta Mater., 2000, 48(7), p 1593-1604

A.S. Kurlov and A.I. Gusev, Tungsten Carbides and W-C Phase Diagram, Neorganicheskie Materialy, 2006, 42(2), p 156-163, [in Russian] [Inorganic Materials, 2006, 42(2), p 121-127, in English]

R. Ahmed, H. Yu, L. Edwards, and J. Santisteban, Neutron Diffraction Residual Strain Measurements in Post-treated Thermal Spray Cermet Coatings, Mater. Sci. Eng. A, 2008, 498, p 191-202

Acknowledgments

Authors acknowledge the support of Youssef Elakwah at Alfaisal University KSA in conducting the nanoindentation experiments. Irina Shakhverdova (Fraunhofer IWS) is thanked for support in evaluation of XRD pattern. Financial support of Saudi Aramco for the research project is also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmed, R., Faisal, N.H., Al-Anazi, N.M. et al. Structure Property Relationship of Suspension Thermally Sprayed WC-Co Nanocomposite Coatings. J Therm Spray Tech 24, 357–377 (2015). https://doi.org/10.1007/s11666-014-0174-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0174-2