Abstract

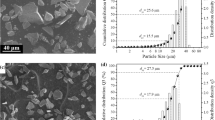

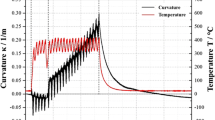

The study presents a comprehensive research on the plasma spray fabrication of TiO2 coatings with microstructural properties adjustable via controlling the respective in-flight properties of the feedstock particles. The in-flight properties can be, in return, governed by tuning the plasma system spray parameters. By determining and linking the two interrelationships, a connection between the important coating characteristics (composition, microstructure, surface and mechanical properties) to the plasma system settings was established. It was shown that by changing the values of six parameters representing the flexibility of the plasma system, the temperatures and velocities of the particles within the jet can be altered from 2125 to 2830 K and 137 to 201 m s−1, respectively. The values of the in-flight temperature critically influenced the efficiency of the coating build-up (values ranging from 8 to 84 μm per 1 torch pass) and the content of anatase phase in the fabricated coatings (0-5.8%), while the in-flight velocity of the TiO2 particles was found to be connected to the porosity of the coatings (ranging from 14.4 to 26.2%) and the adhesion strength at the coating-substrate interface (2.6 × difference).

Similar content being viewed by others

References

L. Hench, Bioceramics—From Concept to Clinic, J. Am. Ceram. Soc., 1991, 74(7), p 1487-1510

J. Xu, D. Joguet, J. Cizek, K. Khor, H. Liao, C. Coddet, and W. Chen, Synthesis and Characterization on Atomphospheric Plasma Sprayed Amorphous Silica Doped Hydrxoyapatite Coatings, Surf. Coat. Technol., 2012, 206(22), p 4659-4665

R. Lima, H. Li, K. Khor, and B. Marple,Biocompatible Nanostructured High-Velocity Oxyfuel Sprayed Titania Coating: Deposition, Characterization, and Mechanical Properties. J. Therm. Spray Technol., 2006, 15(4), p 623-627

R. Lima, B. Marple, H. Li, and K. Khor, Titania Thermal Spray Coatings Made from a Nanostructured Feedstock: An Alternative as a Biomedical Coating, in Proc. ASM Materials and Processes for Medical Devices, ASM International, (2005)

M. Gardon and J. Guilemany, Milestones in Functional Titanium Dioxide Thermal Spray Coatings: A Review. J. Therm. Spray Technol., 2014, 23(4), p 577-595

C. Larsson, P. Thomsen, J. Lausmaa, M. Rodahl, B. Kasemo, and L. Ericson, BBone Response to Surface Modified Titanium Implants: Studies on Electropolished Implants with Different Oxide Thicknesses and Morphology. Biomaterials 1994, 15(13), p 1062-1074

N. Huang, Y. Chen, J. Luo, J. Yi, R. Lu, J. Xiao, Z. Xue, and X. Liu, In Vitro Investigation of Blood Compatibility of Ti with Oxide Layers of Rutile Structure. J. Biomater. Appl., 1994, 8(4), p 404-412

I. Tsyganov, M. Maitz, E. Wieser, F. Prokert, E. Richter, and A. Rogozin, Structure and Properties of Titanium Oxide Layers Prepared by Metal Plasma Immersion Ion Implantation and Deposition, Surf. Coat. Technol., 2003, 174-175, p 591-596

P. Fauchais, Understanding Plasma Spraying, J. Phys. D, 2004, 37(9), p R86-R108

H. Rietveld, Line Profiles of Neutron Powder-Diffraction Peaks for Structure Refinement, Acta Cryst. 22, 151-152 (1967)

S. Forberg, Ceramic Containers for Spent Nuclear Fuel: On the Corrosion Resistance of Rutile, Adv. Ceram., 1986, 20, 321-327

P. Gouma and M. Mills, Anatase-to-Rutile Transformation in Powders, J. Am. Ceram. Soc., 2001, 84(3), p 619-622

R. Shannon and J. Pask, Kinetics of the Anatase-Rutile Transformation, J. Am. Ceram. Soc., 1965, 48(8), p 391-398

J. Cizek and K. Khor, Role of In-Flight Temperature and Velocity of Powder Particles on Plasma Sprayed Hydroxyapatite Coating Characteristics, Surf. Coat. Technol., 2012, 206(8-9), p 2181-2191

G. Taguchi, Quality Engineering in Production Systems, McGraw-Hill, New York, 1988

J. Cizek, K. Khor, and I. Dlouhy, In-Flight Temperature and Velocity of Powder Particles of Plasma-Sprayed TiO2, J. Therm. Spray Technol., 2013, 22(8), p 1320-1327

ASTM International, ASTM F-136 Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401), (2008)

ASTM International, ASTM F-1580 Standard Specification for Titanium and Titanium-6 Aluminum-4 Vanadium Alloy Powders for Coatings of Surgical Implants, (2007)

P. Fauchais, M. Fukumoto, A. Vardelle, and M. Vardelle, Knowledge Concerning Splay Formation: An Invited Review, J. Therm. Spray Technol., 2004, 13(3), p 337-360

International Organization for Standardization, ISO standard 4287: Geometrical Product Specifications—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters, (1997)

W. Oliver, G.M. Pharr, An Improved Technique for Determining Hardness and Elastic-Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7(6), p 1564-1583

P. Ctibor and M. Hrabovsky, Plasma Sprayed TiO2: The Influence of Power of an Electric Supply on Particle Parameters in the Flight and Character of Sprayed Coating, J. Eur. Ceram. Soc., 2010, 30(15), p 3131-3136

R. Ahmed, N. Faisal, S. Knupfer, A. Paradowska, M. Fitzpatrick, K. Khor, and J. Cizek, Neutron Diffraction Residual Strain Measurements in Plasma Sprayed Nanostructured Hydroxyapatite Coatings for Orthopaedic Implants, Mater. Sci. Forum, 2010, 652, p 309-314

L. Dong, K. Cheng, W. Weng, C. Song, P. Du, G. Shen, and G. Han, Hydrothermal Growth of Rutile TiO2 Nanorod Films on Titanium Substrates, Thin Solid Films, 2011, 519(15), p 4634-4640

L. Pawlowski, Suspension and Solution Thermal Spray Coatings, Surf. Coat. Technol., 2009, 203(19), p 2807-2829

R. Tomaszek, L. Pawlowski, L. Gengembre, J. Laureyns, Z. Znamirowski, and J. Zdanowski, Microstructural Characterization of Plasma Sprayed TiO2 Functional Coating with Gradient of Crystal Grain Size, Surf. Coat. Technol., 2006, 201(12), p 45-56

M. Gaona, R.S. Lima, and B.R. Marple, Influence of Particle Temperature and Velocity on the Microstructure and Mechanical Behaviour of High Velocity Oxy-Fuel (hvof)-Sprayed Nanostructured Titania Coatings, J. Mater. Process Technol., 2008, 198(1-3), p 426-435

M. Vilemova, J. Matejicek, R. Musalek, and J. Nohava, Application of Structure-Based Models of Mechanical and Thermal Properties on Plasma Sprayed Coatings, J. Therm. Spray Technol., 2012, 21(3-4), p 372-382

Z. Prochazka, K. Khor, and J. Cizek, Influence of Input Parameters on Splat Formation and Coating Thermal Diffusivity in Plasma Spraying, Adv. Eng. Mater., 2006, 8(7), p 645-650

R. Dhiman, A. McDonald, and S. Chandra, Predicting Splat Morphology in a Thermal Spray Process, Surf. Coat. Technol., 2007, 201(18), p 7789-7801

C. Kang and H. Ng, Splat Morphology and Spreading Behavior Due to Oblique Impact of Droplets onto Substrates in Plasma Spray Coating Process, Surf. Coat. Technol., 2006, 200(18-19), p 5462-5477

M. Planche, B. Normand, E. Suzon, and C. Coddet, The Relationships Between In-Flight particles Characteristics and Coatings Properties Under Plasma Spraying Conditions, in Thermal Spray 2001: New Surfaces for a New Millenium, p 771-777, ASM International, (2001)

Acknowledgments

The present work has been carried out within NETME Centre established thanks to financial support of European Regional Development Fund under the Operational Programme Research and Development for Innovation. The presented results have been obtained within Netme Centre Plus (LO1202) project co-funded by the Ministry of Education, Youth and Sports within the support programme “National Sustainability Programme I”. Support of Czech Science Foundation project GACR 13-35890S is further acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cizek, J., Dlouhy, I., Siska, F. et al. Modification of Plasma-sprayed TiO2 Coatings Characteristics via Controlling the In-flight Temperature and Velocity of the Powder Particles. J Therm Spray Tech 23, 1339–1349 (2014). https://doi.org/10.1007/s11666-014-0132-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0132-z