Abstract

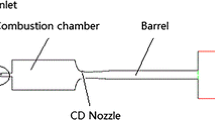

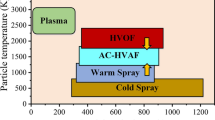

High velocity oxygen fuel (HVOF) thermal spray systems are being used to apply coatings to prevent surface degradation. The coatings of temperature sensitive materials such as titanium and copper, which have very low melting points, cannot be applied using a single-stage HVOF system. Therefore, a dual-stage HVOF system has been introduced and modeled computationally. The dual-spray system provides an easy control of particle oxidation by introducing a mixing chamber. In addition to the materials being sprayed, the thermal spray coating quality depends to a large extent on flow behavior of reacting gases and the particle dynamics. The present study investigates the influence of various operating parameters on the performance of a dual-stage thermal spray gun. The objective is to develop a predictive understanding of various parameters. The gas flow field and the free jet are modeled by considering the conservation of mass, momentum, and energy with the turbulence and the equilibrium combustion sub models. The particle phase is decoupled from the gas phase due to very low particle volume fractions. The results demonstrate the advantage of a dual-stage system over a single-stage system especially for the deposition of temperature sensitive materials.

Similar content being viewed by others

Abbreviations

- A :

-

Empirical coefficient in eddy dissipation model

- A p :

-

Particle cross-sectional area

- B :

-

Empirical coefficient in eddy dissipation model

- c :

-

Turbulent model constant

- C D :

-

Drag coefficient

- C p :

-

Specific heat at constant pressure

- d p :

-

Particle diameter

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}}{F} \) :

-

External force

- h c :

-

Convective heat transfer coefficient

- H :

-

Overall enthalpy

- k :

-

Turbulent kinetic energy

- m p :

-

Mass of particle

- Nu :

-

Nusselt number

- p :

-

Gas pressure

- P k :

-

Production rate of turbulent kinetic energy

- P r :

-

Prandtl number

- R :

-

Gas constant

- R F :

-

Volumetric fuel consumption rate

- Re :

-

Reynolds number

- S :

-

Source term

- t :

-

Time

- T :

-

Temperature

- u i :

-

Velocity in the i-direction

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}}{U} \) :

-

Instantaneous gas velocity vector

- x i :

-

Spatial coordinate in the i-direction

- Y :

-

Fluctuating dilation in compressible turbulence to the overall dissipation rate

- α:

-

Inverse effective Prandtl number

- ε:

-

Rate of turbulent kinetic energy dissipation

- λ:

-

Thermal conductivity

- µ:

-

Molecular viscosity

- µeff :

-

Effective viscosity

- Γ k :

-

Diffusion coefficient of k

- Γε :

-

Diffusion coefficient of ε

- ρ:

-

Density

- σ:

-

Turbulent model constant

- F:

-

Fuel

- g:

-

Gas

- O:

-

Oxidant

- p:

-

Particle

- P:

-

Combustion product

- t:

-

Turbulent

References

R.R. Boyer, An Overview on the Use of Titanium in the Aerospace Industry, Mater. Sci. Eng., 1996, 213, p 103-114

H. Tabbara, S. Gu, and D.G. McCartney, Computational Modeling of Titanium Particles in Warm Spray, Comput. Fluids, 2011, 44, p 358-368

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, 2nd ed., Wiley, Chichester, 2008

D.M. Brunette, P. Tengvall, M. Textor, and P. Thomsen, Titanium in Medicine: Material Science, Surface Science, Engineering, Biological Responses and Medical Applications, Springer, Berlin, 2001

M.J. Donachie, Jr., Titanium: A Technical Guide, 2nd ed., ASM International, Materials Park, 2000

O.E.M. Pohler, Unalloyed Titanium for Implants in Bone Surgery, Injury, 2000, 31, p 7-13

C. Ponticaud, A. Grimaud, A. Denoirjean, P. Lefort, and P. Fauchais, Thermal Spray 2001 New Surfaces for a New Millennium: Proceedings of the International Thermal Spray Conferences, 2001, Singapore.

T. Wu, S. Kuroda, J. Kawakitam, H. Katanoda, and R. Reed, Processing and Properties of Titanium Produced by Warm Spraying, Proceedings of the 2006 International Thermal Spray Conference, 2006, Seattle, Washington, USA.

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkhimov, and V.M. Fomin, Cold Spray Technology, Elsevier, Amsterdam, 2007

J. Browning, Thermal Spray Method and Apparatus for Optimizing Flame Jet Temperature, US patent 5, 330, 798, 1992

J. Kawakita, S. Kuroda, S. Krebs, and H. Katanoda, In-Situ Densification of Ti Coatings by the Warm Spray (Two-Stage HVOF), Process Mater. Trans., 2006, 47, p 1631-1637

J. Kawakita, S. Kuroda, T. Fukushima, H. Katanoda, K. Matsuo, and H. Fukanuma, Dense Titanium Coatings by Modified HVOF Spraying, Surf. Coat. Technol., 2006, 201, p 1250-1255

J. Kawakita, H. Katanoda, M. Watanabe, K. Yokoyama, and S. Kuroda, Warm Spraying: An Improved Spray Process to Deposit Novel Coatings, Surf. Coat. Technol., 2008, 202, p 4369-4373

S. Kuroda, J. Kawakita, M. Watanabe, and H. Katanoda, Warm Spraying—A Novel Coating Process Based on High-Velocity Impact of Solid Particles, Sci. Technol. Adv. Mater., 2008, 9, p 1-17

T. Shamim, C. Xia, and P. Mohanty, Modeling and Analysis of Combustion Assisted Thermal Spray Processes, Int. J. Therm. Sci., 2007, 46, p 755-767

D. Cheng, Q. Xu, G. Tapaga, and E. Lavernia, A Numerical Study of High-Velocity Oxygen Fuel Thermal Spraying Process. Part I: Gas Phase Dynamics, Metall. Mater. Trans. A, 2001, 32, p 1609-1620

S. Gu, C. Eastwick, K. Simmons, and D. McCartney, Computational Fluid Dynamic Modeling of Gas Flow Characteristics in a High-Velocity Oxy-Fuel Thermal Spray System, J. Therm. Spray Technol., 2001, 10, p 461-469

S. Kamnis and S. Gu, 3-D Modeling of Kerosene-Fuelled HVOF Thermal Spray Gun, Chem. Eng. Sci., 2006, 61, p 5427-5439

H. Katanoda, T. Kiriaki, T. Tachibanaki, J. Kawakita, S. Kuroda, and M. Fukuhara, Mathematical Modeling and Experimental Validation of the Warm Spray (Two-Stage HVOF) Process, J. Therm. Spray Technol., 2009, 18, p 401-410

H. Katanoda, H. Morita, M. Komatsu, and S. Kuroda, Experimental and Numerical Evaluation of the Performance of Supersonic Two-Stage High-Velocity Oxy-Fuel Thermal Spray (Warm Spray) Gun, J. Therm. Sci., 2011, 20, p 88-92

A. Dolatabadi, J. Mostaghimi, and V. Pershin, Effect of a Cylindrical Shroud on Particle Conditions in High Velocity Oxy-Fuel (HVOF) Spray Process, J. Mater. Process. Technol., 2003, 137, p 214-224

M. Li and P.D. Christofides, Multi-scale Modeling and Analysis of an Industrial HVOF Thermal Spray Process, Chem. Eng. Sci., 2005, 60, p 3649-3669

D. Cheng, Q. Xu, E. Lavernia, and G. Tapaga, The Effect of Particle Size and Morphology on the In-Flight Behavior of Particles During High Velocity Oxy-Fuel Thermal Spraying, Metall. Mater. Trans. B, 2001, 32, p 525-535

W.E. Ranz and W.R. Marshall, Evaporation from Drops (Part I), Chem. Eng. Prog., 1952, 48, p 141-180

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, M.N., Shamim, T. Effect of Operating Parameters on a Dual-Stage High Velocity Oxygen Fuel Thermal Spray System. J Therm Spray Tech 23, 910–918 (2014). https://doi.org/10.1007/s11666-014-0114-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0114-1