Abstract

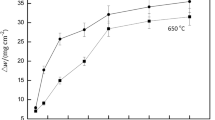

The corrosion behavior of the liquid-phase sintered SiC (LPS-SiC) was studied by dipping in 3.53 mol/L HNO3 aqueous solution at room temperature and 70 °C, respectively. The weight loss, strength reduction and morphology evolution of the SiC specimens during corroding were revealed and also the chemical corrosion process and mechanism of the SiC specimens in the acidic solution were clarified. The results show that the corrosion of the LPS-SiC specimens in the HNO3 solution is selective. The SiC particles are almost free from corrosion, but the secondary phases of BaAl2Si2O8 (BAS) and Y2Si2O7 are corroded via an acid-alkali neutralization reaction. BAS has a higher corrosion rate than Y2Si2O7, resulting in the formation of the bamboo-leaf-like corrosion pits. As the SiC specimens etched in the HNO3 solution at room temperature for 75 days, about 80 μm thickness corrosion layer forms. The weight loss and bending strength reduction of the etched SiC specimens are 2.6 mg/cm2 and 52%, respectively. The corrosion of the SiC specimens is accelerated in the 70 °C HNO3 solution with a rate about five times bigger than that in the same corrosion medium at room temperature.

Similar content being viewed by others

References

D. Kim, H.G. Lee, J.Y. Park, J.Y. Park, and W.J. Kim, Effect of Dissolved Hydrogen on the Corrosion Behavior of Chemically Vapor Deposited SiC in a Simulated Pressurized Water Reactor Environment, Corros. Sci., 2015, 98, p 304–309

L. Zhang, L. Zhang, M. Zhang, X.N. He, and W.M. Tang, Microstructure and Properties of SiC Ceramics Fabricated by Pressureless Sintering at Low-Temperature, Trans. Mater. Heat Treat., 2015, 36, p 7–12

H.J. Yeom, Y.W. Kim, and K.J. Kim, Electrical Thermal and Mechanical Properties of Silicon Carbide-Silicon Nitride Composites Sintered with Yttria and Scandia, J. Eur. Ceram. Soc., 2015, 35, p 77–86

R. Yao, Z. Feng, L. Chen, Y. Zhang, and B. Zhang, Oxidation Behavior of Hi-Nicalon SiC Monofilament Fibers in Air and O2, H2O, Ar Atmospheres, Corros. Sci., 2012, 57, p 182–191

M. Herrmann, K. Sempf, H. Wendrock, M. Schneider, K. Kremmer, and A. Michaelis, Electrochemical Corrosion of Silicon Carbide Ceramics in Sodium Hydroxide, J. Eur. Ceram. Soc., 2014, 34, p 1687–1693

S. Tiwari, R. Balasubramaniam, and M. Gupta, Corrosion Behavior of SiC Reinforced Magnesium Composites, Corros. Sci., 2007, 49(2), p 711–725

S. Somiya, Hydrothermal Corrosion of Nitride and Carbide of Silicon, Mater. Chem. Phys., 2001, 67, p p157–164

Y. Jiang, L.E. Wu, Y.H. Chen, and Y.J. Lu, Microstructure Observation on Corrosion Behavior of Liquid Phase Sintered Silicon Carbide Ceramics, J. Chin. Electron Microsc. Soc., 2009, 28(1), p 46–51

H. Hirayama, T. Kawakubo, A. Goto, and T. Kaneko, Corrosion Behavior of Silicon Carbide in 290 °C Water, J. Am. Ceram. Soc., 1988, 72(11), p 2049–2053

D.Y. Song, S. Kitaoka, and H. Kawamoto, Hot Corrosion of Chemical Vapour Deposited SiC and Si3N4 in Molten Na2SO4 Salt, J. Mater. Sci., 1998, 33, p 1031–1036

L. Zhang, L. Zhang, M. Fang, M. Zhang, X. He, and W. Tang, Microstructures and Characterization of SiC Composites Fabricated by Liquid-phase Sintering at Relatively Lower Temperature, Mater. Res. Innov., 2015, 19(5), p 368–372

GB/T 6569-2006/ISO 14704:2000: Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)-Test Method for Flexural Strength of Monolithic Ceramics at Room Temperature, China National Standardization Management Committee, 2006

Y.Q. Wang, “Research on Preparation and Property of Yttrium Silicate Coating and Crystallite,” Doctoral dissertation, Xian, Shanxi Univ. Sci. Technol., 2012, p 67–70

F. Monteverde, C. Mingazzini, M. Giorgi, and A. Bellosi, Corrosion of Silicon Nitride in Sulphuric Acid Aqueous Solution, Corros. Sci., 2001, 43, p 1851–1863

X. Yang, X.J. Liu, and Z.R. Huang, Surface Cracks of Solid-phase-sintered Silicon Carbide Ceramics and Their Influences on Material Strength, J. Chin. Ceram. Soc., 2014, 42(7), p 841–845

D.E. Cullum, N.L. Hecht, L. Chuck, and S.M. Goodrich, Summary of Results of the Effects of Environments on Mechanical Behavior of High-performance Ceramics, Ceram. Eng. Sci. Proc., 1991, 12, p 1886–1913

T. Sato, Y. Tokunaga, T. Endo, M. Shimada, K. Komeya, M. Komatsu, and T. Kameda, Corrosion of Silicon Nitride Ceramics in Aqueous Hydrogen Chloride Solution, J. Am. Ceram. Soc., 1988, 71(12), p 1074–1079

Acknowledgments

This work was financially supported by Scientific and Technological Research Project, Anhui Province, China (Grant No. 1301022049).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Zhang, M., He, X. et al. Chemical Corrosion of Liquid-Phase Sintered SiC in Acidic/Alkaline Solutions Part 1. Corrosion in HNO3 Solution. J. of Materi Eng and Perform 25, 839–844 (2016). https://doi.org/10.1007/s11665-016-1916-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-1916-8