Abstract

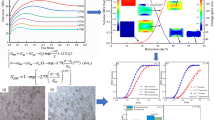

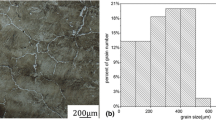

The dynamic recrystallization (DRX) and grain growth mathematical models of 38MnVS6 steel were obtained on the basis of the results from hot compression tests and isothermal annealing tests on a Gleeble-1500 thermo-mechanical simulator. A three-dimensional finite element model was established to investigate the compression process. In order to predict the evolution of DRX volume fraction and austenite grain sizes, a subprogram was designed and coupled in the FE model. The effects of deformation temperatures and strain rates on microstructural evolution and distribution of 38MnVS6 steel during hot compression process were simulated. The simulated results show that the distributions of DRX volume fraction are inhomogeneous in the deformed workpiece, and the degree of DRX increases with increasing deformation temperature and decreasing strain rate. The average rate of DRX increases with the increase of deformation temperature and strain rate. Additionally, with the decrease of deformation temperature and the increase of strain rate, the inhomogeneity of DRX grain sizes increases and the average complete DRX grain sizes become finer. The simulated values of average complete DRX grain sizes show a good agreement with the measured ones.

Similar content being viewed by others

References

Y.C. Lin, M.S. Chen, and J. Zhong, Effect of Temperature and Strain Rate on the Compressive Deformation Behavior of 42CrMo Steel, J. Mater. Process. Technol., 2008, 205(1-3), p 308–315 [in English]

N.T. Switzner, C.J. Van Tyne, and M.C. Mataya, Effect of Forging Strain Rate and Deformation Temperature on the Mechanical Properties of Warm-Worked 304L Stainless Steel, J. Mater. Process. Technol., 2010, 210(8), p 998–1007 [in English]

Y.C. Zhu, W.D. Zeng, J.L. Liu, Y.Q. Zhao, Y.G. Zhou, and H.Q. Yu, Effect of Processing Parameters on the Hot Deformation Behavior of As-Cast TC21 Titanium Alloy, Mater. Des., 2012, 33, p 264–272 [in English]

Y.C. Lin, M.S. Chen, and J. Zhong, Numerical Simulation for Stress/Strain Distribution and Microstructural Evolution in 42CrMo Steel During Hot Upsetting Process, Comput. Mater. Sci., 2008, 43(4), p 1117–1122 [in English]

Y.C. Lin, M.S. Chen, and J. Zhong, Effects of Deformation Temperatures on Stress/Strain Distribution and Microstructural Evolution of Deformed 42CrMo Steel, Mater. Des., 2009, 30(3), p 908–913 [in English]

L.F. Nie, L.W. Zhang, Z. Zhu, and W. Xu, Microstructure Evolution Modeling of FGH96 Superalloy During Inertia Friction Welding Process, Finite Elem. Anal. Des., 2014, 80, p 63–68 [in English]

Q.Q. He, J. Sun, C.X. Yan, J.Y. Zhao, and Z.B. Zhang, Thermo-Mechanical Modeling and Simulation of Microstructure Evolution in Multi-pass H-Shape Rolling, Finite Elem. Anal. Des., 2013, 76, p 13–20 [in English]

Y. Luo, J.M. Peng, H.B. Wang, and X.C. Wu, Effect of Tempering on Microstructure and Mechanical Properties of a Non-quenched Bainitic Steel, Mater. Sci. Eng. A, 2010, 527(15), p 3427–3433 [in English]

J. Wang, J. Chen, Z. Zhao, and X.Y. Ruan, Dynamic Recrystallization Behavior of Microalloyed Forged Steel, J. Iron Steel Res. Int., 2008, 15(3), p 78–81 [in English]

P. Liu, R.P. Liu, Y.S. Wei, H.X. Yang, Q.L. Yong, and Y.Z. Bao, Austenite Dynamic Recrystallization of the Microalloyed Forging Steels 38MnVS During Forging Process, Proc. Eng., 2012, 27, p 63–71 [in English]

C.X. Yue, L.W. Zhang, J.H. Ruan, and H.J. Gao, Modelling of Recrystallization Behavior and Austenite Grain Size Evolution During the Hot Rolling of GCr15 Rod, Appl. Math. Model., 2010, 34(9), p 2644–2653 [in English]

S.L. Liao, L.W. Zhang, C.X. Yue, and J.B. Pei, Experimental Research and Numerical Simulation of Dynamic Microstructure Evolution of GCr15 Steel, J. Plast. Eng., 2008, 15(4), p 159–162 [in Chinese]

Y.S. Jiang, D.C. Ko, and B.M. Kim, Application of the Finite Element Method to Predict Microstructure Evolution in the Hot Forging of Steel, J. Mater. Process. Technol., 2000, 101(1-3), p 85–94 [in English]

S.D. Gu, L.W. Zhang, C.X. Yue, J.H. Ruan, J.L. Zhang, and H.J. Gao, Multi-field Coupled Numerical Simulation of Microstructure Evolution During the Hot Rolling Process of GCr15 Steel Rod, Comput. Mater. Sci., 2011, 50(7), p 1951–1957 [in English]

S.D. Gu, L.W. Zhang, J.H. Ruan, P.Z. Zhou, and Y. Zhen, Constitutive Modeling of Dynamic Recrystallization Behavior and Processing Map of 38MnVS6 Non-quenched Steel, J. Mater. Eng. Perform., 2014, 23(3), p 1062–1068 [in English]

L.F. Nie, L.W. Zhang, Z. Zhu, and W. Xu, Constitutive Modeling of Dynamic Recrystallization Kinetics and Processing Maps of Solution and Aging FGH96 Superalloy, J. Mater. Eng. Perform., 2013, 22(12), p 3728–3734 [in English]

S. Anbuselvan and S. Ramanathan, Hot Deformation and Processing Maps of Extruded ZE41A Magnesium Alloy, Mater. Des., 2010, 31(5), p 2319–2323 [in English]

C.M. Sellars and W.J. Mctegart, On Mechanism of Hot Deformation, Acta Matall., 1966, 14(9), p 1136–1138 [in English)

B. Mirzakhani, M.T. Salehi, S. Khoddam, S.H. Seyedein, and M.R. Aboutalebi, Investigation of Dynamic and Static Recrystallization Behavior During Thermomechanical Processing in a API-X70 Microalloyed Steel, J. Mater. Eng. Perform., 2009, 18(8), p 1029–1034 [in English]

P.D. Hodgson, Microstructure Modelling for Property Prediction and Control, J. Mater. Process. Technol., 1996, 60(1-4, 15), p 27–33 [in English]

A. Momeni, S.M. Abbasi, and H. Badri, Hot Deformation Behavior and Constitutive Modeling of VCN200 Low Alloy Steel, Appl. Mater. Model., 2012, 36(11), p 5624–5632 [in English]

J.J. Jonas, X. Quelennec, L. Jiang, and É. Martin, The Avrami Kinetics of Dynamic Recrystallization, Acta Mater., 2009, 57(9), p 2748–2756 [in English]

K. Farrell and P.R. Munroe, Grain Growth in Fe-30at.%Al, Scripta Mater., 1996, 35(5), p 615–621 [in English]

W. Li and K. Xia, Kinetics of the Grain Growth in a Binary Ti-44Al alloy and a Ternary Ti-44Al-0.15Gd Alloy, Mater. Sci. Eng. A, 2002, 329-331, p 430–434 [in English]

Acknowledgment

The authors appreciate the financial support received from Suzhou Suxin Special Steel Group Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, S., Zhang, L., Zhang, C. et al. Modeling the Effects of Processing Parameters on Dynamic Recrystallization Behavior of Deformed 38MnVS6 Steel. J. of Materi Eng and Perform 24, 1790–1798 (2015). https://doi.org/10.1007/s11665-015-1460-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1460-y