Abstract

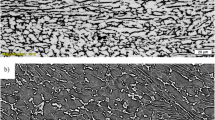

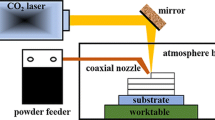

The effect of strain on microstructural changes and the primary alpha (αP) volume fraction as well as the workability of Ti-6Al-4V are studied by isothermal compression of wedge-shaped specimens at the initial temperatures of 850, 900, and 950 °C and platen velocities of 2.5, 25, and 250 mm/min in combination with finite element method. The results show that higher platen velocity leads to a lesser αP volume fraction at all of the temperatures. Higher temperature reduces the αP volume fraction, but increases the impact of strain and platen velocity on the microstructure through the specimen. A more uniform distribution of the primary alpha volume fraction can be achieved by decreasing the initial temperature and/or platen velocity. All of the specimens were free from any defects and can withstand a compression with the normalized Cockcroft-Latham damage value of 0.61.

Similar content being viewed by others

References

T. Seshacharyulu, S. Medeiros, W. Frazier, and Y. Prasad, Hot Working of Commercial Ti-6Al-4V with an Equiaxed α-β Microstructure: Materials Modeling Considerations, Mater. Sci. Eng. A, 2000, 284, p 184–194

J. Kim, N. Reddy, J. Yeom, C. Lee, and N. Park, Artificial Neural Network Modeling of Phase Volume Fraction of Ti Alloy Under Isothermal and Non-isothermal Hot Forging Conditions, J. Mech. Sci. Technol., 2007, 21, p 1560–1565

R. Ding and Z. Guo, Microstructural Evolution of a Ti-6Al-4V Alloy During β-Phase Processing: Experimental and Simulative Investigations, Mater. Sci. Eng. A, 2004, 365, p 172–179

Y.C. Wang and T.G. Langdon, Influence of Phase Volume Fractions on the Processing of a Ti-6Al-4V Alloy by High-Pressure Torsion, Mater. Sci. Eng. A, 2013, 559, p 861–867

I. Weiss, F. Froes, D. Eylon, and G. Welsch, Modification of Alpha Morphology in Ti-6Al-4V by Thermomechanical Processing, Metall. Trans. A, 1986, 17, p 1935–1947

P. Ari-Gur and S. Semiatin, Evolution of Microstructure, Macrotexture and Microtexture During Hot Rolling of Ti-6A1-4V, Mater. Sci. Eng. A, 1998, 257, p 118–127

S. Semiatin, V. Seetharaman, and I. Weiss, Flow Behavior and Globularization Kinetics During Hot Working of Ti-6Al-4V with a Colony Alpha Microstructure, Mater. Sci. Eng. A, 1999, 263, p 257–271

Z. Hu, J. Brooks, and T. Dean, Experimental and Theoretical Analysis of Deformation and Microstructural Evolution in the Hot-Die Forging of Titanium Alloy Aerofoil Sections, J. Mater. Process. Technol., 1999, 88, p 251–265

J. Luo, B. Wu, and M.-Q. Li, 3D Finite Element Simulation of Microstructure Evolution in Blade Forging of Ti-6Al-4V Alloy Based on the Internal State Variable Models, Int. J. Min. Met. Mater., 2012, 19, p 122–130

Y. Prasad, T. Seshacharyulu, S. Medeiros, and W. Frazier, Microstructural Modeling and Process Control During Hot Working of Commercial Ti-6A1-4V: Response of Lamellar and Equiaxed Starting Microstructures, Mater. Manuf. Process., 2000, 15, p 581–604

R. Ding, Z. Guo, and A. Wilson, Microstructural Evolution of a Ti-6Al-4V Alloy During Thermomechanical Processing, Mater. Sci. Eng. A, 2002, 327, p 233–245

T. Seshacharyulu, S. Medeiros, W. Frazier, and Y. Prasad, Microstructural Mechanisms During Hot Working of Commercial Grade Ti-6Al-4V with Lamellar Starting Structure, Mater. Sci. Eng. A, 2002, 325, p 112–125

M.-Q. Li and A.-M. Xiong, New Model of Microstructural Evolution During Isothermal Forging of Ti-6Al-4V Alloy, Mater. Sci. Technol., 2002, 18, p 212–214

W. Yu, M. Li, and J. Luo, Effect of Processing Parameters on Microstructure and Mechanical Properties in High Temperature Deformation of Ti-6Al-4V Alloy, Rare Metal. Mater. Eng., 2009, 38, p 19–24

J. Luo, M. Li, H. Li, and W. Yu, Effect of the Strain on the Deformation Behavior of Isothermally Compressed Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 2009, 505, p 88–95

J. Luo, M. Li, W. Yu, and H. Li, Effect of the Strain on Processing Maps of Titanium Alloys in Isothermal Compression, Mater. Sci. Eng. A, 2009, 504, p 90–98

J.H. Kim, N. Reddy, J.T. Yeom, J.K. Hong, C.S. Lee, and N.-K. Park, Microstructure Prediction of Two-Phase Titanium Alloy During Hot Forging Using Artificial Neural Networks and FE Simulation, Met. Mater. Int., 2009, 15, p 427–437

F. Warchomicka, C. Poletti, M. Stockinger, and T. Henke, Microstructure Evolution During Hot Deformation of Ti-6Al-4V Double Cone Specimens, Int. J. Mater. Form., 2010, 3, p 215–218

X. Fan, H. Yang, Z. Sun, and D. Zhang, Effect of Deformation Inhomogeneity on the Microstructure and Mechanical Properties of Large-Scale Rib-Web Component of Titanium Alloy Under Local Loading Forming, Mater. Sci. Eng. A, 2010, 527, p 5391–5399

S. Abbasi and A. Momeni, Effect of Hot Working and Post-deformation Heat Treatment on Microstructure and Tensile Properties of Ti-6Al-4V Alloy, Trans. Nonferr. Metal. Soc., 2011, 21, p 1728–1734

J. Xiao, D. Li, X. Li, and T. Deng, Constitutive modeling and microstructure change of Ti-6Al-4V during the hot tensile deformation, J. Alloy. Compd., 2012, 541, p 346–352

L. He, A. Dehghan-Manshadi, and R. Dippenaar, The Evolution of Microstructure of Ti-6Al-4V Alloy During Concurrent Hot Deformation and Phase Transformation, Mater. Sci. Eng. A, 2012, 549, p 163–167

W. Yu, M. Li, and J. Luo, Variation Effect of Strain Rate on Microstructure in Isothermal Compression of Ti-6Al-4V Alloy, Rare Met., 2012, 31, p 7–11

J. Hall, Fatigue Crack Initiation in Alpha-Beta Titanium Alloys, Int. J. Fatigue, 1997, 19, p 23–37

Y. Honnorat, Issues and Breakthrough in the Manufacture of Turboengine Titanium Parts, Mater. Sci. Eng. A, 1996, 213, p 115–123

G. Wu, C. Shi, W. Sha, A. Sha, and H. Jiang, Effect of Microstructure on the Fatigue Properties of Ti-6Al-4V Titanium Alloys, Mater. Design, 2013, 46, p 668–674

M.H. Parsa, M.N. Ahmadabadi, H. Shirazi, B. Poorganji, and P. Pournia, Evaluation of Microstructure Change and Hot Workability of High Nickel High Strength Steel Using Wedge Test, J. Mater. Process. Technol., 2008, 199, p 304–313

M. Motyka, J. Sieniawski, and W. Ziaja, Microstructural Aspects of Superplasticity in Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 2014, 599, p 57–63

J. Fluhrer, Deform 3D User’s Manual Version 10.0, Scientific Forming Technologies Corporation, Columbus, OH, 2009

G.F. Vander Voort, Metallography, Principles and Practice, ASM International, Materials Park, 1984

K. Lange, Handbook of Metal Forming, Society of Manufacturing Engineers, Dearborn, 1994

W. Jia, W. Zeng, J. Liu, Y. Zhou, and Q. Wang, On the Influence of Processing Parameters on Microstructural Evolution of a Near Alpha Titanium Alloy, Mater. Sci. Eng. A, 2011, 530, p 135–143

T. Altan, Cold and Hot Forging: Fundamentals and Applications, ASM international, Materials Park, 2005

R.H. Myers, D.C. Montgomery, and C.M. Anderson-Cook, Response Surface Methodology: Process and Product Optimization Using Designed Experiments, Wiley, New York, 2009

M. Shirdar, A. Golshan, S. Izman, and D. Ghodsiyeh, The Application of Surface Response Methodology to the Pretreatment of WC Substrates Prior to Diamond Coating, J. Mater. Eng. Perform., 2014, 23, p 13–24

K. Velmanirajan, R. Narayanasamy, and K. Anuradha, Effect of Chemical Composition on Texture Using Response Surface Methodology, J. Mater. Eng. Perform., 2013, 22, p 3237–3257

S.J. Mirahmadi, M. Hamedi, and S. Ajami, Investigating the Effects of Cross Wedge Rolling Tool Parameters on Formability of Nimonic® 80A and Nimonic® 115 Superalloys, Int. J. Adv. Manuf. Technol., 2014, doi:10.1007/s00170-014-6047-5

Acknowledgment

The financial support for this work was partially provided by MAPNA Group under Grant No. RD-THD-91-05 which is appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mirahmadi, S.J., Hamedi, M. & Habibi Parsa, M. Investigation of Microstructural Uniformity During Isothermal Forging of Ti-6Al-4V. J. of Materi Eng and Perform 23, 4411–4420 (2014). https://doi.org/10.1007/s11665-014-1221-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1221-3