Abstract

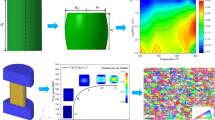

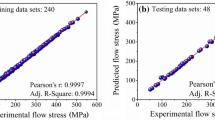

An artificial neural network (ANN) model was applied to simulate the phase volume fraction of titanium alloy under isothermal and non-isothermal hot forging condition. For isothermal hot forging process, equilibrium phase volume fraction at specific temperature was predicted. For this purpose, chemical composition of six alloy elements (i.e. Al, V, Fe, O, N, and C) and specimen temperature were chosen as input parameter. After that, phase volume fraction under non-isothermal condition was simulated again. Input parameters consist of initial phase volume fraction, equilibrium phase volume fraction at specific temperature, cooling rate, and temperature. The ANN model was coupled with the FE simulation in order to predict the variation of phase volume fraction during non-isothermal forging. Ti−6A1−4V alloy was forged under isothermal and non-isothermal condition and then, the resulting microstructures were compared with simulated data.

Similar content being viewed by others

References

E. W. Collings, The Physical Metallurgy of Titanium Alloys, American Society for Metals, Metals Park, OH 44073, (1984).

G. Terlinde, and G. Fischer, Beta titanium alloys, in Christoph Leyens and Manfred Peters (eds), Titanium and Titanium Alloys, WILEY VCH GmbH & Co. KGaA, (2003) 37–57.

R. A. Wood, Titanium Alloys Handbook, Metals and Ceramics Information Center, Battelle, (1972).

E. J. Dayhoff, Neural Network Architecture: An Introduction, VNR Press, New York, (1990).

J. M. Zurada, Introduction to Artificial Neural Systems, PWS Publishing Company, Boston, (1992).

R. Castro, L. Seraphin,Mem. Sci. Rev. Metall. 63 (1966) 1025–1058.

Y. T. Lee, G. Welsch, Young’s modulus and damping of Ti-6A1-4V alloy as a function of heat treatment and oxygen concentration,Mater. Sci. Eng. A. 128 (1990) 77–89.

M. Jain, M.C. Chaturvedi, N.L. Richards, N.C. Goel, Microstructural characteristics in a phase during superplastic deformation of Ti-6A1-4V,Mater. Sci. Eng. A. 145 (1991) 205–214.

S. Malinov, P. Markovsky, W. Sha, and Z. Guo, Resistivity study and computer modelling of the isothermal transformation kinetics of Ti-6A1-4V and Ti-6Al-2Sn-4Zr-2Mo-0.08Si alloys,Journal of Alloys and Compounds. 314 (2001) 181–192.

N.S. Reddy, C.S. Lee, J.H. Kim, S.L. Semiatin, Determination of the beta-approach curve and beta-transus temperature for titanium alloys using sensitivity analysis of a trained neural network,Mater. Sci. Eng. A. 434 (2006) 218–226.

M.L. Meier, D.R. Lesuer, A.K. Mukherjee, The effects of the α/β phase proportion on the superplasticity of Ti-6A1-4V and iron-modified Ti-6A1-4V,Mater. Sci. Eng. A. 154 (1992), 165–173.

S.L. Semiatin, F. Montheillet, G. Shen, J.J. Jonas, Self-consistent modeling of the flow behavior of wrought alpha/beta titanium alloys under isothermal and nonisothermal hot-working conditions,Metall. Mater Trans. A. 33 (2002) 2719–2727.

R. Boyer, G. Welsch, E.W. Collings, Material Properties Handbook: Titanium Alloys, ASM International, Materials Park, OH 44073, (1994).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, J.H., Reddy, N.S., Yeom, J.T. et al. Artificial neural network modeling of phase volume fraction of Ti alloy under isothermal and non-isothermal hot forging conditions. J Mech Sci Technol 21, 1560–1565 (2007). https://doi.org/10.1007/BF03177375

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF03177375