Abstract

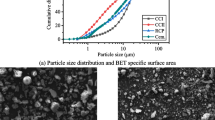

Nine types of trace nano-CeO2-doped WC-11Co cemented carbides designed by orthogonal method were prepared. The variance analysis results show that the relative density increases with increasing sintering temperature in the range of 1400-1450 °C; the hardness is highly dependent on grain size of WC which is closely related to the particle size of the initial WC powder and grain refinement produced by nano-CeO2; the bending strength of WC-11Co cemented carbide with less than 0.15 wt.% of nano-CeO2 is effectively improved because of its effect on the decreasing of porosity and inhibiting the grain growth of WC and martensitic phase transformation of Co; the fracture toughness rises at the beginning then drops later if the particle size of initial WC powder is in the range of 3-11 μm.

Similar content being viewed by others

References

M. Mahmoodan, H. Aliakbarzadeh, and R. Gholamipour, Microstructural and Mechanical Characterization of High Energy Ball Milled and Sintered WC-10 wt.%Co-xTaC Nano Powders, Int. J. Refract. Met. Hard Mater., 2009, 27, p 801–805

F.A. Costa, F.F.P. Medeiros, A.G.P. Silva, U.U. Gomes, M. Filgueira, and C.P. Souza, Structure and Hardness of a Hard Metal Alloy Prepared with a WC Powder Synthesized at Low Temperature, Mater. Sci. Eng. A, 2008, 485, p 638–642

S.X. Zhao, X.Y. Song, J.X. Zhang, and X.M. Liu, Effects of Scale Combination and Contact Condition of Raw Powders on SPS Sintered Near-Nanocrystalline WC-Co Alloy, Mater. Sci. Eng. A, 2008, 473, p 323–329

Z.Z. Fang, X. Wang, T. Ryu, K.S. Hwang, and H.Y. Sohn, Synthesis, Sintering, and Mechanical Properties of Nanocrystalline Cemented Tungsten Carbide—A Review, Int. J. Refract. Met. Hard Mater., 2009, 27, p 288–299

S.I. Cha, Hong SH, Ha G H, Kim B K. Microstructure and Mechanical Properties of Nanocrystalline WC-10Co Cemented Carbides, Scr. Mater., 2001, 44, p 1535–1539

W.B. Liu, X.Y. Song, J.X. Zhang, F.X. Yin, and G.Z. Zhang, A Novel Route to Prepare Ultrafine-Grained WC-Co Cemented Carbides, J. Alloys Compd., 2008, 458, p 366–371

D.D. Gu, Y.F. Shen, L. Zhao, J. Xiao, P. Wu, and Y.B. Zhu, Effect of Rare Earth Oxide Addition on Microstructures of Ultra-Fine WC-Co Particulate Reinforced Cu Matrix Composites Prepared by Direct Laser Sintering, Mater. Sci. Eng. A, 2007, 445-446, p 316–332

D.H. Xiao, Y.H. He, W.H. Luo, and M. Song, Effect of VC and NbC Additions on Microstructure and Properties of Ultrafine WC-10Co Cemented Carbides, Trans. Nonferrous Met. Soc. China, 2009, 19, p 1520–1525

L. Sha, Study on Rare-Earth Doped Cemented Carbides in China, Int. J. Refract. Met. Hard Mater., 2009, 27, p 528–534

C.G. Lin, Action of New Rare Earth Additions in Cemented Carbide, J. Mater. Sci. Technol., 1993, 9(3), p 177–184

J. Xiong, J.G. Yang, and X.H. Guo, Application of Rare Earth Elements in Cemented Carbide Inserts, Drawing Dies and Mining Tools, Mater. Sci. Eng. A, 1996, 209(1-2), p 287–293

Z. Yao, J.J. Stiglich, and T.S. Sudarshan, Nanosized WC-Co Holds Promise for the Future, Met. Powder Rep., 1998, 53(3), p 26–33

S. Liu, Z.L. Huang, G. Liu, and G.B. Yang, Preparing Nano-Crystalline Rare Earth Doped WC-Co Powder by High Energy Ball Milling, Int. J. Refract. Met. Hard Mater., 2006, 24, p 461–464

Y.X. Li, X.Z. Zhou, Y. Wang, and X. You, Preparation of Nano-Sized CeO2 by Mechanochemical Reaction of Cerium Carbonate with Sodium Hydroxide, Mater. Lett., 2004, 58, p 245–249

M.S. Tsai, Powder Synthesis of Nano Grade Cerium Oxide Via Homogenous Precipitation and Its Polishing Performance, Mater. Sci. Eng. B, 2004, 110(2), p 132–134

T. Mori, Y. Wang, J. Drennan, G. Auchterlonie, J.G. Li, and T. Ikegami, Influence of Particle Morphology on Nanostructural Feature and Conducting Property in Sm-Doped CeO2 Sintered Body, Solid State Ionics, 2004, 175, p 641–649

M.G. Sujana, K.K. Chattopadyay, and S. Anand, Characterization and Optical Properties of Nano-Ceria Synthesized by Surfactant-Mediated Precipitation Technique in Mixed Solvent System, Appl. Surf. Sci., 2008, 254, p 7405–7409

M.A. Xueming, J.I. Gang, Z. Ling, and D. Yuanda, Structure and Properties of Bulk Nano-Structured WC-CO Alloy by Mechanical Alloying, J. Alloys Compd., 1998, 264(1-2), p 267–270

S. Liu, D.Q. Yi, Y.X. Li, and D. Zou, Preparation Nano-Crystalline La Doped WC/Co Powder by High Energy Ball-Milling, Acta Metall. Sin. (Engl. Lett.), 2002, 15(5), p 448–452

H. Ngqvist and N. Axen, Abrasion of Cemented Carbides by Small Grits, Tribol. Int., 1999, 32(9), p 527–534

D. Sivaprahasam, S.B. Chandrasekar, and R. Sundaresan, Microstructure and Mechanical Properties of Nanocrystalline WC-12Co Consolidated by Spark Plasma Sintering, Int. J. Refract. Met. Hard Mater., 2007, 25, p 144–152

K.H. Lee, J.W. Yi, and J.S. Park, An Optimization Algorithm Using Orthogonal Arrays in Discrete Design Space for Structures, Finite Elem. Anal. Des., 2003, 40, p 121–135

Q.F. Pan, Effects of Rare Earth Oxides on the Properties of WC-Co Cemented Carbide, Rare Met. Mater. Eng., 1993, 22, p 40–41 ((in Chinese))

S.I. Cha, S.H. Hong, G.H. Ha, and B.K. Kim, Mechanical Properties of WC-10Co Cemented Carbides Sintered from Nanocrystalline Spray Conversion Processed Powders, Int. J. Refract. Met. Hard Mater., 2001, 19, p 397–403

L. Zhang, S. Chen, X.J. Xiong, Y.H. He, B.Y. Huang, and C.F. Zhang, Phase Composition, Transition and Structure Stability of Functionally Graded Cemented Carbide with Dual Phase Structure, J. Cent. South Univ. Technol., 2007, 14, p 149–152

C.H. Xu, X. Ai, and C.Z. Huang, Research and Development of Rare-Earth Cemented Carbides, Int. J. Refract. Met. Hard Mater., 2001, 19, p 159–168

Z.Z. Fang, A. Griffo, B. White, G. Lockwood, D. Belnap, G. Hilmas, and J. Bitler, Fracture Resistant Super Hard Materials and Hardmetals Composite with Functionally Designed Microstructure, Int. J. Refract. Met. Hard Mater., 2001, 19, p 453–459

L. Espie, B. Drevet, and N. Eustathopoulos, Experimental Study of the Influence of Interfacial Energies and Reactivity on Wetting in Metal/Oxide Systems, Metall. Mater. Trans. A, 1994, 25A, p 599–605

Acknowledgments

This study was supported by the Program of Excellent Team at Harbin Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, X., Wang, Y., Peng, F. et al. Optimization of Processing Parameters for WC-11Co Cemented Carbide Doped with Nano-Crystalline CeO2 . J. of Materi Eng and Perform 22, 112–117 (2013). https://doi.org/10.1007/s11665-012-0236-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0236-x