Abstract

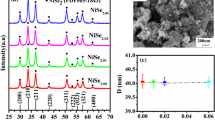

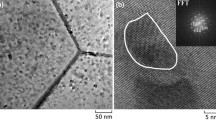

The efficiency of a thermoelectric (TE) device is determined by the temperature difference applied across it and the dimensionless figure␣of merit (ZT) of its TE materials. High ZT value means high performance, which requires high carrier mobility (μ) as well as low lattice thermal conductivity (κ lat); i.e., ZT is roughly proportional to μ/κ lat. Si exhibits good electrical properties, but its κ lat is remarkably high, leading to low ZT. To enhance the ZT, we adopted nanostructuring via dispersion of nanoscale silicide precipitates in bulk Si, which would lead to κ lat reduction while retaining good electrical properties. Here, we focused on VSi2 as the dispersed precipitates, because Si and VSi2 have a eutectic point located in the Si-rich part. The eutectic composition is Si:VSi2 = 91:3, i.e., Si:V = 97:3 in atomic ratio. In the present study, we successfully fabricated Si–VSi2 composite bulks with composition (Si100P3)97V3 and various morphologies by a method combining melt spinning (MS) and spark plasma sintering (SPS). By controlling mainly the MS cooling rate and SPS temperature, the size and dispersion morphology of the VSi2 precipitates were optimized. It was revealed that, on dispersing size-controlled VSi2 precipitates, κ lat decreased while μ did not change significantly, thus μ/κ lat increased. A maximum ZT value of 0.23 at 1070 K was obtained, approximately 37% higher than that of optimized bulk Si.

Similar content being viewed by others

References

T. Kajikawa, Thermoelectrics Handbook: Macro to Nano, Chapter␣50, ed. D.M. Rowe (Boca Raton: CRC, 2006), p. 50.

L.E. Bell, Science 321, 1457 (2008).

G.J. Snyder and E.S. Toberer, Nat. Mater. 7, 105 (2008).

K. Biswas, J. He, I.D. Blum, C.I. Wu, T.P. Hogan, D.N. Seidman, V.P. Dravid, and M.G. Kanatzidis, Nature 489, 414 (2012).

L. Weber and E. Gmelin, Appl. Phys. A 53, 136 (1991).

G.H. Zhu, H. Lee, Y. Lan, X. Wang, G. Joshi, D. Wang, J. Yang, D. Vashaee, H. Guilbert, A. Pillitteri, M. Dresselhaus, G. Chen, and Z. Ren, Phys. Rev. Lett. 102, 196803 (2009).

A.I. Hochbaum, R. Chen, R.D. Delgado, W. Liang, E.C. Garnett, M. Najarian, A. Majumdar, and P. Yang, Nature 451, 163 (2008).

A.I. Boukai, Y. Bunimovich, J.T. Kheli, J.K. Yu, W.A. Goddard, and J.R. Heath, Nature 451, 168 (2008).

J. Tang, H.T. Wang, D.H. Lee, M. Fardy, Z. Huo, T.P. Russell, and P. Yang, Nano Lett. 10, 4279 (2010).

S.K. Bux, R.G. Blair, P.K. Gogna, H. Lee, G. Chen, M.S. Dresselhaus, R.B. Kaner, and J.P. Fleurial, Adv. Funct. Mater. 19, 2445 (2009).

M.S. Dresselhaus, G. Chen, M.Y. Tang, R.G. Yang, H. Lee, D.Z. Wang, Z.F. Ren, J.P. Fleurial, and P. Gogna, Adv. Mater. 19, 1043 (2007).

X.W. Wang, H. Lee, Y.C. Lan, G.H. Zhu, G. Joshi, D.Z. Wang, J. Yang, A.J. Muto, M.Y. Tang, J. Klatsky, S. Song, M.S. Dresselhaus, G. Chen, and Z.F. Ren, Appl. Phys. Lett. 93, 193121 (2008).

Y. Lan, A.J. Minnich, G. Chen, and Z. Ren, Adv. Funct. Mater. 20, 357 (2010).

N. Uchida, T. Tada, Y. Ohishi, Y. Miyazaki, K. Kurosaki, and S. Yamanaka, J. Appl. Phys. 114, 134311 (2013).

Y. Ohishi, K. Kurosaki, T. Suzuki, H. Muta, S. Yamanaka, N. Uchida, T. Tada, and T. Kanayama, Thin Solid Films 534, 238 (2013).

A. Yusufu, K. Kurosaki, Y. Miyazaki, M. Ishimaru, A. Kosuga, Y. Ohishi, H. Muta, and S. Yamanaka, Nanoscale 6, 13921 (2014).

Y. Ohishi, Y. Miyazaki, H. Muta, K. Kurosaki, S. Yamanaka, N. Uchida, and T. Tada, J. Electron. Mater. 44, 2074 (2015).

J. Xie, Y. Ohishi, Y. Miyazaki, A. Yusufu, H. Muta, K. Kurosaki, and S. Yamanaka, J. Appl. Phys. 118, 065103 (2015).

K. Kurosaki, A. Yusufu, Y. Miyazaki, Y. Ohishi, H. Muta, and S. Yamanaka, Mater. Trans. 57, 1018 (2016).

V.K. Zaitsev, M.I. Fedorov, E.A. Gurieva, I.S. Eremin, P.P. Konstantinov, AYu Samunin, and M.V. Vedernikov, Rev. Lett. B 74, 045207 (2006).

J.F. Smith, Bull. Alloy Phase Diagr. 6, 266 (1985).

JCPDS Card Nos. 00-005-0565 (Si) and 01-072-6183 (VSi2) (XRD)

R.E. Honig, RCA Rev. 18, 195 (1957).

J.P. Dismukes, L. Ekstrom, and R.J. Pfaff, J. Phys. Chem. Solids 68, 3021 (1964).

X.B. Zhao, H.Y. Chen, E. Muller, and C. Drasar, J. Alloys Compd. 365, 206 (2004).

B. Du, H. Li, J. Xu, X. Tang, and C. Uher, J. Solid State Chem. 184, 109 (2011).

W. Luo, H. Li, Y. Yan, Z. Lin, X. Tang, Q. Zhang, and C. Uher, Intermetallics 19, 404 (2011).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tanusilp, Sa., Kurosaki, K., Yusufu, A. et al. Enhancement of Thermoelectric Properties of Bulk Si by Dispersing Size-Controlled VSi2 . J. Electron. Mater. 46, 3249–3255 (2017). https://doi.org/10.1007/s11664-016-5066-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-5066-4