Abstract

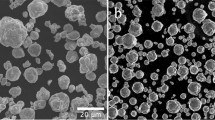

The current work explores the effects of a small addition of Ni on the microstructure and mechanical properties of Sn-Zn eutectic solder alloy (Sn-14.9 at.%Zn). In two sets of experiments, Ni is either added to the eutectic alloy or Zn in the eutectic alloy is replaced by an increasing amount of Ni. The study indicates that small additions of Ni in eutectic Sn-Zn solder (∼0.017 at.%) refines the eutectic microstructure together with the appearance of the small amount of primary Zn plates. Increasing the Ni content to 0.142 at.% and beyond, then an intermetallic phase ϒ-Ni5Zn21 with dendritic morphology appears in the microstructure along with dendrites of primary Sn. The scale of eutectic microstructure shows a decreasing trend till 0.902 at.%Ni with eutectic spacing of 1.98 ± 0.32 μm for this alloy. Further addition of Ni coarsens the microstructure. The replacement of Zn with Ni in the eutectic composition follows a similar trend with a lesser refinement of the microstructure. In both the scenarios, the addition of a small amount of Ni increases the eutectic temperatures till a critical concentration is reached beyond which one can observe a decrease in the eutectic point. The trend is similar for the solid solubility of Zn in Sn while the trend is opposite for the measured eutectic composition, which decreases at the initial stages of Ni addition. Through a detailed measurement of mechanical properties, the study establishes significant improvement of the strength of Sn-Zn solder with small additions of Ni in the alloy with a maximum hardness of 26 ± 1 HV and 0.2% proof stress of 72 ± 3 MPa at room temperature for the eutectic alloy with 0.902 at.%Ni.

Similar content being viewed by others

References

Y. Gao, C. Zou, B. Yang, Q. Zhai, J. Liu, E. Zhuravlev, and C. Schick, J. Alloys Compd. 484, 777 (2009).

M. Abtew and G. Selvaduray, Mater. Sci. Eng. R Rep. 27, 95 (2000).

K. Suganuma, Curr. Opin. Solid State Mater. Sci. 5, 55 (2001).

K. Zeng and K.N. Tu, Mater. Sci. Eng. R Rep. 38, 55 (2002).

C.M.L. Wu, D.Q. Yu, C.M.T. Law, and L. Wang, Mater. Sci. Eng. R Rep. 44, 1 (2004).

Y. Li and C.P. Wong, Mater. Sci. Eng. R Rep. 51, 1 (2006).

H. Ma and J.C. Suhling, J. Mater. Sci. 44, 1141 (2009).

D.A. Shnawah, M.F.M. Sabri, and I.A. Badruddin, Microelectron. Reliab. 52, 90 (2012).

G. Zeng, S. McDonald, and K. Nogita, Microelectron. Reliab. 52, 1306 (2012).

S.B. Xue, Y. Chen, X.C. Lv, and Y.P. Liao, Trans. China Weld. Inst. 26, 1 (2005).

L.H. Qi, J.H. Huang, J.G. Zhang, and Y. Wang, Rare Met. Mater. Eng. 36, 241 (2007).

L. Zhang, S. Xue, L. Gao, Y. Chen, S. Yu, Z. Sheng, and G. Zeng, J. Mater. Sci. 20, 1193 (2009).

S.B. Xue, L. Zhang, L.L. Gao, S.L. Yu, and H. Zhu, Weld. Join. 3, 24 (2009).

Z. Moser, J. Dutkiewicz, W. Gasior, and J. Salawa, Bull. Alloy Phase Diagr. 6, 330 (1985).

S. Kim, K.S. Kim, S.-S. Kim, and K. Suganuma, J. Electron. Mater. 38, 266 (2008).

X. Ren, M. Li, and D. Mao, Electron. Compon. Mater. 11, 15 (2004).

P. Zhang, H. Guo, F. Yang, and J. Xu, in 7th International Conference on Electronic Packaging Technology, vol. 1 (2006).

X. Gang and Q. X. Ming (Masters Thesis Dissertation, Jilin University 2007).

H. Wang, S.B. Xue, and W.X. Chen, China Weld 18, 57 (2009).

L. Sun and L. Zhang, in International Conference on Power Electronics and Energy Engineering 2015, vol. 20 (2015).

B.F. Dyson, T.R. Anthony, and D. Turnbull, J. Appl. Phys. 38, 3408 (1967).

F.H. Huang and H.B. Huntington, Phys. Rev. B 9, 1479 (1974).

K. Suganuma, K. Niihara, T. Shoutoku, and Y. Nakamura, J. Mater. Res. 13, 2859 (1998).

K. Suganuma, T. Murata, H. Noguchi, and Y. Toyoda, J. Mater. Res. 15, 884 (2000).

K.-S. Kim, Y.-S. Kim, K. Suganuma, and H. Nakajima, J. Jpn. Inst. Electron. Packag. 5, 666 (2002).

S. Kashyap, C.S. Tiwary, and K. Chattopadhyay, Intermetallics 19, 1943 (2011).

C.S. Tiwary, D.R. Mahapatra, and K. Chattopadhyay, Appl. Phys. Lett. 101, 171901 (2012).

J.E. Gruzleski and W.C. Winegard, Trans. Metall. Soc. AIME 242, 1785 (1968).

L. Liu, J.F. Li, and Y.H. Zhou, Acta Mater. 57, 1536 (2009).

R. Pandher, B. Singh, S. Sarkar, S. Chegudi, A. K. N. Kumar, K. Chattopadhyay, D. Lodge, and M. de A. Ribas, US20140219711 A1 (2014).

S.C. Cheng and K.L. Lin, J. Electron. Mater. 31, 940 (2002).

Y.S. Kim, K.-S. Kim, C.-W. Hwang, and K. Suganuma, J. Alloys Compd. 352, 237 (2003).

F. Wang, M. O’Keefe, and B. Brinkmeyer, J. Alloys Compd. 477, 267 (2009).

S. Kashyap, C.S. Tiwary, and K. Chattopadhyay, Mater. Sci. Eng. A 559, 74 (2013).

C.S. Tiwary, S. Chakraborty, D.R. Mahapatra, and K. Chattopadhyay, J. Appl. Phys. 115, 203502 (2014).

S. Kashyap, C.S. Tiwary, and K. Chattopadhyay, Mater. Sci. Eng. A 583, 188 (2013).

Acknowledgements

The authors would like to acknowledge the microscopy facility availed at the Advanced Facility for Microscopy and Microanalysis (AFMM), IISc, Bangalore-560012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pandey, P., Tiwary, C.S. & Chattopadhyay, K. Effects of Minute Addition of Ni on Microstructure and Mechanical Properties of Sn-Zn Eutectic Alloy. J. Electron. Mater. 45, 5468–5477 (2016). https://doi.org/10.1007/s11664-016-4742-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4742-8