Abstract

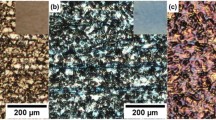

The color of hot-dip galvanized steel sheet was adjusted in a reproducible way using a liquid Zn-Ti metallic bath, air atmosphere, and controlling the bath temperature as the only experimental parameter. Coloring was found only for samples cooled in air and dipped into Ti-containing liquid Zn. For samples dipped into a 0.15 wt pct Ti-containing Zn bath, the color remained metallic (gray) below a 792 K (519 °C) bath temperature; it was yellow at 814 K ± 22 K (541 °C ± 22 °C), violet at 847 K ± 10 K (574 °C ± 10 °C), and blue at 873 K ± 15 K (600 °C ± 15 °C). With the increasing bath temperature, the thickness of the adhered Zn-Ti layer gradually decreased from 52 to 32 micrometers, while the thickness of the outer TiO2 layer gradually increased from 24 to 69 nm. Due to small Al contamination of the Zn bath, a thin (around 2 nm) alumina-rich layer is found between the outer TiO2 layer and the inner macroscopic Zn layer. It is proven that the color change was governed by the formation of thin outer TiO2 layer; different colors appear depending on the thickness of this layer, mostly due to the destructive interference of visible light on this transparent nano-layer. A complex model was built to explain the results using known relationships of chemical thermodynamics, adhesion, heat flow, kinetics of chemical reactions, diffusion, and optics. The complex model was able to reproduce the observations and allowed making predictions on the color of the hot-dip galvanized steel sample, as a function of the following experimental parameters: temperature and Ti content of the Zn bath, oxygen content, pressure, temperature and flow rate of the cooling gas, dimensions of the steel sheet, velocity of dipping the steel sheet into the Zn-Ti bath, residence time of the steel sheet within the bath, and the velocity of its removal from the bath. These relationships will be valuable for planning further experiments and technologies on color hot-dip galvanization of steel by Zn-Ti alloys.

Similar content being viewed by others

References

A.R. Marder: Prog. Mater. Sci., 2000, vol.45, pp. 191–271

A. Semoroz, L. Strezov, and M. Rappaz: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 2695–701

A. Szabo, E. Denes: Mater. Sci. Forum, 2003, vol. 414-415, pp. 45-50

F.M.Bellhouse, A.I.M.Mertense, J.R.McDermid: Mater. Sci. Eng. A. 2007, vol. 463, pp. 147-56

S.Kaboli, J.R.McDermid: Metall. Mater. Trans. A., 2014, vol. 45A, pp. 3938-53

H.Yang, S.Zhang, J.Li, Y.Liu, H.Wang: Surf. Coat. Technol. 2014, vol. 240, pp. 269-74

S.M.A. Shibli, B.N.Meena, R.Remya: Surf. Coat. Technol, 2015, vol. 262, pp. 210-15

G.Liu, J.Xing, S.Ma, Y.He, H.Fu, Y.Gao, Y.Wang, Y.Wang: Metall. Mater. Trans. A, 2015, vol.46, pp. 1900-07

Y.Wang, J.Zeng: Mater. Design: 2015, vol. 69, pp. 64-69

M.Panjan, M.Klanjsej Gunde, P.Panjan, M.Cekada: Surf. Coat. Technol., 2014, vol. 254, pp. 65-72

J.Corredor, C.P.Bergmann, M.Pereira, L.F.P.Dick: Surf. Coat. Technol. 2014, vol. 245, pp. 125-32

D.P.Adams, R.D.Murphy, D.J.Saiz, D.A.Hirschfeld, M.A:Rodriguez, P.G.Kouta, B.H.Jared: Surf. Coat. Technol., 2014, vol. 248, pp. 38-45

R.W. Smyth: US patent 3530013, 1970

P. B. Philip, R. Zeliznak: US patent 37783l5, 1971

M.Tomita, S.Yamamoto: European patent EP0269005A2, 1987

M.Tomita, S.Yamamoto, C. Tominaga, K. Nakayama: British patent GB1243562, 1991

Q. C. Le, J.Z. Cui: Chin. J. Nonferr. Met., 1998, vol. 8, pp. 98-102

Q. C. Le, J. Z. Cui: Acta Metall. Sin., 1999, vol. 12, pp. 1217-22

Q. C. Le, J.Z. Cui, C.H. Hou: Chin. J. Nonferr. Met., 2000, vol. 10, pp. 388- 94

Q.C. Le, J.Z. Cui: Surf. Eng., 2008, vol. 24, pp. 57-62

G. Lévai, M. Godzsák, A. Ender, R. Márkus, T.I. Török: Mater. Sci. Forum, 2013, vol. 729, pp. 61-67

Y.Wang, J.Zheng: Surf. Coat. Technol., 2014, vol. 245, pp. 55-65

J.Emsley: The Elements. Clarendon Press, Oxford, 1989

T.Iida, R.I.L.Guthrie. The Physical Properties of Liquid Metals, Clarendon Press, Oxford, 1993

I.Barin. Thermochemical Properties of Pure Substances, VCh, 1993

T.B. Massalski ed.: Binary Alloy Phase Diagrams, 2nd ed., 3 volumes, ASM International, Materials Park, 1990

F.R.deBoer, R.Boom, W.C.M.Mattens, A.R.Miedema: Cohesion in Metals, North-Holland, Amsterdam, 1988

G.Kaptay: Calphad 2004, vol.28, pp. 115-24

G.Kaptay: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 531-43

D.R.Poirier, G.H.Geiger: Transport Phenomena in Materials Processing, TMS, Warrendale, 1994

G.V.Samsonov (ed.): Fiziko-khimicheskie svoistva okislov—Moskva, Metallurgiia, 1978

B.Predel: Phase Equilibria, Crystallographic and Thermodynamic Data of Binary Alloys, vol 5 of group IV of Landolt-Börnstein Handbook, Springer-Verlag, Berlin, 1991-97

G.Kaptay: Materials equilibria in maco-, micro- and nano-system. Raszter Nyomda, 2011

G.Kaptay: J. Mater. Sci., 2005, vol. 40, pp. 2125-35

G.Kaptay: J. Disp. Sci. Technol., 2012, vol. 33, pp. 130-40

G.Kaptay: Mater. Sci. Forum, 2005, vol. 473-474, pp. 1-10

G.Kaptay, E.Báder, L.Bolyán: Mater. Sci. Forum, 2000, vol. 329-330, pp. 151-56

Y.S.Touloukian, R.K.Kirby, R.E.Taylor, T.Y.R.Lee: Thermal Expansion, IFI/Plenum, NY, 1977

G.Kaptay: Int. J. Mater Res., 2008, vol. 99, pp. 14-17

W. Chen, L. Zhang, Y. Du, B. Huang: Phil. Mag., 2014, vol. 94, pp. 1552-77

G. Ábrahám ed.: Optics, Panem, McGraw-Hill, Budapest, 1998

S. Van Gils, P.Mas, E.Stijns, H.Terryn: Surf. Coat. Technol., 2004, vol. 185, pp. 303-10

Acknowledgments

The corresponding author acknowledges the financial support of project K101781 of the Hungarian Academy of Sciences. The present results are achieved in the Center of Applied Materials Science and Nano-Technology at the University of Miskolc and within the TÁMOP-4.2.2.A-11/1/KONV-2012-0019 project, and carried out as part of the TÁMOP-4.2.2.D-15/1/KONV-2015-0017 project in the framework of the New Széchenyi Plan. The realization of this project is supported by the European Union, and co-financed by the European Social Fund. The authors thank Szendrő Galva Ltd for providing us with SHG Zn and to Salgó Metall Ltd for providing us with titanium shavings. They also thank Dr. Olivér Bánhidi for his help in ICP analysis of the Ti shavings and of the Zn-Ti alloy. The authors appreciate the help of color measurements provided by Dr. Tamás Szabó. The inspiration received from late Dr. Éva Dénes of Dunaferr Ltd (Hungary) is mostly appreciated at the beginning of this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 9, 2015.

Appendix Thermodynamic Properties of the Fe/Zn-Ti/O2 System

Appendix Thermodynamic Properties of the Fe/Zn-Ti/O2 System

Standard formation Gibbs energies of possible Zn oxides and Ti oxides are collected in Table AI.[25] The oxides are positioned along their increasing Ti content in Table AI.

As the Ti content in the Zn bath is below 1 mol pct, the Zn bath is modeled as an infinitely diluted solution in Ti. Thus, the activity coefficient of Ti (\( \gamma_{\text{Ti}}^{\infty } \)) is independent of its mole fraction:

where \( \Delta G_{\text{Ti}}^{E\infty } \left( {{\text{J}}/{\text{mol}}} \right) \) is the partial molar excess Gibbs energy of Ti in liquid Zn, R = 8.3145 J/molK, the universal gas constant, and T (K) is the absolute temperature. Unfortunately, there are no measured data available for \( \Delta G_{\text{Ti}}^{E\infty } \). However, the sign of this quantity is expected as \( \Delta G_{\text{Ti}}^{E\infty } < 0 \), as follows from the existence of stable intermetallic compounds in the Zn-Ti binary equilibrium phase diagram.[26] From the Miedema model,[27] \( \Delta H_{\text{Ti}}^{\infty } \cong - 61 \) kJ/mol, which is in agreement with the expected sign of \( \Delta G_{\text{Ti}}^{E\infty } \). Combining this value with the most probable value of the excess entropy,[28] the most probable equation for the partial excess Gibbs energy of Ti is written as (in kJ/mol)

Substituting Eq. [A2] into Eq. [A1],

The values, calculated by Eq. [A3], are collected in Table AII at different temperatures. One can see that \( \gamma_{\text{Ti}}^{\infty } < 1 \), and also that with the increasing temperature, its value tends toward 1, i.e., the real solution tends toward the ideal solution, in accordance with the general law.[29]

Now, let us estimate the standard Gibbs energies of formation of intermetallic compounds FeZn and FeTi (in kJ/mol):

The numerical values (−8.0 and −62 kJ/mol) in Eqs. [A4] and [A5] are the standard heats of formation of the intermetallic compounds,[32] while parameter \( \tau \cong \) 8300 K (8027 °C) is the average value for the intermetallic compounds.[33] The values, calculated by Eqs. [A4] through [A5], are given in Table AIII.

Rights and permissions

About this article

Cite this article

Levai, G., Godzsák, M., Török, T.I. et al. Designing the Color of Hot-Dip Galvanized Steel Sheet Through Destructive Light Interference Using a Zn-Ti Liquid Metallic Bath. Metall Mater Trans A 47, 3580–3596 (2016). https://doi.org/10.1007/s11661-016-3545-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3545-0