Abstract

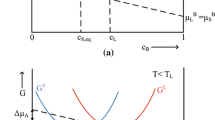

Grain refinement is known to be strongly affected by the solute in cast alloys. Addition of some solute can reduce grain size considerably while others have a limited effect. This is usually attributed to the constitutional supercooling which is quantified by the growth restriction factor, Q. However, one factor that has not been considered is whether different solutes have differing effects on the thermodynamic driving force for solidification. This paper reveals that addition of solute reduces the driving force for solidification for a given undercooling, and that for a particular Q value, it is reduced more substantially when adding eutectic-forming solutes than peritectic-forming elements. Therefore, compared with the eutectic-forming solutes, addition of peritectic-forming solutes into Al alloys not only possesses a higher initial nucleation rate resulted from the larger thermodynamic driving force for solidification, but also promotes nucleation within the constitutionally supercooled zone during growth. As subsequent nucleation can occur at smaller constitutional supercoolings for peritectic-forming elements, a smaller grain size is thus produced. The very small constitutional supercooling required to trigger subsequent nucleation in alloys containing Ti is considered as a major contributor to its extraordinary grain refining efficiency in cast Al alloys even without the deliberate addition of inoculants.

Similar content being viewed by others

References

B.S. Murty, S.A. Kori, and M. Chakraborty: Inter. Mater. Rev., 2002, vol. 47, pp. 3–29.

T.E. Quested: Mater. Sci. Technol., 2004, vol. 20, pp. 1357–69.

A. Cibula: J. Inst. Met., 1951, vol. 80, pp. 1–16.

D.G. McCartney: Inter. Mater. Rev., 1989, vol. 34, pp. 247–60.

M.M. Guzowski, G.K. Sigworth, and D.A. Sentner: Metall. Trans. A, 1987, vol. 18A, pp. 603–19.

P.S. Mohanty and J.E. Gruzleski: Acta Metall. Mater., 1995, vol. 43, pp. 2001–12.

M.A. Easton and D.H. StJohn: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1613–23.

M.A. Easton and D.H. StJohn: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1625–33.

A.L. Greer, P.S. Cooper, M.W. Meredith, W. Schneider, P. Schumacher, J.A. Spittle, and A. Tronche: Adv. Eng.Mater., 2003, vol. 5, pp. 81–91.

M. Johnsson, L. Backerud, and G.K. Sigworth: Metall. Trans. A, 1993, vol. 24A, pp. 481–91.

J.A.Marcantonio and L.F. Mondolfo: Metall. Trans., 1971, vol. 2, pp. 465–71.

P. Schumacher and A.L. Greer: Eighth International Conference on Rapidly Quenched and Metastable Materials, 22–27 Aug, 1993, vol. A181–A182, Switzerland, 1994, pp. 1335–39.

M.A. Easton and D.H. StJohn: Acta Mater., 2001, vol. 49, pp. 1867–78.

D.H. StJohn, M. Qian, M.A. Easton, and P. Cao: Acta Mater., 2011, vol. 59, pp. 4907–21.

M. Johnsson: Thermochim. Acta, 1995, vol. 256, pp. 107–21.

M. Qian, P. Cao, M.A. Easton, S.D. McDonald, and D.H. StJohn: Acta Mater., 2010, vol. 58, pp. 3262–70.

I. Maxwell and A. Hellawell: Acta Metall., 1975, vol. 23, pp. 229–37.

M. Johnsson and L. Baeckerud: Z. Metallkd., 1996, vol. 87, pp. 216–20.

M.A. Easton and D.H. StJohn: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1911–20.

M.A. Easton and D.H. StJohn: Mater. Sci. Eng. A, 2008, vol. 486, pp. 8–13.

F. Wang, Z. Liu, D. Qiu, J.A. Taylor, M.A. Easton, and M.-X. Zhang: Acta Mater., 2013, vol. 61, pp. 360–70

D.H. StJohn, P. Cao, M. Qian, and M.A. Easton: Adv. Eng. Mater., 2007, vol. 9, pp. 739–46.

D.H. StJohn, Q. Ma, M.A. Easton, C. Peng, and Z. Hildebrand: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1669–79.

M.J. Bermingham, S.D. McDonald, M.S. Dargusch, and D.H. St.John: J. Mater. Res., 2008, vol. 23, pp. 97–104.

J.H. Perepezko and W.S. Tong: Nucleation Control, Royal Society, Cambridge, 2003, pp. 447–61.

H.L. Lukas, S.G. Fries, and B. Sundman: Computation Thermodynamics (The CALPHD Method), Cambridge University Press, New York, 2007.

N. Saunders and A.P. Miodownik: CALPHAD (Calculation of Phase Diagrams): A Comprehensive Guide, Pergamon, Oxford; New York, 1998.

J.O. Andersson, T. Helander, L. Ho¨ glund, P. Shi, and B. Sundman: CALPHAD, 2002, vol. 26, pp. 273–312.

S.L. Chen, Y. Zuo, H. Liang, and Y.A. Chang: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 435–46.

S.-W. Chen, Y.-Y. Chuang, Y. Austin Chang, and M. Chu: Metall. Trans. A, 1991, vol. 22A, pp. 2837–48.

N. Saunders: CALPHAD, 1990, vol. 14, pp. 61–70.

J. Grobner, D. Kevorkov, I. Chumak, and R. Schmid-Fetzer: Z. Metallkd., 2003, vol. 94, pp. 976–82.

P. Liang, H.-L. Su, P. Donnadieu, M.G. Harmelin, A. Quivy, P. Ochin, G. Effenberg, H.J. Seifert, H.L. Lukas, and F. Aldinger: Z. Fuer Metallkunde/Mater. Res. Adv. Tech., 1998, vol. 89, pp. 536–40.

J. Grobner, H.L. Lukas, and F. Aldinger: CALPHAD, 1996, vol. 20, pp. 247–54.

H. Feufel, T. Goedecke, H.L. Lukas, and F. Sommer: J. Alloys Compd., 1997, vol. 247, pp. 31–42.

U.R. Kattner, J.C. Lin, and Y.A. Chang: Metall. Trans. A, 1992, vol. 23A, pp. 2081–90.

I. Ohnuma, Y. Fujita, H. Mitsui, K. Ishikawa, R. Kainuma, and K. Ishida: Acta Mater., 2000, vol. 48, pp. 3113–23.

V.T. Witusiewicz, A.A. Bondar, U. Hecht, S. Rex, and T.Y. Velikanova: J. Alloys Compd., 2008, vol. 465, pp. 64–77.

N. Saunders and V.G. Rivlin: Mater. Sci. Technol., 1986, vol. 2, pp. 521–27.

T. Wang, Z. Jin, and J.C. Zhao: J. Phase Equilibria, 2001, vol. 22, pp. 544–51.

I. Ansara, A.T. Dinsdale, and M.H. Rand, eds.: COST 507, European Communities, Belgium, 1998.

A.T. Dinsdale: CALPHAD, 1991, vol. 15, pp. 317–425.

W. Kurz and D.J. Fisher: Fundamentals of Solidification, Trans Tech Publications, Switzerland, 1998.

D.A. Porter, K. Easterling, and M.Y. Sherif: Phase Transformations in Metals and Alloys, CRC Press, Boca Raton, FL, 2009.

J.A. Dantzig and M. Rappaz: Solidification, EPFL Press, Lausanne, 2009.

H. Fredriksson and U. Åkerlind: Thermodynamic Analysis of Solidification Processes in Metals and Alloys. Solidification and Crystallization Processing in Metals and Alloys. Wiley, New York, 2012, pp. 42–98.

M. Glicksman: Thermodynamics of Crystal-Melt Phase Change. Principles of Solidification, Springer, New York, 2011, pp. 27–51.

E Clouet: Modeling of Nucleation Processes. Fundamentals of Modeling for Metals Processing, ASM International, Brussels, 2009, vol. 22A, pp. 203–19.

M.D. Eborall: J. Inst. Met., 1949, vol. 76, pp. 295–320.

F. Wang, D. Qiu, Z.-L. Liu, J.A. Taylor, M.A. Easton, and M.-X. Zhang: Acta Mater., 2013, vol. 61, pp. 5636–45.

F. Wang, D. Qiu, Z.-L. Liu, J.A. Taylor, M.A. Easton, and M.-X. Zhang: J. Appl. Crystallogr., 2014, vol. 47, pp. 770–79.

J.A. Spittle and S. Sadli: Mater. Sci. Technol., 1995, vol. 11, p. 533.

N. Eustathopoulos: Int. Met. Rev., 1983, vol. 28, pp. 189–210.

L. Battezzati: RQ10, Tenth International Conference on Rapidly Quenched and Metastable Materials, 23–27 Aug. 1999, Elsevier, Switzerland, 2001, vol. A304-A306, pp. 103–21.

M. Gunduz and J.D. Hunt: Acta Metall., 1985, vol. 33, 679 pp. 1651–72.

N. Marasli and J.D. Hunt: Acta Mater., 1996, vol. 44, pp. 1085–96.

M. Gunduz and J.D. Hunt: Acta Metall., 1989, vol. 37, p. 1839–45.

K. Keslioglu, M. Gunduz, H. Kaya, and E. Cadirli: Mater. Lett., 2004, vol. 58, pp. 3067–73.

S. Engin, U. Boyuk, and N. Marasli: J. Alloys Compd., 2009, vol. 488, pp. 138–43.

Acknowledgments

The authors are very grateful to the Australian Research Council for funding support (ARC DP10955737). Feng Wang would also like to acknowledge the support of China Scholarship Council.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 1, 2013.

Rights and permissions

About this article

Cite this article

Wang, F., Liu, ZL., Qiu, D. et al. The Influence of the Effect of Solute on the Thermodynamic Driving Force on Grain Refinement of Al Alloys. Metall Mater Trans A 46, 505–515 (2015). https://doi.org/10.1007/s11661-014-2599-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2599-0