Abstract

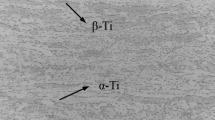

Microstructural evolution of the clad Ti-20Zr-20Cu-20Ni foil brazed CP-Ti alloy has been investigated. For the specimen furnace brazed below 1143 K (870 °C), the joint is dominated by coarse eutectic and fine eutectoid structures. Increasing the brazing temperature above 1163 K (890 °C) results in disappearance of coarse eutectic structure, and the joint is mainly comprised of a fine eutectoid of (Ti,Zr)2Ni, Ti2Cu, Ti2Ni, and α-Ti.

Similar content being viewed by others

References

R. Roger, E.W. Collings and G. Welsch: Materials Properties Handbook: Titanium Alloys, ASM International, Materials Park, OH, 1993, pp. 1-3.

J.L. Walter, M.R. Jackson and C.T. Sims: Titanium and Its Alloys: Principles of Alloying Titanium, ASM International, Materials Park, OH, 1988, pp. 23-33.

J.R. Davis: ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special Purpose Materials, ASM International, Materials Park, OH, 1990, pp. 592-633.

W.F. Smith: Structure and Properties of Engineering Alloys, McGraw-Hill Inc., New York, 1993, pp. 433-84.

C.T. Chang, Y.C. Du, R.K. Shiue and C.S. Chang: Mater. Sci. Eng., 2006, vol. 420A, pp. 155-64.

C.T. Chang, Z.Y. Wu, R.K. Shiue and C.S. Chang: Mater. Lett., 2007, vol. 61 (3), pp. 842-45.

C.T. Chang, R.K. Shiue and C.S. Chang: Scripta Mater., 2006, vol. 54, pp. 853-58.

Z.Y. Wu, T.Y. Yeh, R.K. Shiue and C.S. Chang: ISIJ Int., 2010, vol. 50, pp. 450-54.

R.K. Shiue, S.K. Wu and Y.T Chen: Intermetallics, 2010, vol. 18, pp. 107-114.

D.L. Olsen, I.A. Siewert, S. Liu, and G.R. Edwards, eds.: ASM Handbook, Volume 6, Welding, Brazing and Soldering, ASM International, Materials Park, OH, 1990, pp. 941–47.

C.S. Chang and B. Jha: Welding J., 2003, vol. 82 (10), pp. 28-31.

T.Y. Yang, R.K. Shiue and S.K. Wu: Intermetallics, 2004, vol. 12, pp. 1285-92.

R.K. Shiue, S.K. Wu and S.Y. Chen: Acta Mater., 2003, vol. 51, pp. 1991-2004.

R.K. Shiue, S.K. Wu and C.H. Chan: J. Alloy Compd., 2004, vol. 372, pp. 148-57.

Y. Chan, D.W. Liaw and R.K. Shiue: Int. Refract. Met. Hard. Mater., 2004, vol. 22, pp. 27-33.

P. Villars, A. Prince and H. Okamoto, Handbook of Ternary Alloy Phase Diagrams, ASM International, Materials Park, OH, 1995, pp. 13062-63.

K.P. Gupta: Phase Diagrams of Ternary Nickel Alloys, Indian Institute of Metals, Calcutta, India, 1990, p. 228.

Z.Y. Wu, R.K. Shiue and C.S. Chang: J. Mater. Sci. Technol., 2010, vol. 26 (4), pp. 311-16.

T.B. Massalski: Binary Alloy Phase Diagrams, ASM International, Materials Park, OH, 1990, p. 1494.

The authors gratefully acknowledge the financial support of this research by the National Science Council, the Republic of China, under NSC grant 99-2221-E-002-120-MY3.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 20, 2012.

Rights and permissions

About this article

Cite this article

Yeh, TY., Shiue, RK. & Chang, C.S. Microstructural Evolution of Brazed CP-Ti Using the Clad Ti-20Zr-20Cu-20Ni Foil. Metall Mater Trans A 44, 9–14 (2013). https://doi.org/10.1007/s11661-012-1534-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1534-5