Abstract

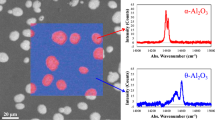

A laboratory-scale chemical vapor deposition (CVD) reactor was used to perform “continuous” Hf doping experiments while the surface of a single-crystal Ni alloy was being aluminized to form an aluminide (β-NiAl) coating matrix for 45 minutes at 1150 °C. The continuous doping procedure, in which HfCl4 and AlCl3 were simultaneously introduced with H2, required a high HfCl4/AlCl3 ratio (>∼0.6) to cause the precipitation of Hf-rich particles (∼0.1 µm) at grain boundaries of the coating layer, with the overall Hf concentration of ∼0.05 to 0.25 wt pct measured in the coating layer by glow-discharge mass spectroscopy (GDMS). Below this ratio, Hf did not incorporate as a dopant into the growing coating layer from the gas phase, as the coating matrix appeared to be “saturated” with other refractory elements partitioned from the alloy substrate. In comparison, the Hf concentration in the aluminide coating layer formed on pure Ni was in the range of ∼0.1 wt pct, which was close to the solubility of Hf estimated for bulk NiAl. Interestingly, the segregation of Hf and the formation of a thin γ′-Ni3Al layer (∼0.5 µm) at the coating surface were consistently observed for both the alloy and pure-Ni substrates. The formation of the thin γ′-Ni3Al layer was attributed to an increase in the elastic strain of the β-NiAl phase, associated with the segregation of Hf as well as other refractory alloying elements at the coating surface. This phenomenon also implied that the coating layer was actually growing at the interface between the γ′-Ni3Al layer and the β-NiAl coating matrix, not at the gas/coating interface, during the early stage of the coating growth.

Similar content being viewed by others

References

G.W. Goward: Mater. Sci. Technol., 1986, vol. 2, pp. 194–200.

B. Nagaraj: U.S. Patent 5,427, 866, 1995.

S.M. Meier, D.M. Nissley, K.D. Sheffler, and T.A. Cruse: Trans. ASME, 1992, vol. 114, pp. 258–63.

S.M. Meier, D.K. Gupta, and K.D. Sheffler: J. Met., 1991, Mar., pp. 50–53.

A. Maricocchi, A. Bartz, and D.J. Wortman: Proc. 1995 Thermal Barrier Coating Workshop, W.J. Brindley, ed., NASA Conference Publication No. 3312, Washington, DC, 1995, p. 79.

A.W. Funkenbusch, J.G. Smeggil, and N.S. Bornstein: Metall. Trans. A, 1985, vol. 16A, pp. 1164–66.

D.K. Gupta: U.S. Patent 4,933,329, 1990.

B.A. Pint: Oxid. Met., 1996, vol. 45, p. 1.

B.A. Pint, I.G. Wright, W.Y. Lee, Y. Zhang, K. Prüßner, and K.B. Alexander: Mater. Sci. Eng., 1998, vol. A245, pp. 201–11.

R. Bianco and R.A. Rapp: J. Electrochem. Soc., 1993, vol. 140, pp. 1181–90.

R. Bianco and R.A. Rapp: J. Electrochem. Soc., 1993, vol. 140, pp. 1191–203.

A. Strawbridge and P.Y. Hou: Mater. High Temp., 1994, vol. 12, pp. 177–81.

R. Prescott, D.F. Mitchell, M.J. Graham, and J. Doychak: Corr. Sci., 1995, vol. 37, pp. 1341–64.

D.C. Tu, C.C. Lin, S.J. Liao, and J.C. Chou: J. Vac. Sci. Technol., 1986, vol. A4, pp. 2601–06.

K.Y. Kim, S.H. Kim, K.W. Kwon, and I.H. Kim: Oxid. Met., 1994, vol. 41, pp. 179–201.

K.Y. Kim, J.H. Jun, and H.G. Jun: Oxid. Met., 1993, vol. 40, pp. 321–35.

G.W. Goward: presented at the Metallic Coatings Specialty Workshop, Hoboken, NJ, Apr. 16, 1997.

B.A. Pint and L.W. Hobbs: J. Electrochem. Soc., 1994, vol. 141, pp. 2443–53.

J. Stringer, I.M. Allam, and D.P. Whittle: Thin Solid Films, 1977, vol. 45, pp. 377–84.

Y. Zhang, W.Y. Lee, J.A. Haynes, I.G. Wright, B.A. Pint, K.M. Cooley, and P.K. Liaw: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2679–87.

W.Y. Lee, Y. Zhang, I.G. Wright, B.A. Pint, and P.K. Liaw: Metall. Trans. A, 1998, vol. 29A, pp. 833–41.

W.Y. Lee and G.Y. Kim: Min. Met. Mater. Soc., 1999, pp. 149–60.

G.Y. Kim, W.Y. Lee, J.A. Haynes, and T.R. Watkins: Metall. Mater. Trans. A, unpublished research, 2003.

S.J. Klepeis, J.P. Benedict, and R.M. Anderson: Mater. Res. Soc. Proc., 1988, vol. 115, p. 179.

A.P. Mykytiuk, P. Semeniuk, and S. Berman: Spectrochimica Acta Rev., 1990, vol. 13, pp. 1–10.

F. Adams and A. Vertes: Fresenius J. Anal. Chem, 1990, vol. 337, p. 638.

R. Pichoir: in Materials and Coatings to Resist High Temperature Corrosion, D.R. Holmes and A. Rahmel, eds., Applied Science Publishers Ltd., London, 1978, pp. 271–91.

G.Y. Kim, L.M. He, J.D. Meyer, and W.Y. Lee: Min. Met. Mater. Soc., 2000, pp. 69–78.

R. Pretorius, C.C. Theron, A. Vantomme, and J.W. Mayer: Crit. Rev. Solid State Mater. Sci., 1999, vol. 24 (I), pp. 1–62.

A.M. Brown and M.F. Ashby: Acta Metall., 1980, vol. 28, pp. 1085–101.

E.G. Colgan: Mater. Sci. Rep., 1990, vol. 5, pp. 1–44.

O. Kubaschewski and C.B. Alock: Metallurgical Thermochemistry, Pergamon Press, Oxford, UK, 1979, p. 184.

HSC Chemistry, Ver. 4.0, Outokumpu, Poli., Finland.

R.D. Noebe, R.R. Bowman, and M.V. Nathal: Int. Mater. Rev., 1993, vol. 38, pp. 193–232.

S.V. Divinski, S. Frank, U. Södervall, and C. Herzig: Acta Mater., 1998, vol. 46, pp. 4369–80.

A.J. Hickl and R.W. Heckel: Metal. Trans. A, 1975, vol. 6, pp. 431–40.

G. Ottaviani: Thin Solid Films, 1982, vol. 93, p. 127.

C.C. Jia, K. Ishida, and T. Nishizawa: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 473–85.

G. Bozzolo, R.D. Noebe, and F. Honecy: Min. Met. Mater. Soc., 1998, pp. 341–68.

W. Blum and D. Hess: Solid State Ionics, 1997, vol. 95, p. 41.

T. Ikeda, A. Almazouzi, H. Numakura, M. Koiwa, W. Sprengel, and H. Nakajima: Acta Mater., 1998, vol. 46, pp. 5369–76.

S. Shankar and L.L. Seigle: Metall. Trans. A, 1978, vol. 9A, pp. 1467–76.

R. Sivakumar and L.L. Seigle: Metall. Trans. A, 1976, vol. 7A, pp. 1073–79.

L. Singheiser and G. Wahl: Thin Solid Films, 1983, vol. 107, pp. 443–54.

I.E. Locci, R.M. Dickerson, A. Garg, R.D. Noebe, J.D. Whittenberger, M.V. Nathal, and R. Darolia: J. Mater. Res., 1996, vol. 11, pp. 3024–38.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, G.Y., He, L.M., Meyer, J.D. et al. Mechanisms of Hf dopant incorporation during the early stage of chemical vapor deposition aluminide coating growth under continuous doping conditions. Metall Mater Trans A 35, 3581–3593 (2004). https://doi.org/10.1007/s11661-004-0194-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-004-0194-5